Summary of Contents for Moog DigiPack III J141-215

- Page 1 MRJ06301 Rev. Orig. Ⅲ DigiPack Parison Wall Thickness Controller J141-215 INSTALLATION, MAINTENANCE USER’S MANUAL...

- Page 2 Description Prepared Checked Approved Orig. New Model Release(EOJ20210) T. Kouda T.Shimizu K.Mashino 15, Mar ‘19 29,Mar’19 15, Mar’19 MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

- Page 3 This technical Document contains information that is proprietary to, and is the express property of Moog Inc., or Moog Inc. subsidiaries except as expressly granted by contract or by operation of law and is restricted to use by only Moog employees and other persons authorized in writing by Moog or as expressly granted by contract or by operation of law.

- Page 4 A shielded cable should be connected to the terminal of J141-215, and the length of skin wire processing should be less than 100 mm. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 5: Table Of Contents

1-6-4. COMMUNICATION AND SSI SNSOR WIRING..............19 1-6-5. TB-2 I/O CIRCUITRY .....................25 1-6-6. TB-3: POWER SUPPLY ....................26 1-6-7. NOISE AND GROUND ISOLATION ................26 MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. - Page 6 2-4-10. SHIFT→F4: Machine Setup ..................69 2-4-11. SHIFT→F5: Communication Mode ................70 2-5. COMMUNICATION PROTOCOL ....................71 2-5-1. EtherNET COMMUNICATION SPECIFICATION ............71 MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

- Page 7 2-7-2. DIE GAP TOOLING SETUP ...................78 2-7-3. PRELIMINARY SET UP ....................79 2-7-4. INITIAL TRIALS ......................80 Reference Drawings CC70353 ---------- Installation CC70355---------- Customer Wiring MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

- Page 8 Figure 1-48 Extrusion Fixed Page 41 Figure 1-49 Filling Fixed Page 41 Figure 1-50 Accumulator setting (Back) Page 42 MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

- Page 9 Page 69 Figure 2-37 [SHIFT]→[F4]: Machine Setup Screen Page 69 Figure 2-38 [SHIFT]→[F5]: Communication Mode Screen Page 70 MRJ06301 VIII © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 10: Digipackⅲ Manual, Installation And Maintenance

Please refer to Figure 1-23 TB-2 Functions for details. serial communication function For other details, please check this manual in detail. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 11: Introduction

Moving the core changes the gap through which the parison passes and controls the wall thickness of the parison. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 12: Figure 1-2 Basic Continuous Blow Molding Machine Control Diagram

③ The servo valve adjusts the flow rate to the core actuator according to the (flow rate) command from DigiPackⅢ. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 13: Figure 1-3 Basic Accumulator Machine Control Diagram

④ By controlling the actuator for the core, control the thickness of the parison at the core die gap portion. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 14: Who Can Install The Digipackⅲ

The system can be satisfactorily calibrated to the machine and started up without assistance or special equipment by following the instructions in this manual. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 15: Installation Time

USB memory is not included with DigiPackⅢ. Refer to section 1-1. for recommended USB. "DIGIPK3.FWM" can download the latest version from the MOOG website https://www.moog.co.jp/products/controllers-software/blow-molding-controllers/digipack3.html MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 16: Backup Battery

USB to DigiPackⅢ. (Refer to 2-4-4. for save/load description) NOTE: New parameter like PURGE/TOOLING is not include. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 17: Digipackⅲ Specification

Front side = IP20, Rear side = IP30 Dimensions: 288 (W) x 240 (H) x 55 (D) mm (not include terminal) Weight: 3.6 kg MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 18: Check List

Set up the control loop Connect the actuator to the die gap tooling and adjust the die gap end points. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 19: Mechanical Installation

Tooling adjustment provisions are also shown. Figure 1-6 Die Gap Tooling Actuator MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 20: Tooling Adjustment

The above comments must be considered for the proper installation of either a Moog supplied die gap tooling actuator or a customer supplied actuator. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 21: Moog Die Gap Tooling Actuators

Figure 1-9 shows an installation example of Moog's die gap core control actuator. DCDT Toolong Posi- tion Transducer Servovalve Tooling Acutuator Figure 1-9 Typical Cylinder Installation MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 22: Customer Supplied Cylinder Requirements

Two servovalves mounting patterns are available: a Cetop 5, NG 10 or a Ø22,2mm, Moog 76 port circle. Figure 1-10 G631-XXX Servo- valve MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 23: Tooling Adjustment

Independent Linearity 0.07 0.05 0.05 0.05 Mechanical Data Mechanical Stroke Body Length Mounting Feet Spacing 280.5 484.5 738.5 890.5 MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 24: The Importance Of Filtration

Teflon tape may be used, but only if applied in such a manner as to keep the edge of the Teflon tape at least two threads away from the end of the fitting. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 25: Hydraulic Power Supply

Monitor for leaks and repair. Replace the flushing filter elements with the elements removed in step 4. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 26: Contamination Control

Currently, MOOG does not sell filters. Please purchase directly from the filter manufacturer. Figure 1-15 Flow Pressure Filter MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 27: Electrical Installation

TB-3:Power connector tightening torque 1.0 Nm) (Screw diameter 3.0 mm, tightening torque 0.6 Nm) Figure 1-16 REAR CONNECTOR MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 28: Wiring

Ethernet (connector name label “Ethernet”). Please refer to Figure 1-17 for connector location. And connector pin assign see below list. Ethernet connector RJ45 socket “Ethernet” Pin No. Signal Connection MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 29: Figure 1-17 Digipackⅲ Installation Drawing

Figure 1-17 DigiPackⅢ Installation Drawing MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 30: Figure 1-18 Servovalve And Transducer Phasing

Figure 1-18 ServoValve and Transducer Phasing Figure 1-19 TB-1 Connections MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 31: Figure 1-20 Tb-1 Functions

Figure 1-20 TB-1 Functions MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 32: Figure 1-21 Tb-2 Connection

Figure 1-21 TB-2 Connection Figure 1-22 TB-2 Connection with Internal Logic Supply with External Logic Supply MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 33: Figure 1-23 Tb-2 Functions

Figure 1-23 TB-2 Functions MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 34: I/O Circuitry

The maximum voltage and current output to each load terminal (TB-2, 18, 19, 20, 22, 23 and 24) is 24VDC and 100 mA MAX/each. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 35: Tb-3: Power Supply

An isolation transformer between the mains and DigiPackⅢ can provide some relief from noise, ground loops and wandering mains. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 36: Figure 1-29 Accumulator Machine Timing Chart

Figure 1-29 Accumulator Machine Timing chart MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 37: Figure 1-30 Continuous Machine Timing Chart

Figure 1-30 Continuous Machine Timing chart MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 38: Calibration Of Touch Screen

Step 4: If the calibration is successful, display will return to Figure 1-31, Restart the controller and finish. Figure 1-31 Touch screen Calibration Figure 1-32 Touch screen calibration display MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

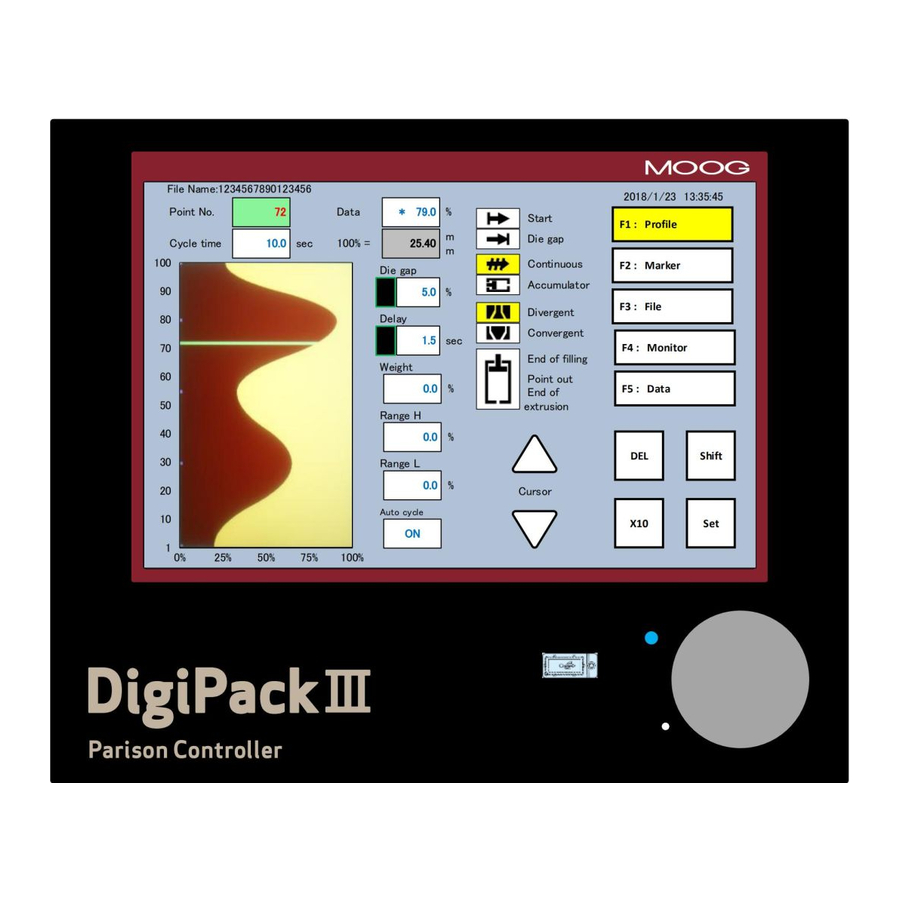

Page 39: Digipackⅲ Front Panel

Increases the sensitivity of the Rotaly Knob by a factor of 10 Push to set value Invalidates the set profile data and changes it to interpolation data. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. - Page 40 Delete and Backup/Restore the storage data.(Backup/Restore for data in USB memory) SHIFT→F4 Machine setting setup SHIFT→F5 Communication parameter setting of Ethernet. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 41: Tooling System Setup

MFB/EFB are located in TB-1.) The Servovalve type that not set is fixed to "0" mA or "0" V, if no output signal and the actuator does not operate, Please review the machine setting. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 42: Figure 1-34 Machine Setup Display (Shift→F4)

Reboot, the parameter returns to its original value. When you press [Reboot] → [SET], DigiPackⅢ will be restarted. Do not apply hydraulic pressure when executing [Reboot]. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 43: Figure 1-36 Example Of Profile Points Change

(Example 100 to 200), the profile of the newly added part is specified as the height "0". See Figure 1-36 Figure 1-36 Example of profile points change MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 44: Set Up Procedure

DigiPackⅢ is Diverge. Example below. Figure 1-38 Die Converge/Diverge Setup Diverge Converge MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 45: Figure 1-39 Die Gap Setup

ROTALY KNOB is stopped. The DCDT voltage indicator will indicate the changed Die Gap position. DCDT +10V -10V +INPUT -INPUT Figure 1-40 DCDT Noise Filter MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 46: Figure 1-41 Die Gap Span Setting

[Zero] (0% position), and the high- light moves to [Span]. (Figure 1-41) Figure 1-41 Die Gap Span Setting MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 47: Figure 1-42 Back

Figure 1-42 and press [SET] or directly touch [Back] on the screen to move up one screen. Figure 1-42 Back MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 48: Figure 1-43 Gain Select

Figure 1-44 Gain setting MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 49: Figure 1-45 Accumulator Setup

(empty position). The empty position is saved, and the [End of Extrusion] of the status monitoring area lights up. The highlight moves to Full (Figure 1-47). Figure 1-46 EMPTY Accumulator Set Up MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 50: Figure 1-47 Full Accumulator Set Up

SHOT SIZE plus DE- LAY. (Figure 1-49) Select either EXTRUSION FIXED or FILLING FIXED and press SET Figure 1-49 Filling Fixed MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 51: Figure 1-50 Accumulator Setting (Back)

[Back] on the screen to go to the setup screen. The Accumulator blow molding machine set up process is now complete. Figure 1-50 Accumulator setting (Back) MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 52: Digipackⅲ Manual, User Operation

After a short learning period, you will be able to readily setup your blow molding machine to mold contain- ers to their required specification. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 53: Parison Control

During filling, the transducer also causes the accumulator to stop filling when Shot Size is achieved. Un-programmed parison MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 54: Parison Programming Benefits

Programmed parison wall thickness control therefore results in higher container production rates using less material per container and higher profits. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 55: With Accumulator Blow Molding Machines

(position error) to a very small value. This feedback process ensures that the actual die gap opening follows the commanded die gap opening very accurately. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 56: Parison Mold Alignment

The actual movement accompanying plastic blow molding and drawing is more complicated. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 57: Man Machine Interface

If you press "ESC" or touch anything other than the numeric keypad area, the screen returns to Figure 2-6 without changing the value. Press the "SET" key to update the value and return to Figure 2-6. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 58: Figure 2-7 Ten Key On The Screen (1)

[C] key clears the input contents and can re-enter. I will explain the rules for entering 10 keys on the next page. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. - Page 59 F1 to F5, "SHIFT" becomes inactive (switch is white). * Please refer to 1-2-6 for the protection of setting screen transition * When setting the accumulator, this switch changes to the [TOOLING] function. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 60: Functions

Lights when each Marker point is reached End of extrusion Lights when the accumulator completes its empty stroke MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 61: Edit Area

The value of any Function Item will not be changed when moving between Function Items unless SET is pressed. This input procedure applies to all Function screens. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 62: Screens Of Edit Area

If change the item value but press ESC without confirmation with the SET key, that value returns. (Some parameters are excluded) If set values are modified, changes take effect during the next machine cycle. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 63: F1: Profile Mode

SET key, and cursor move back to Point No. value. * The profile adjustment affected to next start cycle. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. - Page 64 (TB-2-1). When [Auto cycle] is set to ON, [Cycle time] is automatically updated every interval of each cycle. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 65: Figure 2-12 0%Weight Change

The Weight change will be same from minimum to maximum parison wall thickness program point. Figure 2-13 (-)23.3% Weight Change MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 66: Figure 2-14 0% Range H

The lowest thickness will be fix Figure 2-15 (+)25.0% Range H Change MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 67: Figure 2-16 0% Range L

The highest thick- ness will be fix Figure 2-17 (-)20.0% Range L MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 68: F2: Marker Mode

(TB-2-22) is output. Please refer to Figure 2-19 for the timing. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 69: Figure 2-19 Slope Timing

After inputting a date and time, a timer is set up by SET and a count is started. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 70: F3: File Mode

If you select “YES”: then go to Page 63. If you select “NO” then go to Page 62. Figure 2-21 Select SAVE MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 71: Figure 2-22 File Description Data

Figure 2-22 File Description Figure 2-23 File Description Figure 2-24 File Description Data-Page 1 Data-Page 2 Data-Page 3 MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 72: Figure 2-25 Edit File Name

In that case, previously saved data will be lost. Figure 2-26 Change File Number MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 73: Figure 2-27 Initial Load Screen

[Load]. As a result, all parameters return to their initial values (factory-set values). ※ Machine setting parameters are not changed. Figure 2-28 File Load MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 74: F4: Monitor Mode

To prevent inadvertent damage, setting the Open command to “Disable” in Machine setup display ([SHIFT]→[F4]) will disable this function. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 75: F5: Data Display Mode

“Next” see other page one by one. This screen mode is display only, parameter editing is not possible. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 76: Shift→F1: Set Up Mode

-> Monitored Spool position (4-20mA) with +-10V if EFB mode. 02h : DCDT input voltage -> Monitored DCDT Position (0-100%) with 0-10V. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 77: Shift→F3: File Delete And Backup/Restore

Memory is not in slot, below message occurred and can not continue Backup/Restore. “ ” USB is not insert or format is not correct MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 78: Shift→F4: Machine Setup

Machine setup is covered in detail in the DigiPackⅢ Instal- lation manual at 1.9.2.1 Machine settings. Figure 2-37 [SHIFT]→[F4]: Machine Setup Screen MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 79: Shift→F5: Communication Mode

If DHCP is ON, automatically set this parameter. 0 – 65535 Port No. Figure 2-38 [SHIFT]→[F5]: Communica- tion Mode Screen MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 80: Communication Protocol

READ PROFILE DATA (EACH DATA OR BLOCK DATA) PC→DigiPackⅢ file No P-addr "n" can be omitted, in that case 1 … DigiPackⅢ→PC Error Data MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. - Page 81 No Date and time data are handled in DigiPackⅢ→PC Error decimal character string Error, accessing unregistered file MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 82: Wave

DEVICE NAME PC→DigiPackⅢ DigiPackⅢ→PC Error Variable length character data 2.5.5.2. SERIAL NUMBER PC→DigiPackⅢ DigiPackⅢ→PC Error Variable length character data MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 83: Interface Control

※Interface data: 32 bit hexadecimal number ※Refer to Section 2.5.6.3 for the composition of interface data DigiPackⅢ→PC Error MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. - Page 84 The number is as shown in the table of input in 2.5.6.3. Level ... 2 hexadecimal digits. 00 = Open, Other than 00 = Closed. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

-

Page 85: Other

-10mA~+10mA 32767 DAC#4-MFB 20mA Selected -20mA~+20mA 32767 MFB current DAC#4-MFB 50mA Selected 32767 -50mA~+50mA DAC#4-MFB100mA Selected 32767 -100mA~+100mA MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 86: Profile Data List

[0.1%] -1 ~ 1000 Profile point 200 [0.1%] PURGE gap 0~1000 [F2] [0.1%] TOOLING gap 0~1000 [F2] [0.1%] MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 87: Setting Up

Section 1-9-3. , DIE GAP TOOLING SETUP. To achieve the minimum change over time it is essential that this procedure be followed and the requested information recorded. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 88: Preliminary Set Up

1 and program point 200 and the resulting die gap program will be a constant die gap opening between points 1 and 200. MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II. -

Page 89: Initial Trials

MRJ06301 © MOOG 2019 This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

Need help?

Do you have a question about the DigiPack III J141-215 and is the answer not in the manual?

Questions and answers

This one no work

The provided context does not explicitly mention common issues with the Moog DigiPack III J141-215. However, it does note changes from the previous model, such as the removal of physical push-button switches and LEDs, reliance on a touch screen, and the limited compatibility of USB memory devices. Potential issues could arise from these changes, including screen operation reliability and USB memory compatibility.

For specific known issues, additional documentation would be required.

This answer is automatically generated