Table of Contents

Advertisement

Tubeline Manufacturing Limited

6455 Reid Woods Drive RR #4

Elmira, Ontario, Canada N3B 2Z3

Email:

sales@tubeline.ca

Fax: 519.669.5808

Tel: 519.669.9488

Toll-free (North America): 1.888.856.6613

www.tubeline.ca

Operator's Manual

Keep this manual with the machine at all times.

Bale Processor

Boss I - 20 Series

Rev. 1-4

PRINTED IN CANADA

40252

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tubeline BALE BOSS 1 20 Series

- Page 1 Tubeline Manufacturing Limited 6455 Reid Woods Drive RR #4 Elmira, Ontario, Canada N3B 2Z3 Email: sales@tubeline.ca Fax: 519.669.5808 Tel: 519.669.9488 Toll-free (North America): 1.888.856.6613 www.tubeline.ca Operator’s Manual Keep this manual with the machine at all times. Bale Processor Boss I - 20 Series Rev.

-

Page 2: Operator's Manual

Operator’s Manual Thank you for choosing the Tubeline Boss 1 - 20 Series Bale Processor. Our hope is that it will give you many years of productive service. Please read and understand this manual and the machine before operation. This manual covers both 3720 and 3820 models. -

Page 3: Table Of Contents

Table of Contents Operator’s Manual ....... . Warranty and Limitation of Liability ......I Serial Plate Location . - Page 4 Section 10 - Part Breakdowns & Lists ..... . . 10-1 Loading Plate ........10-2 Ram .

- Page 5 Intentionally Left Blank...

-

Page 6: Section 1 - Introduction

Provide this manual to any new owners and/or operators. Bale Sizes Tubeline Boss 20 series machines can load and shred all types of forage in large square bales. Model 3720 specifications: Maximum bale weight is 1500lbs (680 kg). -

Page 7: Section 2 - Safety

Section 2 - Safety NOTICE: This safety alert symbol is found throughout this manual to call attention to instructions involving yourself and others working around the machine. Failure to follow these instructions can result in injury or death. This symbol means: •... -

Page 8: Personal Protective Equipment

Personal Protective Equipment WARNING: Wear work boots, gloves, and safety glasses when maintaining or repairing machine. WARNING: Wear work boots and ear protection when operating machine. DANGER: Secure loose clothing, hair, accessories, etc before operating or maintaining the TL50SLV. Maintenance Safety Know and follow good work practices when assembling, mounting, maintaining, repairing, removing and storing this product: •... -

Page 9: Transport Safety

station. Never leave the equipment unattended with the engine running or with this product raised on the loader. Transport Safety • Be aware of the added weight and width of this product. • Reduce travel speeds accordingly, especially when traveling over rough ground. •... -

Page 10: Section 3 - Safety Sign Locations

Section 3 - Safety Sign Locations Bale Processor Boss I - 20 Series - Section 3 - Safety Sign Locations... -

Page 11: Placement Or Replacement Of Safety Signs

DESCRIPTION DE23960 Boss 1 Decal 32.5 x 5.5 DE28146 Tubeline Decal 4” x 16” DE28705 Tubeline Decal 2.0” x 8.3 “ DE28724 Bale Processor BossI - 2.0 x 12 Decal DE37511 Boss I-3820 Model Decal DE37512 Boss I-3720 Model Decal... -

Page 12: Safety Decals

Safety Decals DE41712 - Hand Pinch Hazard DE41713 - Hydrulic Fluid Puncture Hazard Keep clear of machine while operating. Do not attempt to find hydraulic leaks with Do not attempt to free material by hand. pg.7-1 hand. Consult operators manual ( May result in serious injury and/or death. - Page 13 DE41902V - Chain Entanglement Hazard. DE41912 - Cutting Hazard. Keep hands clear of rotating parts while Sharp knives can cause dismemberment. Wait for machine running. Do not operate without moving parts to stop before attempting to repair. shielding in place. Do not wear loose clothing while operating.

-

Page 14: Section 4 - Power Unit Specifications

Section 4 - Power Unit Specifications IMPORTANT Exceeding any of the recommended power unit specifications CAN result in damage to your power unit and/or this product and WILL void all Tubeline warranties. Minimum Maximum 20 GPM at 2500 PSI 40 GPM at 3000 PSI... -

Page 15: Control Switch Functions

Section 5 - Functions & Adjustments Control Switch Functions NOTICE: The Boss I 20 series machine can be operated without electrical controls.However this removes the ability to stop the ram and top beater independantly from the flail drum. With the handheld electrical control positioned as shown in Fig.1, the three toggle switch functions are: •... -

Page 16: Flail Drum Guards Adjustment

Flail Drum Guards Adjustment Flail drum guards are a great way to restrict the amount of material that is feed through the flail drum. However longer materials may be restricted too much and become entangled in the guards. Follow these instructions to remove or change the spacing of the flail drum guards. 1. -

Page 17: Removing Cutting Knives

Removing Cutting Knives Removing the knives offers less resistance and faster processing when shorter material is being fed through the Boss I. DANGER: Only remove knives when machine is disconnected from power unit. Wear work gloves to avoid cutting hands on serrated edges. To remove knives follow these instructions: WARNING: You may want to clamp the knife blade(s) to the frame... -

Page 18: Section 6 - Processor Operation

Section 6 - Processor Operation DANGER Failure to obey the following procedure will result in death or serious injury. Avoid contacting overhead wires. WARNING Failure to obey the following procedures could result in death or serious injury. Never lift this product: above the operator’s eye level OR to a height where visibility is obstructed, whichever is lower. -

Page 19: Processor Hydraulic Connection

NOTICE Refer to your power unit’s operator’s manual for safe operating limit and use of counterweights. Processor Hydraulic Connection SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (Section 2) BEFORE BEGINNING ANY HYDRAULIC CONNECTION. Disconnect the hydraulic hose quick couplers from one another and attach the quick couplers to your power unit as per the instructions in your power unit’s operator’s manual. -

Page 20: Section 7 - Processor Maintenance

Inspect and tighten Allen screws on bearing. Repairs When making repairs, use only genuine Tubeline parts or, for fasteners, hydraulic hoses or hydraulic fittings, use only properly rated parts. Order safety decals for replacement parts that have a safety decal on the original part. -

Page 21: Section 8 - Processor Service

Section 8 - Processor Service SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (Section 2) BEFORE BEGINNING ANY PROCESSOR SERVICE. WARNING Hydraulic fluid under pressure can penetrate skin, resulting in serious injury or death. Always relieve hydraulic pressure before disconnecting lines. Shut off engine, set parking brake and relieve hydraulic pressure before connecting or disconnecting hydraulic lines. -

Page 22: Section 9 - Grease Points

Section 9 - Grease Points Bale Processor Boss I - 20 Series - Section 9 - Grease Points... - Page 23 Intentionally Left Blank...

-

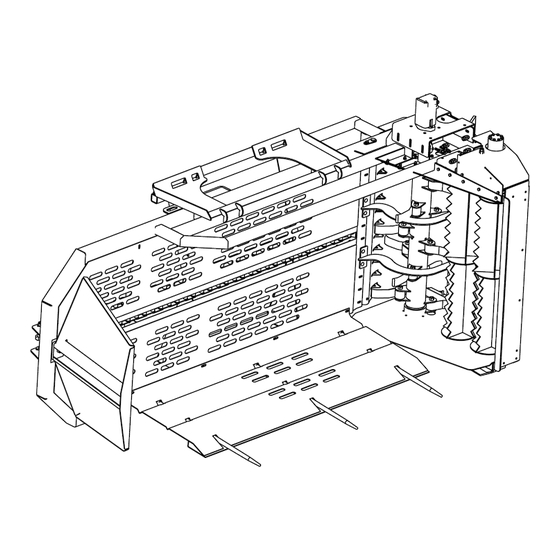

Page 24: Section 10 - Part Breakdowns & Lists

Section 10 - Part Breakdowns & Lists Bale Processor Boss I - 20 Series - Section 10 - Part Breakdowns & Lists 10-1... -

Page 25: Loading Plate

Loading Plate 10-2 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 26 Loading Plate ITEM PART NUMBER DESCRIPTION 25783 Loading Plate 39510 Conus 1 Nut CB 3/8-16 X0.75 Z5 Carriage Bolt - 3/8-16 x 3/4” Grade 5 Zinc HNC3/8 Serrated Hex Nut LA-MFE43 43” Tine Bale Processor Boss I - 20 Series - Section 10 - Part Breakdowns & Lists 10-3...

-

Page 27: Ram

10-4 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 28 ITEM PART NUMBER DESCRIPTION 36350 Ram Guide 39992 3720 Bed Chain (81X Chain) 39993 3820 Bed Chain (81X Chain) B1 123 Bottom Ram Slider Plate B1 150 BS200138A Idler HB 5/8-11X2 Z5 HB .625 x 2 Hex Bolt HN 5/8 HN .625 Hex Nut PB 5/8-11X2 PB .625 x 2 Plow Bolt...

-

Page 29: Rear Idler

Rear Idler 10-6 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 30 Rear Idler ITEM PART NUMBER DESCRIPTION 36308 Bearing Adjustment 36353 Bearing Plate 39992 3720 Bed Chain - (81X Chain) 39993 3820 Bed Chain - (81X Chain) BEA UCF208-24-1.5 1 1/2” 4 Bolt Flange Bearing BS200138A Idler HB 5/8-11X2 Z5 Hex Bolt 5/8-11x2 Grade 5 Zinc Plated Hex Cap Screw HN 1/2 Hex Nut 1/2”-13 Grade 5 Zinc Plated Finished LN 5/8 N...

-

Page 31: Front Chain Drive

Front Chain Drive 10-8 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 32 Front Chain Drive ITEM PART NUMBER DESCRIPTION 36695 Ram Motor Plate 39993 Ram Chain 39997 Chain - #60 x 39 Links (+ Connector Link) 39999 Keystock - .375 X .375 X 1.25 BEA UCF208-24-1.5 Flange Bearing BS200141A Bed Chain Sprocket Weldment CB 3/8-16 X1.25 Z5 Carriage Bolt - 3/8-16 x 1 1/4”...

-

Page 33: Flail Drum Assembly

Flail Drum Assembly 10-10 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 34 Flail Drum Assembly ITEM QTY PART NUMBER DESCRIPTION NOTE 39678 Flail Drum Brkdwn Pg.10-14 36395 Motor Mount VAL 1002 Hydraulic Motor SK 61258 Seal Kit for Eaton Hydraulic Motor 104-1002-006 36376 Flail Spacer BEA P208-108DI 1.5” Pillow Block Bearing CB 1/2-13 X1.5 Z5 Carriage Bolt - 1/2-13 x 1 1/2”...

-

Page 35: Flail Drum (Taper Lock Hub) Breakdown

Flail Drum (Taper Lock Hub) Breakdown *Taper lock drum will replace welded style flail drum. 10-12 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 36 Flail Drum (Taper Lock Hub) Breakdown *Taper lock drum will replace welded style flail drum. ITEM QTY PART NUMBER DESCRIPTION NOTE 39678 Boss I 20 Series Complete Taper Lock Drum Assembly Inc. All Items 39677 Flail Drum Inc. Items 3-6 30070 Flail Mount Lug 39921...

-

Page 37: Flail Drum Guards

Flail Drum Guards 10-14 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 38 Flail Drum Guards ITEM PART NUMBER DESCRIPTION 36306 Flail Rib CB 3/8-16 X1 Z5 Carriage Bolt - 3/8-16 x 1” Grade 5 Zinc HNC3/8 Serrated Hex Nut Bale Processor Boss I - 20 Series - Section 10 - Part Breakdowns & Lists 10-15...

-

Page 39: Top Beaters

Top Beaters 10-16 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 40 Top Beaters ITEM PART NUMBER DESCRIPTION 36312 Hyd. Motor Mount 36972 Top Beater 40256 Chain - #60, 49 Links (+ Connector Link) B1 084 Top Beater BEA 42852 BEA SA205-16+BEA PF205 BEA PF205 PF205 Bearing Flange BEA SA205-16 1” Bearing Insert CB 3/8-16 X1 Z5 Carriage Bolt - 3/8-16 x 1”...

-

Page 41: Front Shields

Front Shields 10-18 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 42 Front Shields ITEM PART NUMBER DESCRIPTION 36311 Skid Shoe 36375 Bolt-On Flail Sideplate 36379 Left Beater Shield 36380 Top Beater Shield 36384 Lower Rear Housing Cover 36920 Side Shield CB 3/8-16 X1 Z5 Carriage Bolt - 3/8-16 x 1” Grade 5 Zinc HBC3/8X0.75 Hex Bolt Cerrated 3/8-16 x 3/4 Zinc Flange Bolt HBC3/8X1...

-

Page 43: Discharge Chute

Discharge Chute 10-20 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 44 Discharge Chute ITEM PART NUMBER DESCRIPTION 36304 Folding Flail 36305 Link 36307 Clamp Handle 36307M Clamp Handle 36930 Retaining Pin 37508 Knife HB #10-24X0.75 FHSCS Hex Bolt - 3/16”-24 x 3/4” Flat Socket Cap Screw HB 1/2-13X1.5 Z5 Hex Bolt 1/2-13x1 1/2 Grade 5 Zinc Plated Hex Cap Screw HB 3/8-16X2 Z5 Hex Bolt 3/8-16x2 Grade 5 Zinc Plated Hex Cap Screw HBC3/8X0.75...

-

Page 45: Discharge Flap

Discharge Flap 10-22 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 46 Discharge Flap ITEM PART NUMBER DESCRIPTION 36318 Deflector 36932 Rubber Deflector HIN 3.5X3.5 Hinge 36938 Shield Adjuster 37843 Rubber Deflector Bolt Plate HBC1/4X0.75 Hex Bolt Cerrated 1/4-20 x 3/4 Zinc Flange Bolt HBC3/8X1 Hex Bolt Cerrated 3/8-16 x 1 Zinc Flange Bolt HNC1/4 Serrated Hex Nut HNC3/8...

-

Page 47: Manifold Block

Manifold Block 10-24 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 48 Manifold Block ITEM PART NUMBER DESCRIPTION 36392 Valve Mount CB 3/8-16 X1 Z5 Carriage Bolt - 3/8-16 x 1” Grade 5 Zinc HBC3/8X1 Hex Bolt Cerrated 3/8-16 x 1 Zinc Flange Bolt HNC5/16 Serrated Hex Nut LN 3/8 N LN 3/8-16 Zinc Plated Nylon Insert Lock Nut Manifold Block may vary.

-

Page 49: Electrical Schematic- Cti

Electrical Schematic- CTI 10-26 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 50 Electrical Schematic - CTI ITEM PART NUMBER DESCRIPTION NOTE BS B1 107 Boss I Toggle Switch Wiring Harness Inc Items 1-13 26203 Toggle Switch for Boss I (Double Pole) BS C-0203-N Textured Case Cover BS TF-2315TX Top Foot Enclosure with Textured Finish TL180-150 1/2 NPT 6-12mm Gland Connector TL270101-250...

-

Page 51: Electrical Schematic- Fps

Electrical Schematic- FPS 10-28 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 52 Intentionally Left Blank...

-

Page 53: Hydraulic Layout - Cti

Hydraulic Layout - CTI 10-30 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 54 Hydraulic Layout - CTI ITEM PART NUMBER DESCRIPTION 28036 Manifold Block 28143 Hose - HH72 - 12AT1(12MP,10FJXH)HCL 72” 39834 Hose - HH26 - 10AT1(10FJXH,10FJXH) HCL 26” 39835 Hose - HH18 - 6AT1(8FJXH,8FJXH) HCL 18” 39837 Hose - HH42 - 6AT1(8FJXH,8FJXH) HCL 42” 43702 Check Valve 1/4 O-ring to Jic 44811...

-

Page 55: Hydraulic Layout - Fps

Hydraulic Layout - FPS 10-32 Section 10 - Part Breakdowns & Lists - Bale Processor Boss I - 20 Series... - Page 56 Hydraulic Layout - FPS ITEM PART NUMBER DESCRIPTION 40613 Manifold Block 40614 Shuttle Valve 40615 1/2” Check Valve Fitting 40616 3/8” Check Valve Fitting 40617 Manual Flow Control (c/w dial) 40618 Complete Electric Pause - Manual Flow Control FPS 40700 Valve Body (c/w plugs &...

- Page 57 Intentionally Left Blank...

-

Page 58: Section 11 - Options

Section 11 - Options Bale Processor Boss I - 20 Series - Section 11 - Options 11-1... -

Page 59: Third Beater Kit

Third Beater Kit 11-2 Section 11 - Options - Bale Processor Boss I - 20 Series... - Page 60 Third Beater Kit ITEM QTY PART NUMBER DESCRIPTION NOTE 36916 3rd Beater Kit Incl. All Items 36915 Idler Sprocket Spacer 36921 3rd Beater Chain Guard 36934 3rd Beater Frame 40255 Chain - #60, 49 Links B1 084 Top Beater BEA 42852 BEA SA205-16 + BEA PF205 BEA PF205 Flange (3 Hole) - PF205 NTL...

-

Page 61: High Flow Kit - Cti

High Flow Kit - CTI ITEM PART NUMBER DESCRIPTION 28036 Manifold Block 36392 Valve Mount 36399 Hydraulic Motor Mount 42272 High Flow Hydraulic Motor CB 1/2-13 X1.5 Z5 Carriage Bolt - 1/2-13 x 1 1/2” Grade 5 Zinc CB 3/8-16 X1 Z5 Carriage Bolt - 3/8-16 x 1”... -

Page 62: High Flow Kit - Canimex

High Flow Kit - Canimex ITEM PART NUMBER DESCRIPTION 36392 Valve Mount 36399 Hydraulic Motor Mount 42179 Boss I Canimex Manifold 42272 High Flow Hydraulic Motor 43066 Canimex Manifold Bracket CB 1/2-13 X1.5 Z5 Carriage Bolt - 1/2-13 x 1 1/2" Grade 5 Zinc CB 3/8-16 X1 Z5 Carriage Bolt - 3/8-16 x 1"... -

Page 63: High Flow Layout - Cti

High Flow Layout - CTI 11-6 Section 11 - Options - Bale Processor Boss I - 20 Series... - Page 64 High Flow Layout - CTI ITEM PART NUMBER DESCRIPTION 28036 Manifold Block 28143 Hose - HH72 - 12AT1(12MP,10FJXH)HCL 72” 39835 Hose - HH18 - 6AT1(8FJXH,8FJXH) HCL 18” 39836 Hose - HH40 - 6AT1(8FJXH,8FJXH) HCL 40” 39837 Hose - HH42 - 6AT1(8FJXH,8FJXH) HCL 42” 42272 High Flow Hydraulic Motor 43226...

-

Page 65: High Flow Layout - Canimex

High Flow Layout - Canimex 11-8 Section 11 - Options - Bale Processor Boss I - 20 Series... - Page 66 High Flow Layout - Canimex ITEM QTY PART NUMBER DESCRIPTION 23896 Hose - HH24 - 12AT1(12FJ,12FJ) HCL 24” 42179 Boss I Canimex Manifold Block 42272 High Flow Hydraulic Motor 43107 Hose - HH72 - 12AT1(12MP,12FJXH90S)HCL 72” 43108 Hose - HH76 - 12AT1(12MP,12FJXH90S)HCL 76” 43221 Hose - HH15 - 6AT1(6FJX,6FJX) HCL 15”...

-

Page 67: High Flow Electrical Harness - Cti

High Flow Electrical Harness - CTI ITEM QTY PART NUMBER DESCRIPTION NOTE 45960 Boss I CTI Electrical Harness - Complete Incl. Items 2,3 28276 Boss I CTI Valve Wiring Harness BS B1 107 Boss I Toggle Switch Wiring Harness 11-10 Section 11 - Options - Bale Processor Boss I - 20 Series... -

Page 68: High Flow Electrical Harness - Canimex

High Flow Electrical Harness - Canimex ITEM PART NUMBER DESCRIPTION NOTE 45958 Boss I HF Canimex Harness - Complete Incl. Items 2,3 45959 Boss I HF Canimex Harness BS B1 107 Boss I Toggle Switch Wiring Harness Bale Processor Boss I - 20 Series - Section 11 - Options 11-11... -

Page 69: Section 12 - Torque Value Charts

Section 12 - Torque Value Charts Imperial Torque Values 12-1 Section 12 - Torque Value Charts - Bale Processor Boss I - 20 Series... -

Page 70: Metric Torque Values

Metric Torque Values Bale Processor Boss I - 20 Series - Section 12 - Torque Value Charts 12-2... - Page 71 Index Adjusting CTI Manifold Dials . . 5-1 After Every 10 Hours of Operation . 7-1 Bale Sizes . . 1-1 Before Each Use . . 7-1 Before First Use . . 7-1 Control Manifold Functions - CTI . . 5-1 Control Switch Functions .

Need help?

Do you have a question about the BALE BOSS 1 20 Series and is the answer not in the manual?

Questions and answers