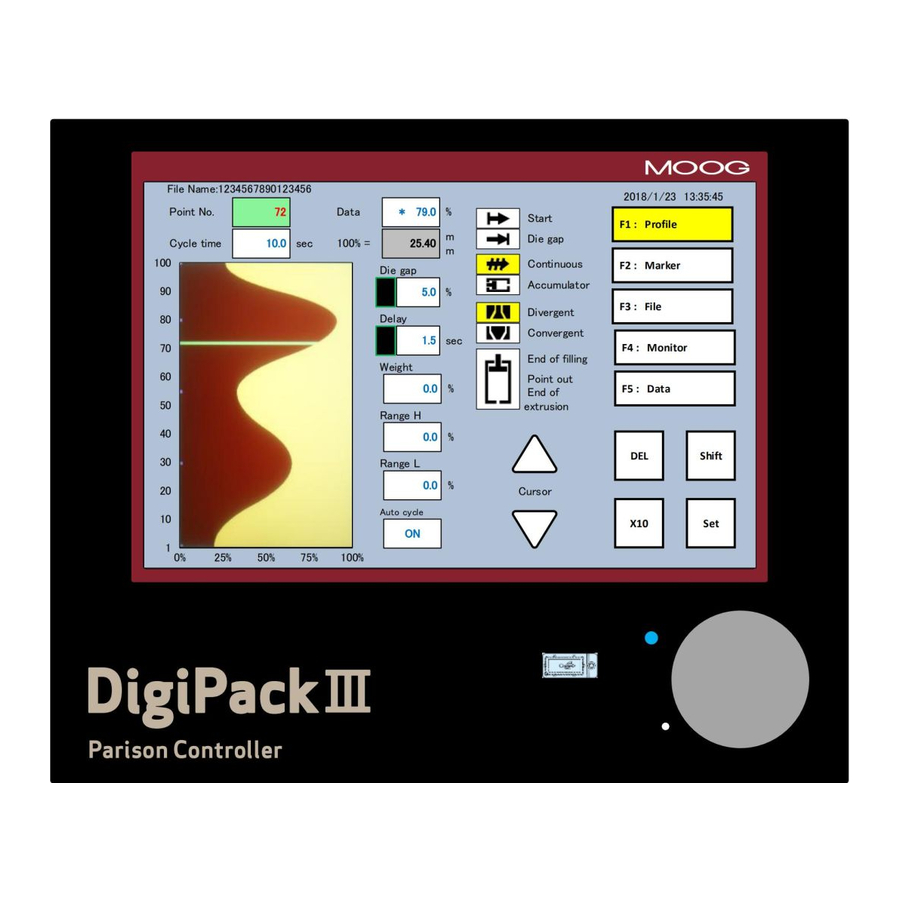

Moog DigiPack III J141-215 Manuals

Manuals and User Guides for Moog DigiPack III J141-215. We have 1 Moog DigiPack III J141-215 manual available for free PDF download: Installation, Maintenance And User Manual

Moog DigiPack III J141-215 Installation, Maintenance And User Manual (89 pages)

Parison Wall Thickness Controller

Brand: Moog

|

Category: Controller

|

Size: 6 MB

Table of Contents

Advertisement