Summary of Contents for Alpha-InnoTec LWP Series

- Page 1 Air/water heat pumps Operating Manual 83059700gUK – Translation of the operating manual...

-

Page 2: Table Of Contents

Table of Contents 13 Faults About this operating manual ..................17 ........ 3 Validity ................3 14 Dismantling and disposal ........18 Other applicable documents ....... 3 14.1 Dismantling ..............18 Symbols and markings ........... 3 14.2 Disposal and recycling ..........18 Contact ................ -

Page 3: About This Operating Manual

About this operating manual 1.3 Symbols and markings This operating manual is part of the device. Before working on or with the device, read the Symbol Meaning operating manual carefully and follow it for all Safety-relevant information. Warning activities at all times, especially the warnings and of physical injuries. -

Page 4: Contact

1.4 Contact Heating contractor Plumber Addresses for purchasing accessories, for service cases or for answers to questions about the device Refrigeration system installer (maintenance work) and this operating manual can be found on the internet and are kept up-to-date: During the warranty and guarantee period, service Germany: www.alpha-innotec.de work and repairs may only be carried out by personnel EU: www.alpha-innotec.com... -

Page 5: Disposal

2.5 Disposal Improper action Requirements for minimum scale and corrosion Media harmful to the environment damage in hot water heating systems: Improper disposal of environmentally hazardous media Proper planning, design and commissioning (refrigerant) damages the environment: Closed system with regard to corrosion Collect media safely. -

Page 6: Description

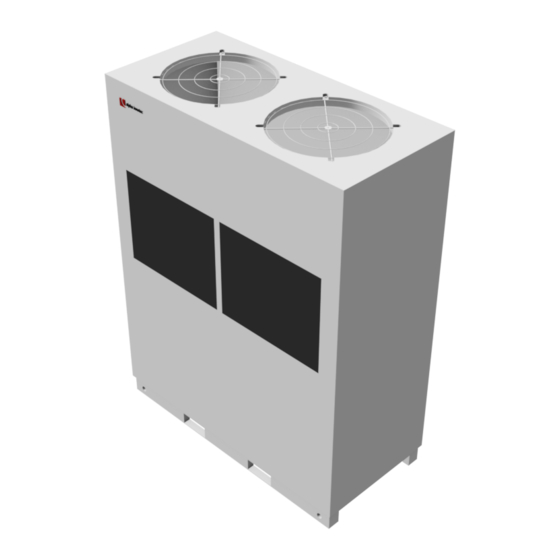

Description 3.3 Layout NOTE This section essentially names 3.1 Delivery condition: described in this operating manual. 1 Compressor 2 Switch box cover 1 Edge protection (styrofoam 3 Fans angled strips) 4 Evaporator 2 Wooden strip, screwed 5 Condenser on under all sides Nameplate 3.2 Wall-mounted controller: The nameplate is attached at the following point on the... -

Page 7: Accessories

3.4 Accessories Cooling Cooling is integrated in the units. The following The following accessories are available for the device options are possible for units with cooling function through the manufacturer's local partner: operating manual for the heating and heat pump Domestic hot water tank controller): Active cooling... -

Page 8: Operation And Care

Operation and care Delivery, storage, transport and installation NOTE The device is operated via the control panel 5.1 Scope of supply of the heating and heat pump controller operating manual for the heating and Check delivery immediately after receipt for heat pump controller). -

Page 9: Installation

Ideally, the device should be transported with a lift Dispose of the transport and packaging material in truck. an environmentally friendly way and in accordance with local regulations. Do not tilt the heat pump by more than 45°. 5.4 Installation Transport with a crane Devices can be lifted with a crane. -

Page 10: Hydraulic Installation

Hydraulic installation Vertical connection Heat pump from below: View from inside: Flush the heating circuit thoroughly before connecting the unit to the heating circuit. Secure all connections to prevent twisting. Cross-sections and lengths of the pipes for the heating circuit are adequately dimensioned. The connection line between the heat pump and the building must also be taken into account. -

Page 11: Condensate Drain

Horizonzal connection Electrical installation Open break-outs on the right sidewall Trim the 4 hoses (accessories) to length if required. Likewise the condensate hose, which Connect the electrical cables hangs loose from the condensate pan. Attach the hoses and the condensation hose and ATTENTION lead out on the right side. -

Page 12: Heating Water Quality

8.1 Heating water quality NOTE For detailed information refer, among other things, to the VDI Guidelines damage in hot water heating systems). Required pH value: 8.2 – 10 aluminium materials: value: 8.2 – 8.5 1 Feed-through glands Fill the system only with demineralised heating 2 Soft starter water (VE water) or VDI 2035 water (low-salt 3 Cable glands... -

Page 13: Insulate Hydraulic Connections

NOTE The activities in this section are only necessary for the integration of storage tanks in series . Complete the work steps quickly, otherwise the maximum return temperature may be exceeded and the heat pump switches to high-pressure fault. valve right increase to the left to reduce it. -

Page 14: Commissioning

Commissioning 12 Maintenance Relevant planning & design data of the system is documented in full. NOTE recommend that conclude maintenance agreement with an accredited of the operation of the heat pump system. heating company. System is air-free. Installation check using the rough checklist has 12.1 Basic principles been completed successfully. -

Page 15: Yearly Maintenance

12.3 Yearly maintenance 13 Faults Record the quality of the heating water analytically. Read out the cause of the fault via the diagnostics program of the heating and heat pump controller. suitable measures without delay. Contact the local partner of the manufacturer or the factory's customer service. - Page 16 Subject to technical amendments without notice | 83059700gUK – Translation of the operating manual | ait-deutschland GmbH...

-

Page 17: Technical Data/Scope Of Supply

LWP 450AR3 Technical data/Scope of supply Performance data LWP450AR3 At A7/W35 per EN14511 At A7/W45 per EN14511 At A2/W35 per EN14511 At A10/W35 per EN14511 At A-7/W35 per EN14511 At A-15/W65 per EN14511 At A-7/W55 per EN 14511 At A35/W18 At A35/W7 Operating limits °C... -

Page 18: Performance Curves / Operating Limits / Heating

Performance curves / operating limits / heating LWP 450AR3 Qh (kW) Temp„ (°C) Pe (kW) 35°C 1VD 55°C 1VD 35°C 2VD 55°C 2VD Temp„ (°C) Temp„ (°C) ∆p (bar) Temp” (C°) 0,125 0,100 0,075 0,050 0,025 ”p∆ 0,000 10,0 “” (m³/h) Temp„... -

Page 19: Performance Curves / Cooling

Performance curves / cooling LWP 450AR3 Q0 (kW) Temp¤ (°C) Pe (kW) 7°C 1VD 18°C 1VD 10°C 2VD 18°C 2VD Temp¤ (°C) Temp¤ (°C) ∆p (bar) Temp” (C°) 0,125 0,100 0,075 0,050 0,025 ”p∆ 0,000 10,0 “©(m³/h) Temp„ (°C) 823279a “©... - Page 20 Dimensioned drawing 2323 1245 296,3 Key: 819491 Subject to technical change without notice. All dimensions in mm. Rear view Side view from the right Plan view Subject to technical amendments without notice | 83059700gUK – Translation of the operating manual | ait-deutschland GmbH...

Need help?

Do you have a question about the LWP Series and is the answer not in the manual?

Questions and answers