Summary of Contents for Wilden PX1500 Advanced Series

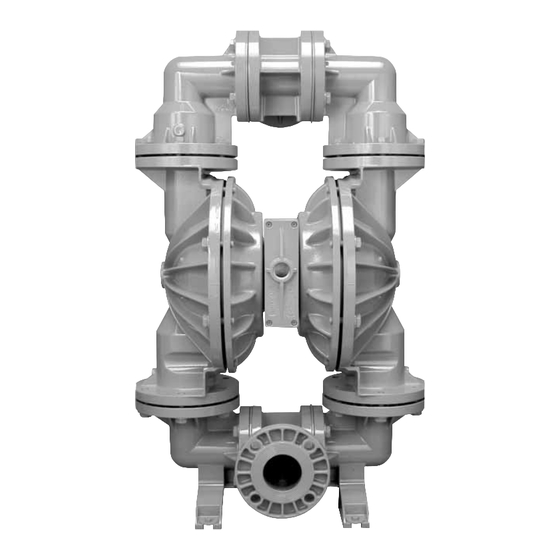

- Page 1 Engineering Operation & Maintenance PX1500 ™ Advanced Series Metal Pump W h e r e I n n o v a t i o n F l o w s www.wildenpump.com WIL-11230-E-11 Replaces WIL-11230-E-10...

-

Page 2: Table Of Contents

..........1 SECTION 2 WILDEN PUMP DESIGNATION SYSTEM ....... . .2 SECTION 3 HOW IT WORKS—PUMP &... -

Page 3: Cautions-Read First

CAUTION: The process fl uid and cleaning fl uids must be chemically compatible with all wetted CAUTION: Tighten all hardware prior to installation. pump components (see E4). CAUTION: Do not exceed 82°C (180°F) air inlet temperature for Pro-Flo X™ models. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... -

Page 4: Wilden Pump Designation System

0693 Center Ported, NPT, PFA Coated 0544 DIN flange NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION. NOTE: Not all models are available with all material options. Viton ® is a registered trademark of DuPont Dow Elastomers. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... - Page 5 H O W I T W O R K S — P U M P The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern through the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke.

-

Page 6: Dimensional Drawings

0.8 DIA. PX150 0 Al u min um D r o p - I n Ty p e DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 25.0 16.3 29.9 32.2 16.4 23.5 14.1 12.1 10.1 11.1 WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... - Page 7 PX150 0 S t a i n l e s s S te e l D r o p - I n Ty p e DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 25.6 30.1 32.1 17.1 16.6 23.2 10.1 REV A WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 8 METRIC (mm) STANDARD (inch) 26.0 18.3 31.3 35.3 35.1 18.4 16.6 23.3 14.0 12.0 10.1 11.0 DIN (mm) ANSI (inch) 200 DIA. 7.5 DIA. 160 DIA. 6.0 DIA. 18 DIA. 0.8 DIA. REV A WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

-

Page 9: Px1500 Performance

PX1500 P X 1 5 0 0 P E R F O R M A N C E... -

Page 10: Operating Principle

fl ow and an even than the fl ow and exhaust is the highest greater decrease in rate, effi ciency porting. fl ow rate setting air consumption. is improved and possible operating costs are reduced. WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 11: How To Use This Ems Curve

The fl ow rate and air consumption at Setting sect the horizontal discharge pressure line. 2 are found to be 18.2 lpm (4.8 gpm) and 7.9 After locating your EMS points on the EMS /h (4.7 scfm) respectively. PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... - Page 12 fl ow rate. optimal EMS setting. For this example the EMS setting is 1.8. WILDEN PUMP & ENGINEERING, LLC PX1500 Performance...

- Page 13 (or interpolating) this point on the curve, draw a vertical line downward until reaching the bottom scale on the chart and identify the air X Factor (fi gure 7). For this example the air X Factor is 0.40 PX1500 Performance WILDEN PUMP & ENGINEERING, LLC...

-

Page 14: Px1500 Aluminum Performance Curves Rubber-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 15: Tpe-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 16: Ptfe-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 17: Full Stroke Ptfe-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 18: Ultra-Flex™-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 19: Px1500 Stainless Steel Performance Curves Rubber-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 20: Tpe-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 21: Ptfe-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 22: Full Stroke Ptfe-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 23: Ultra-Flex™-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 24: Px1500 Stainless Steel Drop-In Performance Curves Rubber-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 25: Tpe-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 26: Ptfe-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 27: Full Stroke Ptfe-Fitted

P E R F O R M A N C E PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 28: Ultra-Flex™-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... -

Page 29: Suction Lift Curves

& A L L O Y C S U C T I O N L I F T C A P A B I L I T Y Full Stroke PTFE Diaphragms Traditional Rubber Diaphragms UltraFlex Diaphragms Traditional PTFE Diaphragms TPE Diaphragms PX1500 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 30: Px1500 Stainless Steel Drop-In

P X 1 5 0 0 S TA I N L E S S S T E E L DROP-IN S U C T I O N L I F T C A P A B I L I T Y WILDEN PUMP & ENGINEERING, LLC PX1500 Performance... - Page 31 N O T E S...

- Page 32 S U G G E S T E D I N S T A L L A T I O N Wilden pumps are designed to meet the performance specifi cations using the standard Wilden muffl er. Other requirements of even the most demanding pumping muffl...

- Page 33 AIR OPERATED PUMPS: To stop the pump from pumping equipment such that it can be reached safely in an emergency situation. operating in an emergency situation, simply close the WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

-

Page 34: Assembly / Disassembly

fl uid Pump discharge rate can be controlled by limiting the all affect the parts life of a Wilden pump. Periodic volume and/or pressure of the air supply to the pump. inspections have been found to offer the best An air regulator is used to regulate air pressure. - Page 35 Use to properly discharge manifold from the liquid expose the valve balls and valve align center section liquid chambers. seats. Inspect ball cage area of chamber. manifold for excessive wear or damage. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 36 Note: Replace worn parts with genuine Wilden parts for reliable performance. Step 7 Step 8 Step 9 Using a 15/16" wrench, loosen the...

- Page 37 Inspect diaphragm assembly and assembly can be removed from the shaft for signs of wear or chemical center section. attack. Replace all worn parts with genuine Wilden parts for reliable performance. Finding Sleep Spares easier...

- Page 38 fl uid. • Snap Ring Pliers ® The Wilden PX1500 metal pumps utilize a revolutionary Pro-Flo air distribution • O-Ring Pick system. Proprietary composite seals reduce the co effi cient of friction and allow the PX1500 to run lube-free.

- Page 39 “notched end“ fi rst, this end incorporates the urethane o-ring and will be damaged as it slides over the ports cut in the sleeve. Note: Seals should not be removed from pilot spool. Seals are not sold separately. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 40 (04-2621-52). The submersible air valve gasket can bleed port located at the front of the be purchased as a spare part or included with the center block. purchase of a new Pro-Flo X™ pump. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 41 Slowly insert the center shaft with a rotating motion. This will complete the resizing of the seal. • Perform these steps for the remaining seal. Figure A Figure B NEEDLE NOSE PLIERS SHAFT SEAL TAPE SHAFT SEAL TAPE WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

-

Page 42: Exploded View & Parts Listing

E X P L O D E D V I E W & P A R T S L I S T I N G PX1500 ALUMINUM E X P L O D E D V I E W WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... - Page 43 Air Valve Assembly includes items 2 and 3. Metal Center Block Assembly includes item 13, 15 and 16. Plastic Center Block Assembly includes item 9, 10, 13, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 44 Air Valve Assembly includes items 2 and 3. Metal Center Block Assembly includes item 13, 15 and 16. Plastic Center Block Assembly includes item 9, 10, 13, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 45 N O T E S...

-

Page 46: Px1500 Stainless Steel

E X P L O D E D V I E W & P A R T S L I S T I N G PX1500 STAINLESS STEEL E X P L O D E D V I E W WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... - Page 47 Air Valve Assembly includes items 2 and 3. Metal Center Block Assembly includes item 13, 15 and 16. Plastic Center Block Assembly includes item 9, 10, 13, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 48 Air Valve Assembly includes items 2 and 3. Metal Center Block Assembly includes item 13, 15 and 16. Plastic Center Block Assembly includes item 9, 10, 13, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 49 N O T E S...

-

Page 50: Px1500 Stainless Steel Drop-In

E X P L O D E D V I E W & P A R T S L I S T I N G E X P L O D E D V I E W PX1500 STAINLESS STEEL DROP-IN CONFIGURATION (0677/0678) WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... - Page 51 Air Valve Assembly includes items 2 and 3. Metal Center Block Assembly includes item 13, 15 and 16. Plastic Center Block Assembly includes item 9, 10, 13, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 52 Air Valve Assembly includes items 2 and 3. Metal Center Block Assembly includes item 13, 15 and 16. Plastic Center Block Assembly includes item 9, 10, 13, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

-

Page 53: Elastomer Options

15-1120-56 Conductive Buna-N 15-1010-86 15-1060-86 PTFE 15-1010-55-42 15-1080-55 15-1200-55 Full Stroke PTFE 15-1040-55-42 15-1080-55 15-1209-55 Wil-Flex™ 15-1010-58 15-1065-57 15-1080-58 15-1120-58 Aluminum Stainless Steel 15-1121-03 Alloy C 15-1121-04 Used in conjunction with metalic valve seat. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11... - Page 54 76 mm (3") Advanced™ aluminum pumps require special PTFE diaphragms (P/N 15-1010-55-42). 76 mm (3") Advanced™ aluminum pumps use unique ball, seats and gaskets not found on Advanced™ stanless steel and alloy C pumps. WILDEN PUMP & ENGINEERING, LLC WIL-11230-E-11...

- Page 55 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

- Page 56 FLUID DYNAMICS™ POLYMER BLENDING SYSTEMS SYSTEM ONE® neptune1.com CENTRIFUGAL PUMPS blackmer.com GRISWOLD™ CENTRIFUGAL PUMPS WILDEN® griswoldpump.com AIROPERATED DIAPHRAGM PUMPS wildenpump.com MAAG® GROUP GEAR PUMPS, PELLETIZING, & FILTRATION SYSTEMS maag.com PSG reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 06-2012...

Need help?

Do you have a question about the PX1500 Advanced Series and is the answer not in the manual?

Questions and answers