Summary of Contents for GE CRxFlex

- Page 1 Measurement & Control Technologies Computed Radiography CRxFlex CRxFlex Operating Manual V1.1 LL ID 51179524...

-

Page 2: Table Of Contents

Preventive Maintenance ....................18 Quality Control ......................18 Environmental Protection ....................19 Safety Directions ......................20 General safety instructions .......................... 21 Getting started with the CRxFlex ..............22 Starting the Digitizer Remote Display ................22 Starting Rhythm RT .....................22 Starting the CRxFlex ....................25 Scanning an Image .....................26 Stopping the CRxFlex ....................29... - Page 3 Re-erasing an Image Plate ..................30 Cleaning the Optics Unit ....................31 Troubleshooting ......................34 Digitizer Remote Display ..........................34 Connection Problems ..........................34 Removing a jammed image plate ........................ 35 Technical Specifications ................36 CRxFlex Operating Manual V1.1...

-

Page 4: Introduction To This Manual

1 Introduction to this Manual Scope This manual contains information for safe and effective operation of the CRxFlex digitizer system. It describes the basic operation with Rhythm RT. For more details on Rhythm RT or Rhythm RT Lite consult the online manual of the respective application. -

Page 5: Disclaimer

Disclaimer GE Sensing and Inspection Technologies assumes no liability for use of this document if any unauthorized changes have been made to the content or format. Every care has been taken to ensure the accuracy of the information in this document. -

Page 6: Introduction To Crxflex

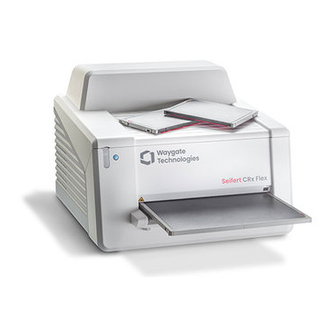

Intended Use CRxFlex: The CRxFlex will be used in an industrial environment by qualified staff to scan X-ray or Gamma-ray exposed cassettes, containing an imaging plate for non-destructive testing applications. It results in a digital image which is sent to the dedicated workstation. -

Page 7: Configuration

Configuration The system consists of: The CRxFlex Digitizer including the accessory kit. Cassette in different sizes with image plate. Following image plate types are available: IPS for CRxFlex IPC2 for CRxFlex IPU for CRxFlex Workstation for image processing and identification. -

Page 8: Connections

Operation Controls The CRxFlex interfaces with the user via: The Erase Button The Status Indicator The Power Button The Digitizer Remote Display for CRxFlex status and error messages The Rhythm RT front end with graphical user interface CRxFlex Operating Manual V1.11... -

Page 9: The Erase Button

After pressing the erase button, the upper part of the status indicator is continuously lighting up in blue and the CRxFlex starts erasing the imaging plate of the cassette inserted next. If no cassette with imaging plate has been inserted after 60 seconds, the system automatically returns to standby mode. -

Page 10: Compatibility

Compatibility The CRxFlex must only be used in combination with other equipment or components if these are expressly recognized by GE as compatible. Changes or additions to the equipment must only be carried out by persons authorized to do so by GE. Such changes must comply with best engineering practices and all applicable laws and regulations. - Page 11 Applications of hazardous substances in this medical device are required to achieve its intended clinical uses, and/or to provide better protection to human beings and/or to environment, due to lack of reasonably (economically or technically available substitutes. CRxFlex Operating Manual V1.1...

-

Page 12: Equipment Classification

Operation Continuous operation Connectivity The CRxFlex is connected to the workstation via network connection and uses the DICOM protocol to communicate with the workstation. Training The user must have received adequate training on the safe and effective use of the product before attempting to work with it. -

Page 13: Installation

CRxFlex and that it is easily accessible. Caution: If the CRxFlex is installed inside of an X-ray room it must be protected from stray radiation by proper shielding. - Page 14 The CRxFlex is equipped with two handles at the bottom left and right sides to move the device easily to another location. Follow the instructions as illustrated below to lift the CRxFlex out of the packing and to carry it to another location.

-

Page 15: Labels

Labels Always take into account the markings and labels provided on the inside and outside of the CRxFlex. A brief overview of these markings and labels and their meaning is given below. Safety warning, indicating that the CRxFlex manuals should be consulted before making any connections to other equipment. - Page 16 WEEE Symbol, see section about Environmental Protection. CRxFlex Operating Manual V1.11...

-

Page 17: Safety Instructions For Laser Products

Safety Instructions for Laser Products The CRxFlex is a Class 1 Laser Product. It uses one laser diode of a 120 mW type, classification class IIIb, wavelength 640-670 nm. The laser beam’s deflection frequency is 120 - 170 Hz. The laser beam divergence is 12 mrad. -

Page 18: Cleaning Of Image Plates

Preventive maintenance has to be done by a qualified field service engineer. Not performing the regular maintenance by appropriately certified people can have impact on warranty commitments. Quality Control Apply regular quality control according local regulations. CRxFlex Operating Manual V1.11... -

Page 19: Environmental Protection

If your equipment or replaced spare parts contain batteries or accumulators please dispose of them separately according to local regulations. For battery replacements please contact your local sales organization. CRxFlex Operating Manual V1.1... -

Page 20: Safety Directions

Changes, additions or maintenance to the product carried out by persons without appropriate qualifications and training. Using unapproved spare parts. Caution: Position the CRxFlex so that it is possible to disconnect the mains power connection if required. CRxFlex Operating Manual V1.11... -

Page 21: General Safety Instructions

As is the case for all technical devices, the CRxFlex must be operated, cared for and serviced correctly. A regular quality control is recommended. If you do not operate the CRxFlex correctly or if you do not have it serviced correctly, the manufacturer is not liable for resulting disturbances, damages or injuries. ... -

Page 22: Getting Started With The Crxflex

4. Button to confirm the message 5. Connection status and IP address Note: The connection status is either “connected” or “offline”. Starting Rhythm RT Start Rhythm RT and select CRxFlex (Ethernet option from the available scanner pull down menu. CRxFlex Operating Manual V1.11... - Page 23 Enter component, technique and study data before proceed with scanning. Change over to the CRxFlex Digitizer Interface: CRxFlex Operating Manual V1.1...

- Page 24 Note: For more details on Rhythm RT configuration please consult the online help manual. CRxFlex Operating Manual V1.11...

-

Page 25: Starting The Crxflex

Check for presence of cassettes and/or image plates. Establish connection to the workstation. During the self-test, which takes approx. 1 minute, the CRxFlex status indicator is blinking yellow. Note: During the self-test, you cannot activate any function. If the CRxFlex has completed the self-test successfully, the CRxFlex enters the operator mode and the status indicator is continuously lighting up in green. -

Page 26: Scanning An Image

Scanning an Image The CRxFlex digitizer interface allows for the configuration and acquisition of images from the CRxFlex digitizer hardware. When active, the following interface will be available. On connection to the digitizer, the scan button will be enabled. To start a scan proceed as follows’... - Page 27 5. Insert the exposed cassette containing the image plate into the cassette slot of the CRxFlex. Make sure to insert the cassette with the black side to the top and with the shutter opening mechanism and the locking mechanism inside the CRxFlex. Make sure that the cassette is firmly pushed to the right side of the slot.

- Page 28 Rhythm acquisition software. This information is also logged to a file and can be used to diagnose issues with connectivity. Final acquired image(s will be availale in the view images tab and can be transferred to Rhythm Review for final analysis. CRxFlex Operating Manual V1.11...

-

Page 29: Stopping The Crxflex

Stopping the CRxFlex Before Switching Off Check that the CRxFlex is not scanning an image plate. If the CRxFlex is scanning an image plate, the status indicator is blinking green. Switching Off It is recommended to switch off the CRxFlex at the end of the day. -

Page 30: Operating The Crxflex

At the end of a normal digitizing cycle, the CRxFlex returns an erased image plate. However, in the following cases, you must re-erase the image plate before re-using it in order to prevent ghost images from interfering with the image of interest: ... -

Page 31: Cleaning The Optics Unit

Cleaning the Optics Unit Cleaning the optics unit is required if stripes parallel to the image plate movement can be seen in the image. When you recognize this type of artifact, when using the CRxFlex, clean the optics unit using the cleaning brush. - Page 32 3. Open the lid positioned at the right side. 4. Clean the scan line. Your last movement must be continuous from the rear to the front. 5. Re-insert the cleaning brush. CRxFlex Operating Manual V1.11...

- Page 33 6. Close the cassette unit. Caution: Misuse of the bowden wire leads to bending, which causes a complicated replacement of the cleaning brush. CRxFlex Operating Manual V1.1...

-

Page 34: Troubleshooting

Connection status and IP address Connection Problems In case the status indicator of the CRxFlex is blinking red, the user should look at the “status” of the Digitizer Remote Display to decide whether CRxFlex internal problems or connection problems occurred. -

Page 35: Removing A Jammed Image Plate

NOTE: Never use force to clear the jammed image plate. If it is not possible to gently remove the image plate, call your local service organization. NOTE: After a jam, the image plate can be used again if not damaged. 4. Close the front cover. CRxFlex Operating Manual V1.1... -

Page 36: Technical Specifications

Type of product Digitizer Commercial name CRxFlex Model number 5176/200 Original seller / manufacturer GE Sensing & Inspection Technologies GmbH Functional Data Principle High performance table-top flatbed digitizer Eraser Inline Medium Resolution (MR 100 µm / x µm (x LP / mm... - Page 37 2.0 / 1.0 A Mains frequency 50 / 60 Hz Europe: min. 10 A, max. 16 A Mains fuse protection USA & Japan: min. 10 A, max. Standby max. 60W Power consumption During operation max. 220W CRxFlex Operating Manual V1.1...

- Page 38 I/O tables, laptop, accessories CRxFlex Consumables *symbolic picture Imaging Plates IPC2 image plate for CRxFlex High Speed Image Plate Available in a number of formats, IPS image plate for CRxFlex Medium Resolution Image Plate please consult sales for detailed...

Need help?

Do you have a question about the CRxFlex and is the answer not in the manual?

Questions and answers