Table of Contents

Advertisement

Quick Links

SILEA

EH

, MEDLEY

EH

, TRIO

EH

INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Pull Installation........................................................2

Drawer Removal & Installation.............................3

Pendaflex Bars..........................................................4

Digital Lock..............................................................6

Adjustable Shelves...................................................7

Side Access Locker..................................................9

Floating Shelves.....................................................11

Mobile PED............................................................13

Trough & End Caps..............................................14

Hanging MOD Panels..........................................16

Worksurface Joining.............................................18

Wall Mount Worksurface....................................21

Wall Access Panel Build.......................................22

Modular Station Build..........................................24

Wall Mount Wall...................................................31

Wall Shelf...............................................................33

Magnetic Wall........................................................35

Wall Mount Cabinet/Workwall..........................36

Wall Mount Filler Strip........................................38

Surface Mount Units.............................................40

Surface Mount Inserts..........................................42

External Tops.........................................................43

Legs..........................................................................46

Riser/Laptop Tray Attach.....................................49

External Stiffener...................................................51

Full MOD and Half MOD HGT ADJ................56

Telescoping HGT ADJ..........................................60

Shrouded T Height ADJ.......................................75

Bookcase Height ADJ...........................................78

Height Adjustable Settings...................................80

Height Adjustable Electrical Setup......................81

R. 12/18

Advertisement

Table of Contents

Summary of Contents for Gunlocke SILEAEH

-

Page 1: Table Of Contents

SILEA , MEDLEY , TRIO INSTALLATION INSTRUCTIONS TABLE OF CONTENTS Pull Installation............2 Drawer Removal & Installation......3 Pendaflex Bars............4 Digital Lock..............6 Adjustable Shelves...........7 Side Access Locker..........9 Floating Shelves.............11 Mobile PED............13 Trough & End Caps..........14 Hanging MOD Panels..........16 Worksurface Joining..........18 Wall Mount Worksurface........21 Wall Access Panel Build........22 Modular Station Build..........24 Wall Mount Wall...........31... -

Page 2: Pull Installation

S2013-0002-00 ASSEMBLY INSTRUCTION REV A DATE: 11-JUL-2018 PULL INSTALLATION GENERAL NOTES: 1. ALWAYS PROTECT THE PULLS AND DRAWERS DURING INSTALLATION. 2. MAKE SURE TO POSITION THE PULL PROPERLY TO LINE UP WITH THE SCREW HOLES 3. DEPENDING ON THE HARDWARE PACK, THE NUMBER OF PULLS AND SCREWS WILL VARY. PULL HARDWARE SCREW 8X32 -1 FLAT HEAD PH FRONT MOUNT PULL... -

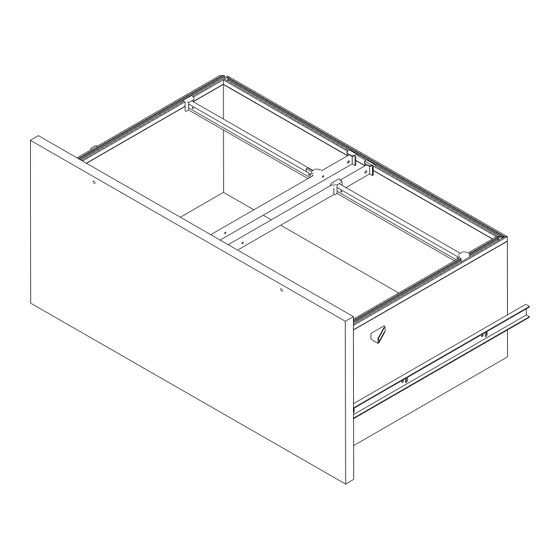

Page 3: Drawer Removal & Installation

ASSEMBLY INSTRUCTIONS S2013-0004-00 REV A DRAWER REMOVAL AND INSTALLATION DATE: 03-AUG-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. BE CAREFUL WHEN INSTALLING SLIDES AND DO NOT USE FORCE. DRAWER REMOVAL AND INSTALLATION SETUP PAGE 1 OF 1... -

Page 4: Pendaflex Bars

ASSEMBLY INSTRUCTION 19013-0022-00 REV B PENDAFLEX BARS DATE: 05-NOV-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. LAMINATE AND WOOD/PAINT PENDAFLEX BARS ARE LOCATED IN THE SAME POSITION. PENDAFLEX BAR EXAMPLE **PENDAFLEX-PENDAFLEX **PENDAFLEX BAR-DRAWER SIDE** BAR SIDE** PENDAFLEX BARS SETUP 1 DEPENDING ON THE DRAWER BODY, DIFFERENT LENGTHS OF PENDAFLEX BARS WILL BE PROVIDED 2 WHEN MOVING PENDAFLEX BARS, BE CAREFUL AS TO NOT DAMAGE THE UNIT OR THE BARS 15W DRAWER BODY... - Page 5 18W DRAWER BODY 30W DRAWER BODY 36W DRAWER BODY PAGE 2 OF 2...

-

Page 6: Digital Lock

ASSEMBLY INSTRUCTIONS S2013-0005-00 REV A DIGITAL LOCK DATE: 20-JUL-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. DIGITAL LOCK SETUP PAGE 1 OF 1... -

Page 7: Adjustable Shelves

19013-0018-00 ASSEMBLY INSTRUCTION REV A DATED: 13-JUL-2018 ADJUSTABLE SHELVING GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. INSTALLATION PROCESS FOR THE ADJUSTABLE SHELF IS THE SAME FOR LAM, WOOD AND PAINT. 3. SHELVES WILL BE INSTALLED IN THE UNIT. ADJUSTABLE SHELVING HARDWARE WOOD/PAINT LAMINATE... - Page 8 SHELF PIN AND SHELF CLIP TIGHTEN DOWN SCREW PAGE 2 OF 2...

-

Page 9: Side Access Locker

ASSEMBLY INSTRUCTIONS 19013-0016-00 REV: B SIDE ACCESS LOCKER DATE: 13-NOV-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. WOOD/PAINT UNITS WILL SHIP ASSEMBLED. LAMINATE UNITS WILL SHIP UNASSEMBLED. WARNING LEVEL UNIT BEFORE MOUNTING DOOR. SIDE ACCESS LOCKER HARDWARE #6x5/8 SILVER #10x5/8 BLK M7 x .7 x 25mm... - Page 10 SHOE RACK COAT HOOK SHOE RACK COAT HOOK SCREW 5/8"LG BLACK PAN HEAD (8 PLCS) SCREW M4 x .7 25mm LG PAN HD HINGE DR GLASS LAMINATE DR HINGE LAMINATE HINGE PRESS IN SCREW PLACE AND DIRECTLY TIGHTEN INTO ALUM SCREWS FRAME, PILOT HOLES...

-

Page 11: Floating Shelves

S2013-0007-00 ASSEMBLY INSTRUCTION REV A DATE: 03-JUL-2018 FLOATING SHELF GENERAL NOTES 1. ALWAYS PROTECT THE FLOATING SHELF HARDWARE AND SHELF DURING INSTALLTION. 2. THE MANUFACTURER ASSUMES NO RESPONSIBILITY FOR THE METHOD AND FASTENERS USED TO ATTACH THE FLOATING SHELF SUPPORTS. IT IS THE RESPONSIBILITY OF THE INSTALLER / END USER TO DETERMINE THE APPROPRIATE METHOD OF ATTACHMENT BASED ON THE TYPE OF WALL MATERIAL AND/OR STUDS AVAILABLE. - Page 12 CAN ADJUST PIN HORIZONTALLY SEE DETAIL A IF NEEDED DETAIL A USE AN OPEN END WRENCH TO ADJUST THE SHELF ANGLE SCREW IN THE LOCKING BOLT *END RESULT* **THE SHELF DOES NOT ATTACH TO THE WALL AND CAN BE REMOVED** PAGE 2 OF 2...

-

Page 13: Mobile Ped

SA013-0016-00 ASSEMBLY INSTRUCTIONS REV: C DATE 03-JUL-2018 MOBILE PEDESTAL MOBILE PEDESTAL GENERAL NOTES 1. ALWAYS PROTECT UNIT DURING INSTALLATION MOBILE PEDESTAL HARDWARE CASTER #10X3/4" HWH #8 HD MOBILE PEDESTAL SETUP 1 REMOVE CASTERS AND SCREWS FROM THEIR BAGS 2 ALIGN THE CASTERS TO THE PILOT HOLES ALONG WITH SCREWS 3 SCREW EACH CASTER INTO PLACE 3/4"... -

Page 14: Trough & End Caps

ASSEMBLY INSTRUCTIONS S2013-0003-00 REV B TROUGH AND END CAPS DATE: 05-NOV-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. DEPENDING ON PREFERENCE IT MAY BE EASIER TO INSTALL THE TROUGH BEFORE ATTACHING THE WORKSURFACE. 3. NEED TO ATTACH BACK PANELS BEFORE INSTALLING THE TROUGH. TROUGH AND END CAP HARDWARE SCR #10X3/4"... - Page 15 TROUGH ON TOP OF PANEL #10 X.75 SCREW **CAREFULLY ATTACH END CAPS** PAGE 2 OF 2...

-

Page 16: Hanging Mod Panels

ASSEMBLY INSTRUCTIONS 19013-0019-00 REV B HANGING MOD PANELS DATE: 05-NOV-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. THIS INSTRUCTION SHEET SHOWS THE CONSTRUCTION WITH TWO DESK PEDS. 3. THE MANUFACTURER ASSUMES NO RESPONSIBILITY IF THE MOD PANEL BREAKS DUE TO IMPROPER INSTALLATION. MODESTY PANEL HARDWARE LAMINATE HARDWARE WOOD/PAINT HARDWARE... - Page 17 8X5/8" WOOD SCREW 10X5/8" WOOD SCREW MODESTY PANEL ROUGHLY FOUR INCHES FROM THE BACK PANEL **FINAL POSITION** PAGE 2 OF 2...

-

Page 18: Worksurface Joining

19013-0021-00 ASSEMBLY INSTRUCTION REV A WORKSURFACE JOINING DATE: 16-JUL-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. WHEN ATTACHING WORKSURFACES BE CAREFUL AS SOME WORKSURFACES MAY NOT COME WITH A LEG OR PED. 3. LAMINATE UNITS WILL RECEIVE A DIFFERENT MOUNTING BRACKET THAN WOOD/PAINT. 4. - Page 19 **MAIN UNIT IS LEVELED AND IN POSITION** 16.500 1.500 8X1 FLAT HEAD SCREW WOOD/PAINT SETUP **THESE ARE THE RECOMMENED DIMENSIONS, YOU MAY NEED TO ALTER THEM TO PROPERLY CENTER BRACKETS** 10X3/4 WOOD SCREW LAMINATE SETUP **RECOMMENED TO CENTER BRACKET(S) WITH ADJOINING WORKSURFACE IF UNIT REQUIRES TWO BRACKETS, EVENLY SPACE THEM APART** PAGE 2 OF 3...

- Page 20 FLUSHED **FINAL OUTPUT** PAGE 3 OF 3...

-

Page 21: Wall Mount Worksurface

ASSEMBLY INSTRUCTIONS 12013-5044-00 Rev F WALL MOUNTING Date: 06-NOV-2018 WORKSURFACES GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. THE MANUFACTURER ASSUMES NO RESPONSIBILITY FOR THE METHOD AND FASTENERS USED TO ATTACH BRACKET(S) TO THE WALL. IT IS THE RESPONSIBILITY OF THE INSTALLER / END USER TO DETERMINE THE APPROPRIATE METHOD OF ATTACHMENT BASED ON THE TYPE OF WALL MATERIAL AND/OR STUDS AVAILABLE. -

Page 22: Wall Access Panel Build

S2013-0012-00 ASSEMBLY INSTRUCTION REV A WALL ACCESS PANEL BUILD DATE: 4-DEC-2018 GENERAL NOTES: 1. ALWAYS PROTECT THE UNIT WHEN INSTALLING. 2. WOOD/PAINT WILL SHIP ASSEMBLED. HARDWARE BASEPLATE SCREW SPRINGCLIP SCREW HINGE SPRINGCLIP #8X3/4" PAN HEAD #8X1/2" PAN HEAD DOWEL CONNECTOR COMPOSITE MINI BOLT **THE BASE PLATE WILL ALSO BE INCLUDED IN THE SHIPPED HARDWARE** **SCREW SIZE MAY VARY FROM WOOD/PAINT TO LAMINATE**... - Page 23 SPRINGCLIP SPRINGCLIP SCREW #8X1/2" PAN HEAD CONNECTOR COMPOSITE MINI BOLT BASE PLATE WILL GO HERE DOWEL BASEPLATE SCREW #8X3/4" PAN HEAD HINGE BASEPLATE LOCATION SECOND PART TO SPRING CLIP...

-

Page 24: Modular Station Build

ASSEMBLY OF 19013-0024-00 REV B MODULAR PRODUCTS DATE: 07-NOV-2018 INSTALLATION GENERAL NOTES 1. ALWAYS PROTECT THE UNITS DURING INSTALLATION. 2. TYPICAL ATTACHMENT METHODS SHOWN - PRODUCT VARIATIONS MAY OCCUR. MODULAR ATTACHMENT HARDWARE WORKSURFACE SPRING CLIP MODESTY PANEL CORNER BRACKET CAM FASTENER 8mm DOWEL ALIGNMENT BRACKET SUPPORT... - Page 25 CHASSIS ASSEMBLY PEDESTAL TYPES DRAWER PEDESTALS SHELF PEDESTALS FALSE PEDESTALS (DRAWERS REMOVED) (SHELF/ INSET BACK REMOVED) REAR GLIDE ACCESS REAR GLIDE ACCESS REMOVE SHELF (QUICK RELEASE) REMOVE & LABEL DRAWERS INSET BACK IS ATTACHED WITH SPRING CLIPS RE-INSTALL IN SAME LOCATIONS AT THE TOP - PULL FORWARD TO REMOVE UNASSEMBLED UNITS WORKSURFACE JUNCTION SUPPORT...

- Page 26 CHASSIS ASSEMBLY WALL ACCESS PANEL ATTACHMENT TO A PEDESTAL SIDE PANEL TO A FALSE PEDESTAL END PANEL ALIGN CORNER TO CORNER SECURE WITH ANGLE BRACKETS (3/4" SCREWS) SCREW THROUGH SIDE PANELS (1-1/4" SCREWS) ALIGN BACK & BOTTOM EDGES FULL HEIGHT BACK PANEL ATTACHMENT TO A PEDESTAL SIDE PANEL ALIGN BOTTOM EDGES...

- Page 27 CHASSIS ASSEMBLY SINGLE PEDESTAL BREAK FRONT MODESTY PANEL/ FALSE PEDESTAL ASSEMBLY (MODEL NO. GS2SDMF...) ASSEMBLE FALSE PEDESTAL (LH FALSE PEDESTAL SHOWN) ASSEMBLE BREAK FRONT MODESTY PANEL DETERMINE BREAK FRONT INSET DRILL OUT (3) BLIND HOLES ALIGN WITH MODESTY PANELS HOLES SECURE WITH 50mm CONFIRMAT SCREWS ATTACH SPRING CLIPS BEFORE...

- Page 28 CHASSIS ASSEMBLY RUNOFF FILLER PANEL ATTACHMENT GUIDE RUNOFF ASSEMBLY AND ATTACHMENT WHERE TO CONNECT TO THE RUNOFF BACK ATTACH BACK TO RUNOFF PEDESTAL LH RUNOFF RH RUNOFF STANDARD STANDARD PEDESTAL PEDESTAL FASTENERS LH RUNOFF RH RUNOFF FALSE PEDESTAL FALSE PEDESTAL ALIGNMENT DOWELS SCREW THROUGH BACK STRETCHER...

- Page 29 WORKSURFACE ATTACHMENT FULL DEPTH WORKSURFACE OVERHANGS SIDE OVERHANG FRONT/ BACK OVERHANG 0.060 0.060 (0.870) DRAWERS/ DOORS REMOVED CHASSIS PREPARATION ADD BRACKETS TO TOP EDGES OF BACK AND END PANELS ADD BRACKETS TOP AND BOTTOM TO SECURE BACK PANEL TO PEDESTAL SCREW THROUGH STRETCHER TO SECURE BACK PANEL (1-1/4"...

- Page 30 WORKSURFACE ATTACHMENT TROUGH WORKSURFACE OVERHANGS SIDE OVERHANG FRONT/ BACK OVERHANG 0.060 0.307 0.870 DRAWERS/ DOORS REMOVED CHASSIS PREPARATION ADD BRACKETS TO TOP EDGES OF WALL ACCESS PANEL SCREW THROUGH TROUGH TO ATTACH TO SCREW THROUGH STRETCHER FILLER PANEL TO SECURE FILLER PANEL (3/4"...

-

Page 31: Wall Mount Wall

19013-0013-00 ASSEMBLY INSTRUCTIONS REV A DATE: 11-JUL-2018 WALL MOUNT WALL GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. THE MANUFACTURER ASSUMES NO RESPONSIBILITY FOR THE METHOD AND FASTENERS USED TO ATTACH BRACKET(S) TO THE WALL. IT IS THE RESPONSIBILITY OF THE INSTALLER / END USER TO DETERMINE THE APPROPRIATE METHOD OF ATTACHMENT BASED ON THE TYPE OF WALL MATERIAL AND/OR STUDS AVAILABLE. - Page 32 WALL MOUNT WALL SETUP 3 IF ONE BRACKET IS BEING USED (30", 36", 60", 66" 72" 84" & 90" WOOD WALL), ALIGN THE CENTER OF THE BRACKET WITH THE EVENTUAL CENTERLINE OF THE WOOD WALL (FIG. 5) AND MARK. IF TWO BRACKETS ARE BEING USED (96", 102" & 108"), EACH BRACKET SHOULD BE INSET 1-1/2"...

-

Page 33: Wall Shelf

ASSEMBLY INSTRUCTIONS SA013-0023-00 REV D SHELVING Date 03-JUL-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. INSTALLATION PROCESS FOR ACCESSORY SHELVES IS THE SAME FOR LAMINATE, WOOD, PAINT AND ALUMINUM SHELVES. SHELVING HARDWARE DOWEL PIN 8MM X 38MM *FOR TWO PIECE ACCESSORY SHELVES* PLASTIC SELF ADHESIVE 0.5 X 0.2 X 0.03 ALUMINUM SHELF SET UP... - Page 34 TWO PIECE WOOD SHELF SET UP ADDITIONAL STEPS A ADJUST LEVELING GLIDES TO LEVEL SHELF 1 ENGAGE LIP INSIDE OF ALUMINUM CHANNEL B APPLY SHIMS TO THE SHELF IF IT NEEDS TO BE LEVELED 2 CAREFULLY ROLL DOWN SHELF UNTIL FULL ENGAGEMENT 3 WHEN INSTALLING A TWO PIECE SHELF, INSERT THE DOWEL PIN INTO THE FIRST SHELF THAT WAS INSTALLED 4 INSTALL THE SECOND SHELF IN THE SAME MANNER AS THE FIRST,...

-

Page 35: Magnetic Wall

ASSEMBLY INSTRUCTION S2013-0008-00 REV A MAGNETIC WALLS DATE: 16-JUL-2018 GENERAL NOTES 1. ALWAYS PROTECT THE MAGNETIC WALL HARDWARE AND THE MAGNETIC WALL DURING INSTALLATION 2. THE MANUFACTURER ASSUMES NO RESPONSIBILITY FOR THE METHOD AND FASTENERS USED TO ATTACH BRACKET(S) TO THE WALL. IT IS THE RESPONSIBILITY OF THE INSTALLER / END USER TO DETERMINE THE APPROPRIATE METHOD OF ATTACHMENT BASED ON THE TYPE OF WALL MATERIAL AND OR STUDS AVAILABLE. -

Page 36: Wall Mount Cabinet/Workwall

ASSEMBLY INSTRUCTIONS SA013-0020-00 REV: D WALL MOUNTED CABINET AND WORKWALL DATE 09-JUL-2016 GENERAL NOTES 1. ALWAYS PROTECT THE CABINET DURING INSTALLATION. 2. THE MANUFACTURER ASSUMES NO RESPONSIBILITY FOR THE METHOD AND FASTENERS USED TO ATTACH BRACKET(S) TO THE WALL. IT IS THE RESPONSIBILITY OF THE INSTALLER / END USER TO DETERMINE THE APPROPRIATE METHOD OF ATTACHMENT BASED ON THE TYPE OF WALL MATERIAL AND/OR STUDS AVAILABLE. - Page 37 WALL MOUNTED WORKWALL BOX SETUP 1 TAKE THE WALL MOUNT BRACKETS OFF OF THE UNIT FROM THEIR SHIPPING POSITION 2 DETERMINE THE DESIRED HEIGHT TO THE TOP OF THE UNIT. MEASURE DOWN "X" INCHES FOR BRACKET MOUNTING LOCATION AND MARK THE LOCATIONS 3 ONCE THE BRACKETS ARE SCREWED INTO PLACE, LIFT UNIT ONTO THE BRACKETS ATTACHED TO THE WALL **THESE UNITS ARE VERY HEAVY AND REQUIRE SEVERAL PEOPLE TO LIFT UP INTO POSITION** **THIS INSTALLATION IS VERY SIMILAR TO WALL MOUNT CABINETS SETUP**...

-

Page 38: Wall Mount Filler Strip

19013-0026-00 ASSEMBLY INSTRUCTION REV A WALL MOUNT FILLER STRIP DATE: 03-DEC-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. INSTALLTION METHOD THE SAME FOR GLASS, WALL MOUNT WALL OVERHEADS, AND TACKZONES. HARDWARE RUBBER GASKET WITH ADHESIVE WALL MOUNT FILLER STRIP SETUP 1 PLACE UNIT FACE DOWN ON A SOLID SURFACE 2 REMOVE STRIP REVEALING ADHESIVE AND PLACE ON BACK OF THE UNIT 3 ONCE ON ATTACHED TO THE WALL... - Page 39 VARIOUS EXAMPLES WALL MOUNT WALL TACKZONE w/ STEEL BACKER MAY NEED TO CUT STRIPS WALL MOUNT WALL OVERHEADS WALL MOUNT GLASS WHITEBOARD IN TACKZONE PAGE 2 OF 2...

-

Page 40: Surface Mount Units

SA013-0012-00 ASSEMBLY INSTRUCTIONS REV B DATE: 16-JUL-2018 SURFACE MOUNTED UNITS GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. WARNING 1) DO NOT USE THIS UNIT WITHOUT THE MOUNTING TAPE. 2) DO NOT LEAN ON, BUMP OR LOAD THIS UNIT FOR A PERIOD OF 12 HOURS AFTER MOUNTING. 3) WOOD PRODUCTS ARE HEAVIER THAN THEY APPEAR. - Page 41 3 LIFT ONE END OF THE UNIT APPROXIMATELY 3" AS SHOWN. REMOVE PROTECTIVE COVER FROM THE TAPE, THEN CAREFULLY LOWER UNIT BACK INTO THE POSITION MARKED BY THE MASKING TAPE. REPEAT THIS PROCEDURE FOR THE OTHER END PANEL APPROX. 3" MOUNTING TAPE PAGE 2 OF 2...

-

Page 42: Surface Mount Inserts

SA013-0025-00 ASSEMBLY INSTRUCTIONS REV B 03-JUL-2018 SMC GLASS INSERT GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. SURFACE MOUNTED TACKBOARDS WILL INSTALL IN THE SAME FASHION AS GLASS. 3. ONE PIECE SURFACE MOUNTED TACKBOARDS WILL HAVE VELCRO IN THE SAME POSITIONS. SMC GLASS INSERT HARDWARE VELCRO 1"... -

Page 43: External Tops

19013-0025-00 ASSEMBLY INSTRUCTION REV A DATE: 14-NOV-2018 EXTERNAL TOPS GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. ONCE THE TAPE IS APPLIED TO THE UNIT, IT WILL NOT COME OFF WITHOUT DAMAGING THE UNIT. HARDWARE FELT DOUBLE SIDED TAPE EXTERNAL TOPS SETUP 1 HAVE THE UNIT WHICH IS GETTING THE EXTERNAL TOP IN A COMFORTABLE POSITION AS TO PLACE THE TOP ON WITH EASE (MAY BE EASIER TO NOT HAVE THE UNIT IN THE FINIAL POSITION IF POSSIBLE) - Page 44 DO NOT PLACE FELT ON END PANELS DO NOT PLACE TAPE ON BACK PANELS OR END PANELS PAGE 2 OF 3...

- Page 45 WALL MOUNTS ARE FLUSHED ON SIDE, SURFACE MOUNTS ARE 1/16" OVERHANG BOTH SIDES AND TOWERS ARE 1/32" OVERHANG BOTH SIDES ROUGHLY 1/16" OFFSET PAGE 3 OF 3...

-

Page 46: Legs

ASSEMBLY INSTRUCTIONS 19013-0014-00 REV B LEGS DATE: 19-NOV-2018 GENERAL NOTES 1. ALWAYS PROTECT THE WORKSURFACE DURING INSTALLATION. 2. ALWAYS LEVEL UNIT(S) AT FINAL LOCATION. 3. WHEN ATTACHING GLASS SLAB BASES, RIBS SHOULD FACE OUT. -WARNING- IF YOU ARE PLACING THESE LEGS ON A SOLID SURFACE TOP, IT IS VERY IMPORTANT TO MAKE SURE YOU USE THE 3/4"... - Page 47 ANGLED / VERTICAL LEG ATTACHMENT SETUP 1 ATTACH LEG TO WORKSURFACE USING PILOT HOLES 1" PAN HEAD WOOD SCREWS (10 PER LEG) 1" FLAT HEAD WOOD SCREWS (9 PER LEG) COLUMN LEG ATTACHMENT SETUP 1 PLACE COLUMN LEG AT DESIRED LOCATION HEX HEAD 2 DRILL 1/8"...

- Page 48 MODULAR TOP LEG ATTACHMENT SETUP 1 LAY THE TOP DOWN ON THE GROUND AND PLACE THE LEGS IN POSITION WITH THE DIMENSIONS AS SHOWN 2 ONCE IN POSITION, MARK THE POSITIONS OF THE HOLES AND REMOVE THE LEGS TO PRE-DRILL HOLES 3 ONCE THE HOLES ARE PRE-DRILLED, PLACE THE LEGS BACK INTO POSITION AND SCREW INTO PLACE **IF YOU DO NOT PLACE THE LEGS IN THE LISTED DIMENSION, YOU MAY RUN INTO ISSUES WITH THE GROMMET HOLES AND OR OTHER FIXTURES**...

-

Page 49: Riser/Laptop Tray Attach

ASSEMBLY INSTRUCTION 19013-0017-00 REV B RISER/LAPTOP TRAY ATTACH DATE: 06-NOV-2018 GENERAL NOTES 1. PROTECT THE UNIT DURING INSTALLATION 2. RISER AND LAPTOP HAVE SPECIFIC DIMENSIONS TO FOLLOW 3. LAMINATE WILL GET TWO SCREWS FOR THE CORNER BRACKETS 4. DOUBLE SIDED TAPE WILL BE LOCATED ON THE BOTTOM OF THE LAPTOP TRAY AND RISER RISER/LAPTOP TRAY HARDWARE METAL RISER HARDWARE LAPTOP TRAY HARDWARE... - Page 50 RISER ASSEMBLY SETUP 1 LINE UP THE METAL RISER 2 SCREW INTO THE WORKSURFACE THERE ARE PILOT HOLES IN THE WORKSURFACE TO ALIGN THE BRACKETS PROPERLY 1" PAN HEAD WOOD SCREW PAGE 2 OF 2...

-

Page 51: External Stiffener

ASSEMBLY INSTRUCTIONS 19013-0015-00 REV: A EXTERNAL STIFFENER ATTACHMENT DATE 09-JUL-2018 GENERAL NOTES 1. ALWAYS PROTECT THE WORKSURFACE DURING INSTALLATION. 2. RECOMMENDED TO DRILL PILOT HOLES FOR ALL ATTACHMENT HOLES. EXTERNAL STIFFENER HARDWARE EXTERNAL STIFFENER #10 X 3/4", WOOD SCREW, HEX HEAD EXTERNAL STIFFENER ATTACHMENT SETUP CENTER EXTERNAL STIFFENER ON WORKSURFACE;... -

Page 52: Credenzas-Bridges-Returns Hgt Adj

ASSEMBLY INSTRUCTION S2013-0006-00 REV B 24D CREDENZAS-BRIDGES-RETURNS DATE: 28-NOV-2018 HGT ADJ INSTALLATION GENERAL NOTES: 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. LAMINATE UNITS WILL SHIP SEPERATELY WHILE WOOD/PAINT WILL SHIP AS ONE UNIT. 3. IF THE UNIT REQUIRES TO BE MOUNTED TO THE WALL, THE COMPANY ASSUMES NO RESPONSIBILITY FOR THE METHOD AND FASTENERS USED TO ATTACH BRACKET(S) TO THE WALL. - Page 53 **LEVEL THE UNIT IN THE GENERAL AREA** BOLT M8X10 HEX HD BOLT M8X10 HEX HD BOLT M6X16 HEX HD BOLT M6X16 HEX HD **REMOVE PANEL AND SLIDE DOWN THE MOTOR** **REMOVE DRAWERS AND SLIDE DOWN THE MOTOR** SHIPS CONNECTOR 15MM X15MM KNOCKED DOWN COMPOSITE MINI BOLT 8MM X 38MM D0WEL...

- Page 54 **UNITS THAT RECEIVE WALL MOUNT BRACKETS** SLIDE DOWN ONTO ATTACH TO WALL FIRST WALL ATTACH BRACKET SCR TP-A 10X5/8 PN PH HEIGHT MAY VARY DEPENDING ON ATTACHMENT AREA RECOMMENED TO NOT GO ABOVE 8 INCHES FROM THE CUT-OUT **VIEW HAS MISSING COMPONENTS **SLIDE THE BRACKET ONTO THE WALL BRACKET TO SHOW WHERE THE SCREWS GO** THEN SCREW INTO PLACE**...

- Page 55 **EXAMPLE OF CRED, BRIDGE AND RETURN BRACKET POSITIONS** **CRED** **BRIDGE** WILL REQUIRE WALL MOUNTING BRACKETS **RETURN** PAGE 4 OF 4...

-

Page 56: Full Mod And Half Mod Hgt Adj

ASSEMBLY INSTRUCTIONS S2013-0009-00 REV B FULL MOD AND HALF MOD HGT ADJ DATE: 14-NOV-2018 GENERAL NOTES 1. ALWAYS PROTECT THE UNIT DURING INSTALLATION. 2. LAMINATE UNITS WILL SHIP AS COMPONENTS WHILE WOOD/PAINT SHIP AS ONE UNIT. FULL MOD AND HALF MOD HGT ADJ HARDWARE LAMINATE HARDWARE 8MM X 38MM D0WEL COMPOSITE MINI BOLT... - Page 57 REMOVE PANEL SCR M8X10 HEX HD 10X1-1/4 PH PH SCR M6X16 HEX HD 8MM X 38MM D0WEL COMPOSITE MINI BOLT 8MM X 38MM D0WEL SCR 1/2 LG #8 HEX HD & #10 WSHR SCR 3/4 LG #8 HEX HD CONNECTOR 15MM X15MM &...

- Page 58 SCR 10X5/8 PN PH SHOULD BE A GAP **YOU WILL NEED TO TURN UNIT ON AND RAISE THE HEIGHT TO SCREW THE TOP TO THE BRACKET** SCR 10X5/8 PN PH SCR 10X2 FT PH POSITION MAY VARY DEPENDING ON THE USER RECOMMENDED POSITION PAGE 3 OF 4...

- Page 59 10X1-1/4 PH PH 8MM X 38MM D0WEL **HALF MOD SETUP IS THE SAME AS THE FULL MOD EXCEPT FOR THE REMOVAL OF THE BACK PANEL** PAGE 4 OF 4...

-

Page 60: Telescoping Hgt Adj

S2013-0010-00 ASSEMBLY INSTRUCTIONS REV A DATE: 9-AUG-2018 TELESCOPING HEIGHT ADJUSTABLE DESK GENERAL NOTES 1. ALWAYS PROTECT THE UNITS DURING INSTALLATION. 2. LAMINATE AND WOOD/PAINT MODELS WILL HAVE DIFFERING HARDWARE BUT THE SAME SETUP 3. THIS INSTRUCTION SHEET SHOWS THE ASSEMBLY OF A LAMINATE FREE STANDING DESK AND EXTENSION DESK 4. - Page 61 S2013-0010-00 REV A FASTENERS 8mm DOWELS MINI-FIX MINI-FIX 10X3/4 HWH #8 SCR 10X1-1/4" SCR 10X2" FLAT HOUSING BOLT HEX HEAD PAN HEAD PHILLIPS HEAD PHILLIPS CABLE HOLDER M6X16 SCR 10X5/8" 10X1/2" CABLE HOLDER CORRUGATED PAN HEAD PAN HEAD HWH #8 3/8"...

- Page 62 LAMINATE DESK SETUP 1 PLACE THE MOTOR SECTION OF THE TELESCOPING BASE INTO THE DESIRED POSITION MAKING SURE IT IS LEVEL AND VERTICAL. ONCE IN PLACE, SLIDE THE MOTOR IN THE SLOT AND SCREW INTO PLACE 2 WITH ASSISTANCE, PLACE THE TELESCOPING BRACKETS ON THE TELESCOPING BASE MOTOR WITH (4) M6X16 PAN HEADS. FOR THE TELSCOPING BASE, THE FLANGES WILL BE ON THE OUTSIDE OF THE LAMINATE PANEL 3 PLACE THE SECOND BASE AT THE OPPOSITE END.

- Page 63 SCR M8X10 HEX HD SEE DETAIL A NOTE: -FLANGE LOCATED BEHIND LAMINATE PANEL ALAN HEAD, 4 LOCATIONS SCR M6X16 HEX HD SEE DETAIL B NOTE: MAKE SURE GLIDES ARE IN AND THE UNIT IS NOTE: IF THE SECOND BASE IS A TELESCOPING BASE, LEVEL SIDE TO SIDE AND PLUM FRONT TO BACK REPEAT STEPS 1 AND...

- Page 64 LH AND RH SEE DETAIL G BRACKETS SEE DETAIL H 10X3/4 HWH #8 HEX HEAD (6X PER) DETAIL G DETAIL H SCALE 0.200 SCALE 1.000 NOTE: 2-HANDED BRACKETS FOR EACH TELESCOPING BASE NOTE: CAREFULLY FLIP THE WORK SURFACE REPEAT STEP 6 IF UNIT IS FREE STANDING AND PLACE IT ONTO THE BASES BOTTOM VIEW SEE DETAIL I...

- Page 65 NOTE: PLUG THE TWO MOTOR CABLES INTO THE CONTROL BOX. THEN PLACE THE HANDSET CORD THROUGH THE WIRE ACCESS HOLE IN THE BRACKET AND INTO THE CONTROL BOX. LAST, THE POWER CORD WILL NEED TO BE PLUGGED INTO THE CONTROL BOX. ALL OF THESE CORDS SHOULD BE ORGANIZED WITH THE 3/8" DIAMETER CABLE HOLDERS.

- Page 66 INSIDE SEE DETAIL N DETAIL N NOTE: SCREW THE EXTENSION SUPPORT SCALE 0.250 PANEL BRACKET TO THE INSIDE OF NOTE: USE FOUR 10X1-1/4" PAN HEADS THE EXTENSION SUPPORT PANEL WITH TO ATTACH THE EXTENSION 10X5/8" PAN HEAD USING THE PILOT SUPPORT PANEL TO THE HOLES.

- Page 67 WOOD / PAINT DESK SETUP FREE STANDING DESK 1 PLACE UNIT IN DESIRED LOCATION MAKING SURE UNIT IS LEVEL. LOCATE POWER SOURCE AND REMOVE THE METAL SHROUDS TO THE BASE THAT POWER SOURCE SITS BELOW. 2 RUN POWER CORD THROUGH THE BASE TO THE FLOOR MONUMENT. USE THE CABLE HOLDERS TO SECURE THE CORD TO THE WORK SURFACE.

- Page 68 NOTE: UNIT SHOWN UPSIDE DOWN FOR REFERENCE ATTACH THE INSIDE METAL SHROUD BY PUTTING THE POWER SLOTS ONTO THE BED FRAME SEE DETAIL Q CORD BRACKETS AND PULLING THE SHROUD DOWN. DETAIL Q SCALE 0.025 SCALE 0.080 ATTACH POWER CORD TO WORK SURFACE WITH CABLE HOLDER AND 5/8"...

- Page 69 NOTE: MAKE SURE DOWELS ARE IN END PANEL AND LINE UP IN THE BASE. SEE DETAIL S SEE DETAIL R NOTE: SCREW THE EXTENSION SUPPORT PANEL BRACKET TO THE INSIDE OF THE EXTENSION SUPPORT PANEL WITH 10X5/8" PAN HEAD USING THE PILOT HOLES.

- Page 70 EXTENSION TO WORK SURFACE / WALL ACCESS PANEL MODELS WALL ACCESS PANEL EXTENSION WORK SURFACE FASTENERS 10X5/8" 10X1-1/4" GROMMET PANHEAD PANHEAD INSTALLATION 1 ONCE THE WORKSURFACE HAS BEEN SET, PUSH THE EXTENSION UP TO THE WALL WHERE THE BACK OF THE END PANEL SITS FLUSH TO THE BACK EDGE OF THE WORK SURFACE.

- Page 71 NOTE: SHOWN WITHOUT PED, WORKSURFACE, AND TOP OF WALL ACCESS NOTE: ONCE WALL ACCESS PANEL IS LEVEL PANEL FOR REFERENCE AND PLUM. SCREW THE ENDS INTO WORK SURFACE USING THE TWO INSIDE SEE DETAIL Y 2" BRACKETS. SCREW THE TWO ENDS INTO BOTH SIDES USING THE 1-1/4"...

- Page 72 MODESTY PANEL ATTACHMENT - METAL / WOOD / PAINT / LAMINATE METAL METAL MODESTY 10X3/4 PANHEADS WOOD-PAINT 8X7/8 10X5/8 SMALL BRACKET PANHEADS MODESTY PANHEADS LARGE BRACKET LAMINATE 10X1/2" 10X3/4 HWH #8 HWH #8 MODESTY LARGE BRACKET SMALL BRACKET HEX HEAD HEX HEAD METAL MODESTY PANEL ATTACHMENT 1 LOCATE THE PILOT HOLES ON THE WORKSURFACE THAT LINE UP WITH THE END HOLES AND CENTER HOLE.

- Page 73 2 USE THE 10X3/4" PAN HEADS TO ATTACH THE REST OF THE HOLES IN THE METAL MODESTY. WOOD-PAINT-LAMINATE MODESTY PANEL ATTACHMENT 1 DETERMINE WHAT TYPE OF UNIT THIS IS ATTACHING TO. IF THE UNIT IS A FREE STANDING TELESCOPING UNIT, THE LARGE BRACKETS WILL GO ON THE OUTSIDE (4) PILOT HOLES.

- Page 74 2 ON THE WORK SURFACE, LOCATE THE (8) PILOT HOLES THAT WILL LINE UP WITH THE (2) LARGE BRACKETS. FOR WOOD, USE THE 8X7/8" PAN HEADS AND SCREW THE LARGE BRACKETS INTO THE WORKSURFACE. ONCE THOSE HAVE BEEN SECURED, ATTACH THE SMALL BRACKETS USING THOSE 8X7/8" PAN HEADS. FOR LAMINATE, USE THE 10X3/4"...

-

Page 75: Shrouded T Height Adj

ASSEMBLY INSTRUCTION S2013-0011-00 REV A DATE: 04-DEC-2018 SHROUDED T HEIGHT ADJ GENERAL NOTES: 1. ALWAYS PROTECT THE UNIT WHEN INSTALLING. 2. LAMINATE AND WOOD/PAINT WILL INSTALL THE SAME WAY BUT SCREWS MAY VARY. 3. BOTH LAMINATE AND WOOD/PAINT WILL SHIP UNASSEMBLED. 4. - Page 76 SHROUDED T HEIGHT ADJ INSTALLATION SETUP 1 CLEAR A LARGE AREA SO THAT NOTHING WILL DAMAGE THE UNIT WHEN CONSTRUCTING 2 PLACE THE TOP ON THE GROUND AND ONCE THERE, BOLT IN THE PLATES TO THE LEGS THEN LINE UP THE LEGS TO THE PILOT HOLES AND SCREW INTO PLACE AND ATTACH THE PLATES TO THE BOTTOM OF THE LEGS 3 ONCE THE LEGS ARE ATTACHED, SCREW THE MOD TROUGH BRACKET TO THE TOP THEN LINE UP THE MODESTY PANEL AND SCREW INTO PLACE (IF DESIRED, YOU MAY SCREW THE CONTROL BOX AND HANDSET INTO PLACE NOW)

- Page 77 PANELS ARE CONNECT WITH SPRINGCLIPS CONNECTOR COMPOSITE MINI BOLT SCR 10X1/2 HEX DOWEL **TOP AND LEGS ARE NOT SHOWN IN THE VIEW. PEDS CAN MOVE AROUND IF NEEDED.** PAGE 3 OF 3...

-

Page 78: Bookcase Height Adj

S2013-0013-00 ASSEMBLY INSTRUCTION REV A BOOKCASE HEIGHT ADJ DATE: 05-DEC-2018 GENERAL NOTES: 1. ALWAYS PROTECT THE UNIT WHEN INSTALLING. 2. DEPENDING ON THE SIZE OF THE UNIT, A STIFFENER BAR WILL BE INCLUDED TO ATTACH TO THE WORKSURFACE. HARDWARE M6 12MM BOLT WASHER LOCK M6 25MM BOLT GLIDE... - Page 79 THERE ARE PILOT HOLES TO LINE UP BRACKET SCR 10X3/4 PN HD SCR 8X5/8 PN PH SCR 10X2 FT PH PAGE 2 OF 2...

-

Page 80: Height Adjustable Settings

12013-6008-00 INSTRUCTIONS HANDSET Rev C LINAK DL5 DL6 Date 03-JUL-2018 WARNING Failure to install product as instructed, use of hardware other than that which is provided, or failure to comply with instructions can result in product failure, personal injury, and/or property damage. WARNING When operating the table, ensure the table can operate to the lowest and highest points of travel without interference. -

Page 81: Height Adjustable Electrical Setup

TYPICAL HEIGHT ADJ MOTOR WIRE ELECTRICAL SETUP HANDSET WIRE POWER CORD **THE POWER CORD GOES INTO THE AC INPUT AND THROUGH THE GROMMET HOLE, THE MOTOR CABLES GO INTO THE NUMERIC INPUTS 1&2, AND THE HANDSET GOES INTO THE A1 INPUT** **THE POWER CORD WILL GET THE PLASTIC COVER TO PROTECT THE WIRES. - Page 82 TYPICAL HEIGHT ADJ ELECTRICAL SETUP EXAMPLE PAGE 2 OF 2...

Need help?

Do you have a question about the SILEAEH and is the answer not in the manual?

Questions and answers