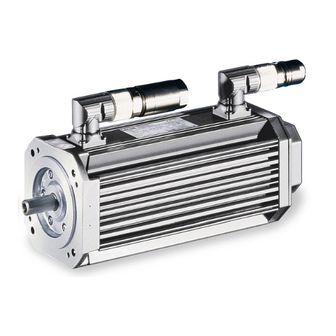

Lenze M Series Supplement To Operating Instructions

Asynchronous servo motors with spring-applied brake mounted on the b-bearing side

Hide thumbs

Also See for M Series:

- Operating instructions manual (46 pages) ,

- Mounting instructions (37 pages) ,

- Manual (16 pages)

Summary of Contents for Lenze M Series

- Page 1 M... MCA19, MCA21 Asynchronous servo motors with spring−applied Supplement to Operating Instructions EN brake mounted on the B−bearing side...

- Page 2 Additions to the "Maintenance and repair" section: Stop! When replacing the brake, complete rotor or the hub, the spare part from the corresponding Lenze repair kit must always be used. Characteristics and maintenance of the BFK457−16 R and BFK458−18 spring−applied brakes. Encoder dismounting and mounting.

-

Page 3: Table Of Contents

..........Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 4: Mechanical Installation

Stop! If a safety encoder is used, all maintenance and installation work must be performed at the Lenze site. Otherwise any warranty will expire and Lenze GmbH will not accept any liability for consequential damage. The IG2048−5V−V3 can be mounted on the brakes described here and must safety encoder not be dismounted and mounted. -

Page 5: Spring−Applied Brake − Holding Brake

Fig. 2 Design of an INTORQ BFK458 spring−applied brake: basic module E (complete stator) + rotor + hub + flange Stator Rotor with friction lining Fixing screws Armature plate Flange Sleeve bolts Air gap Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 6: Maintenance/Repair

Inspection of the brake integrated in the motor: ¯ Check ventilation function and After 1 million cycles at the latest activation/deactivation Shorter intervals in the case of frequent emergency ¯ Measure air gap (re−adjust air gap, if necessary), stops! ^ 2.1.4 Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 7: Wear On Spring−Applied Brakes

¯ Damage by vibration of the torque support at the sleeve bolts, cylindrical pins, and armature plate ¯ Check springs for damage ¯ Check armature plate and flange or end shield – Max. run−in depth = rated air gap of the design size Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 8: Maintenance

Measuring Width across Sleeve bolts Two−flat Width across range [Nm] flats [mm] lever flats [mm] BFK457−16 20 to 100 " −−−−− −−−−− −−−−− square BFK458−18 20 to 100 " 13 x " square square Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 9: Dismounting The Mca19 And 21 Fan Cover

1. Disconnect the mains plug (1) of the fan. 2. Loosen the four screws (2) with which the fan is fitted onto the non−drive end shield and remove the fan. Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 10: Bfk457−16R Air Gap

(1) using a feeler gauge and compare the values to the data "s " in the Lrated table, ^ 5. If the value measured, "s ", is outside the tolerance (^ 5), the rotor must be Lrated replaced (^ 12). Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 11: Checking And Re−Adjusting The Bfk458−18 Air Gap

1/6 revolution changes the air gap by approx. 0.15 mm 4. Tighten the fixing screws (6) with 24.6 Nm. 5. Repeat the air gap check and re−adjust the air gap again, if necessary, or replace the brake. Lenze ¯ MA 33.0012 ¯ 1.0... -

Page 12: Replacing The Brake

Stop! If a safety encoder is used, all maintenance and installation work must be performed at the Lenze site. Otherwise any warranty will expire and Lenze GmbH will not accept any liability for consequential damage. Tools required ¯ Allen key width across flats 1.5 ¯... -

Page 13: Bfk457−16R

Stop! When replacing the brake, the complete rotor or the hub, the spare part from the corresponding Lenze repair kit must always be used. It can be ordered from the Lenze Service, specifying the motor serial number and the motor material number. - Page 14 2. The hub (8) must be heated to 150 − 160 °C and then removed from the shaft by means of an extractor. (If necessary, have this work carried out by the Lenze Service staff). 3. Remove circlip (7.1) 4.

- Page 15 SL = 0, i.e. the rotor must be enabled to move freely. Stop! Ensure that the screws of the emergency manual release/transport locking device have been removed! Lenze ¯ MA 33.0012 ¯ 1.0...

-

Page 16: Bfk458−18

Stop! When replacing the brake, complete rotor or the hub, the spare part from the corresponding Lenze repair kit must always be used. It can be ordered from the Lenze Service, specifying the motor serial number and the motor material number. - Page 17 2. The hub (8) must be heated to 150 − 160 °C and then removed from the shaft by means of an extractor. (If necessary, have this work carried out by the Lenze Service staff). 3. Remove circlip (7.1) 4.

- Page 18 6. Perform a functional check of the brake. When the voltage is switched on, the air gap between the magnet housing and the armature plate must be SL = 0, i.e. the rotor must be enabled to move freely. Lenze ¯ MA 33.0012 ¯ 1.0...

-

Page 19: Encoder Mounting

3 Nm, clamping the torque plate against the lower M4 nut (10.2). Stop! The torque plate must be tension−free and has to be positioned at right angles to the motor−encoder shaft. Otherwise the service life of the encoder bearings may be reduced! Lenze ¯ MA 33.0012 ¯ 1.0... - Page 20 © 01/2019 | MA 33.0012 | .Z!z | 1.0 | TD09 ã Q Lenze Drives GmbH Postfach 10 13 52, 31763 Hameln Breslauer Straße 3, 32699 Extertal GERMANY HR Lemgo B 6478 Ü +49 5154 82−0 Ø +49 5154 82−2800 Ù...

Need help?

Do you have a question about the M Series and is the answer not in the manual?

Questions and answers