Table of Contents

Advertisement

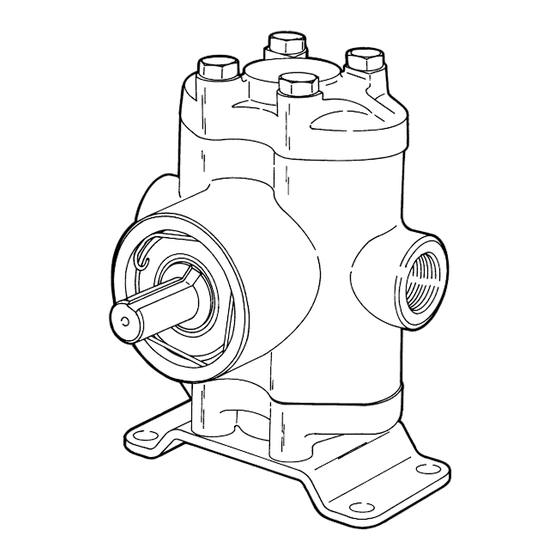

& 5321C &5322C & 5321C-H & 5322C-H 53702 53703

Pentair

375 5th Ave., New Brighton, MN 55112

Phone: (651)766-6300 -OR- 800-424-9776 Fax: 800-323-6496

www.hypropumps.com

EU Authorized Representative:

Original Instruction Manual

KEEP FOR FUTURE REFERENCE

Series 5315C & 5320C & 5330C & 5324C & 5324C

Small Twin

QNET BV Hommerterweg 286

EC

REP

6436 AM Amstenrade, The Netherlands

KvK Zuid-Limburg 14091511

Piston and Plunger Pumps

®

Hypro

Small Twin

and Plunger Pumps

Piston

®

Form L-1574

Rev. B

Advertisement

Table of Contents

Need help?

Do you have a question about the 5330C Series and is the answer not in the manual?

Questions and answers