Summary of Contents for PSG Wilden H1500 Saniflo HS Series

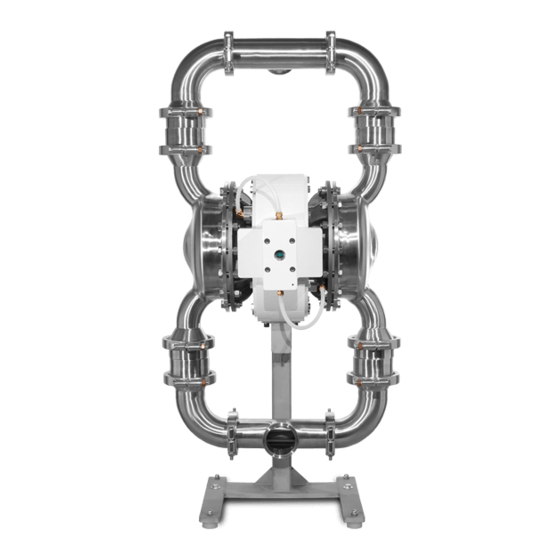

- Page 1 Engineering Operation & Maintenance H1500 HS Metal Pump Where Innovation Flows wildenpump.com...

-

Page 2: Table Of Contents

T A B L E O F C O N T E N T S SECTION 1 CAUTIONS—READ FIRST! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . -

Page 3: Cautions-Read First

S e c t i o n 1 C A U T I O N S — R E A D F I R S T ! CAUTION: Do not apply compressed air to the ex- CAUTION: All piping, valves, gauges and other com- haust port —... -

Page 4: Wilden Pump Designation System

S e c t i o n 2 P U M P D E S I G N A T I O N S Y S T E M LEGEND H1500 / XXXXX / XXX / XX / XX / XXXX H1500 SANIFLO™... -

Page 5: How It Works-Pump & Air Distribution System

S e c t i o n 3 H O W I T W O R K S — P U M P D I S T R I B U T I O N S Y S T E M The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. -

Page 6: Dimensional Drawings

S e c t i o n 4 D I M E N S I O N A L D R A W I N G H150 0 H S Ve r t i c a l l y- M o un te d, C e n te r - Por te d w i t h Ba l l / M u s hr oom Va l ve DIMENSIONS ITEM... -

Page 7: Performance

S e c t i o n 5 P E R F O R M A N C E H1500 HS FULL-STROKE INTEGRAL PISTON DIAPHRAGM-FITTED Ship Weight ......115 kg (254 lb) Air Inlet . -

Page 8: Suggested Installation, Operation & Trouwbleshooting

S e c t i o n 6 S U G G E S T E D I N S T A L L A T I O N Wilden pumps are designed to meet the performance MUFFLER: Sound levels are reduced below OSHA specifi- ®... - Page 9 S U G G E S T E D I N S T A L L A T I O N This illustration is a generic representation of an air-operated double-diaphragm pump. NOTE: In the event of a power failure, the air shut-off valve AIR-OPERATED PUMPS: To stop the pump from operating should be closed if restarting of the pump is not desirable in an emergency situation, simply close the air shut-off...

-

Page 10: Disassembly / Reassembly

S U G G E S T E D O P E R A T I O N & M A I N T E N A N C E OPERATION: The H1500 HS pumps are pre-lubricated and do not the fluid discharge pressure or increasing the air inlet pressure . - Page 11 S e c t i o n 7 P U M P D I S A S S E M B L Y TOOLS REQUIRED: CAUTION: Before any maintenance or repair is attempted, the compressed air line to the pump should be discon- •...

- Page 12 P U M P D I S A S S E M B L Y Step 5 Step 6 Next, remove the clamp bands that secure the ball valve Loosen the nut and remove the inlet manifold clamp bands . housing to the liquid chamber .

- Page 13 P U M P D I S A S S E M B L Y Step 9 Step 10 Using the appropriate-sized wrenches, disconnect the inlet Next, remove the liquid chamber from the center section manifold from the center section . assembly .

-

Page 14: Air Valve/Center Section Disassembly

A I R V A L V E / C E N T E R - S E C T I O N D I S A S S E M B L Y Step 13 Step 14 After loosening, remove the outer piston and diaphragm Loosen tubing nuts located at each pressure relief valve . - Page 15 A I R V A L V E / C E N T E R - S E C T I O N D I S A S S E M B L Y Step 18 Using a pair of snap-ring pliers, remove one snap-ring from the the air valve body . Inspect air piston, air valve body and air valve end cap for nicks, gouges, chemical attack or abrasive wear .

- Page 16 A I R V A L V E / C E N T E R - S E C T I O N D I S A S S E M B L Y Step 21 Step 22 After removing tubes inspect or replace the O-rings as needed . Using the appropriate-sized wrench, remove the air chamber fasteners .

- Page 17 A I R V A L V E / C E N T E R - S E C T I O N D I S A S S E M B L Y Step 25 Step 26 Using an air nozzle with a rubber tip, apply air to the air mani- This will force the power cylinder cover away from the power fold tube port .

- Page 18 A I R V A L V E / C E N T E R - S E C T I O N D I S A S S E M B L Y Step 29 Step 30 Using an air nozzle with a rubber tip, apply air to the air mani- Retain the shaft bushings for use in reassembly .

-

Page 19: Power Cylinder Reassembly

P O W E R C Y L I N D E R R E A S S E M B L Y Step 1 Step 2 Step 3 After attaching the diaphragm shaft and Next, place the power cylinder and Insert new guide rings in outer grooves . -

Page 20: Reassembly Hints & Tips

R E A S S E M B L Y H I N T S & T I P S REASSEMBLY: SHAFT SEAL INSTALLATION: Upon performing applicable maintenance to the air distri- PRE-INSTALLATION: bution system, the pump can now be reassembled . Please •... -

Page 21: Clean In Place - Cip

C L E A N I N P L A C E — C I P The design of the H1500 HS pump allows for ease of cleaning . • Typical chemicals include NaOH (sodium hydroxide) caus- The H1500 HS pump can be cleaned in place without disas- tic for wash and light acid and sanitizers for rinse . -

Page 22: Exploded View & Parts Listing

S e c t i o n 8 E X P L O D E D V I E W & P A R T S L I S T I N G E X P L O D E D V I E W H1500 SANIFLO TPE-FITTED PTFE-FITTED... - Page 23 E X P L O D E D V I E W & P A R T S L I S T I N G P A R T S L I S T I N G H1500 SANIFLO H1500/SZSII/… H1500/SSSII/…...

-

Page 24: H1500 Saniflo™ Hs 1935/2004/Ec

E X P L O D E D V I E W & P A R T S L I S T I N G 1 9 3 5 / 2 0 0 4 / E C E X P L O D E D V I E W H1500 SANIFLO LW0127 REV. - Page 25 E X P L O D E D V I E W & P A R T S L I S T I N G 1 9 3 5 / 2 0 0 4 / E C P A R T S L I S T I N G H1500 SANIFLO H1500/SZSII/…...

-

Page 26: Elastomer Options

S e c t i o n 9 E L A S T O M E R O P T I O N S H1500 SANIFLO™ HS FULL-STROKE FULL-STROKE FULL-STROKE BACKUP DIAPHRAGMS DIAPHRAGMS DIAPHRAGMS DIAPHRAGMS VALVE BALL GASKET, 3” GASKET, 4” MATERIAL (Color Code) (Color Code) - Page 27 DECLARATION OF CONFORMITY STATEMENT OF COMPLIANCE TO REGULATIONS (EC) NO 1935/2004 ON MATERIALS AND ARTICLES INTEDNDED TO COME INTO CONTACT WITH FOOD (as per Article 16 of EGULATION (EC) No 1935/2004) Wilden Pump & Engineering, LLC, 22069 Van Buren Street, Grand Terrace, CA 92313-5607 USA, certifies as the manufacturer that the Air-Operated Double Diaphragm pumps listed below comply with the European Community Regulation 1935/2004/(EC) for Food Contact Materials.

- Page 28 N O T E S...

- Page 29 N O T E S...

- Page 30 N O T E S...

- Page 31 Each and every product manufactured by Wilden Pump and Engineering, LLC is built to meet the highest standards of quality . Every pump is functionally tested to insure integrity of operation . Wilden Pump and Engineering, LLC warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first .

- Page 32 Where Innovation Flows reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 11-2018 ® Authorized PSG Representative: 22069 Van Buren St., Grand Terrace, CA 92313-5607 P: +1 (909) 422-1730 •...

Need help?

Do you have a question about the Wilden H1500 Saniflo HS Series and is the answer not in the manual?

Questions and answers