Table of Contents

Advertisement

Instruction Manual

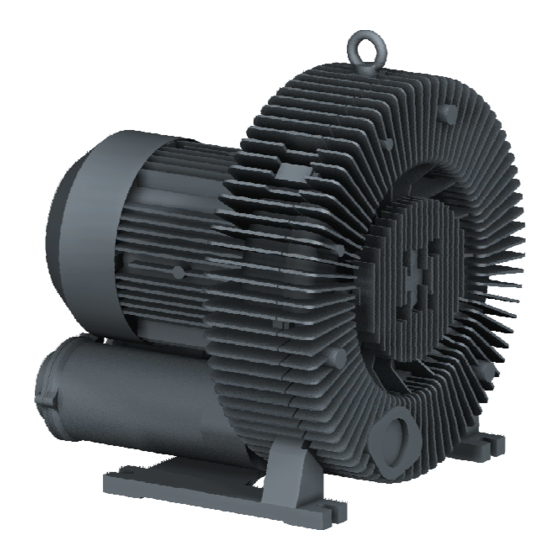

Samos

Side Channel Blower

SB 0050 D0, SB 0080 D0, SB 0140 D0, SB 0200 D0, SB 0310 D0,

SB 0430 D0, SB 0530 D0, SB 0710 D0, SB 1100 D0, SB 1400 D0,

SB 0080 D2, SB 0140 D2, SB 0200 D2, SB 0310 D2, SB 0530 D2, SB 1100 D2

Busch Produktions GmbH

Schauinslandstraße 1, 79689 Maulburg

Germany

0870145123/A0000_en / Original instructions / Modifications reserved

07/09/2018

Advertisement

Table of Contents

Summary of Contents for BUSCH Samos Series

- Page 1 SB 0430 D0, SB 0530 D0, SB 0710 D0, SB 1100 D0, SB 1400 D0, SB 0080 D2, SB 0140 D2, SB 0200 D2, SB 0310 D2, SB 0530 D2, SB 1100 D2 Busch Produktions GmbH Schauinslandstraße 1, 79689 Maulburg...

-

Page 2: Table Of Contents

Table of Contents Table of Contents 1 Safety........................... 3 2 Product Description ..................... 4 2.1 Operating Principle....................5 2.2 Application ......................5 2.3 Start Controls ....................... 5 2.4 Optional Accessories..................... 5 2.4.1 Vacuum Regulating Valve................5 2.4.2 Pressure Regulating Valve................6 2.4.3 Inlet Filter ....................6 2.4.4 Silencer ......................6 3 Transport ........................ -

Page 3: Safety

Safety Prior to handling the machine, this instruction manual should be read and understood. If anything needs to be clarified, please contact your Busch representative. Read this manual carefully before use and keep for future reference. This instruction manual remains valid as long as the customer does not change anything on the product. -

Page 4: Product Description

2 | Product Description Product Description Single-stage IN OUT MTB EB Double-stage Suction connection Motor terminal box Discharge connection Nameplate Eye bolt NOTE Technical term. In this instruction manual, we consider that the term ‘machine’ refers to the ‘side channel blower’. -

Page 5: Operating Principle

Conveying of other media leads to an increased thermal and/or mechanical load on the machine and is permissible only after a consultation with Busch. The machine is intended for the placement in a non-potentially explosive environment. -

Page 6: Pressure Regulating Valve

3 | Transport 2.4.2 Pressure Regulating Valve The pressure regulating valve controls pressure when the machine is used on overpres- sure duties. 2.4.3 Inlet Filter The inlet filter protects the machine against dust and other solids in the process gas. The inlet filter is available with a cartridge. -

Page 7: Installation

Installation | 5 • Low vibration (V < 2.8mm/s) If the storage time exceeds 4 years: • Replace and relubricate the bearings with specific grease type: ESSO Unirex N3 • Clean and relubricate the bearing intermediate place • Replace and relubricate the shaft seals Installation 5.1 Installation Conditions ~40 mm... -

Page 8: Connecting Lines / Pipes

5 | Installation If the machine is installed at an altitude greater than 1000 meters above sea level: • Contact your Busch representative, the motor should be derated or the ambient temperature limited. If the machine is installed outdoor: • Provide a protective cover against the weathering effects. -

Page 9: Electrical Connection

• Provide an overload protection according to EN 60204-1 for the motor. • Make sure that the motor of the machine will not be affected by electric or electro- magnetic disturbance from the mains; if necessary seek advice from Busch. • Connect the protective earth conductor. -

Page 10: Wiring Diagram Three-Phase Motor

6 | Commissioning Connection motor protection: 5.3.2 Wiring Diagram Three-Phase Motor NOTICE Incorrect direction of rotation. Risk of damage to the machine! • Operation in the wrong direction of rotation can destroy the machine in a short time! Prior to start-up, ensure that the machine is operated in the right direction. If the rotation of the motor must be changed: •... - Page 11 Commissioning | 6 CAUTION Noise of running machine. Risk of damage to hearing! If persons are present in the vicinity of a non noise insulated machine over extended periods: • Make sure that ear protection is being used. • Make sure that the installation conditions (see Installation Conditions [► 7]) are com- plied with.

-

Page 12: Maintenance

• Check the electrical connections and the monitoring devices. • Clean the inlet and outlet silencer. Every 20000 hours, at the • Have a major overhaul on the machine (contact latest after 5 years Busch). 12 / 24 0870145123_SB0050-1400D0_D2_A0000_IM_en... -

Page 13: Cleaning From Dust And Dirt

Risk of premature failure! Loss of efficiency! • It is highly recommended that any dismantling of the machine that goes beyond any- thing that is described in this manual should be done through Busch. WARNING Machines contaminated with hazardous material. -

Page 14: Decommissioning

9 | Decommissioning Busch will only accept machines that come with a completely filled in and legally binding signed ‘Declaration of Contamination’. (Form downloadable from www.buschvacuum.com) Decommissioning • Shut down the machine and lock against inadvertent start up. • Vent the connected lines to atmospheric pressure. -

Page 15: Troubleshooting

The motor is not supplied • Check the power supply. with the correct voltage. The motor is defective. • Repair the machine (con- tact Busch). The machine does not start; One power supply lead is in- • Check the fuses, terminals humming noise. - Page 16 Wiring Dia- gram Three-Phase Motor Different density of con- • Take conversion of pres- veyed medium sure value into account. Contact Busch if neces- sary. Change in blade profile due • Check the impeller, clean soiling. or replace if necessary.

-

Page 17: Technical Data

Technical Data | 12 12 Technical Data SB 0050 D0 SB 0080 D0 SB 0140 D0 Nominal pumping speed m³/h 50 / 60 80 / 100 140 / 175 volume flow (50Hz / 60Hz) Max. differential pressure hPa (mbar) abs. -90 / -120 -100 / -100 120 / 150... - Page 18 12 | Technical Data SB 0430 D0 SB 0530 D0 Nominal pumping speed m³/h 415 / 500 530 / 620 volume flow (50Hz / 60Hz) Max. differential pressure hPa (mbar) -180 / -160 -220 / -200 -260 / -260 -200 / -160 -300 / -300 vacuum version abs.

- Page 19 Technical Data | 12 SB 1100 D0 Nominal pumping speed m³/h 1050 / 1250 volume flow (50Hz / 60Hz) Max. differential pressure hPa (mbar) abs. -190 / -150 -290 / -270 -360 / -380 vacuum version (50Hz / 60Hz) Max. differential pressure hPa (mbar) abs.

- Page 20 12 | Technical Data SB 0080 D2 SB 0140 D2 SB 0200 D2 Nominal pumping speed m³/h 85 / 100 150 / 180 230 / 270 volume flow (50Hz / 60Hz) Max. differential pressure hPa (mbar) abs. -210 / -250 -280 / -320 -320 / -350 -340 / -380...

- Page 21 Technical Data | 12 SB 1100 D2 Nominal pumping speed m³/h 1120 / 1340 volume flow (50Hz / 60Hz) Max. differential pressure hPa (mbar) abs. -300 / -220 -410 / -340 -440 / -440 vacuum version (50Hz / 60Hz) Max. differential pressure hPa (mbar) abs.

-

Page 22: Eu Declaration Of Conformity

This Declaration of Conformity and the CE-mark affixed to the nameplate are valid for the machine within the Busch scope of delivery. This Declaration of Conformity is issued under the sole responsibility of the manufacturer. When this machine is integrated into a superordinate machinery the manufacturer of the superordinate machinery (this can be the operating company, too) must conduct the conformity assessment process for the superordinate machine or plant, issue the Declaration of Conformity for it and affix the CE-mark. - Page 23 Note...

- Page 24 Czech Republic Netherlands Turkey www.buschvacuum.cz www.busch.nl www.buschvacuum.com Denmark New Zealand United Arab Emirates www.busch.dk www.busch.com.au www.busch.ae Finland Norway United Kingdom www.busch.fi www.busch.no www.busch.co.uk France Peru www.busch.fr www.busch.com.pe www.buschusa.com Germany Poland www.busch.de www.busch.com.pl www.buschvacuum.com 0870145123/A0000_en / © Busch Produktions GmbH...

Need help?

Do you have a question about the Samos Series and is the answer not in the manual?

Questions and answers