Summary of Contents for Nord Drivesystems NORDAC BASE SK 180E Series

- Page 1 BU 0180 – en NORDAC BASE (SK 180E / SK 190E) ® Users Manual for Frequency Inverters...

- Page 2 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Documentation Title: BU 0180 Order – No.: 6071802 Series: SK 1x0E FI series: SK 180E, SK 190E Device types: SK 1x0E-250-112-O ... SK 1x0E-750-112-O 0.25 – 0.75 kW, 1~ 110-120 V, Out: 230 V SK 1x0E-250-323-B ...

-

Page 3: Table 1: Version List

Any editing or amendment or other utilisation of the document is prohibited. Publisher Getriebebau NORD GmbH & Co. KG Getriebebau-Nord-Straße 1 • 22941 Bargteheide, Germany • http://www.nord.com/ Fon +49 (0) 45 32 / 289-0 • Fax +49 (0) 45 32 / 289-2253 Member of the NORD DRIVESYSTEMS Group BU 0180 en-4118... - Page 4 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters BU 0180 en-4118...

-

Page 5: Table Of Contents

Table of Contents Table of Contents General ............................... 10 Overview ............................10 Delivery ............................13 Scope of delivery..........................13 Safety, installation and operating instructions .................. 17 Warning and hazard information ...................... 22 1.5.1 Warning and hazard information on the product ..............22 1.5.2 Warning and hazard information in the document .............. - Page 6 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 3.2.3.1 Plug connectors for power connections 3.2.3.2 Plug connectors for control connection 3.2.4 Potentiometer adapter, SK CU4-POT ................. 71 Commissioning ............................72 Factory settings ..........................72 Selecting the operating mode for motor control ................73 4.2.1 Explanation of the operating modes (P300) ...............

- Page 7 Table of Contents 8.4.5 Reduced output current due to the heat sink temperature ..........189 Operation with FI circuit breakers....................190 System bus ............................ 191 Energy Efficiency ........................... 194 Motor data - characteristic curves ....................195 8.8.1 50 Hz characteristic curve ....................195 8.8.2 87 Hz characteristic curve (only 400V devices) ..............

- Page 8 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters List of illustrations Figure 1: Device with internal SK CU4-......................... 11 Figure 2: Device with external SK CU4-........................ 11 Figure 3: Name plate ............................. 27 Figure 4: Example of motor size adaptation ......................

- Page 9 List of tables List of tables Table 1: Version list ..............................3 Table 2: Warning and hazard information on the product ..................22 Table 3: Standards and approvals ......................... 23 Table 4: Standards and approvals for explosion hazard environments ..............24 Table 5: Assignment of braking resistors to frequency inverter ................

-

Page 10: General

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 1 General The SK 1x0E series is based on the tried and tested NORD platform. The devices are characterised by their compact design and optimum control characteristics, and have uniform parametrisation. The devices have sensor-less current vector control with a wide range of settings. -

Page 11: Figure 1: Device With Internal Sk Cu4

1 General • 2 digital outputs • Separate temperature sensor input (TF+/TF-) • NORD system bus for connecting additional modules, with switchable terminating resistance and address which can be set using DIP switches. • Four separate parameter sets, switchable online •... - Page 12 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters The SK CU4-POT potentiometer adapter is an exception among the "SK CU4 Modules", since it is not integrated in the device but attached to it. Communication between "intelligent" option modules and the device takes place via the system bus. Intelligent option modules are modules with their own processor and communication technology, as is the case with field bus modules, for example.

-

Page 13: Delivery

1 General 1.2 Delivery Check the equipment immediately after delivery / unpacking for transport damage such as deformation or loose parts. If there is any damage, contact the carrier immediately and carry out a thorough assessment. Important! This also applies even if the packaging is undamaged. 1.3 Scope of delivery NOTICE Defect in the device... - Page 14 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Customer unit for installation device for: Internal bus interfaces CANopen, DeviceNet, EtherCAT, Ethernet/IP, Powerlink, Profibus DP, Profinet IO Model SK CU4- … Section 3.2.1 "Internal customer interfaces SK CU4-…...

- Page 15 1 General Set for mounting the device, separate from the Wall mounting for the device motor (e.g. to a wall). Model SK TIE4-WMK-… ( Section 2.1.2 "Wall mounting") Set for mounting a technology unit, SK TU4-..., Wall mounting for SK TU4-… separate from the device (e.g.

- Page 16 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters AC Power connector for attaching to the device Power connection for making a detachable connection for supply (for power input, power output, lines (e.g. mains supply line) motor output) Model SK TIE4-…...

-

Page 17: Safety, Installation And Operating Instructions

1 General 1.4 Safety, installation and operating instructions Before working on or with the device, please read the following safety instructions extremely carefully. Please pay attention to all other information from the device manual. Non-compliance can result in serious or fatal injuries and damage to the device or its surroundings. These safety instructions must be kept in a safe place! 1. - Page 18 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2. Qualified experts For the purposes of these basic safety instructions, qualified personnel are persons who are familiar with the assembly, installation, commissioning and operation of this product and who have the relevant qualifications for their work.

- Page 19 1 General Installation and assembly The installation and cooling of the device must be implemented according to the regulations in the corresponding documentation. The permissible mechanical and climatic ambient conditions (see technical data in the manual for the device) must be complied with. The device must be protected against impermissible loads.

- Page 20 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Operation Where necessary, systems in which the devices are installed must be equipped with additional monitoring and protective equipment according to the applicable safety requirements (e.g. legislation concerning technical equipment, accident prevention regulations, etc.).

- Page 21 1 General • Explosive concentrations of dust may cause explosions if ignited by hot or sparking objects. Such explosions may cause serious or fatal injuries to persons or severe material damage. The drive must comply with the specifications of "Planning guideline for the operating and •...

-

Page 22: Warning And Hazard Information

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 1.5 Warning and hazard information Under certain circumstances, hazardous situations may occur in association with the frequency inverter. In order to give explicit warning of possibly hazardous situations, clear warning and hazard information can be found on the device and in the relevant documentation. -

Page 23: Warning And Hazard Information In The Document

1 General 1.5.2 Warning and hazard information in the document The warning and hazard information in this document are located at the beginning of the section which describes the action which may result in the corresponding hazards. The warning and hazard information is classified as follows according to the risk and the severity of the resulting injuries. -

Page 24: Table 4: Standards And Approvals For Explosion Hazard Environments

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Devices which are configured and approved for use in explosion hazard environments ( Section 2.5 "Operation in potentially explosive environments ") comply with the following directives and standards. Applied Approval Directive... -

Page 25: Ul And Csa Approval

1 General 1.6.1 UL and CSA approval File No. E171342 Categorisation of protective devices approved by the UL according to United States Standards for the inverters described in this manual is listed below with essentially the original wording. The categorisation of individually relevant fuses or circuit breakers can be found in this manual under the heading “Electrical Data”. - Page 26 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Size valid description 1 - 2 generally valid “Suitable For Use On A Circuit Capable Of Delivering Not More Than 100 000 rms Symmetrical Amperes, 480 Volts Maximum” and minimum one of the two following alternatives. When used together with or without Accessory SK TU4-MSW: “Suitable For Use On A Circuit Capable Of Delivering Not More Than 10 000 rms Symmetrical Amperes, 480 Volts Maximum”...

-

Page 27: Type Code / Nomenclature

1 General 1.7 Type code / nomenclature Unique type codes have been defined for the individual modules and devices. These provide individual details of the device type and its electrical data, protection class, fixing version and special versions. A differentiation is made according to the following groups: Frequency inverter Optional module Motor... -

Page 28: Frequency Inverter Type Code

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 1.7.2 Frequency inverter type code SK 180E-370-323-B (-C) (-xxx) Special version IP protection class: Standard = IP55, C = IP66, C-NSD = IP69K Radio interference filter: O = without, A = class A1(C2), B= class B (C1) Mains voltage: x12 = 115 V, x23 = 230 V, x40 = 400 V Number of mains phases: 1xx = single phase, 3xx = 3-phase (with 230 V to 1.1 kW: 1~/3~) -

Page 29: Type Code, Connection Unit For Technology Unit

1 General 1.7.4 Type code, connection unit for technology unit SK TI4-TU-BUS (-C) IP protection class: Standard = IP55 C = "coated" IP66 Suitable NET = Mains option module (e.g. TU4-24V-…) device types: Bus option module (e.g. CANopen: TU4-CAO Group: TU = Technology unit SK TI4 = Connection unit SK TI4 Device series: (...) Options, only implemented if required. -

Page 30: Version In Protection Class Ip55, Ip66, Ip69K

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 1.9 Version in protection class IP55, IP66, IP69K The SK 1x0E is available in IP55 (standard) or IP66, IP69K (optional). The additional modules are available in protection classes IP55 (standard) or IP66 (optional). A protection class that differs from the standard (IP66, IP69K) must always be specified in the order when ordering! There are no restrictions or differences to the scope of functionality in the protection classes that have... -

Page 31: Assembly And Installation

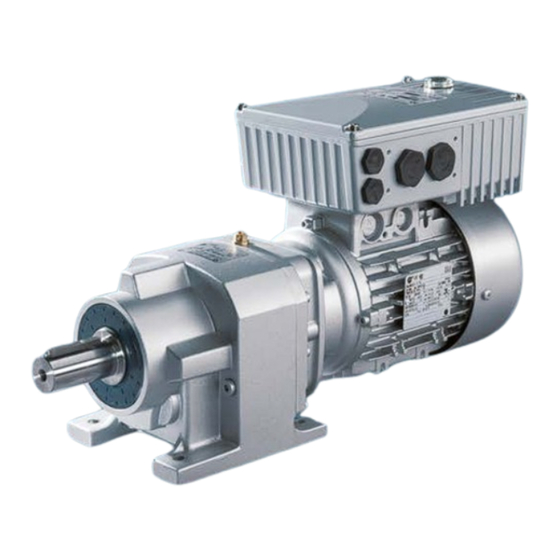

2 Assembly and installation 2 Assembly and installation 2.1 Installation SK 1x0E The devices are available in various sizes depending on their output. They can be mounted on the terminal box of a motor or in its immediate vicinity. Motor-mounted version Wall-mounted version When a complete drive unit (gear unit + motor + SK 1x0E) is delivered, the device is always fully installed and tested. -

Page 32: Work Procedures For Motor Installation

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.1.1 Work procedures for motor installation If necessary, remove the original terminal box from the NORD motor, so that only the base of the terminal box and the motor terminal strip remain. Set the bridges for the correct motor circuit at the motor terminal strip, and connect the pre-fabricated cables for motor and PTC connections to the respective connection points on the motor. -

Page 33: Adapters For Different Motors

2 Assembly and installation 2.1.1.1 Adapters for different motors In some cases, the terminal box attachments are different for different motor sizes. Therefore, it may be necessary to use adapters to mount the device. In order to ensure that the maximum IPxx protection class of the device is provided for the entire unit, all elements of the drive unit (e.g. -

Page 34: Dimensions, Sk 1X0E Mounted On Motor

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.1.1.2 Dimensions, SK 1x0E mounted on motor Size Housing dimensions SK 1x0E / Motor Weight of SK 1x0E without motor Motors ∅ g approx. [kg] Size 63 177.0 Size 71 177.5... -

Page 35: Wall Mounting

2 Assembly and installation 2.1.2 Wall mounting As an alternative to wall mounting, the device can also be installed close to the motor using an optional wall-mounting kit. Wall mounting kit SK TI4-WMK-… (…1-K, …1-NSD) This wall-mounting kit provides a simple method for installing the device close to the motor. The SK TIE4-WMK-1-K version is made of plastic. - Page 36 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Mounting Wall mounting kit Housing dimensions Total Weight dimensions Approx. [kg] ∅ Size 1 SK TIE4-WMK-1-EX Part. No. 275 175 053 Size 2 SK TIE4-WMK-1-EX Part. No. 275 175 053 All dimensions in [mm] BU 0180 en-4118...

-

Page 37: Installation Of Optional Modules

2 Assembly and installation 2.2 Installation of optional modules Modules must not be inserted or removed unless the device is free of voltage. The slots may only be used for the intended modules. 2.2.1 Option locations on device Figure 5: Option locations, size 1 Figure 6: Option locations, size 2 View from left, size 1 View from right, size 1... - Page 38 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Option Position Meaning Size Comments location Internal Mounting location for customer units SK CU4- … Internal Mounting location for internal braking resistor Only for size 2 on side Mounting location for •...

-

Page 39: Installation Of Internal Customer Unit Sk Cu4

2 Assembly and installation 2.2.2 Installation of internal customer unit SK CU4-… (installation) Information Installation location of customer unit Installation of the SK CU4-... customer unit separately from the device is not permitted. If must always be installed inside the device in the intended position (option location 1). Only one customer unit can be installed per device! Prefabricated cables are provided with the customer unit. -

Page 40: Installation Of External Technology Units Sk Tu4

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.2.3 Installation of external technology units SK TU4-… (attachment) The technology units SK TU4-…(-C) require a connection unit SK TI4-TU-…(-C). This is the only way to create a closed functional unit. This can be attached to the device or installed separately by means of the optional SK TIE4-WMK-TU wall-mounting kit. -

Page 41: Braking Resistor (Bw) - (From Size 2)

2 Assembly and installation 2.3 Braking resistor (BW) - (from size 2) During dynamic braking (frequency reduction) of a three-phase motor, electrical energy is returned to the inverter if necessary. From size 2 and above, an internal or external braking resistor can be used to avoid a shut-down of the device due to overvoltage. -

Page 42: External Braking Resistor Sk Bre4

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters NOTICE! Damage due to incorrect parameterisation Incorrect settings of parameters (P555), (P556) and (P557) impair the correct function of the braking resistor and may destroy both this and the frequency inverter. After setting the parameter "Factory Setting"... -

Page 43: Table 5: Assignment Of Braking Resistors To Frequency Inverter

2 Assembly and installation In addition SK BRW4-… type brake resistors are available for mounting on a wall near to the device. Electrical data Designation Resistance Max. continuous power Energy consumption (IP67) SK BRx4-1-100-100 100 W 2.2 kWs 100 Ω SK BRx4-1-200-100 200 Ω... -

Page 44: Electrical Connection

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.4 Electrical Connection WARNING Electric shock Dangerous voltages can be present at the mains input and the motor connection terminals even when the device is not in operation. •... -

Page 45: Wiring Guidelines

2 Assembly and installation 2.4.1 Wiring guidelines The soft starters have been developed for use in an industrial environment. In this environment, electromagnetic interference can affect the device. In general, correct installation ensures safe and problem-free operation. To meet the limiting values of the EMC directives, the following instructions should be complied with. -

Page 46: Electrical Connection Of Power Unit

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.4.2 Electrical connection of power unit NOTICE EMC Interference to the environment This device produces high frequency interference, which may make additional suppression measures necessary in domestic environments ( Section 8.3 "Electromagnetic compatibility (EMC)"). The use of shielded motor cables is essential in order to maintain the specified radio interference suppression level. -

Page 47: Motor Cable (U, V, W, Pe)

2 Assembly and installation As delivered, the device is configured for operation in TN or TT networks. With this, the mains filter has its normal effect and leakage current. A network that is earthed in the neutral point must be used, and with single-phase devices a zero conductor must be used! Adaptation to IT networks –... -

Page 48: Braking Resistor (+B, -B) - (From Size 2)

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters For multiple motor operation the total motor cable length consists of the sum of the individual cable lengths. NOTICE Output switching Switching a motor cable under load causes an impermissibly high load on the device. Components in the power section may be damaged and destroyed either immediately or in the long term. -

Page 49: Electrical Connection Of The Control Unit

2 Assembly and installation 2.4.3 Electrical connection of the control unit Connection data: Terminal bar X4, X5 Cable Ø * [mm²] 0.2 … 1.5 0.2 … 1.5 Ø cable * [mm²] 0.2 … 0.75 0.2 … 0.75 AWG standard 24-16 24-16 Tightening torque [Nm]... -

Page 50: Control Terminal Details

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.4.3.1 Control terminal details Labelling, function AIN: Analogue input Digital output ASI+/-: Integrated AS interface DIN: Digital input 10 V: 10 V DC reference voltage for AIN SYS+/-: System bus 24 V:... - Page 51 2 Assembly and installation Analogue inputs Actuation of device by external controller, potentiometer or the like. Resolution 12Bit Matching of the analogue signals is performed via P402 and P403. U= 0 …10 V, R =30 kΩ + 10 V Reference voltage: 5 mA not short-circuit resistant I= 0/4 …...

- Page 52 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters AS Interface Control of device via simple field bus level: Actuator/sensor interface 26.5 – 31.6 V Only usable for yellow AS interface cable, feed via black cable not possible.

-

Page 53: Operation In Potentially Explosive Environments

2 Assembly and installation 2.5 Operation in potentially explosive environments WARNING Danger of explosion due to electricity Electric sparks may ignite an explosive atmosphere. • Do not open the device in an explosive atmosphere and do not remove any covers (e.g. diagnostic openings). -

Page 54: Options For Atex Zone 22, Category 3D

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters ( 1 ) Year of manufacture ( 2 ) Marking of the device (ATEX) II 3D Ex tc IIIB T125 °C Dc X IP55: II 3D Ex tc IIIC T125 °C Dc X IP66: Categorisation: •... - Page 55 2 Assembly and installation Bus interfaces SK CU4-CAO(-C) 275271001 / (275271501) SK CU4-DEV(-C) 275271002 / (275271502) SK CU4-ECT(-C) 275271017 / (275271517) SK CU4-EIP(-C) 275271019 / (275271519) SK CU4-PBR(-C) 275271000 / (275271500) SK CU4-PNT(-C) 275271015 / (275271515) SK CU4-POL(-C) 275271018 / (275271518) IO -Extensions SK CU4-IOE(-C) 275271006 / (275271506)

-

Page 56: Maximum Output Voltage And Torque Reduction

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Terminal SK ATX-POT Terminal Terminal Name wire colour SK CU4-24V… SK CU4-IOE SK 1x0E +10 V reference [11] [11] [11] black AGND / 0V [12] [12] [12] / [40] green Analogue input [14]... - Page 57 2 Assembly and installation In addition, care must be taken that a NORD motor from the motor list (P200) is set. If a standard 4-pole NORD motor or a motor from a different manufacturer is not used, the data for the motor parameters ((P201) to (P208)) must be adjusted to those on the motor rating plate.

-

Page 58: Eu Conformity Declaration - Atex

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.5.1.5 EU conformity declaration - ATEX BU 0180 en-4118... -

Page 59: Operation In Potentially Explosive Environments - Eac Ex

2 Assembly and installation 2.5.2 Operation in potentially explosive environments - EAC Ex All of the conditions which must be observed for operation of the frequency inverter in an explosion hazard environment according to EAC Ex are listed below. All of the conditions according to ... -

Page 60: Further Information

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 2.5.2.2 Further Information Further information regarding explosion protection can be found in the following sections. Description Section "Options for ATEX Zone 22, category 3D" 2.5.1.2 "Maximum output voltage and torque reduction" 2.5.1.3 "Commissioning information"... -

Page 61: Outdoor Installation

2 Assembly and installation 2.6 Outdoor installation The device and the technology units (SK TU-...) can be installed outdoors under the following conditions: • IP66 version (incl. UV-resistant blank screw caps, see special measures, section 1.9 "Version in protection class IP55, IP66, IP69K"), •... -

Page 62: Display, Operation And Options

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 3 Display, operation and options WARNING Electric shock When devices are open, electrically conducting elements (e.g. connection terminals, connection cables, PCBs, etc.) are freely accessible. These may be live, even if the device has been switched off. •... -

Page 63: Control And Parametrisation Boxes / Software

3 Display, operation and options 3.1.1 Control and Parametrisation Boxes / Software All parameters can be conveniently accessed for reading or editing by means of an optional SimpleBox or ParameterBox. The modified parameter data is stored in the non-volatile EEPROM memory. -

Page 64: Connection Of Multiple Devices To One Parametrisation Tool

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 3.1.2 Connection of multiple devices to one parametrisation tool In principle it is possible to access several frequency inverters via the ParameterBox or the NORD CON software. In the following example, communication is made via the parameterisation tool, by tunnelling the protocols of the individual devices (max. -

Page 65: Optional Modules

3 Display, operation and options 3.2 Optional modules 3.2.1 Internal customer interfaces SK CU4-… (installation of modules) Internal customer units allow the scope of functionality of the devices to be extended without changing the physical size thereof. The device provides an installation location for the installing an appropriate option. -

Page 66: External Technology Units Sk Tu4

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 3.2.2 External technology units SK TU4-… (module attachment) External technology units allow the scope of functionality of the devices to be extended in a modular way. Depending on the type of module, different versions are available (differentiated according to IP protection class, with/without connector etc.). -

Page 67: Table 7: External Bus Modules And Io Expansions Sk Tu4

3 Display, operation and options Type IP55 IP66 Designation Part Number Document SK TU4-PNT-C 275 281 165 TI 275281165 SK TU4-PNT-M12 275 281 122 TI 275281122 SK TU4-PNT-M12-C 275 281 172 TI 275281172 I/O extension SK TU4-IOE 275 281 106 TI 275281106 SK TU4-IOE-C 275 281 156... -

Page 68: Plug Connectors

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 3.2.3 plug connectors The use of optionally available plug connectors for power and control connections not only makes it possible to replace the drive unit with almost no loss of time in case of servicing, but also minimises the danger of installation errors when connecting the device. -

Page 69: Plug Connectors For Control Connection

3 Display, operation and options Connector (selection) Type Data Designation Material no. Document Power input 500 V, 16 A SK TIE4-HANQ8-K-LE-MX 275 135 030 TI 275135030 Power input 500 V, 16 A SK TIE4-HAN10E-M1B-LE 275 135 070 TI 275135070 Power input 500 V, 16 A SK TIE4-HAN10E-M2B-LE 275 135 000... - Page 70 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Connector (selection) Type Version Designation Part Number Document Power supply Connector SK TIE4-M12-POW 275 274 507 TI 275274507 Sensors / actuators Socket SK TIE4-M12-INI 275 274 503 TI 275274503 Initiators and 24 V Connector...

-

Page 71: Potentiometer Adapter, Sk Cu4-Pot

3 Display, operation and options 3.2.4 Potentiometer adapter, SK CU4-POT The R and L digital signals can be directly applied to digital inputs 1 and 2 of the frequency inverter. The potentiometer (0 - 10 V) can be evaluated via an analogue input of the frequency inverter, or via an I/O extension. -

Page 72: Commissioning

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 4 Commissioning WARNING Unexpected movement Connection of the supply voltage may directly or indirectly set the drive unit into motion. This may cause an unexpected movement of the drive unit and the machine which is connected to it. This unexpected movement may cause severe or fatal injuries and/or material damage. -

Page 73: Selecting The Operating Mode For Motor Control

4 Commissioning 4.2 Selecting the operating mode for motor control The frequency inverter is able to control motors with all efficiency classes (IE1 to IE4). Motors which we manufacture are produced as asynchronous motors in efficiency classes IE1 to IE3, whereas IE4 motors are produced as synchronous motors. -

Page 74: Motor Control Commissioning Steps

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters "Ø" = Parameter has no significance "-" = Leave the parameter in the factory setting "√" = Setting of the parameter is relevant "!" = Setting of the parameter is important Group Parameter Operating mode... - Page 75 4 Commissioning 8. Select the operating mode (P300) 9. Determine / adjust the current control (P312 – P316) 10. PMSM only: a. Select the control method (P330) b. Make the settings for the starting behaviour (P331 … P333) Information NORD IE4 Motors Further information for commissioning NORD IE4 motors with NORD frequency inverters can be found in the technical information TI80_0010.

-

Page 76: Starting Up The Device

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 4.3 Starting up the device The frequency inverter can be started up by making parameter adjustments using the ControlBox and the ParameterBox (SK CSX-3H or SK PAR-3H) or the NORD CON PC-based software. When doing this, the changes to the parameters are stored in the internal EEPROM. -

Page 77: Dip Switches (S1, S2)

4 Commissioning 4.3.2.2 DIP switches (S1, S2) The analogue inputs in the device are suitable for current voltage setpoints. correct processing current setpoints (0-20mA / 4-20mA) the relevant DIP switch (S1 – bit 2 or 3) must be set to current signals ("ON"). DIP switch (S1 –... -

Page 78: Commissioning Examples

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 4.3.3 Commissioning examples All SK 1x0E models can be operated as delivered. Standard motor data for a 4-pole standard asynchronous motor of the same power is parameterised. The PTC input must be bypassed, if a motor with PTC is not available. -

Page 79: Temperature Sensors

4 Commissioning 4.4 Temperature sensors The current vector control of the frequency inverter can be further optimised by the use of a temperature sensor. By continuous measurement of the motor temperature, the highest precision of regulation by the frequency inverter and the associated optimum speed precision of the motor is achieved at all times. - Page 80 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Connection examples SK CU4-IOE / SK TU4-IOE-… Connection of a KTY-84 to either of the two analogue inputs of the relevant option is possible. In the following examples, analogue input 2 of the particular optional module is used. SK CU4-IOE SK TU4-IOE (Illustration shows a section of the terminal strips)

- Page 81 4 Commissioning SK 1x0E Connection of a KTY-84 to either of the two analogue inputs of the SK 1x0E is possible. In the following examples, analogue input 2 of the frequency inverter is used. SK 1x0E *If necessary, also Terminal 40 Parameter settings (Analogue input 2) The following parameters must be set for the function of the KTY84-130.

-

Page 82: As Interface (As-I)

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 4.5 AS Interface (AS-i) This section is only relevant for device of type SK 190E. 4.5.1 The bus system General information The Actuator-Sensor-Interface (AS interface) is a bus system for the lower field bus level. It is fully defined in the AS interface Complete Specification and standardised as per EN 50295, IEC62026. -

Page 83: Bus Structure And Topology

4 Commissioning – or via M12 flange connector Technical data for AS interface Designation Value AS-i supply, PWR connection (yellow cable) 24 V DC, max. 25 mA Slave profile S-7.A I/O-Code ID Code External ID Code 1 / 2 Address 1A –... -

Page 84: Commissioning

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Control unit / Automation device AS interface power unit AS interface master AS interface yellow cable AS-Interface AS-Interface Slave (SK 190E) Slave (SK 190E) observe max. power load Sensors Actuators Sensors... -

Page 85: Displays

4 Commissioning Control voltage connection AS Interface connection Type e.g. AUX line of a PELV AS-i(+) AS-i(-) 24 V DC SK 190E The control unit of the frequency inverter is not supplied from the AS-I line. The auxiliary voltage that is required for this is generated by the device itself. -

Page 86: Addressing

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Initiators can be directly connected to the digital inputs of the frequency inverter. Actuators can be connected via the available digital outputs of the device. The following connections are each provided for four reference data bits: Status BUS IN... -

Page 87: Certificate

4 Commissioning The options for addressing the AS Interface Slave with an addressing device in practice are listed in the following. Version 1 Using addressing device which equipped with an M12 connector for AS-i AS-i AS-i connecting to the AS-i bus, you can Power Master Power... -

Page 88: Parameter

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 5 Parameter WARNING Unexpected movement Connection of the supply voltage may directly or indirectly set the drive unit into motion. This may cause an unexpected movement of the drive unit and the machine which is connected to it. This unexpected movement may cause severe or fatal injuries and/or material damage. - Page 89 5 Parameter For this purpose, the device is equipped with a power supply which generates the 24 V DC control voltage that is required by applying the mains voltage (see Section 2.4.2 "Electrical connection of power unit"). Limited adaptations of individual functions of the relevant devices can be implemented via DIP switches.

-

Page 90: Parameter Overview

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 5.1 Parameter overview Operating displays P000 Operating display P001 Selection of display value P002 Display factor P003 Display factor Basic parameters P100 Parameter set P101 Copy parameter set P102 Acceleration time P103 Deceleration time... - Page 91 5 Parameter Control terminals P400 Function Setpoint inputs P401 Analogue input mode P402 Adjustment: 0% P403 Adjustment: 100% P404 Analogue input filter P410 Min. freq. Auxiliary setpoint P411 Max. Freq. Auxiliary P412 Nom. val. process ctrl. P413 PI control P comp. setpoint P414 PI control I comp.

-

Page 92: Description Of Parameters

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 5.2 Description of parameters Parameter number Array values Parameter text; top: Display in ParameterBox, bottom: Meaning Special features (e.g. only available in device model SK xxx) (S) Parameter of type Supervisor, depending on setting in P003 (P) Parameter, to which different values can be assigned depending on the selected parameter set (selection in P100) Parameter value range... -

Page 93: Operating Displays

5 Parameter 5.2.1 Operating displays Abbreviations used: • FI = Frequency inverter • SW = Software version, stored in P707. • S = Supervisor parameters are visible or hidden depending on P003. Parameter Parameter Setting value / Description / Note Supervisor {factory setting} Operating display... -

Page 94: Basic Parameters

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters R rotor ident 61 = the rotor resistance determined by measurement ((P220) Function 2) 62 = L stray stator ident stray inductance determined measurement ((P220) Function 2) L stator ident 63 = the inductance determined by measurement ((P220) Function 2) - Page 95 5 Parameter Acceleration time P102 (Acceleration time) 0 ... 320.00 sec The start-up time is the time corresponding to the linear frequency rise from 0 Hz to the set maximum frequency (P105). If an actual setpoint of <100 % is being used, the acceleration time is { 2.00 } reduced linearly according to the setpoint which is set.

- Page 96 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Maximum frequency P105 (Maximum frequency) 0.1 ... 400.0 Hz The frequency supplied by the FI after being enabled and once the maximum setpoint is present, e.g. analogue setpoint corresponding to P403, a correspondingly fixed frequency or maximum via the SimpleBox / ParameterBox.

- Page 97 5 Parameter Brake reaction time P107 (Brake reaction time) 0 ... 2.50 s Electromagnetic brakes have a physically-dependent delayed reaction time when actuated. This can cause a dropping of the load for lifting applications, as the brake only takes over the load after { 0.00 } a delay.

- Page 98 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Disconnection mode P108 (Disconnection mode) This parameter determines the manner in which the output frequency is reduced after "Blocking" 0 ... 13 (controller enable Low). { 1 } 0 = Block voltage: The output signal is switched off immediately.

- Page 99 5 Parameter DC brake current P109 (DC brake current) 0 ... 250 % Current setting for the functions of DC current braking (P108 = 3) and combined braking (P108 = { 100 } The correct setting value depends on the mechanical load and the required deceleration time. A higher setting brings large loads to a standstill more quickly.

- Page 100 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Brake delay off P114 (Brake release time) 0 ... 2.50 s Electromagnetic brakes have a delayed reaction time during ventilation, which depends on physical factors. This can lead to the motor running while the brake is still applied, which will { 0.00 } cause the inverter to switch off with an overcurrent report.

-

Page 101: Motor Data / Characteristic Curve Parameters

5 Parameter 5.2.3 Motor data / Characteristic curve parameters Parameter Setting value / Description / Note Supervisor Parameter set {factory setting} Motor list P200 (Motor list) 0 ... 73 The factory settings for the motor data can be changed with this parameter. The factory setting in parameters P201...P209 is a 4-pole IE1 - DS standard motor with the nominal FI power setting. - Page 102 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Nominal motor frequency P201 (Nominal motor frequency) 10.0 ... 399.9 Hz The motor nominal frequency determines the V/f break point at which the FI supplies the nominal voltage (P204) at the output.

- Page 103 5 Parameter Motor circuit P207 (Motor circuit) 0 ... 1 0 = star 1 = delta { see information } The motor circuit is decisive for stator resistance measurement (P220) and therefore critical for current vector control. Information Default setting The default setting is dependent upon the FI nominal power and the setting in P200.

- Page 104 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Dynamic boost P211 (Dynamic boost) 0 ... 150 % The dynamic boost affects the torque generating current and is therefore a load-dependent parameter. The factory 100% setting is also sufficient for typical applications. { 100 } Too high a value can lead to overcurrent in the FI.

- Page 105 5 Parameter Time boost precontrol P216 (Time boost precontrol) 0.0 ... 10.0 sec This parameter is used for 3 functionalities { 0.0 } Time limit boost lead: Application time increased starting current. Only with linear characteristic curve (P211 = 0% and P212 = 0%). Time limit for suppression of pulse switch-off (P537): enables start-up under heavy load.

- Page 106 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P2xx Control/characteristic curve parameters Output voltage P204 P211 P215 P210 Output frequency P201 NOTE: P216 Time "typical" Settings for the... Current vector control (factory setting) Linear V/f characteristic curve P201 to P209 = Motor data P201 to P209 = Motor data P210 = 100%...

- Page 107 5 Parameter P220 Para. identification (Parameter identification) 0 … 2 With devices with output of 2.2 KW, the motor data is determined automatically by the device via these parameters. In many cases, better drive behaviour is achieved with the measured motor { 0 } data.

- Page 108 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P241 Inductivity PMSM [-01] [-02] (Inductivity PMSM) 0.1 ... 200.0 mH The typical asymmetric reluctances of the PMSM are compensated with this parameter. The stator inductances can be measured by the frequency inverter (P220) { all 20.0 } [-01] = d axis (L [-02] = q axis (L...

-

Page 109: Speed Control

5 Parameter 5.2.4 Speed control An incremental rotary encoder does not need to be connected. For this reason, the parameters that are exclusively used to configure a rotary encoder (P301, P312 – P328, P334) are not described in this manual. The parameters concerned are present in the software of the device in spite of this. It must be ensured that these parameters are always left at the factory settings. - Page 110 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Torque current controller P P312 (Torque current controller P) 0 ... 1000 % Current controller for the torque current. The higher the current controller parameters are set, the more precisely the current setpoint is maintained.

- Page 111 5 Parameter Field weakening controller P P318 (Field weakening controller P) 0 ... 800 % The field weakening controller reduces the field setpoint when the synchronous speed is exceeded. Generally, the field weakening controller has no function; for this reason, the field { 150 } weakening controller only needs to be set if speeds are set above the nominal motor speed.

- Page 112 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters PLC functionality P350 (PLC functionality) 0 ... 1 Activate the integrated PLC { 0 } 0 = Off: the PLC is not active, the frequency inverter is actuated in accordance with parameters (P509) and (P510).

- Page 113 5 Parameter P355 [-01] PLC Integer Setpoint (PLC Integer Setpoint) [-10] 0x0000 … 0xFFFF Data can be exchanged with the PLC via this INT array. This data can be used by the appropriate process variables in the PLC. all = { 0 } P356 [-01] PLC Long Setpoint...

-

Page 114: Control Terminals

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 5.2.5 Control terminals Parameter Parameter Setting value / Description / Note Supervisor {factory setting} P400 [-01] Function Setpoint inputs (Setpoint inputs function) [-07] [-01] Analogue input 1, Function of analogue input 1 integrated in the FI 0 ... - Page 115 5 Parameter 13 = Current limit, "Current limited" depends on parameter (P536). This value corresponds to 100% of the setpoint value. When the set limit value is reached, the output voltage is reduced in order to limit the output current. 14 = Current switch-off, "Current limit switch-off", depends on parameter (P536), this value corresponds to 100% of the setpoint value.

- Page 116 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P401 [-01] Analog input mode (Mode analog input) [-06] This parameter determines how the frequency inverter reacts to an analog signal which is less 0 ... 5 than the 0% adjustment (P402).

- Page 117 5 Parameter 3 = - 10V – 10V: If a setpoint smaller than the programmed adjustment 0% (P402) is present, this can cause a change in direction rotation. This allows rotation direction reversal using a simple voltage source and potentiometer. E.g.

- Page 118 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P402 [-01] Adjustment: 0% (Analog input adjustment: 0%) [-06] -50.00 ... 50.00 V This parameter sets the voltage that should correspond with the minimum value of the selected function for the analog input.

- Page 119 5 Parameter P403 [-01] Adjustment: 100% (Analog input adjustment: 100%) [-06] -50.00 ... 50.00 V This parameter sets the voltage that should correspond with the maximum value of the selected function for the analog input. { all 0.00 } [-01] = Analog input 1: analog input 1, integrated into the FI [-02] = Analog input 2: analog input 2, integrated into the FI [-03] = External analog input 1, "External analog input 1": Analog input 1 of the first IO extension [-04] = External analog input 2, "External analog input 2": Analog input 2 of the first IO...

- Page 120 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P404 Analogue input filter [-01] [-02] (analogue input filter) 10 ... 400 ms Adjustable digital low-pass filter for the analogue signal. Interference peaks are hidden, the reaction time is extended. { all 100 } [-01] = Analogue input 1: analogue input 1 integrated in the device [-02] = Analogue input 2: analogue input 2 integrated in the device...

- Page 121 5 Parameter Ramp time PI setpoint P416 (Ramp time PI setpoint value) 0.00 ... 99.99 sec This parameter is only effective when the function PI process controller is selected. { 2.00 } Ramp for PI setpoint P417 [-01] Offset analogue output (Offset analogue output) [-02] -10.0 ...

- Page 122 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P418 [-01] Function Analogue output (Analogue output function) [-02] 0 ... 60 [-01] = First IOE, AOUT of the first I/O extension (SK xU4-IOE) { all 0 } [-02] = Second IOE, AOUT of the second I/O extension (SK xU4-IOE) only with Analogue functions (max.

- Page 123 5 Parameter 30 = Set freq before ramp, "Setpoint frequency before frequency ramp", displays the frequency produced by any upstream controllers (ISD, PID, etc.). This is then the target frequency for the power stage after it has been adjusted via the start-up or braking ramp (P102, P103).

- Page 124 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Value Function Description Signal Fixed frequency 1 The frequency from P465 [01] is added to the actual setpoint High value. Fixed frequency 2 The frequency from P465 [02] is added to the actual setpoint High value.

- Page 125 5 Parameter Value Function Description Signal ... 43 reserved 3-wire direction 01 “3-wire control direction change” Flank (normally open button) 3-W-Ctrl. Start-Right This control function provides an alternative to enable R/L 01 (normally “3-wire control start right” (01/02), in which a permanently applied level (maintained signal) Flank open button) is required.

- Page 126 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Value Function Description Signal Clockw. disable + fast As for setting 31, however coupled to the function "Fast Stop". "Disable clockwise rotation + Fast Stop" Anticlockw. disable + fast As for setting 32, however coupled to the function "Fast Stop".

- Page 127 5 Parameter Automatic start P428 Automatic start) 0 ... 1 In the standard setting (P428 =0 Off) the inverter requires a flank to enable (signal change from "low high") at the relevant digital input. { 0 } In the setting On 1 the FI reacts to a High level. This function is only possible if the FI is controlled using the digital inputs.

- Page 128 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 10 = Overtemp. Warn. Motor, "Motor overtemperature warning": The motor temperature is evaluated. Motor is too hot. The warning is given immediately, overheating switch-off after 2 seconds. 11 = Torque curr.

- Page 129 5 Parameter P436 Dig. out. hysteresis [-01] [-02] (Hysteresis of digital outputs) 1 ... 100 % [-01] = Digital output 1, Digital output 1 of the frequency inverter { 10 } [-02] = Digital output 2, Digital output 2 of the frequency inverter Difference between switch-on and switch-off point to prevent oscillation of the output signal.

- Page 130 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P465 [-01] Fixed frequency field (Fixed frequency / Frequency array) [-15] -400.0 ... 400.0 Hz In the array levels, up to 15 different fixed frequencies can be set, which in turn can be encoded for the functions 50…54 in binary code for the digital inputs.

- Page 131 5 Parameter P480 [-01] Function BusIO In Bits (Bus I/O In Bits function) [-12] 0 ... 80 The Bus I/O In Bits are perceived as digital inputs. They can be set to the same functions (P420). { [-01] = 01 } With devices with an integrated AS interface, the I/O bits can be used by the interface itself (bit 0 ...

- Page 132 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P480 … P481 Using flags With the aid of the two flags it is possible to define simple, logical sequences of functions. To do this, the "triggers" for a function (e.g. a motor PTC overtemperature warning) are defined in parameter (P481) in arrays [-07] - "Flag 1"...

-

Page 133: Additional Parameters

5 Parameter P483 [-01] Hyst. BusIO Out Bits (Hysteresis of Bus I/O Out Bits [-10] 1 … 100 % Difference between switch-on and switch-off point to prevent oscillation of the output signal. { all 10 } [-01] = Bus / AS-i Dig Out1 (Bus IO Out Bit 0 + AS-i 1) [-02] = Bus / AS-i Dig Out2 (Bus IO Out Bit 1 + AS-i 2) - Page 134 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Master function output P503 (Master function output) For master-slave applications this parameter specifies on which bus system the master transmits 0 ... 3 the control word and the master values (P502) for the slave. On the slave, parameters (P509), { 0 } (P510), (P546 ) define the source from which the slave obtains the control word and the master values from the master and how these are to be processed by the slave.

- Page 135 5 Parameter Automatic error P506 acknowledgement (Automatic error acknowledgement) 0 ... 7 In addition to the manual error acknowledgement, an automatic one can also be selected. { 0 } No automatic error acknowledgement. 1 ... 5 = Numberof permissible automatic error acknowledgements within one mains-on cycle. After mains off and switch on again, the full amount is again available.

- Page 136 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters USS baud rate P511 (USS baud rate) 0 ... 3 Setting of the transfer rate (transfer speed) via the RS485 interface. All bus participants must have the same baud rate setting. { 3 } 4800 Baud 19200 Baud...

- Page 137 5 Parameter P515 [-01] CAN address (CAN address (system bus)) [-03] 0 ... 255 Setting of the system bus address. { all 32 [-01] = Slave address, Receive address for system bus or { all 20 [-02] = Broadcast slave address, system bus reception address (slave) [-03] = Master address, "Broadcast master address", transmission address for system bus (master) NOTE: If up to four FI are to be linked via the system bus, the addresses must be set as follows ...

- Page 138 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Flying start P520 (Flying start) 0 ... 4 This function is required to connect the FI to already rotating motors, e.g. in fan drives. Motor frequencies >100Hz are only picked up in speed controlled mode (Servo mode P300 = ON). { 0 } 0 = Switched off, no flying start.

- Page 139 5 Parameter P525 [-01] Load control max (Load monitoring maximum value) [-03] 1 ... 400 % / 401 Selection of up to 3 auxiliary values: { all 401 } [-01] = Auxiliary value 1 [-02] = Auxiliary value 2 [-03] = Auxiliary value 3 Maximum load torque value.

- Page 140 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Mode Load control P529 (Load monitoring mode) 0 ... 3 The reaction of the frequency inverter to an infringement of the defined monitoring range ((P525) … (P527)) after the elapse of the delay time (P528) is specified by parameter (P529). { 0 } 0 = Fault and warning, After the elapse of the time defined in (P528), an infringement of the monitoring range produces a fault ("E12.5").

- Page 141 5 Parameter A warning C12.5 is always given after the elapse of half of the set error triggering time (P528). This also applies if a mode is selected for which no fault message is generated. If only a maximum or minimum value is to be monitored, the other limit must be deactivated or must remain deactivated.

- Page 142 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters t Motor P535 t Motor) 0 … 24 The motor temperature is calculated depending on the output current, the time and the output frequency (cooling). If the temperature limit value is reached then switch off occurs and error { 0 } message E002 (motor overheating) is output.

- Page 143 5 Parameter Pulse disconnection P537 (Pulse disconnection) 10 ... 200 % / 201 This function prevents rapid shutdown of the FI according to the load. With the pulse switch-off enabled, the output current is limited to the set value. This limitation is implemented by brief { 150 } switching off of individual output stage transistors, the actual output frequency remains unchanged.

- Page 144 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Mode phase sequence P540 (Mode phase sequence) 0 ... 7 For safety reasons this parameter can be used to prevent a rotation direction reversal and therefore the incorrect rotation direction. { 0 } This function does not operate with active position control (P600 ≠...

- Page 145 5 Parameter P542 Set analogue output [-01] [-02] (Set analogue output) [-01] = First IOE, AOUT of the first I/O extension (SK xU4IOE) 0.0 ... 10.0 V [-02] = Second IOE, AOUT of the second I/O extension (SK xU4IOE) { all 0.0 } only with The analogue output of the FI can be set with this function, independently of the actual operating SK CU4-IOE or...

- Page 146 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P546 [-01] Function Bus setpoint (Function of bus setpoint) [-03] 0 ... 32 In this parameter, a function is allocated to the output setpoint during bus actuation. { [-01] = 1 } NOTE: For further details, please refer to the relevant bus manual or the description for...

- Page 147 5 Parameter P552 CAN Master cycle [-01] [-02] (CAN Master cycle time) 0.0 / 0.1 … 100.0 ms In this parameter, the cycle time for the system bus master mode and the CAN open encoder is set (see P503/514/515): { all 0.0 } [01] = CAN Master function, Cycle time for system bus master functions [02] = CANopen Abs.

- Page 148 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Chopper P limitation P555 (Chopper power limitation) 5 ... 100 % With this parameter it is possible to program a manual (peak) power limit for the brake resistor. The switch-on delay (modulation level) for the chopper can only rise to a certain maximum { 100 } specified limit.

-

Page 149: Information

5 Parameter DC Run-on time P559 (DC Run-on time) 0.00 ... 30.00 s Following a stop signal and the braking ramp, a direct current is briefly applied to the motor to fully bring the drive to a stop. Depending on the inertia, the time for which the current is applied { 0.50 } can be set in this parameter. - Page 150 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P701 [-01] Last fault 1 ... 5 (Last fault 1...5) [-05] 0.0 ... 25.4 This parameter stores last faults (please see section "Error messages"). The SimpleBox / ControlBox must be used to select the corresponding memory location 1...5- (Array parameter), and confirmed using the OK / ENTER key to read the stored error code.

- Page 151 5 Parameter P706 [-01] P set last error (Parameter set, last error 1… 5) [-05] 0 ... 3 This parameter stores the parameter set code that was active when the error occurred. Data for the previous 5 faults are stored. The SimpleBox / ControlBox must be used to select the corresponding memory location 1...5- (Array parameter), and confirmed using the OK / ENTER key to read the stored error code.

- Page 152 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P709 [-01] Analog input voltage (Voltage analogue input) [-07] -100 ... 100 % Displays the measured analogue input value. [-01] = Analogue input 1, function of analogue input 1 integrated into the FI [-02] = Analogue input 2, function of analogue input 2 integrated into the FI [-03] =...

- Page 153 5 Parameter Current frequency P716 (Actual frequency) -400.0 ... 400.0 Hz Displays the actual output frequency. Current speed P717 (Actual rotation speed) -9999 ... 9999 rpm Displays the actual motor speed calculated by the FI. Present Actual setpoint P718 [-01] frequency [-03] (Actual setpoint frequency)

- Page 154 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Current Cos phi P725 (Actual cosj) 0.00 ... 1.00 Displays the actual calculated cos ϕ of the drive. Apparent power P726 (Apparent power) 0.00 ... 300.00 kVA Displays the actual calculated apparent power.

- Page 155 5 Parameter Phase V current P733 (V phase current) 0.0 ... 999.9 A Displays the actual V phase current. NOTE: This value can deviate somewhat from the value in P719, due to the measurement procedure used, even with symmetrical output currents. Phase W current P734 (W phase current)

- Page 156 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters P740 [-01] PZD bus In (Process data Bus In) [-17] 0000 ... FFFF (hex) This parameter provides Control word, source from [-01 ] = Control word information about P509.

- Page 157 5 Parameter Data base version P742 (Database version) 0 ... 9999 Displays the internal database version of the FI. Inverter type P743 (Inverter type) 0.00 ... 250.00 Displays the inverter power in kW, e.g. "1.50" ⇒ FI with 1.5 kW nominal power. Configuration level P744 (Configuration level)

- Page 158 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters CANopen status P748 (CANopen status (system bus status)) 0000 ... FFFF Shows the status of the system bus. (hex) Bit 0: 24V Bus supply voltage 0 ... 65535 (dec) Bit 1: CANbus in "Bus Warning"...

- Page 159 5 Parameter Stat. parameter lost P754 (Parameter loss statistics) 0 ... 9999 Number of parameters lost during the operating period P714. Stat. system error P755 (System fault statistics) 0 ... 9999 Number of system faults during the operating period P714. Stat.

-

Page 160: Operating Status Messages

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 6 Operating status messages The device and technology units generate appropriate messages if they deviate from their normal operating status. There is a differentiation between warning and error messages. If the device is in the status "Start disabled", the reason for this can also be displayed. -

Page 161: Diagnostic Leds On Device

6 Operating status messages SimpleBox - display The SimpleBox displays an error with its number and the prefix "E". In addition, the current fault can be displayed in array element [-01] of parameter (P700). The last error messages are stored in parameter P701. -

Page 162: Messages

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 6.3 Messages Error messages Display in the SimpleBox / ControlBox Fault Cause Text in the ParameterBox • Remedy Group Details in P700 [-01] / P701 E001 Overtemp. Inverter Inverter temperature monitoring "Inverter overtemperature"... - Page 163 6 Operating status messages E004 Overcurrent module Error signal from module (short duration) • Short-circuit or earthing fault at FI output • Motor cable is too long • Use external output choke • Brake resistor faulty or resistance too low ...

- Page 164 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters E010 10.0 Bus Timeout Telegram time-out / Bus off 24V int. CANbus • Data transfer is faulty. Check P513. • Check physical bus connections • Check bus protocol program process. •...

- Page 165 6 Operating status messages 12.5 Load monitor Switch-off due to overshooting or undershooting of permissible load torques ((P525) … (P529)) for the time set in (P528). • Adjust load. • Change limit values ((P525) ... (P527)). • Increase delay time (P528). •...

- Page 166 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 20.7 Illegal Inst. Access "Illegal instruction access" 20.8 Program memory error "Program memory error" (EEPROM error) 20.9 Dual-ported RAM 21.0 NMI error (Not used by hardware) 21.1 PLL error 21.2 ADU error "Overrun"...

- Page 167 6 Operating status messages C003 Overcurrent, I t limit Warning: Inverter: I t limit has triggered, e.g. > 1.3 x I 60s (please also note P504) • Continuous overload at FI output Overcurrent, chopper I Warning: I t limit for the brake chopper has triggered, 1.3x value attained for 60s (also note P554, if present, as well as P555, P556, P557) •...

- Page 168 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Switch-on block messages Display in the SimpleBox / Reason: Cause ControlBox Text in the ParameterBox • Remedy Group Details in P700 [-03] I000 Disable voltage from IO If the function "disable voltage"is parameterised, input (P420 / P480) is at Low Set "input High"...

-

Page 169: Faq Operational Problems

6 Operating status messages 6.4 FAQ operational problems Fault Possible cause Remedy • Check connections and supply Device will not start (all LEDs • No mains voltage or wrong mains cables off) voltage • Check switches / fuses • Reset enable Device does not react to •... -

Page 170: Table 12: Faq Operational Problems

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters • Check P400 Motor speed does not • Analogue input function • P420, check active fixed correspond to setpoint "Frequency addition" another frequencies setpoint is present • Check bus setpoints •... -

Page 171: Technical Data

7 Technical data 7 Technical data 7.1 General data for frequency inverter Function Specification Output frequency 0.0 … 400.0 Hz Pulse frequency 3.0 … 16.0 kHz, factory setting = 6 kHz Power reduction > 8 kHz with 115 / 230 V device, > 6 kHz with 400 V device Typical overload capacity 150 % for 60 s, 200 % for 3.5 s Efficiency... -

Page 172: Electrical Data

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 7.2 Electrical data The following table lists the electrical data for frequency inverters. The details based on measurement series for the operating modes are for orientation purposes and may deviate in practice. The measurement series were made at the rated speed with 4-pole NORD standard motors The following factors have a particular influence on the determined limiting values: Wall mounted... -

Page 173: Electrical Data 1~ 115 V

7 Technical data 7.2.1 Electrical data 1~ 115 V Device type SK 1x0E… -250-112- -370-112- -550-112- -750-112- Size 230 V 0.25 kW 0.37 kW 0.55 kW 0.75 kW Nominal motor power (4-pole standard motor) 240 V ½ hp ¾ hp 1 hp Mains voltage 115 V... -

Page 174: Electrical Data 1/3~230 V

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 7.2.2 Electrical data 1/3~230 V Device type SK 1x0E… -250-323- -370-323- -550-323- Size 230 V 0.25 kW 0.37 kW 0.55 kW Nominal motor power (4-pole standard motor) 240 V ½... - Page 175 7 Technical data Device type SK 1x0E… -750-323- -111-323- -151-323- Size 230 V 0.75 kW 1.10 kW 1.5 kW Nominal motor power (4-pole standard motor) 240 V 1 hp 1½ hp 2 hp Mains voltage 230 V 1/3 AC 3 AC 200 …...

-

Page 176: Electrical Data 3~ 400 V

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 7.2.3 Electrical data 3~ 400 V Device type SK 1x0E… -250-340- -370-340- -550-340- -750-340- -111-340- Size 400 V 0.25 kW 0.37 kW 0.55 kW 0.75 kW 1.1 kW Nominal motor power (4-pole standard motor) 480 V... - Page 177 7 Technical data Device type SK 1x0E… -151-340- -221-340- Size 400 V 1.5 kW 2.2 kW Nominal motor power (4-pole standard motor) 480 V 2 hp 3 hp Mains voltage 400 V 3 AC 380 … 480 V, - 20% / + 10%, 47 … 63 Hz 6.0 A 7.0 A Input current...

-

Page 178: Additional Information

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8 Additional information 8.1 Setpoint processing Figure 15 Setpoint processing BU 0180 en-4118... -

Page 179: Process Controller

8 Additional information 8.2 Process controller The process controller is a PI controller which can be used to limit the controller output. In addition, the output is scaled as a percentage of a master setpoint. This provides the option of controlling any downstream drives with the master setpoint and readjusting using the PI controller. -

Page 180: Process Controller Parameter Settings

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Frequency inverter Setpoint of pilot machine AIN 1 Controller limit Enable right DIN 1 P415 in % of setpoint Actual position CR AIN 2 Controller limit P415 Nominal position CR via parameter P412 8.2.2 Process controller parameter settings... -

Page 181: Electromagnetic Compatibility (Emc)

8 Additional information 8.3 Electromagnetic compatibility (EMC) If the device is installed according to the recommendations in this manual, it meets all EMC directive requirements, as per the EMC product standard EN 61800-3. 8.3.1 General Provisions As of July 2007, all electrical equipment which has an intrinsic, independent function and which is sold as an individual unit for end users, must comply with Directive 2004/108/EEC (formerly Directive EEC/89/336). -

Page 182: Emc Evaluation

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.3.2 EMC evaluation Two standards must be observed when evaluating electromagnetic compatibility. 1. EN 55011-1 (environmental standard) The limits are defined in dependence on the basic environment in which the product is operated in this standard. -

Page 183: Emc Of Device

8 Additional information 8.3.3 EMC of device NOTICE EMC Interference to the environment This device produces high frequency interference, which may make additional suppression measures necessary in domestic environments ( Section 8.3.3 "EMC of device"). The use of shielded motor cables is essential in order to maintain the specified radio interference suppression level. -

Page 184: Figure 17: Wiring Recommendation

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters EMC overview of standards that are used in accordance with EN 61800-3 as checking and measuring procedures: Interference emission Cable-related emission EN 55011 (interference voltage) C1 (mounted on motor) Radiated emission EN 55011 (interference field strength) -

Page 185: Eu Declaration Of Conformity

8 Additional information 8.3.4 EU Declaration of Conformity BU 0180 en-4118... -

Page 186: Reduced Output Power

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.4 Reduced output power The frequency inverters are designed for certain overload situations. For example, 1.5x overcurrent can be used for 60 s. For approx. 3.5 s a 2x overcurrent is possible. A reduction of the overload capacity or its time must be taken into account in the following circumstances: •... -

Page 187: Reduced Overcurrent Due To Time

8 Additional information 8.4.2 Reduced overcurrent due to time The possible overload capacity changes depending on the duration of an overload. Several values are cited in this table. If one of these limiting values is reached, the frequency inverter must have sufficient time (with low utilisation or without load) in order to regenerate itself. -

Page 188: Reduced Overcurrent Due To Output Frequency

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.4.3 Reduced overcurrent due to output frequency To protect the power unit at low output frequencies (<4.5Hz) a monitoring system is provided, with which the temperature of the IGBTs (insulated-gate bipolar transistor) due to high current is determined. -

Page 189: Reduced Output Current Due To Mains Voltage

8 Additional information 8.4.4 Reduced output current due to mains voltage The devices are designed with thermal characteristics according to the nominal output currents. Accordingly, for lower mains voltages, higher currents cannot be taken off in order to maintain the stated power constant. -

Page 190: Operation With Fi Circuit Breakers

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.5 Operation with FI circuit breakers With the frequency inverter (except 115V devices), leakage currents of ≤ 16 mA are to be expected if the mains filter is active. It is designed for operation on frequency inverters for the protection of persons. -

Page 191: System Bus

8 Additional information 8.6 System bus The device and many of the associated components communicate with each other via the system bus. This bus system is a CAN bus with CANopen protocol. Up to four frequency inverters and their components (field bus module, absolute encoder, I/O modules etc.) can be connected to the system bus. - Page 192 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Physical structure Standard 2x2, twisted pair, shielded, stranded wires, wire cross-section ≥0.25 mm² (AWG23), Physical design surge impedance approx. 120 Ω max. 20 m total expansion (network), Bus length max.

- Page 193 8 Additional information Example of frequency inverter addressing Frequency Addressing via DIP switch S2 Resulting Node inverter DIP2 DIP1 Frequency inverters FI 1 FI 2 FI 3 FI 4 BU 0180 en-4118...

-

Page 194: Energy Efficiency

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.7 Energy Efficiency WARNING Unexpected movement due to overload In case of overload of the drive there is a risk that the motor will "break down" (= sudden loss of torque). An overload may be caused e.g. -

Page 195: Motor Data - Characteristic Curves

8 Additional information 8.8 Motor data - characteristic curves The possible characteristic curves with which the motors can be operated are explained in the following. The rating plate data of the motor is relevant for operation with the 50 Hz or 87 Hz characteristic curve (... - Page 196 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Frequency Parameterisation data of frequency inverter Motor inverter (IE2) [Nm] Y/Δ cos ϕ [Ω] SK 1xxE-… SK … [min-1] [Hz] [kW] 80SH/4 550-323-A* 3.73 1415 2.39 0.55 Δ...

-

Page 197: 87 Hz Characteristic Curve (Only 400V Devices)

8 Additional information 8.8.2 87 Hz characteristic curve (only 400V devices) ( Variation 01:17) The 87 Hz - characteristic represents an 87 Hz characteristic curve (4-pole motor) M/Mn extension of the speed adjustment range with constant motor nominal torque. following points must be met for realisation: •... -

Page 198: 100 Hz Characteristic Curve (Only 400 V Devices)

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.8.3 100 Hz characteristic curve (only 400 V devices) ( Variation 01:20) An operating point 100 Hz/400 V can be Kennlinie 100 Hz (4-poliger Motor) 100 Hz characteristic curve (4-pole motor) selected for a greater speed adjustment M/Mn range with up to a ratio of 1:20. - Page 199 8 Additional information Frequency Parameterisation data of frequency inverter Motor inverter (IE3) [Nm] Y/Δ cos ϕ [Ω] SK 1xxE-… SK … [min-1] [Hz] [kW] 80SP/4 750-340-A 2.44 2935 1.77 0.75 0.73 Δ 10.4 80LP/4 111-340-B 3.58 2930 2.13 0.84 Δ 90SP/4 151-340-B 4.86...

-

Page 200: Standardisation Of Setpoint / Target Values

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 8.9 Standardisation of setpoint / target values The following table contains details for the standardisation of typical setpoint and actual values. These details relate to parameters (P400), (P418), (P543), (P546), (P740) or (P741). Name Analogue signal Bus signal... -

Page 201: Definition Of Setpoint And Actual Value Processing (Frequencies)

8 Additional information 8.10 Definition of setpoint and actual value processing (frequencies) The frequencies used in parameters (P502) and (P543) are processed in various ways according the following table. Setpoint source and Signal processing Control and motor setpoint selection and ramp model (determination of slip) Output to ... -

Page 202: Maintenance And Servicing Information

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 9 Maintenance and servicing information 9.1 Maintenance Instructions NORD frequency converters are maintenance free provided that they are properly used (please see chapter 7 "Technical data"). Dusty environments If the device is being used in a dusty environment, the cooling-vane surfaces should be regularly cleaned with compressed air. -

Page 203: Service Notes

9 Maintenance and servicing information 9.2 Service notes Out technical support is available to reply to technical queries. If you contact our technical support, please have the precise device type (rating plate/display), accessories and/or options, the software version used (P707) and the series number (name plate) at hand. -

Page 204: Abbreviations

NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters 9.3 Abbreviations FI (switch) Analogue input Leakage current circuit breaker AS-i (AS1) AS Interface Frequency inverter ASi (LED) Status LED – AS interface In / Out (Input / Output) Asynchronous machine, asynchronous Field current (Current vector control) motor... - Page 205 Key word index Key word index ATEX Zone 22, Cat. 3D......53 ATEX 3-Wire-Control ..........125 EU conformity declaration ......58 ATEX Absolute minimum frequency (P505) ..134 ATEX Zone 22, Cat. 3D......59 Acceleration time (P102) ......95 Automatic error acknowledgement P506 ..135 Actual Automatic flux optimisation ......

- Page 206 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Control terminals ........50, 114 Control unit connection ........49 EAC Ex ......... 20, 24, 35, 53, 59 Copy parameter set (P101) ......94 Certificate ..........60 CSA .............

- Page 207 Key word index Flying start (P520) ........138 Link circuit last error (P705) ......150 Flying start offset (P522) ......138 Load drop ............97 Flying start resolution (P521)....... 138 Load factory setting ........138 Function Load monitoring ........132, 140 Bus I/O In Bits (P480) ......

- Page 208 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Nominal speed (P202) ......102 Peak current PMSM (P244) ......108 Nominal voltage (P204) ......102 PI control I-component (P414) ....120 Star Delta connection (P207) ....103 PI control P-component (P413) ....

- Page 209 Key word index Reduced output power ........ 186 Statistic Relays Mains failure (P752) ........ 158 Set (P541) ..........144 Overcurrent (P750) ........158 Reluctance angle IPMSM (P243) ....108 Overvoltage (P751) ......... 158 Repairs ............203 Statistics Retrofitting the device ........33 Customer error (P757) ......

- Page 210 NORDAC BASE (SK 180E / SK 190E) – Users Manual for Frequency Inverters Usage rate brakeres. (P737) ....... 155 Voltage –q (P724) ........153 Usage rate Motor (P738) ......155 USS address (P512) ........136 Wall-mounting ..........35 USS baud rate (P511) ......... 136 Warning messages ......

- Page 211 Key word index BU 0180 en-4118...

Need help?

Do you have a question about the NORDAC BASE SK 180E Series and is the answer not in the manual?

Questions and answers