Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operating Manual

Advertisement

Table of Contents

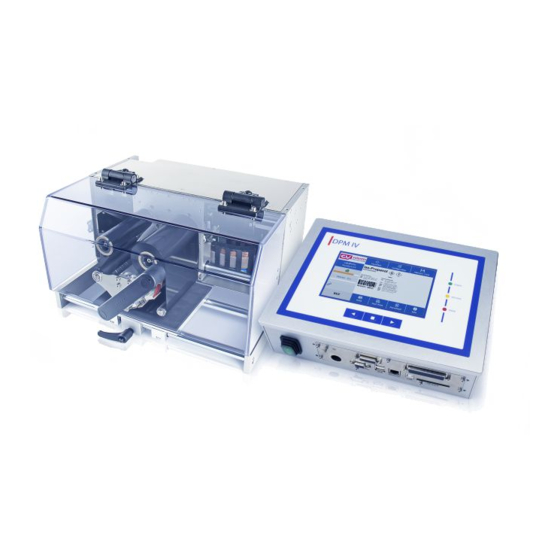

Summary of Contents for Carl Valentin DPM IV

- Page 2 It must not be concluded from the missing labelling that it is not a registered brand or a registered trademark. Carl Valentin print modules comply with the following EU directives • EG Low-Voltage Directive (2014/35/EU) •...

-

Page 3: Table Of Contents

DPM IV Table of Contents Table of Contents Table of Contents ................3 Notes on this Document ............5 User Notes ................5 Instructions ................5 Cross References ..............6 Safety Instructions ..............7 General Safety Instructions ............. 7 Safety Handling when Working with Electricity ....... 9 Environmentally-Friendly Disposal ........ - Page 4 Table of Contents DPM IV Layout Diagrams ..............87 10.1 CPU ..................87 10.2 Power Supply Unit ..............88 Pin Assignment of Control Unit ......... 89 Index ..................91 Service Instructions 05.19...

-

Page 5: Notes On This Document

DPM IV Notes on this Document Notes on this Document 1.1 User Notes This service manual is intended for qualified service and maintenance staff. This manual contains information about the electronics and the mechanical part of the direct print module. -

Page 6: Cross References

Notes on this Document DPM IV 1.3 Cross References References to specific items in a figure are marked with letters. They Drawings are identified with parentheses in the text, e.g. (A). If no figure number is provided, letters in the text always refer to the graphic directly above the text. -

Page 7: Safety Instructions

DPM IV Safety Instructions Safety Instructions 2.1 General Safety Instructions Workplace and Keep the area around the device clean during and after method of working maintenance. Work in a safety-conscious manner. Store dismantled device parts in a safe place while maintenance is being performed. - Page 8 Safety Instructions DPM IV Protective equipment WARNING! Risk of injury in case of missing or faulty protective equipment. After performing maintenance work, attach all safety equipment (covers, safety precautions, ground cables etc.). Replace faulty parts and those which have become unusable.

-

Page 9: Safety Handling When Working With Electricity

Safety Instructions DPM IV There are warning stickers on the direct print modules that draw your attention to dangers. Therefore the warning stickers are not to be removed as then you and others cannot be aware of dangers and may be injured. -

Page 10: Environmentally-Friendly Disposal

It may only be organised, used and disposed of by the manufacturer. Valentin products accordingly labelled can therefore be returned to Carl Valentin GmbH. This way, you can be sure your old equipment will be disposed of correctly. -

Page 11: Retrofit With Options

DPM IV Retrofit with Options Retrofit with Options 3.1 Brake CAUTION! Risk of injury due to short circuit. Before opening the housing cover, disconnect the device from the mains supply and wait for a moment until the power supply unit has discharged. -

Page 12: Counter-Pressure Plate (Valentin)

Retrofit with Options DPM IV 3.2 Counter-Pressure Plate (Valentin) Figure 2 1. For the attachment of the optional Valentin counter-pressure plate (A), appropriate threaded holes are designated at the bottom of the print mechanics (D). The suitable screws (B) are included with delivery of this option. -

Page 13: Protective Cover For The Control Unit Ip65

DPM IV 3.3 Protective cover for the control unit IP65 NOTICE! By mounting the optional protective cover, the protection class IP 65 according to DIN EN 60529 is achieved for the control unit of DPM IV. Figure 3 05.19 Service Instructions... - Page 14 Retrofit with Options DPM IV 1. Successively remove the four screws (C) on the back on the control unit (A), slide on the sealing rings (B) and screw in the screws (C) again. 2. Connect the connection cable print mechanics/control unit (F) to the control unit (A).

- Page 15 Retrofit with Options DPM IV NOTICE! Check that all cables are safely enclosed by the grommets (M) so that no water or dust can enter. Too large grommets and loose cables lead to entering of impurities into the case. Suitable cable grommets in different sizes are available ex works.

-

Page 17: Electronics (Replace Components)

DPM IV Electronics (Replace Components) Electronics (Replace Components) DANGER! Risk of death via electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait for a moment until the power supply unit has discharged. -

Page 18: Input/Output Board

Electronics (Replace Components) DPM IV 4.2 Input/Output Board NOTICE! The inputs/outputs can be tested in the Service Functions. In case of an active input, the position corresponding to this input changes to 1. To activate an output, move the cursor to the corresponding position and set value 1. -

Page 19: Distributor Board

DPM IV Electronics (Replace Components) 4.3 Distributor Board Figure 8 1. Remove the control unit from the electrical outlet. Removing the distributor board 2. Unscrew the four screws on the rear and remove the front plate (see chapter 4.1, page 17). -

Page 20: Cpu Pcb

Electronics (Replace Components) DPM IV 4.4 CPU PCB Figure 9 Removing the NOTICE! CPU PCB Save the configuration onto a CF card. 1. Unplug the control unit from the electrical outlet. 2. Unscrew the four screws on the rear and remove the front plate (see chapter 4.1, page 17). - Page 21 DPM IV Electronics (Replace Components) Installing the 1. If not available, move the cover of the CF card slot (C) from the CPU PCB old CPU to the new CPU. 2. Insert the CPU PCB (D) with the interface sockets into the connection plate and turn the hexagonal bolts of the serial interface if necessary.

-

Page 22: Battery

Electronics (Replace Components) DPM IV 4.5 Battery DANGER! Danger of explosion due to improper replacement of the battery! Use non-conductive tools. Pay attention to polarity. Figure 10 Removing the battery 1. Unplug the control unit from the electrical outlet. -

Page 23: Power Supply Unit

DPM IV Electronics (Replace Components) 4.6 Power Supply Unit Figure 11 Removing the power 1. Unplug the control unit from the electrical outlet. supply unit 2. Unscrew the four screws on the rear and remove the front panel (see chapter 4.1, page 17). -

Page 24: Hmi Components

Electronics (Replace Components) DPM IV 4.7 HMI Components Figure 12 1. Unplug the control unit from the electrical outlet. Removing HMI components 2. Unscrew the four screws on the rear and remove the front plate (B) (see chapter 4.1, page 17). Disconnect all connecting cables at the plug-in connectors while removing the front plate. - Page 25 DPM IV Electronics (Replace Components) Installing HMI 1. Place the connection board (D) for the transparent keyboard, components tighten the screws and plug in the connection cable (C). 2. Place the seal (F) into the depression and carefully place the new graphic module (A) onto it.

- Page 26 Electronics (Replace Components) DPM IV Service Instructions 05.19...

-

Page 27: Mechanics (Replace Components)

DPM IV Mechanics (Replace Components) Mechanics (Replace Components) 5.1 Printhead CAUTION! The printhead can be damaged by static electricity discharges and impacts! Set up the direct print module on a grounded, conductive surface. Ground your body, e.g. by wearing a grounded wristband. - Page 28 Mechanics (Replace Components) DPM IV 1. Do not touch the contacts of the printhead. Installing the printhead 2. Position the new printhead in the printhead support. 3. Tighten again the screws (A). 4. Connect the printhead cable (C). 5. Insert the transfer ribbon.

-

Page 29: Transfer Ribbon Tension Adjustment

DPM IV Mechanics (Replace Components) 5.2 Transfer Ribbon Tension Adjustment Figure 14 For a regular print quality it is necessary that the transfer ribbon is to tighten even over its width. Use the nuts (A) to regulate a different transfer ribbon tension by a sideways overturn of the printhead. -

Page 30: Angle Adjustment

Mechanics (Replace Components) DPM IV 5.3 Angle Adjustment Figure 15 The installation angle of the printhead (B) is default 26° to the print surface. However, manufacturing tolerances of printhead and mechanics can require another angle. CAUTION! Damage of printhead by unequal use! Higher wastage of ribbon by faster ripping. -

Page 31: Printhead Bracket

DPM IV Mechanics (Replace Components) 5.4 Printhead Bracket Figure 16 Removing the 1. Open the dust cover or remove it by unscrewing the four screws at the hinges. printhead bracket 2. Remove the transfer ribbon 3. Push the print carriage into an appropriate service position. If necessary, remove the counter-pressure plate. -

Page 32: Linear Bearing For Printhead Bracket

Mechanics (Replace Components) DPM IV Installing the 1. Carefully install the new printhead bracket (B) into the linear bearing. printhead bracket 2. Install the discs and the springs. 3. Tighten the two nuts (A). NOTICE! Tighten the nuts (A) the same on both sides, so that the printhead bracket (B) with the printhead is pulled through the springs against the short-stroke cylinder. -

Page 33: Short-Stroke Cylinder

DPM IV Mechanics (Replace Components) 5.6 Short-Stroke Cylinder Figure 18 1. Remove the printhead bracket (see chapter 5.4, page 31). Removing short stroke cylinder 2. Remove the screws (A). 3. Press the ring of the respective push-in fitting (C) and carefully remove this from the pneumatic tube (D). -

Page 34: Transfer Ribbon Roller

Mechanics (Replace Components) DPM IV 5.7 Transfer Ribbon Roller Figure 19 Removing the transfer 1. Open the dust cover or remove it by unscrewing the four screws at the hinges. ribbon roller 2. Remove the transfer ribbon. 3. Push the print carriage into an appropriate service position. -

Page 35: Toothed Belt 'Motor

DPM IV Mechanics (Replace Components) 5.8 Toothed Belt 'Motor' Figure 20 Remove the 1. Unscrew the six countersunk screws (C) and remove the top toothed belt cover (E). 2. Push the print carriage into an appropriate service position. 3. Remove the locking ring (H). -

Page 36: Linear Toothed Belt

Mechanics (Replace Components) DPM IV 5.9 Linear Toothed Belt Figure 21 Removing the linear 1. Unscrew the six countersunk screws (F) and remove the top cover toothed belt (G). 2. Push the print carriage into an appropriate service position. 3. Remove the two lock nuts (A) and the below washer. - Page 37 DPM IV Mechanics (Replace Components) Installing the linear 1. Cut a new toothed belt (endless yard goods) to the correct length toothed belt depending on the print length of the device (see the Spare parts list or length corresponding to the removed belt).

-

Page 38: Print Carriage

Mechanics (Replace Components) DPM IV 5.10 Print Carriage Figure 22 Removing print 1. Unscrew the four screws (G) and remove the top cover (J). carriage 2. Unscrew the six countersunk screws (E) and remove the top cover (F). 3. Push the print carriage into an appropriate service position. - Page 39 DPM IV Mechanics (Replace Components) 9. Unscrew the screws (Q). 10. Hold the print carriage (M) and pull the top guiding shaft (K) with the flange (L) out of the hole in the side panel (P) and remove them. Remove the slider (R) for the zero point control while this procedure.

-

Page 40: Print Carriage Pcb And Connecting Cable In The Energy Chain40

Mechanics (Replace Components) DPM IV 5.11 Print Carriage PCB and Connecting Cable in the Energy Chain Figure 24 Replacing the print 1. Remove the print carriage (see chapter 5.10, page 38). carriage PCB and the NOTICE! connecting cable in the... - Page 41 DPM IV Mechanics (Replace Components) Installing the print 1. Insert new connecting cables in the energy chain between the carriage PCB and the motor PCB and the print carriage PCB. connecting cable in the 2. Close the energy chain. For this procedure, close the opening energy chain crossbars (C, Figure 24).

-

Page 42: Valve

Mechanics (Replace Components) DPM IV 5.12 Valve Figure 25 Removing the valve 1. Removing the print carriage (see chapter 5.10, page 38). NOTICE! It is not necessary to remove the print carriage for printing systems from print length 240 mm. In this case, remove the print unit cover at the rear to work from the back of the device. - Page 43 DPM IV Mechanics (Replace Components) 1. Place a new valve (C, Figure 25) and press forward the complete Installing the valve bracket for the valve (D, Figure 25) with components. 2. Tighten the screw (B, Figure 25). 3. Connect the pneumatic tube (E, Figure 25).

-

Page 44: Zero Sensor And End Position Sensor

Mechanics (Replace Components) DPM IV 5.13 Zero Sensor and End Position Sensor Figure 26 Figure 27 Removing the zero 1. Unscrew the six countersunk screws (C) and remove the top sensor and the end cover (B). position sensor 2. Push the print carriage into an appropriate service position. - Page 45 DPM IV Mechanics (Replace Components) Installing the zero 1. Place the new end position sensor and tighten it with the screw sensor and the end (D, Figure 26). position sensor 2. Place the new zero sensor and tighten it with the screw (A, Figure 26).

-

Page 46: Transfer Ribbon Rewinder/Unwinder

Mechanics (Replace Components) DPM IV 5.14 Transfer Ribbon Rewinder/Unwinder Figure 28 1. Unscrew the six countersunk screws and remove the top cover. Removing the rewinder 2. Unscrew the six countersunk screws and remove the rear cover. 3. Open dust cover or remove it by unscrewing four screws at the hinges. - Page 47 DPM IV Mechanics (Replace Components) 4. Install the transfer ribbon roller (A, Figure 28). 5. Place the drive plate (B, Figure 28), the spring (E, Figure 28) and the washer (C, Figure 28) and tighten it with the screw (D, Figure 28) (see Notice below).

-

Page 48: Encoder

Mechanics (Replace Components) DPM IV 5.15 Encoder Figure 29 Removing the encoder 1. Unscrew the six countersunk screws and remove the top cover. 2. Unscrew the six countersunk screws and remove the rear cover. 3. Open dust cover or remove it by unscrewing four screws at the hinges. - Page 49 DPM IV Mechanics (Replace Components) 1. Press the new encoder (C, Figure 29) in the bracket (B, Figure Installing the encoder 29). 2. Place the encoder (C, Figure 29) with the bracket (B, Figure 29) from behind in the print carriage.

-

Page 50: Top Linear Bearing

Mechanics (Replace Components) DPM IV 5.16 Top Linear Bearing Figure 30 1. Unscrew the six countersunk screws and remove the top cover. Removing the top linear bearing 2. Open dust cover or remove it by unscrewing four screws at the hinges. - Page 51 DPM IV Mechanics (Replace Components) 5. Unscrew the two screws (C, Figure 31). 6. Unscrew the screw (H, Figure 31). 7. Hold the print carriage (K, Figure 31) and pull the top guiding shaft (A, Figure 31) with the flange (B, Figure 31) from the hole in the side panel (G, Figure 31) and remove them.

-

Page 52: Bottom Linear Bearing

Mechanics (Replace Components) DPM IV 5.17 Bottom Linear Bearing Figure 32 1. Unscrew the three countersunk screws and the two cylinder Removing the bottom linear bearing screws (J). 2. Open dust cover or remove it by unscrewing four screws at the hinges. - Page 53 DPM IV Mechanics (Replace Components) 5. Unscrew the two screws (E, Figure 32). 6. Unscrew the screw (I, Figure 32). 7. Hold the print carriage (K, Figure 32) and pull the guiding shaft below (F, Figure 32) with the flange (D, Figure 32) from the hole in the side panel (G, Figure 32) and remove them.

-

Page 54: Cover Sensor

Mechanics (Replace Components) DPM IV 5.18 Cover Sensor Figure 35 Removing the 1. Unscrew the six countersunk screws (C) and remove the top cover. cover sensor 2. Unscrew the three countersunk screws and the two cylinder screws (D) and remove the bottom cover. - Page 55 DPM IV Mechanics (Replace Components) Installing the 1. Place the new cover sensor (G) and fasten the two screws (H). cover sensor Insert the appropriate connector into the motor PCB. 2. Install the cable tie on the bottom side of the connection plate.

-

Page 56: Motor Pcb

Mechanics (Replace Components) DPM IV 5.19 Motor PCB Figure 36 Removing the 1. Unscrew the six countersunk screws (D) and remove the top motor PCB cover (C). 2. Unscrew the six countersunk screws (I) and remove the rear cover (H). - Page 57 DPM IV Mechanics (Replace Components) Installing the 1. Place the new motor PCB (F) and tighten it with the four screws motor PCB (G). 2. Tighten the two hexagonal bolts (E). 3. Insert all connectors into the motor PCB (F).

-

Page 58: Pressure Sensor

Mechanics (Replace Components) DPM IV 5.20 Pressure Sensor Figure 37 1. Unscrew the six countersunk screws and remove the top cover. Removing the pressure sensor 2. Open the dust cover or remove it by unscrewing the four screws at the hinges. - Page 59 DPM IV Mechanics (Replace Components) Installing the 1. Place the new pressure sensor (H) onto the connector block (I) pressure sensor and tighten it with the two screws (E). 2. Place the connector block (I) with the pressure sensor (H).

- Page 60 Mechanics (Replace Components) DPM IV Service Instructions 05.19...

-

Page 61: Cleaning

DPM IV Cleaning Cleaning DANGER! Risk of death by electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait for a moment until the power supply unit has discharged. NOTICE! When cleaning the printing system, personal protective equipment such as safety goggles and gloves are recommended. -

Page 62: Transfer Ribbon Roller

Cleaning DPM IV 6.2 Transfer Ribbon Roller A soiled ribbon roller can lead to reduced print quality and can affect transport of material. Figure 38 1. Open dust cover or remove it by unscrewing four screws at the hinges. 2. Remove the transfer ribbon. -

Page 63: Printhead

DPM IV Cleaning 6.3 Printhead Printing can cause accumulation of dirt at printhead e.g. by colour particles of transfer ribbon, and therefore it is necessary to clean the printhead in regular periods depending on operating hours, environmental effects such as dust etc. - Page 64 Cleaning DPM IV Service Instructions 05.19...

-

Page 65: Error Correction

DPM IV Error Correction Error Correction Error message Cause Remedy Line too high Line rises up completely or Move line down partly over the upper edge of (increase Y value). label. Check rotation and font. Line too low Line rises up completely or Move line up (reduce Y value). - Page 66 Error Correction DPM IV Error message Cause Remedy Length mask Invalid length of received mask Check sent data. statement. Check connection PC - printer. Unknown mask Transferred mask statement is Check sent data. invalid. Check connection PC - printer. Missing ETB No end of data found.

- Page 67 DPM IV Error Correction Error message Cause Remedy Application Selected application identifier is Check code data. Identifier not available in GS1-128. HIBC definition F Missing HIBC system sign. Check definition of HIBC code. Missing primary code. System clock Real Time Clock function is Change battery.

- Page 68 Error Correction DPM IV Error message Cause Remedy Drive write- Memory card is write-protected. Deactivate write protection. protected Directory not file Attempt to indicate a directory Correct your entry. as file name. File already open Attempt to change a file during Select another file.

- Page 69 DPM IV Error Correction Error message Cause Remedy Zero point Defective photocell. Change photocell. Compressed air Pressure air is not connected. Check pressure air. External releaser External print release signal is Check input signal. missing. Row too long Wrong definition of column Reduce the column width res.

- Page 70 Error Correction DPM IV Error message Cause Remedy IGP error Protocol error IGP. Check sent data. Time generation Printing creation was still active Reduce print speed. at print start. Use printers' output signal for synchronization. Use bitmap fonts to reduce generating time.

- Page 71 DPM IV Error Correction Error message Cause Remedy Scanner layout Scanner data does not Check adjustment of scanner. difference correspond to bar code data. Check scanner settings / connection. COM break Serial interface error. Check settings for serial data transmission as well as cable (printer-PC).

- Page 72 Error Correction DPM IV Error message Cause Remedy Housing open When starting the print order Close the housing cover and the housing cover is not closed. start the print order anew. EAN.UCC code Transferred EAN.UCC code is Verify bar code data (see invalid.

- Page 73 DPM IV Error Correction Error message Cause Remedy IP occupied The IP address was already Assign a new IP address. assigned. Print asynchronous The label photocell does not Check label size and gap size. work in the order as it is expected according to print data.

- Page 74 Error Correction DPM IV Error message Cause Remedy Script failure LUA script is incorrect. Check the script. Script user error Error in LUA script user input. Correct the input value. No reprint available No label data for reprinting Send new label data to the available.

-

Page 75: Control Inputs And Outputs

DPM IV Control Inputs and Outputs Control Inputs and Outputs By means of a maximum of 16 control inputs and outputs which, in the following, are also referred to as ports, different functions of the printer system can be triggered and operating states can be displayed. - Page 76 Control Inputs and Outputs DPM IV Configuration of D-Sub socket Figure 41 Port 1 to Port 16 = Assignment for I/O Profile Std_Direct Port Description / Function 11 (Input) Print start 12 (Input) No function 13 (Input) Counter reset 14 (Input)

- Page 77 DPM IV Control Inputs and Outputs Port Description / Function + 5 VDC 5 Volt DC output for external use. Max. 1 A. This voltage is provided from direct print module and can be used e.g. as control voltage. Never apply any external voltage to this output.

- Page 78 Control Inputs and Outputs DPM IV Port 1 to Port 16 = Assignment for I/O Profile StdFileSelDirect Port Description / Function 11 (Input) Print start 12 (Input) Error reset 13 (Input)* Number of the file to load Bit 0 (Input)

- Page 79 DPM IV Control Inputs and Outputs Port 1 to Port 16 = Assignment for I/O Profile SP_Direct0 Port Description / Function 11 (Input) Print start 12 (Input) No function 13 (Input) Counter reset 14 (Input) No function 15 (Input) Error reset...

- Page 80 Control Inputs and Outputs DPM IV Plug Connector Technical data Type D-Sub connector High Density 26-pin. / connector Manufacturer W+P-Products Reference number 110-26-2-1-20 Output Voltages (connected with GND-PE) + 24 V / 1 A Fuse: Polyswitch / 30 V / 1 A...

- Page 81 DPM IV Control Inputs and Outputs Example 1 Device connection to a machine with S7-300 SPS. Figure 42 Example 2 Device connection to a operating panel. Figure 43 05.19 Service Instructions...

- Page 82 Control Inputs and Outputs DPM IV Device connection version if 'Option: 2. LED'. Example 3 Figure 44 When connecting a reed contact with a control input, the contact must Precautions have a switching capacity of min. 1 A in order to prevent the contact from sticking due to the inrush current.

-

Page 83: Wiring Plans

DPM IV Wiring Plans Wiring Plans 9.1 Control Unit Figure 45 05.19 Service Instructions... -

Page 84: Print Mechanics (Left Version)

Wiring Plans DPM IV 9.2 Print Mechanics (Left Version) Figure 46 Service Instructions 05.19... -

Page 85: Print Mechanics (Right Version)

DPM IV Wiring Plans 9.3 Print Mechanics (Right Version) Figure 47 05.19 Service Instructions... - Page 86 Wiring Plans DPM IV Service Instructions 05.19...

-

Page 87: Layout Diagrams

DPM IV Layout Diagrams 10 Layout Diagrams 10.1 CPU BAT 1 (CR2032) Figure 48 Jumper plan INIT programming closed closed Boot/software programming closed open Delivery closed open 05.19 Service Instructions... -

Page 88: Power Supply Unit

Layout Diagrams DPM IV 10.2 Power Supply Unit Figure 49 100-240 VAC input 48V output Protective conductor connection Service Instructions 05.19... -

Page 89: Pin Assignment Of Control Unit

DPM IV Pin Assignment of Control Unit 11 Pin Assignment of Control Unit 1 - LED green Lighting = Speed 100 MBit Off = Speed 10 MBit 2 - LED orange Lighting = Connection active Flashing = Data transfer Off = No connection... - Page 90 Pin Assignment of Control Unit DPM IV Service Instructions 05.19...

-

Page 91: Index

DPM IV Index 12 Index angle adjustment (printhead) ............. 30 battery, replacing ................22 brake, retrofit ..................11 cleaning general information ................. 61 printhead ..................63 transfer ribbon roller ................ 62 connecting cable in energy chain, replacing ........ 40, 41 control inputs/control outputs .... - Page 92 Index DPM IV input/output board, replacing .............. 18 instructions ................... 5 jumper plan, CPU ................87 layout diagrams CPU ....................87 power supply ................... 88 linear bearing (bottom), replacing ..........52, 53 linear bearing (printhead bracket), replacing........32 linear bearing (top), replacing ............50, 51 linear toothed belt, replacing ............

- Page 93 DPM IV Index options, retrofit brake ....................11 counter-pressure plate (Valentin) ........... 12 protective cover for control unit IP65 ........13, 14, 15 power supply unit layout diagram ................88 replacing ..................23 pressure sensor, replacing ............58, 59 primary fuses, replacing ..............17 print carriage PCB, replacing .............

- Page 94 Index DPM IV valve, replacing ................42, 43 wiring plans control unit ..................83 print mechanics (left version) ............84 print mechanics (right version) ............85 zero sensor, replacing ..............44, 45 Service Instructions 05.19...

Need help?

Do you have a question about the DPM IV and is the answer not in the manual?

Questions and answers