Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Farmet Triolent TX 300 N

- Page 1 OPERATING MANUAL TRIOLENT TX 300 N | TX 350 N Edition: 3 | effective from: 1. 1. 2011 IČ: Farmet a. s. telefon: +420 491 450 111 46504931 web: www.farmet.cz Jiřinková 276 DIČ: CZ46504931 fax: +420 491 450 136 e-mail: farmet@farmet.cz 552 03 Česká...

- Page 2 Manual TRIOLENT TX 300 N | TX 350 N Dear customer, TRIOLENT Carried cultivators are quality products of Farmet a.s. Ceska Skalice. You can fully utilise the advantages of your machine after thoroughly studying the operating manual. The serial number of the machine is punched on the production label and written in the operating manual (see Table 1).

-

Page 3: Table Of Contents

Manual TRIOLENT TX 300 N | TX 350 N TABLE OF CONTENTS MACHINE LIMIT PARAMETERS ..................4 Technical parameters ......................4 Safety statement ........................4 A. GENERAL INSTRUCTIONS FOR USE ................4 Protective Tools ........................5 B. MACHINE TRANSPORT USING TRANSPORT MEANS ..........5 C. -

Page 4: Machine Limit Parameters

Manual TRIOLENT TX 300 N | TX 350 N MACHINE LIMIT PARAMETERS The machine is designed for soil cultivation up to a depth of 35cm when agricultural soil cultivation. Another type of use exceeding the determined purpose is considered as disallowed. -

Page 5: Protective Tools

Manual TRIOLENT TX 300 N | TX 350 N It must be demonstrably familiarised with the safety regulations for work with the machine and must practically master the machine operation, (10) The machine may not be operated by juveniles. -

Page 6: Machine Handling Using Lifting Equipment

Manual TRIOLENT TX 300 N | TX 350 N C. MACHINE HANDLING USING LIFTING EQUIPMENT The lifting equipment and tying means designed for handling of the machine must have their load capacity at least identical with the weight of the handled machine. - Page 7 Manual TRIOLENT TX 300 N | TX 350 N Do not approach the rotary parts of P 53 H the machine, if these are not at rest, i.e. they do not turn. Fig. 1 - Location of safety labels on the machine:...

-

Page 8: Description

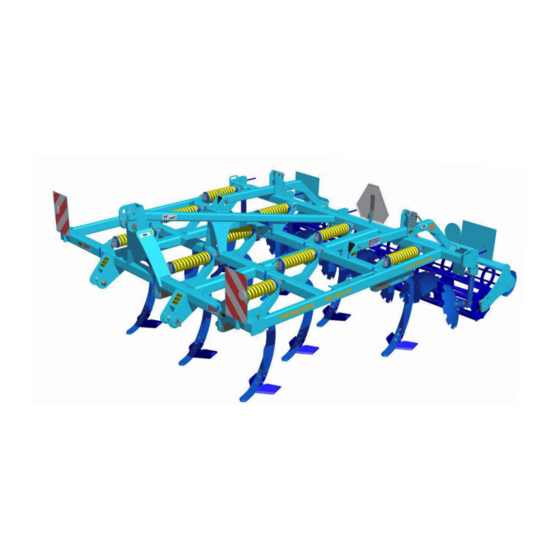

Manual TRIOLENT TX 300 N | TX 350 N 1. DESCRIPTION TRIOLENT TX 300 N, TX 350 N The machine is structurally solved as carried. The machine is equipped with TPS 3 suspension (additional equipment and with the “KIROVEC” suspension). TRIOLENT consists of a framework with three rows of shares with automatic spring protection. - Page 9 Manual TRIOLENT TX 300 N | TX 350 N Description and setting of the RING roller The roller with wheels consisting of ring segments is attached to the frame. There is a row of leveller blades in front of the roller. The height as well as angle of the blades can be adjusted. The correct setting of the blades is essential for the correct function of the roller.

-

Page 10: Machine Assembly At The Customer

The table of requirements for the towing means for work with the machine: Requirement for the tractor engine power for cultivator TRIOLENT TX 300 N 110-190 kW* Requirement for the tractor engine power for cultivator TRIOLENT TX 350 N... -

Page 11: Machine Transport On Roads

Manual TRIOLENT TX 300 N | TX 350 N Connect the machine using the TPS suspension bar to the lower arms of the rear TPS of the tractor, secure the TPS arms using pins against disconnecting. The machine aggregated with the tractor changes the distribution of the weight to the individual axles of the tractor. -

Page 12: Adjusting The Working Depth Of The Machine

Manual TRIOLENT TX 300 N | TX 350 N Bring the machine into the transport position. The operator is obliged to pay increased attention during transport on roads, due to the transport dimensions of the machine. The operator must observe the valid regulations for transport on roads (laws, decrees) after connecting the machine to the tractor, for reason of a change of the axle load. - Page 13 Manual TRIOLENT TX 300 N | TX 350 N Tractor's three- Three-point Rear frame Rear swinging point pull rod flange gates frames with rollers Tractor hydraulics arms Fig. 7 – Machine adjustment procedure Auxiliary handle for disc setting 13 │ 22...

-

Page 14: Share Securing

Manual TRIOLENT TX 300 N | TX 350 N Table of orientation depth of the machine TRIOLENT Setting Setting (mm) (mm) Orientation depth Orientation depth scale scale SHARE SECURING The basic setting of the securing spring is performed by the manufacturer at 395 ± 5 mm so it is horizontal. -

Page 15: Placement Of Top Left And Right Shares On The Machine

Manual TRIOLENT TX 300 N | TX 350 N PLACEMENT OF TOP LEFT AND RIGHT SHARES ON THE MACHINE TRIOLENT TX 300 N TRIOLENT TX 350 N 15 │ 22... -

Page 16: Machine Maintenance And Repairs

Manual TRIOLENT TX 300 N | TX 350 N 6. MACHINE MAINTENANCE AND REPAIRS Observe the safety instructions for treatment and maintenance. If it is necessary to weld during the repair and have the machine connected to the tractor, it must have disconnected supply cables from the alternator and the accumulator. -

Page 17: Machine Lubrication Schedule

Manual TRIOLENT TX 300 N | TX 350 N 8. MACHINE LUBRICATION SCHEDULE During machine maintenance and its lubrication, it is necessary to observe the safety regulations. Tab. 4 LUBRICATION POINT INTERVAL LUBRICANT - Daily, always before the work with the machine. -

Page 18: Servicing And Warranty Conditions

11.2.8 The warranty is conditioned by using the genuine spare parts of the manufacturer. Prepared by: Technical Department, Farmet a.s., Jirinkova 276, Ceska Skalice 552 03, On 25 November 2010, total number of pages 20, changes reserved. 18 │ 22... -

Page 19: Letter Of Guarantee

The warranty is bound to the machine and is not void upon an owner change. The warranty is limited to the disassembly and assembly, possibly replacement or repair of the defective part. The decision, whether to replace or repair the defective part, is up to the contractual workshop of Farmet. VII. -

Page 20: Ce Certificate Of Conformity

CE CERTIFICATE OF CONFORMITY EG-KONFORMITÄTSERKLÄRUNG DÉCLARATION CE DE CONFORMITÉ СЕРТИФИКАТ СООТВЕТСТВИЯ ЕС DEKLARACJA ZGODNOŚCI WE Мы Nous Farmet a.s. Jiřinková 276 552 03 Česká Skalice Czech Republic DIČ: CZ46504931 Tel/Fax: 00420 491 450136 Vydáváme na vlastní zodpovědnost toto prohlášení. Hereby issue, on our responsibility, this Certificate. - Page 21 CE CERTIFICATE OF CONFORMITY EG-KONFORMITÄTSERKLÄRUNG DÉCLARATION CE DE CONFORMITÉ СЕРТИФИКАТ СООТВЕТСТВИЯ ЕС DEKLARACJA ZGODNOŚCI WE Мы Nous Farmet a.s. Jiřinková 276 552 03 Česká Skalice Czech Republic DIČ: CZ46504931 Tel/Fax: 00420 491 450136 Vydáváme na vlastní zodpovědnost toto prohlášení. Hereby issue, on our responsibility, this Certificate.

Need help?

Do you have a question about the Triolent TX 300 N and is the answer not in the manual?

Questions and answers