Daikin intelligent Touch Manager BACnet DCM014A51 Design Manual

Server gateway

Hide thumbs

Also See for intelligent Touch Manager BACnet DCM014A51:

- Design manual (118 pages) ,

- Quick user manual (14 pages)

Summary of Contents for Daikin intelligent Touch Manager BACnet DCM014A51

- Page 1 DG_DCM014A51_02-19 intelligent Touch Manager™ (iTM) BACnet® Server Gateway DCM014A51 DESIGN GUIDE...

-

Page 2: Table Of Contents

1.2 BACnet Compatibility ........................7 1.3 System Outline ..........................7 2. VRV System Overview ........................... 8 2.1 Types of Daikin VRV Systems ......................8 2.2 DIII-Net System and Group Addresses ..................9 2.3 Remote Controller Group and Group Address ................9 2.4 Commanding Mode Change for Heat Recovery and Heat Pump Systems ......... - Page 3 5.1 Device Object Type ........................35 5.2 System Control Type ........................35 5.3 Analog Input Object Type ......................41 5.4 Analog Value Object Type ......................42 5.5 Binary Input Object Type ......................43 5.6 Binary Output Object Type ......................44 5.7 Binary Value Object Type ......................

- Page 4 3.1 System Control (one per system) ..................... 109 3.2 Indoor Unit Points (for each indoor unit) ................. 110 3.3. Outdoor Unit Points (for each outdoor unit) ................111 4.1 iTM BACnet Server Gateway Activation ................... 113 4.2 CSV Configuration ........................114 5.

- Page 5 1.3 Front Panel..........................128 1.4 Side Panel ..........................129 1.5 Environmental Conditions ......................129 2. Electrical Wiring ..........................130 2.1 Removing Wiring Cover from Rear Face ................... 130 2.2 Connecting DIII-Net-Compatible Air Conditioning Equipment ..........130 2.3 Wiring Specifications ........................ 131 3.

-

Page 6: Part 1. Overview

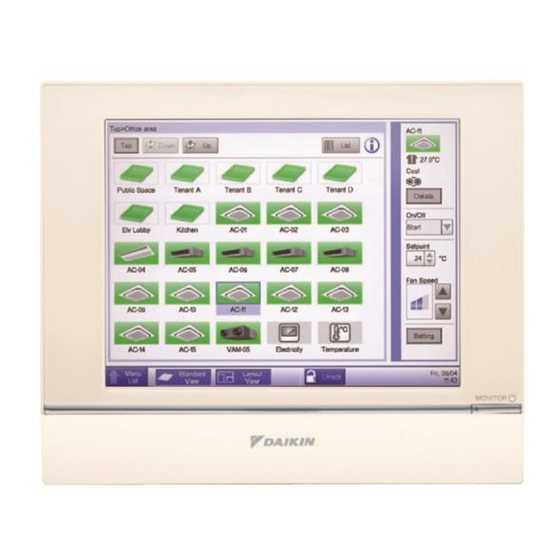

Part 1. Overview Part 1. Overview 1. DCM014A51 iTM BACnet® Server Gateway The intelligent Touch Manager™ (iTM) is now capable of serving as a BACnet interface for Building Management System (BMS) integration. The iTM BACnet Server Gateway option (DCM014A51) will provide BMS integrators the ability to monitor and control VRV indoor units via the BACnet/IP protocol. -

Page 7: Bacnet Compatibility

1.3 System Outline 1. Typical BACnet Server Gateway Application: Figure 2. Typical Daikin VRV System 2. The iTM BACnet Server Gateway (DCM014A51) software option provides communication between the VRV system and the BMS. The operation and monitoring of the VRV systems through BACnet communication uses the BACnet/IP protocol. -

Page 8: Vrv System Overview

(i.e., programming) for the control of the VRV system, except for field settings configurations. The iTM BACnet Server Gateway can be used for monitoring, scheduling, control, and interlock operation. A BMS can be used in conjunction with the Daikin controllers to share operation workload to reduce project costs. -

Page 9: Diii-Net System And Group Addresses

Part 1. Overview 2.2 DIII-Net System and Group Addresses 1. The DIII-Net system consists of the following: a. Up to 10 VRV outdoor units (daisy chained). b. Up to 128 indoor units. 2. The iTM (central controller) and DIII-Net system consists of the following: a. - Page 10 Part 1. Overview 3. Assigning one group address to a remote controller group: Figure 6. Assigning One Group Address to a Remote Controller Group 4. Assigning a group address to each indoor unit in a remote controller group: Figure 7. Assigning a Group Address to Each Indoor Unit in a Remote Controller Group Note: As shown in the figures above, a remote controller group consists of several indoor units wired to the same remote controller.

-

Page 11: Commanding Mode Change For Heat Recovery And Heat Pump Systems

Part 1. Overview 2.4 Commanding Mode Change for Heat Recovery and Heat Pump Systems What is a Changeover Master? 1. When the VRV contractor has commissioned a Heat Pump system, an indoor unit can be nominated as the changeover master. This allows the nominated unit to change the mode of operation for all units connected to the same outdoor unit. -

Page 12: Changeover Master And Secondary (Non-Master) Indoor Units

Part 1. Overview 2.5 Changeover Master and Secondary (Non-Master) Indoor Units 1. Cool and heat modes are only available for selection on the cool/heat changeover master indoor unit. The following table indicates the available operating modes for secondary indoor units in the system based on the selected mode of the master indoor unit. Secondary indoor units in the When the master system can be set to:... - Page 13 Part 1. Overview 3. Dry Mode a. When selected, the setpoint is based on the room temperature as not to over cool. 1. Setpoint = Return Air (when the Return Air ≤ 75°F). 2. Setpoint = Return Air – 1°F (when the Return Air > 76°F). b.

-

Page 14: Itm Overview

Part 1. Overview 3. iTM Overview 3.1 Indoor Unit Management Point 1. The iTM manages the indoor unit groups as an Indoor Unit Management Point only when a group address is assigned (see 2.3 Remote Controller Group and Group Address) to an indoor unit(s). - Page 15 Part 1. Overview Figure 10. Relationship between Setpoints, Setback, and Setpoint Range Limitation 3. Setback a. The Setback function keeps the room temperature at a moderate level with the setback setpoints when the indoor unit is off (when the room is unoccupied). The indoor unit only turns on if the room temperature rises to meet the Cool Setback Setpoint in cooling mode, or if the room temperature falls to meet the Heat Setback Setpoint in heating mode.

-

Page 16: Automatic Control

Part 1. Overview 4. Timer Extension a. The Timer Extension is used to turn the indoor unit off (after a specified time has expired) when it is turned on manually by the iTM or remote controller during unoccupied hours. It can be set for 30, 60, 90, 120 (default), 150, or 180 minutes. - Page 17 Part 1. Overview g. The Daylight Savings Time (DST) setting automatically adjusts the iTM clock to insure scheduled operation times are met. Figure 12. Typical Weekday Office Schedule 2. iTM Auto-Changeover a. Using the advanced auto-changeover functions in the iTM, the BMS programming time is significantly reduced.

- Page 18 Part 1. Overview Figure 13. Cool/Heat Changeover Logic Case 2: Changeover at the secondary changeover temperature. 1. By default, the secondary changeover temperature is 1°F above the primary changeover temperature for cooling, or 1°F below the primary changeover temperature for heating, which is configurable between 1°F –...

- Page 19 Part 1. Overview 2. Individual Method: a. Changeover is evaluated by, and affects, each indoor unit individually. b. Used in application with the Heat Recovery system. Figure 15. Individual Method 3. Average Method: a. Changeover is evaluated based on the average of the room temperature and average setpoints in the changeover group.

- Page 20 Part 1. Overview c. The setpoints can be different in each indoor unit within the changeover group. The demand is calculated based on the setpoints in comparison to room temperature for each indoor unit. The demand within the Primary Changeover deadband (PCd) is considered as no demand.

-

Page 21: Part 2. Functional Specifications

Part 2. Functional Specifications 1. Introduction The Daikin iTM BACnet® Server Gateway operates as a BACnet interpreter using the services defined by BACnet to return the status of the indoor units connected to the DIII network. It also sends configuration commands to the indoor units, in response to requests from the BMS (i.e., BACnet Client) which... -

Page 22: Bacnet Network Number

2. The following Device ID is recommended to be used as the default for the System Device. a. For the Device ID: 1. 530000 → 53 represents Daikin’s BACnet vendor ID. 2. 530000 → 0000 represents no port or group address assigned 2. -

Page 23: Itm And Bacnet® Server Gateway Logic

Part 2. Functional Specifications 4bytes 2bytes Device Instance Number Not used (zero) 2. Settings related to the BACnet Server Gateway functions such as the device instance number can be done from the BACnet Server Gateway configuration in the iTM Service Settings menu. Refer to the iTM BACnet Server Gateway Commissioning manual for more details. -

Page 24: Vrv System Monitor/Control Objects

Part 2. Functional Specifications 3. Auto-changeover a. The iTM handles the cool/heat auto-changeover for the Changeover Group that consists of all indoor units in Heat Pump systems, or under BS units in Heat Recovery system. b. The Changeover Group is configured in the iTM. c. - Page 25 Part 2. Functional Specifications remote controller group, the indoor unit that receives the command will decide if it should follow the command. 5. During the iTM BACnet Server Gateway commissioning, the BACnet objects can be enabled and disabled. If an object is disabled, the object will not be available to be controlled and/or monitored by the BMS.

- Page 26 Part 2. Functional Specifications Inactive Active Instance Object_Name Type Remarks Text-1 Text-2 Text-3 Text-4 Text-5 Text-6 Text-7 Text-8 Remote Controller Prohibit Permit Prohibit Stop Only (On_Off) Remote Controller Prohibit Permit Prohibit (Operation Mode) Remote Controller Prohibit Permit Prohibit (Setpoint) Filter Sign Status Normal Alarm Filter Sign Reset...

-

Page 27: System Control Device

Part 2. Functional Specifications Number of valid digits Object Name Celsius Fahrenheit “Room Temperature” One decimal place One decimal place "Occ Cooling Setpoint" "Occ Heating Setpoint" "Unocc Cooling Setpoint" "Unocc Heating Setpoint" One decimal place Integer "Max Cooling Setpoint" "Min Cooling Setpoint" "Max Heating Setpoint"... - Page 28 Part 2. Functional Specifications 2. The BACnet Server in iTM sends the new PV to Management Point in iTM. The BACnet Server in iTM then starts a 10 minute timer. 3. If the value in Management Point is changed (i.e., the indoor unit accepted the new value and sent back the new status to iTM), the Management Point in iTM sends the new value to the BACnet Server in iTM.

- Page 29 Part 2. Functional Specifications EXAMPLE 3 – Operation Mode to Changeover Slave Unit Step BACnet® Server in iTM Management Point in iTM Indoor Unit Operation mode: Operation mode: Cool Operation mode: Cool Pre-condition Cool Sets PV: Fan, previous PV: Cool Operation ...

-

Page 30: Outdoor Unit Device

Part 2. Functional Specifications 4.5. Outdoor Unit Device 1. Each outdoor unit monitoring item (called object) is mapped to a BACnet object (called outdoor unit object) and to an ObjectID instance number, as indicated in the table below. 2. Both of the objects types BI and MI set the text shown in the table below in the Description Property in accordance with the value of Present_Value. - Page 31 Part 2. Functional Specifications Main Outdoor Unit Points Inactive Active Remarks Instance Object_Name Type Text-1 Text-2 Text-3 Text-4 Text-5 Text-6 Text-7 Text-8 M_Condensing Pressure *2,*3 M_Evaporating Pressure *2,*3 M_Condensing Temperature *1,*2,*3 M_Evaporating Temperature *1,*2,*3 M_Inverter Compressor 1 *2,*3 Speed M_Inverter Compressor 2 *2,*3 Speed M_Fan Step...

- Page 32 Part 2. Functional Specifications Sub-1 Outdoor Unit Points Inactive Active Remarks Instance Object_Name Type Text-1 Text-2 Text-3 Text-4 Text-5 Text-6 Text-7 Text-8 S1_Condensing Pressure *2,*3 S1_Evaporating Pressure *2,*3 S1_Condensing Temperature *1,*2,*3 S1_Evaporating Temperature *1,*2,*3 S1_Inverter Compressor 1 Speed *2,*3 S1_Inverter Compressor 2 Speed *2,*3 S1_Fan Step *2,*3...

- Page 33 Part 2. Functional Specifications Sub-2 Outdoor Unit Points Inactive Active Remarks Instance Object_Name Type Text-1 Text-2 Text-3 Text-4 Text-5 Text-6 Text-7 Text-8 S2_Condensing Pressure *2,*3 S2_Evaporating Pressure *2,*3 S2_Condensing *1,*2,*3 Temperature S2_Evaporating *1,*2,*3 Temperature S2_Inverter Compressor 1 *2,*3 Speed S2_Inverter Compressor 2 *2,*3 Speed S2_Fan Step...

- Page 34 Part 2. Functional Specifications [Temperature (Celsius / Fahrenheit) Objects] [Non-Temperature Objects] Number of Number of valid digits Object Name Object Name valid digits Celsius Fahrenheit System Capacity Code Integer Outdoor Air Temperature Integer Integer M_Inverter Compressor 1 Speed M_Condensing Temperature M_Inverter Compressor 2 Speed M_Evaporating Temperature M_Fan Step...

-

Page 35: Properties

Object_Type BACnetObjectType DEVICE ■ System_Status BACnetDeviceStatus Fixed to OPERATIONAL ■ Vendor_Name CharacterString DAIKIN Industries LTD ■ Vendor_Identifier Unsigned16 Fixed to 53 (= DAIKIN) ■ Model_Name CharacterString Fixed to "Indoor Unit" ■ Firmware_Revision CharacterString Application_Software_ ■ CharacterString Version □ - Location CharacterString Port No. - Page 36 Part 2. Functional Specifications Continued from previous page. Support Compatible R: Readable ■ = Yes Property Identifier Property Datatype Remarks Class W: Writable □ = No Configurable ■ with BACnet® APDU_Segment_Timeout Unsigned Server/Gateway Configuration (*) Configurable ■ with BACnet® APDU_Timeout Unsigned Server/Gateway Configuration (*)

- Page 37 Property Identifier Property Datatype Remarks Class W: Writable □ = No Configurable with ■ BACnet® Server/ Object_Identifier BACnetObjectIdentifier Gateway Configuration ■ Fixed to “Daikin iTM Object_Name CharacterString Server Control" ■ Object_Type BACnetObjectType DEVICE ■ Fixed to System_Status BACnetDeviceStatus OPERATIONAL ■...

- Page 38 Part 2. Functional Specifications Continued from previous page. Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No Configurable with ■ BACnet® Server/ APDU_Segment_Timeout Unsigned Gateway Configuration (*) Configurable with ■ BACnet® Server/ APDU_Timeout Unsigned Gateway...

- Page 39 ■ Fixed to System_Status BACnetDeviceStatus OPERATIONAL ■ DAIKIN Industries Vendor_Name CharacterString ■ Fixed to 53 Vendor_Identifier Unsigned16 (= DAIKIN) ■ Fixed to "Daikin iTM Model_Name CharacterString Server Control" ■ Firmware_Revision CharacterString Application_Software_ ■ CharacterString Version □ - Location CharacterString DIII-Net connection ■...

- Page 40 Part 2. Functional Specifications Continued from previous page. Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No Configurable with ■ APDU_Segment_Timeout Unsigned the Trial Operation tool (*) Configurable with ■ APDU_Timeout Unsigned the Trial Operation tool (*)

-

Page 41: Analog Input Object Type

Part 2. Functional Specifications 5.4 Analog Input Object Type Support* Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType ANALOG_INPUT ■ Present_Value REAL □... -

Page 42: Analog Value Object Type

Part 2. Functional Specifications 5.5 Analog Value Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType ANALOG_VALUE ■ Present_Value REAL □... -

Page 43: Binary Input Object Type

Part 2. Functional Specifications 5.6 Binary Input Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType BINARY_INPUT ■ Present_Value BACnetBinaryPV [Alarm Status] Sets an error code ■... -

Page 44: Binary Output Object Type

Part 2. Functional Specifications 5.7 Binary Output Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType BINARY_OUTPUT ■ Present_Value BACnetBinaryPV Sets the string ■... -

Page 45: Binary Value Object Type

Part 2. Functional Specifications 5.8 Binary Value Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType BINARY_VALUE ■ Present_Value BACnetBinaryPV Sets the string ■... -

Page 46: Multi-State Input Object Type

Part 2. Functional Specifications 5.9 Multi-State Input Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType MULTI-STATE_INPUT ■ Present_Value Unsigned Sets the string ■... -

Page 47: Multi-State Output Object Type

Part 2. Functional Specifications 5.10 Multi-State Output Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType MULTI-STATE_OUTPUT ■ Present_Value Unsigned Sets the string ■... -

Page 48: Multi-State Value Object Type

Part 2. Functional Specifications 5.11 Multi-State Value Object Type Support Compatible R: Readable ■ = Yes, Property Identifier Property Datatype Remarks Class W: Writable □ = No ■ Object_Identifier BACnetObjectIdentifier ■ Object_Name CharacterString ■ Object_Type BACnetObjectType MULTI-STATE_VALUE ■ Present_Value Unsigned Sets the string ■... -

Page 49: Error Response In Bacnet® Communication

Part 2. Functional Specifications 6. Error Response in BACnet® Communication When a request from a BACnet Client cannot be processed, one of the Protocol Data Unit (PDU)’s listed below is returned. Error PDU Error Class Error Code Request for accessing an unimplemented object OBJECT (1) UNKNOWN_OBJECT (31) Request for accessing an unimplemented property... -

Page 50: Detailed Description Of Objects

Part 2. Functional Specifications 7. Detailed Description of Objects 7.1 Specifications Common to All Objects For each communication status of an indoor unit, objects related to that indoor unit and system control device are treated in BACnet as follows: 1. Indoor unit communicating normally Other BACnet devices can access all objects for the indoor unit. - Page 51 Part 2. Functional Specifications Warning: Command priority control on objects of type Value. During a WriteProperty (Multiple) service execution, the command priority control is applied according to the BACnet specifications. Commands/setting changes can be issued to each indoor unit from the iTM Setup screen and the Remote Controller (remote controller operation) (hereinafter collectively called "local operation").

-

Page 52: Individual Object Specifications

Part 2. Functional Specifications 7.2 Individual Object Specifications 1. Individual indoor unit object specifications a. Occupancy Mode Member number: 1 Object name: Occupancy Mode Object type: Multistate Output Description: Controls the indoor unit based on the occupancy status. Present_Value property: 1: Unocc 2: Occ 3: Standby... - Page 53 Part 2. Functional Specifications 2. Unit On_Off Status Member number: 2 Object name: Unit On_Off Status Object type: Binary Input Description: Monitors the indoor unit on/off status. Present_Value property: ACTIVE: On INACTIVE: Off Notes: 1. The IN_ALARM flag of the Status_Flags property of this object for an indoor unit in error is not TRUE.

- Page 54 Part 2. Functional Specifications 5. Room Temperature Member number: 5 Object name: Room Temperature Object type: Analog Input Description: Monitors the room temperature received from the indoor unit. Present_Value property: Room temperature detected by the indoor unit (or remote controller). Notes: 1.

- Page 55 Part 2. Functional Specifications 7. Occ Heating Setpoint Member number: 7 Object name: Occ Heating Setpoint Object type: Analog Value Description: Monitors/configures the indoor unit setpoint (heat). Present_Value property: Setpoint (heat) used by the indoor unit. Notes: 1. The unit is degrees Celsius (°C) or degrees Fahrenheit (°F), depending on the iTM system settings.

- Page 56 Part 2. Functional Specifications Response to command Setback temperature from BMS Present_Value (cool) Out_of_Service property Error TRUE ErrorClass=PROPERTY No change ErrorCode=WRITE_ACCESS_DENIED FALSE Change ← When the Out_Of_Service property changes from TRUE to FALSE, the Present_Value changes to the value set on the iTM. If the unoccupied cooling setpoint point is set by the iTM, the BMS does not need to change the Out_Of_Service property unless a value change is needed.

- Page 57 Part 2. Functional Specifications 2. The number of significant digits is up to one decimal place for degrees Celsius and zero decimal places for degrees Fahrenheit. 3. The settable values are fixed by the system (10.0 to 31.1 [°C] / 50 to 88 [°F]). If a value outside the range is written, it is corrected to the upper/lower limit value.

- Page 58 Part 2. Functional Specifications 10. Max Cooling Setpoint Member number: 10 Object name: Max Cooling Setpoint Object type: Analog Value Description: Monitors/configures the upper limit for the indoor unit setpoint range (cool). Present_Value property: Upper limit for the setpoint range (cool) on the indoor unit. Notes: 1.

- Page 59 Part 2. Functional Specifications The next COV notification is issued when the temperature further changes for 1°C/1°F or more from the value of the Present_Value property that triggered the previous COV notification. 11. Min Cooling Setpoint Member number: 11 Object name: Min Cooling Setpoint Object type: Analog Value...

- Page 60 Part 2. Functional Specifications COV notification is issued when a change of 1°C/1°F or more is detected. The next COV notification is issued when the temperature further changes for 1°C/1°F or more from the value of the Present_Value property that triggered the previous COV notification.

- Page 61 Part 2. Functional Specifications 6. When subscribed to COV notification, the COV_Increment property is fixed to 1.0 and cannot be changed. COV notification is issued when a change of 1°C/1°F or more is detected. The next COV notification is issued when the temperature further changes for 1°C/1°F or more from the value of the Present_Value property that triggered the previous COV notification.

- Page 62 Part 2. Functional Specifications 5. Relinquish_Default property is fixed to 16°C/60°F. 6. When subscribed to COV notification, the COV_Increment property is fixed to 1.0 and cannot be changed. COV notification is issued when a change of 1°C/1°F or more is detected. The next COV notification is issued when the temperature further changes for 1°C/1°F or more from the value of the Present_Value property that triggered the previous COV notification.

- Page 63 Part 2. Functional Specifications 16. Fan Speed Member number: 16 Object name: Fan Speed Object type: Multistate Value Description: Monitors/configures the indoor unit fan speed level. Present_Value property (Description property string): 1: Low 2: Reserved 3: Medium 4: Reserved 5: High 6: Reserved 7: Reserved 8: Auto...

- Page 64 Part 2. Functional Specifications 17. Airflow Direction Member number: 17 Object name: Airflow Direction Object type: Multistate Value Description: Monitors/configures the airflow direction for the indoor unit. Present_Value property: 1 to 5: P0 to P4 Note: 1. The indoor unit has separate airflow direction settings for "cool mode" and "heat mode". This object configures and reads the airflow direction for the current operation mode.

- Page 65 Part 2. Functional Specifications 2. The present value property of the “Current Unit Operation” object is determined by the combination of present value property of the “Occupancy Mode” object and the state of the indoor unit management point on iTM as indicated in the following table: Occupancy Mode Standby Unocc...

- Page 66 Part 2. Functional Specifications Notes: 1. When more than one indoor unit is connected to a single remote controller group, the BMS should only send commands to the indoor unit that is designated to receive the command for the remote controller group (unit #0). BMS should not send commands to other indoor units in the remote control group.

- Page 67 Part 2. Functional Specifications 2. Present_Value writing The following table shows how the object will work depending on the combination of the current value in Present_Value and value in the command. Value in command INACTIVE ACTIVE Current value Changes to ACTIVE. However, after 10 minutes, the object INACTIVE Remains as-is...

- Page 68 Part 2. Functional Specifications INACTIVE: Off (Thermo-off) 28. Compressor Status Member number: 28 Object name: Compressor Status Object type: Multistate Input Description: Monitors the operating status of the outdoor unit compressor connected to the indoor unit. Present_Value property: 1: The outdoor unit compressor connected to the indoor unit is stopped (Off). 2: The outdoor unit compressor connected to the indoor unit is operating (Oil-return operation included) (On).

- Page 69 Part 2. Functional Specifications 32. Return Air Temperature Member number: 32 Object name: Return Air Temperature Object type: Analog Input Description: Monitors the return air temperature of the indoor unit. Present_Value property: Return air temperature of the indoor unit. Remarks: (1) Units are set to ℃/ F depending on the system settings.

-

Page 70: Individual System Control Object Specifications

Part 2. Functional Specifications (3) The value range is (-50.0 to 120.0[℃] / -58.0 to 248.0[゚F]). 36. EV Position Member number: 36 Object name: EV Position Object type: Analog Input Description: Monitors the EV position of the indoor unit. Present_Value property: EV position of the indoor unit. -

Page 71: Individual Outdoor Unit Object Specifications

Part 2. Functional Specifications ACTIVE: Enable INACTIVE: Disable Note: 1. Relinquish_Default property is fixed to "INACTIVE". 3. Timed Override Minutes Member number: 3 Object name: Timed Override Minutes Object type: Multistate Value Description: Monitors/sets the time for the Timer Extension in iTM. Present_Value property: 1: 30 minutes 2: 60 minutes... - Page 72 Part 2. Functional Specifications Description: Monitors the communication status of the outdoor unit. Present_Value property: ACTIVE: Outdoor unit communicating in error INACTIVE:Outdoor unit communicating normally Remarks: (1) Even if the outdoor unit is communicating in error, the Reliability property will not change to UNRELIABLE_OTHER, but will remain as NO_FAULT_DETECTED.

- Page 73 Part 2. Functional Specifications 5. Oil Return Mode Member number: 5 Object name: Oil Return Mode Object type: Binary Input Description: Monitors whether the outdoor unit is in oil return operation. Present_Value property: ACTIVE: The outdoor unit is in oil return operation. INACTIVE: The outdoor unit is not in oil return operation.

- Page 74 Part 2. Functional Specifications 9. Outdoor Air Temperature Member number: 9 Object name: Outdoor Air Temperature Object type: Analog Input Description: Monitors the outdoor air temperature around the outdoor unit. Present_Value property: The outdoor air temperature around the outdoor unit Remarks: (1) Units are set to ℃/ F depending on the system settings.

- Page 75 Part 2. Functional Specifications Description: Monitors the evaporating pressure of the outdoor unit. Present_Value property: Evaporating pressure of the outdoor unit Remarks: (1) Units are in psi. (2) The number of valid digits is to two decimal places. (3) The value range is (-28.45 to 284.47[psi]) (-2.0 to 20.0 [kgf/cm2] 12.

- Page 76 Part 2. Functional Specifications 14. M_Inverter Compressor 1 Speed S1_Inverter Compressor 1 Speed S2_Inverter Compressor 1 Speed Member number: 104 (M_Inverter Compressor 1 Speed) 204 (S1_Inverter Compressor 1 Speed) 304 (S2_Inverter Compressor 1 Speed) Object name: M_Inverter Compressor 1 Speed S1_Inverter Compressor 1 Speed S2_Inverter Compressor 1 Speed Object type:...

- Page 77 Part 2. Functional Specifications Description: Monitors the fan step of the outdoor unit. Present_Value property: Fan step of the outdoor unit Remarks: (1) There are no units of measurement. (2) The number of valid digits is an integer. (3) The value range is (0 to 8) for VRV IV, and (0 to 255) for VRV IV R. 17.

- Page 78 Part 2. Functional Specifications 19. M_Hot Gas Temperature (Compressor 1) S1_Hot Gas Temperature (Compressor 1) S2_Hot Gas Temperature (Compressor 1) Member number: 109 (M_Hot Gas Temperature (Compressor 1) 209 (S1_Hot Gas Temperature (Compressor 1)) 309 (S2_Hot Gas Temperature (Compressor 1) Object name: M_Hot Gas Temperature (Compressor 1) S1_Hot Gas Temperature (Compressor 1)

- Page 79 Part 2. Functional Specifications Description: Monitors the temperature of the outdoor unit liquid pipe heat exchanger. Present_Value property: Temperature of the outdoor unit liquid pipe heat exchanger Remarks: (1) Units are set to ℃/゚F depending on the system settings. (2) The number of valid digits is an integer for both Celsius and Fahrenheit. (3) The value range is (-50 to 120[℃] / -58 to 248[゚F]).

- Page 80 Part 2. Functional Specifications (2) The number of valid digits is an integer for both Celsius and Fahrenheit. (3) The value range is (-50 to 120[℃] / -58 to 248[゚F]). 24. M_Liquid Pipe Temperature (Deicer) S1_Liquid Pipe Temperature (Deicer) S2_Liquid Pipe Temperature (Deicer) Member number: 114 (M_Liquid Pipe Temperature (Deicer) 214 (S1_Liquid Pipe Temperature (Deicer)) 314 (S2_Liquid Pipe Temperature (Deicer)

- Page 81 Part 2. Functional Specifications 26. M_Gas Pipe Temperature (HX Lower) S1_Gas Pipe Temperature (HX Lower) S2_Gas Pipe Temperature (HX Lower) Member number: 116 (M_Gas Pipe Temperature (HX Lower) 216 (S1_Gas Pipe Temperature (HX Lower)) 316 (S2_Gas Pipe Temperature (HX Lower) Object name: M_Gas Pipe Temperature (HX Lower) S1_Gas Pipe Temperature (HX Lower)

- Page 82 Part 2. Functional Specifications Object type: Analog Input Description: Monitors the compressor suction temperature of the outdoor unit. Present_Value property: Compressor suction temperature of the outdoor unit Remarks: (1) Units are set to ℃/゚F depending on the system settings. (2) The number of valid digits is an integer for both Celsius and Fahrenheit. (3) The value range is (-50 to 120[℃] / -58 to 248[゚F]).

- Page 83 Part 2. Functional Specifications 31. M_Subcool EV Position S1_Subcool EV Position S2_Subcool EV Position Member number: 121 (M_Subcool EV Position) 221 (S1_Subcool EV Position) 321 (S2_Subcool EV Position) Object name: M_Subcool EV Position S1_Subcool EV Position S2_Subcool EV Position Object type: Analog Input Description: Monitors the EV position of the outdoor unit (sub cool heat exchanger)

-

Page 84: Report Function

Part 2. Functional Specifications 8. Report Function 8.1 COV Notification The subscribed COV notification (DS-COV-B) is supported. 1. Subscribed COV Notification Requests for COV subscription are received by the SubscribeCOV service. a. Setting Confirmed/Unconfirmed COV notification with/without confirmation. Supported as defined in the BACnet® specifications. b. - Page 85 Part 2. Functional Specifications The COV notification support for each object is as follows: Indoor unit device System control device Instance Instance Object_Name Type Object_Name Type Number Number Occupancy Mode Enable ITM Schedule Operation Enable ITM Auto Changeover Unit On_Off Status Operation Alarm Status Timed Override Minutes...

- Page 86 Part 2. Functional Specifications *Objects other than those listed above, as well as, outdoor unit devices objects, are not supported by COV. The following error is returned to a SubscribeCOV request for an object that does not support COV: Outdoor device: ErrorPDU (Class = OBJECT, Code = OPTIONAL_FUNCTIONALITY_NOT_SUPPORTED) Indoor device: RejectPDU (UNRECOGNIZED_SERVICE) Design Guide DCM014A51...

-

Page 87: Error Codes

Part 2. Functional Specifications 9. Error Codes Indoor Unit Type Error Code Description DK_SkyAir | DK_VRV "External protection device activated" DK_SkyAir | DK_VRV | DK_RA "Malfunction of ID unit PCB" DK_SkyAir | DK_VRV | DK_RA "Malfunction of drain level control system" DK_RA "High pressure control in heating freeze-up protection control in cooling"... - Page 88 Part 2. Functional Specifications Continued form previous page. Indoor Unit Type Error Code Description DK_SkyAir "Malfunction of liquid pipe thermistor (Refrigerant circuit and others)" DK_SkyAir | DK_VRV | DK_RA "Malfunction of gas pipe thermistor (Refrigerant circuit and others)" DK_SkyAir | DK_VRV "Malfunction of high pressure sensor"...

-

Page 89: Pics

Part 2. Functional Specifications 10. PICS BACnet® Protocol Implementation Conformance Statement Date: Feb. 5, 2016 Vendor Name: DAIKIN INDUSTRIES, Ltd. Product Name: intelligent Touch Manager™ Product Model Number: DCM601A71 Applications Software Version: 2.06.00* Firmware Revision: 000.001 BACnet® Protocol Revision: Product Description: This product provides the function of monitoring and operating the air-conditioner. - Page 90 Part 2. Functional Specifications Standard Object Types Supported: 1. Analog Input a. Return Air Temperature, Discharge Air Temperature, Liquid Pipe Temperature, Gas Pipe Temperature, EV position, All Outdoor Unit's AI Object Dynamically Creatable: Dynamically Deletable: Optional Properties Supported: Reliability Writable Properties: Proprietary Properties: Property Range Restrictions: b.

- Page 91 Part 2. Functional Specifications 5. Binary Value Dynamically Creatable: Dynamically Deletable: Optional Properties Supported: Description, Reliability, Inactive_Text, Active_Text Writable Properties: Present_Value Proprietary Properties: Property Range Restrictions: 6. Device a. Outdoor Unit Object Dynamically Creatable: Dynamically Deletable: Optional Properties Supported: Max_Segment_Accepted, Local_Time, Local_Date, UTC_Offset, Daylight_Saving_Status, APDU_Segment_Timeout, Description Writable Properties:...

- Page 92 Part 2. Functional Specifications 9. Multi-state Value Dynamically Creatable: Dynamically Deletable: Optional Properties Supported: Reliability, Description, State_Text, Priority_Array, Relinquish_Default Writable Properties: Present_Value Proprietary Properties: Property Range Restrictions: Data Link Layer Options: ■ BACnet IP, (Annex J) ■ BACnet IP, (Annex J), Foreign Device ...

-

Page 93: Bacnet® Interoperability Building Blocks Supported (Bibbs)

Part 2. Functional Specifications 11. BACnet® Interoperability Building Blocks Supported (BIBBs) 11.1 Data Sharing BIBBs BIBB Type Supported BACnet® Service Initiate Execute □ DS-RP-A Data Sharing-ReadProperty–A ReadProperty ■ DS-RP-B Data Sharing-ReadProperty–B ReadProperty □ DS-RPM-A Data Sharing-ReadPropertyMultiple–A ReadPropertyMultiple ■ DS-RPM-B Data Sharing-ReadPropertyMultiple–B ReadPropertyMultiple □... -

Page 94: Alarm And Event Management Bibbs

Part 2. Functional Specifications 11.2 Alarm and Event Management BIBBs BIBB Type Supported BACnet® Service Initiate Execute ConfirmedEventNotification □ AE-N-A Alarm and Event-Notification–A UnconfirmedEventNotification ConfirmedEventNotification Alarm and Event-Notification □ AE-N-I-B Internal–B UnconfirmedEventNotification ConfirmedEventNotification Alarm and Event-Notification □ AE-N-E-B External–B UnconfirmedEventNotification □... -

Page 95: Device Management Bibbs

Part 2. Functional Specifications 11.5 Device Management BIBBs BIBB Type Supported BACnet® Service Initiate Execute Who-Is □ DM-DDB-A Device Management - Dynamic Device Binding–A I-Am Who-Is ■ DM-DDB-B Device Management - Dynamic Device Binding–B I-Am Who-Has □ DM-DOB-A Device Management - Dynamic Object Binding–A I-Have Who-Has ■... -

Page 96: Network Management Bibbs

Part 2. Functional Specifications 11.6 Network Management BIBBs BIBB Type Supported BACnet® Network Layer Message Initiate Execute Establish-Connection-To-Network Network Management - Connection □ NM-CE-A Establishment–A Disconnect-Connection-To-Network Establish-Connection-To-Network Network Management - Connection □ NM-CE-B Establishment– B Disconnect-Connection-To-Network Who-Is-Router-To-Network I-Am-Router-To-Network Network Management - Router □... -

Page 97: Bacnet™ Gateway (Bacnetgw) And Itm Protocol Comparison

・Time_Of_Active_Time_Reset 12. BACnet™ Gateway (BACnetGW) and iTM Protocol Comparison This section describes the following differences between BACnetGW (Ver. 6.34.00) and iTM: 1. Functions removed from BACnetGW 2. Functions changed from BACnetGW Note that "Additions from BACnetGW" are omitted from this section as they are described in the main body of these specifications. -

Page 98: Functions Changed From Bacnetgw

AI, AV, BI,BV, MI, Protocol_Object_Types_Supported MO, Device,NotificationClass MO, MV, Device Follows the iTM Daylight_Saving_Status Fixed to FALSE clock settings Device Fixed to “Daikin ITM Object_Name DAIKIN MasterStation III (for Server Control” system During D3 initialization: Fixed to control ) System_Status... - Page 99 Continued from previous page Object Before (BACnetGW After (iTM for North Property Identifier Type (Ver6.34.00)) America) Object_Name DAIKIN MasterStation III Outdoor unit name During D3 initialization: DOWNLOAD_IN_PROGRE Fixed to System_Status OPERATIONAL Normal: OPERATIONAL Fixed to “D-BACS BACnet Fixed to “Outdoor Model_Name Gateway”...

- Page 100 Continued from previous page Continued from previous page Before (BACnetGW After (iTM for North Object Type Property Identifier (Ver6.34.00)) America) Property Analog Input IN_ALARM (TRUE: Analog IN_ALARM (Always FALSE) (Room maximum/minimum error) Temperature) FAULT (TRUE: FAULT (TRUE: Communication Communication error or error or Sensor error) Sensor error) Status_Flags...

- Page 101 Continued from previous page Continued from previous page Property Before (BACnetGW After (iTM for North Object Type Identifier (Ver6.34.00)) America) Binary Input 2 or 5-character error Description 2-character error codes (Alarm Status) codes IN_ALARM (TRUE: IN_ALARM (TRUE: Alarm is present) Alarm is present) FAULT (TRUE: FAULT (TRUE:...

-

Page 102: Part 3. Commissioning Procedure

Gather the object information listed below ([1] - [6]) before visiting the site. Obtain this information from the Daikin sales person or Sales Representative for the object. (Fill in the information related to the object in the blank space of [1] - [6].) 1. - Page 103 Part 3. Commissioning Procedure DIII-Net DIII-Net DIII-Net DIII-Net Group Device ID Device ID Device ID Device ID Group Group Group Address (Instance #) (Instance #) (Instance #) (Instance #) Address Address Address 2:1-00 2:2-00 2:3-00 2:4-00 2:1-01 2:2-01 2:3-01 2:4-01 2:1-02 2:2-02 2:3-02...

- Page 104 Part 3. Commissioning Procedure 4. Working drawings 1. Cable routing diagram (provides the following information): a. The number and locations of the iTM. b. The number and locations of the iTM Plus Adaptors. c. Material (e.g., drawings) identifying the number of indoor units and mapping between the addresses and locations of indoor units.

- Page 105 Part 3. Commissioning Procedure Monitor/control from BMS for System Points each indoor unit Enable iTM Schedule Enable Auto-Changeover Operation Timed Override Minutes System Forced Off Note: All system points are enabled cannot be disabled. 6. Items monitored from the BMS for all outdoor units. Outdoor unit point name in CSV File (General/Main) Monitor from BMS for each indoor unit (yes/no) Communication Status...

- Page 106 Part 3. Commissioning Procedure Outdoor unit point name in CSV File (Sub_1) Monitor from BMS for each indoor unit (yes/no) S1_Condensing Pressure S1_Evaporating Pressure S1_Condensing Temperature S1_Evaporating Temperature S1_Inverter Compressor 1 Speed S1_Inverter Compressor 2 Speed S1_Fan Step S1_EV Position 1 S1_EV Position 2 S1_Hot Gas Temperature (Compressor 1) S1_Hot Gas Temperature (Compressor 2)

- Page 107 Part 3. Commissioning Procedure 1. IP address for the iTM IP Address Ex. 192.168.0.1 Subnet mask Ex. 255.255.255.0 Default gateway address Ex. 192.168.0.100 2. IP address temporarily used for the test service operation (but will not be used after the test operation).

-

Page 108: Foreign Device

Part 3. Commissioning Procedure 2. Foreign Device 2.1 Foreign Device Setting 1. When the iTM BACnet® Server Gateway is on a different subnet from the BMS, a BACnet Broadcast Management Device (BBMD) is required and the iTM BACnet Server Gateway should be registered as a Foreign Device. -

Page 109: Bacnet® Point List

Part 3. Commissioning Procedure 3. BACnet® Point List What is a point list? If connecting the indoor units to the BMS using the iTM BACnet Server Gateway, it is necessary for the sales engineer to create a “points list” and submit it to the BMS integrator. The point list includes the BACnet object information required when monitoring/controlling the indoor unit from the BMS via iTM BACnet Server Gateway. -

Page 110: Indoor Unit Points (For Each Indoor Unit)

Part 3. Commissioning Procedure 3.2 Indoor Unit Points (for each indoor unit) Instance Number Object Name Type Occupancy Mode Unit On_Off Status Alarm Status Operation Mode Room Temperature Occ Cooling Setpoint Occ Heating Setpoint Unocc Cooling Setpoint Unocc Heating Setpoint Max Cooling Setpoint Min Cooling Setpoint Max Heating Setpoint... -

Page 111: Outdoor Unit Points (For Each Outdoor Unit)

Part 3. Commissioning Procedure 3.3. Outdoor Unit Points (for each outdoor unit) Instance Instance Object Name (Common) Type Object Name (Main) Type Communication Status M_Condensing Pressure Operation Mode M_Evaporating Pressure Outdoor Unit Alarm Status M_Condensing Temperature Defrost Mode M_Evaporating Temperature Oil Return M_Inverter Compressor 1 Speed Electric Power... - Page 112 Part 3. Commissioning Procedure Instance Instance Object Name (Sub_1) Type Object Name (Sub_2) Type S1_Condensing Pressure S2_Condensing Pressure S1_Evaporating Pressure S2_Evaporating Pressure S1_Condensing Temperature S2_Condensing Temperature S1_Evaporating Temperature S2_Evaporating Temperature S1_Inverter Compressor 1 Speed S2_Inverter Compressor 1 Speed S1_Inverter Compressor 2 Speed S2_Inverter Compressor 2 Speed S1_Fan Step S2_Fan Step...

-

Page 113: Itm Bacnet Server Gateway Activation

Part 3. Commissioning Procedure 4. Commissioning the BACnet® Server Gateway on the iTM 4.1 iTM BACnet Server Gateway Activation 1. From the Service Settings tab of the iTM, click on the Activation icon. 2. On the Activation Setup page, click the Add button to open the keyboard dialog box, and enter the activation key for the iTM BACnet Server Gateway option. -

Page 114: Csv Configuration

Part 3. Commissioning Procedure 4.2 CSV Configuration 1. How to export the CSV file. a. Insure that all indoor units have been added/recognized before exporting the CSV file — set indoor unit name (ex. Room 101), enable Unocc Setpoints, Setpoint Range Limitation and configure Auto-changeover in the iTM. - Page 115 Part 3. Commissioning Procedure f. Remove the USB drive from the iTM and insert into PC. The CSV file is displayed in the root directory. g. Open the CSV file. BACnet Common Settings BACnet Points Settings h. BACnet® communication settings “COMMONSETTING”. DCM014A51 Design Guide...

- Page 116 Part 3. Commissioning Procedure i. BACnet® point setting “PNTSETTING”. 1. Enable or disable each point as required to meet the controls specification. Column PNTSETTING_IN-H PNTSETTING_IN-D Comments (Title) (Default Value) Pnt_Name 1:1-00 Indoor unit name - DO NOT CHANGE Addr 1:1-00 Group Address - DO NOT CHANGE Pny_ID Assigned by iTM –...

- Page 117 Part 3. Commissioning Procedure 2. How to import the CSV File. a. Save the CSV file on the USB drive – Do not change the file name. b. Insert the USB drive in the iTM USB port. c. Login to the “Service Mode” from the iTM [List Screen]. d.

- Page 118 Part 3. Commissioning Procedure If the data in the CSV file imports successfully, the “Information Check” screen will display “No error”. However, this does not ensure the data is correct. ===== ===== ===== ===== ===== ===== No error g. Press “Close” to reboot the iTM. h.

- Page 119 Part 3. Commissioning Procedure i. Import error message details. Type of Error Error message Detail of Error There is no description of a file version in CSV file. CSV File Version does not match. There is an incorrect file version in the CSV file.

-

Page 120: Connecting The Test Operation Pc And Itm Via The Cross Cable Or The Hub/Switch Using 100Base-Tx Straight Cable

Part 3. Commissioning Procedure 5. Connecting the test operation PC and iTM via the cross cable or the hub/switch using 100BASE-TX straight cable. 5.1 Connecting a Test PC to the iTM. Verify that the CSV file is commissioned correctly and the required points are visible to the BMS by using a BACnet®... -

Page 121: Return The Ip Address Of The Test Pc To The Original Address After The Test Operation

Part 3. Commissioning Procedure 3. Select "Internet Protocol (TCP / IPv4)" [1] and click the Properties button [2]. The "Internet Protocol (TCP / IPv4) Properties" dialog box opens. This dialog box shows the test operation PC's current IP address [3], subnet mask [4], and default gateway address [5]. 4. -

Page 122: Reference

Part 3. Commissioning Procedure 6. Reference 6.1 Possible Causes for Unconnected iTM and Test Operation PC 1. When using the Ethernet (LAN): Is the correct IP address set for the PC? Is the cable type correct? [1] When connecting via the hub/switch: Straight cable. [2] When connecting the iTM and test operation PC directly: Cross cable. -

Page 123: Handover To Bms

Part 3. Commissioning Procedure Handover to BMS 7.1 CSV File 1. Keep a copy of the CSV file with the proper configurations for record. 7.2 Network Settings 1. To allow the BMS to access the indoor unit information, change the iTM network settings according to network administrator requirements. -

Page 124: Part 4. Programming Guide

Part 4. Programming Guide Part 4. Programming Guide 1. Typical Requirements 1.1 Typical Indoor Unit Schedule Set by BMS Master Schedule Mode Time Setpoint Occupant Note BMS to create Optimum Start Unoccupied for more than 30 Can adjust 8:00am to Cool 72 setpoint +/-2... -

Page 125: Setpoint Range Limitation

Part 4. Programming Guide 2.2 Setpoint Range Limitation Mode Min Setpoint Max Setpoint Occupant Note Can adjust setpoint from Allows ± 2 F adjustment from Cool Mode F to 74 F from a zone F in Cooling and 68 F in controller. -

Page 126: Notes

Part 4. Programming Guide 4. The Remote Controller On/Off and Mode adjustment can be prohibited during the occupied hours. However, On/Off may need to be permitted during the unoccupied period for the Timed Override operation. 3. Notes 3.1 Indoor Unit EEPROM 1. -

Page 127: Part 5. Installation Manual

B. [DIII] The communication line connection terminals for “DIII-NET” enable communications with DAIKIN’s air conditioning equipment. C. [LINE, PHONE] The port used when subscribing to the DAIKIN “Air Conditioning Network Service System” online monitoring service for air-conditioning systems. A separate maintenance contact is necessary for “Air Conditioning Network Service System”... -

Page 128: Front Panel

Part 5. Installation Manual D. [RESERVE] No Use. E. [RS-485] The terminals for connecting serial equipment. F. [plus ADP IF] The terminals for connecting one or more iTM plus adaptors when the iTM is used to control additional air conditioning devices. G. -

Page 129: Side Panel

Part 5. Installation Manual Off: Hardware error or power Off F. [LAN LINK] LED (Green): The LED that indicates the hardware connection is established normally between the iTM and the equipment connected to the LAN port. It is lit when there is no error. -

Page 130: Electrical Wiring

Part 5. Installation Manual 2. Electrical Wiring This section describes the procedure for connecting the iTM with Daikin air conditioning devices and other equipment. In addition to the indoor units, the iTM can monitor and control a wide variety of equipment. -

Page 131: Wiring Specifications

The “centralized controller” refers to the equipment (e.g. the iTM) that controls multiple indoor units. In addition to the iTM, the Daikin product portfolio includes a wide range of centralized controllers suitable for different applications or building sizes. These controllers can be used in combination to construct an optimal air conditioning control system. - Page 132 Part 5. Installation Manual e. To change the setting of the iTM to SLAVE, flip the DIII MASTER switch located under the front slide cover to the up position (see figure below). When installing multiple centralized controllers, only set the highest-priority controller to MASTER, and set all other controllers to SLAVE according to the following order of priority.

- Page 133 Part 5. Installation Manual A. SERVICE LAN B. LAN SW 4. Connecting an emergency stop input device or power meter. The iTM can perform operations such as an emergency stop of indoor units according to the external signal input device, and an electricity usage calculation for each indoor unit (for power proportional distribution) according to the pulse inputs from a power meter.

- Page 134 Part 5. Installation Manual 6. Wiring specifications • Cable type: CPEV cable • Core thickness: AWG 22-19 • Cable length: 656 ft. or less Pulse width A. Pulse width: 20 to 400 ms B. Pulse interval: 100 ms or more 7.

- Page 135 Part 5. Installation Manual 8. Wiring specifications • Cable type: CPEV or FCPEV cable • Core thickness: AWG 22-19 • Cable length: The overall cable length between the iTM and the terminal iTM Plus Adaptor is 164 ft. or less. •...

-

Page 136: Basic Setup Of Intelligent Touch Manager

Part 5. Installation Manual 3. Basic Setup of intelligent Touch Manager™ After checking all connections are correct and secure, begin the iTM basic setup. The basic setup refers to the preparative settings for monitoring and controlling the air conditioning system using the iTM. -

Page 137: Turning On Power Supply To Intelligent Touch Manager™ And Air Conditioners

Part 5. Installation Manual 2. Move BACKUP switch to ON, and attach the front switch cover back to original position. If the power supply is OFF for a long period of time (six months or more), turn OFF the BACKUP switch. 3.2 Turning on Power Supply to intelligent Touch Manager™... -

Page 138: Appendix A. Bacnet® Gateway (Dms502B71) And Itm Protocol Comparison

Part 5. Installation Manual Appendix A. BACnet® Gateway (DMS502B71) and iTM Protocol Comparison This appendix describes the following differences between BACnet Gateway (Ver. 6.34.00) and iTM BACnet Server Gateway (Ver. 2.04.00): • Functions removed from BACnet Gateway • Functions changed from BACnet Gateway Note that "Additions from BACnet Gateway"... -

Page 139: Appendix B. Supported Indoor Unit Models And Monitoring Control Items

Part 5. Installation Manual Appendix B. Supported Indoor Unit Models and Monitoring Control Items The following table includes a list of objects for each of the supported indoor unit models compatible with the iTM BACnet® Server Gateway function. FFQ Indoor Unit Mini-Split &... - Page 140 Part 5. Installation Manual FFQ Indoor Unit SkyAir Outdoor Mini-Split & for Multi-split & Indoor Instance SkyAir FTXS Super Multi Plus Object Name VRV Indoor Unit Unit Processing Indoor Units (DTA112BA51 (except Unit (KRP928) Adaptor FTXS) Required) Return Air ✓ ✓...

-

Page 141: Appendix C. Supported Outdoor Unit Models

Part 5. Installation Manual Appendix C. Supported Outdoor Unit Models Regarding outdoor units models compatible with the BACnet® server, the list is as follows: VRV IV Heat Pump supported ODU VRV IV Heat Recovery supported ODU Model name Model name RXYQ72TATJU RXYQ72TAYDU REYQ72TATJU... - Page 142 Part 5. Installation Manual VRV IV Aurora™ Heat Pump ODU VRV IV Aurora™ Heat Recovery ODU Model name Model name RXLQ72TATJU RXLQ144TAYCU RELQ72TATJU RELQ144TAYCU RXLQ96TATJU RXLQ192TAYCU RELQ96TATJU RELQ192TAYCU RXLQ120TATJU RXLQ240TAYCU RELQ120TATJU RELQ240TAYCU RXLQ144TATJU RXLQ72TAYDU RELQ144TATJU RELQ72TAYDU RXLQ192TATJU RXLQ96TAYDU RELQ192TATJU RELQ96TAYDU RXLQ240TATJU RXLQ120TAYDU RELQ240TATJU...

-

Page 143: Appendix D. Itm Specifications, Dimensions, And System Wiring

Part 5. Installation Manual Appendix D. iTM Specifications, Dimensions, and System Wiring 1. Specifications intelligent Touch Manager™ iTM Plus Adaptor (option) Model No. DCM601A71 DCM601A72 Power Supply (Externally supplied) 24 VAC, 60 Hz 24 VAC, 60 Hz Power Consumption 23 Watts 23 Watts Operating Temp Range 32-104... - Page 144 Part 5. Installation Manual iTM Plus Adaptor DCM601A72 Design Guide DCM014A51...

-

Page 145: System Configuration And Wiring

Part 5. Installation Manual 3. System Configuration and Wiring iTM – DIII-Net Wiring* A. Outdoor unit B. OUT - OUT communication (terminal) C. IN - OUT communication (terminal) D. Indoor unit E. A maximum of 16 indoor units can be connected per remote controller group. F. - Page 146 Part 5. Installation Manual iTM Ethernet Connection* A. Rear face of iTM B. LAN cable • Applicable cable standard: 100Base-TX or 10Base-T • Connector standard: RJ-45 C. Hub D. PC *Do not use power over Ethernet connection. Only use Ethernet cabling dedicated for communication.

- Page 147 Part 5. Installation Manual iTM Plus Adaptor Connection A. iTM B. iTM Plus Adaptor C. Plus ADP IF (iTM) D. Plus ADP IF (iTM Plus Adaptor) E. iTM Plus Adaptor where termination resistor must be enabled. (For details, refer to the “iTM Plus Adaptor Installation Manual” (EM11A030).) DCM014A51 Design Guide...

- Page 148 Only qualified personnel must complete installation. WARNING Consult your Daikin contractor regarding relocation and reinstallation of the remote controller. Improper installation may result in electric shock or fire. Electrical work must be performed in accordance with relevant local and national regulations, and with the instructions in this installation manual.

Need help?

Do you have a question about the intelligent Touch Manager BACnet DCM014A51 and is the answer not in the manual?

Questions and answers