Summary of Contents for Grunbeck GENO-EDI-X

- Page 1 Operation Manual Electrodeionisation System GENO-EDI-X with GENO-EDI-tronic Version: December 2018 Order no. 024 770 901-inter...

-

Page 2: Table Of Contents

3.1 Functional principle of electrodeionisation ............................10 Components of the electrodeionisation module (EDI module) ....................11 PRODUCT DESCRIPTION (GENO-EDI-X) ............................12 1 | T .................................... 12 YPE DESIGNATION PLATE 2 | F ....................................12 LOW CHART DESIGN ... - Page 3 Electrodeionisation System GENO-EDI-X Publisher's information All rights reserved. Copyright by Grünbeck Wasseraufbereitung GmbH Printed in Germany Effective with the date of edition indicated on the cover sheet. -We reserve the right to modifications, especially with regard to technical progress- Reprints, translations into foreign languages, electronic storage or digital copying of this operation manual –...

- Page 4 Manufacturer: Grünbeck Wasseraufbereitung GmbH Josef-Grünbeck-Str. 1 89420 Hoechstaedt/Germany Responsible for documentation: Roland Rehberger System designation: Electrodeionisation system GENO-EDI-X System size: 100, 180, 360, 720, 1100, 1450, 2000, 2700 System number: Refer to type designation plate Applicable directives: Machinery Directive (2006/42/EC)

-

Page 5: Ageneral Information

Electrodeionisation System GENO-EDI-X A General information 1 | Preface Thank you for opting for a Grünbeck product. Backed by decades of experience in the area of water treatment, we provide solutions for all kind of processes. All Grünbeck systems and devices are made of high-quality materials. -

Page 6: General Safety Information

In addition, intended use also implies that the system may only be operated when it is in proper working order. Any errors must be eliminated at once. The GENO-EDI-X is exclusively designed for use in the indus- trial and commercial field. Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx... -

Page 7: Protection From Water Damage

Electrodeionisation System GENO-EDI-X 3.4 Protection from water damage Warning! In order to properly protect the installation site against water damage: A sufficiently dimensioned floor drain system must be available or a water stop device (refer to chapter C “Accessories”) must be installed. -

Page 8: Disposal

Electrodeionisation System GENO-EDI-X 5 | Disposal Comply with the applicable national regulations. Packaging Dispose of the packaging in an environmentally friendly manner. If this symbol (crossed out waste bin) is on the product, this Product product is subject to the European Directive 2012/19/EU. This means that this product or the electrical and electronic compo- nents must not be disposed with household waste. -

Page 9: Bbasic Information

Electrodeionisation System GENO-EDI-X B Basic information 1 | Laws, regulations, standards In the interest of good health, rules cannot be ignored when it comes to the processing of drinking water. This operation manual takes into consideration the current guidelines and stipulates information that you will need for the safe operation of your water treatment system. -

Page 10: Functional Principle Of Electrodeionisation

(unpressurised) is then either directed to the drain or returned to the inlet of the reverse osmosis system to be fed again. The electrodeionisation system GENO-EDI-X has a recovery of 90 - 95 %. Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx... -

Page 11: Components Of The Electrodeionisation Module (Edi Module)

Electrodeionisation System GENO-EDI-X 3.2 Components of the electrodeionisation module (EDI module) Permeate inlet Diluate outlet Concentrate outlet Anode (+) Cathode (-) Concentrate chamber with ion exchanger resin Diluate chamber with ion exchanger resin Anion membrane (A) Cation membrane (C) Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx... -

Page 12: Cproduct Description (Geno-Edi-X)

Serial number: Order number: Fig. C-1: Type designation plate of the electrodeionisation system GENO-EDI-X 2 | Flow chart design Fig. C-2: Flow chart of GENO-EDI-X Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx... -

Page 13: Basic Function Of The Electrodeionisation System Geno-Edi-X ( Without Options )

Y7 are closed. There is no voltage present at the EDI module. The GENO-EDI-X system receives a start signal from the level control system of the diluate tank. Then, the EDI controller trans- mits the start signal to the RO controller. - Page 14 After a set rinsing sequence, the RO system receives its stop signal and the valves move to the following positions: inlet rejec- tion valve Y8 and inlet valve Y7 closed. Now, the GENO-EDI-X system remains in standby mode until the next request is made. *Diluate = deionate, ultra-pure water...

-

Page 15: Description Of The Components

Permeate When the set maximum permeate pressure value is exceeded, pressure sensor the GENO-EDI-X system STOP takes place with a time delay. Visual indication in the control electronics. Indicates the diluate pressure value in the control electronics. P5 must be at least 0.2 bar higher than P6! - Page 16 < 20 µS/cm measured via Q4 valve of permeate (option). Locked in case of errors in the GENO-EDI-X system. Visual indication in the control electronics. Opens for an adjustable time after EDI start. Opens after start of EDI until a conductivity of 20 µS/cm meas- Permeate inlet re- ured via Q4 is undershot (option).

- Page 17 Visual alarm signal on the frequency converter and in the control electronics. GENO-EDI-X system STOP. Visual indication in the control electronics. L4a+ full signal, GENO-EDI-X system STOP Level control L4b- request, GENO-EDI-X system START system of diluate L4c- additional and emergency feed (option)

-

Page 18: Technical Specifications

Electrodeionisation System GENO-EDI-X 5 | Technical specifications Table C-1: Technical Electrodeionisation system GENO-EDI-X specifications 1100 1450 2000 2700 Connection data Nominal connection diameter of [DN] permeate feed line (screw connection) Nominal connection diameter of [DN] diluate outlet line (screw connection) -

Page 19: Intended Use

Electrodeionisation System GENO-EDI-X 6 | Intended use The electrodeionisation system GENO-EDI-X is designed for the further quality enhancement of permeate generated by a reverse osmosis system. The most common areas of application for the diluate produced (ultra-pure water) are: - Steam sterilisation... -

Page 20: Application Limits

2.79) + (ppm SiO x 1.94) Note: The diluate from GENO-EDI-X system is not drinking water! For the determination of this value, the formulae in section E, chapter 1 must be used! Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx... -

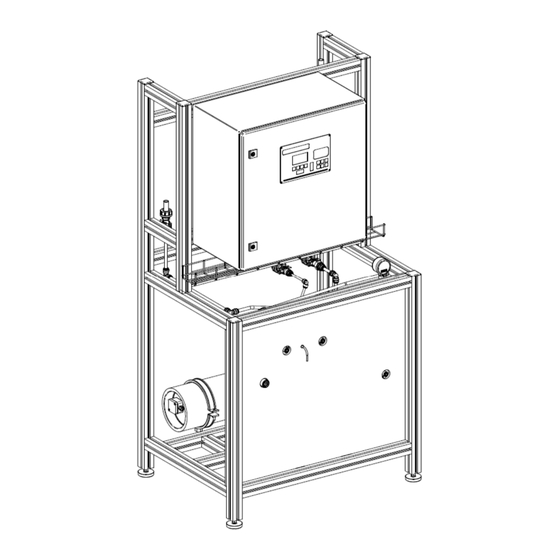

Page 21: Scope Of Supply

Electrodeionisation System GENO-EDI-X 8 | Scope of supply 8.1 Standard equipment Device that is ready for connection for the continuous, electrochemical, residual demineralisation of permeate originating from a reverse osmosis system, completely pre-assembled to an anodised aluminium system rack. Microprocessor controller with LCD graphic display... -

Page 22: Optional Features

Module for outputting measuring values to control centre Quality-controlled diluate rejection Rejection of diluate prior to filling the pure water tank (conductivity-controlled) For GENO-EDI-X 100 through 360 770 815 For GENO-EDI-X 720 through 2700 770 875 Measuring of conductivity and temperature of... - Page 23 *Stripping gas = oil-free, compressed air Pure water tank for intermediate storage of the diluate flowing unpressurised from the GENO-EDI-X electrodeionisation systems Tank version: All tanks are pre-assembled, with PVC overflow pipe as well as connections for the inlet, diluate and the suction line of the pressure booster system.

-

Page 24: Wearing Parts

Electrodeionisation System GENO-EDI-X Pressure booster system 730 790 GENO-FU-X 2/40-1 NE Compact, pressure-controlled pump aggregate consisting of a centrifugal pump completely made of stainless steel as well as an integrated pressure and flow meter for pump control and dry-run protection. -

Page 25: Dinstallation

Electrodeionisation System GENO-EDI-X D Installation 1 | General installation information The installation site must offer adequate space. For installation and service work, sufficient clearance (> 50 cm, > 20 cm from the wall) must be provided around the system. A foundation of a sufficient size and adequate load carrying capacity must be pro- vided. -

Page 26: Water Connection

Testing of the tightening torques on the bolts of the EDI module Tighten any bolts according to specification. Applies to: GENO-EDI-X 720 / 1100 / 1450 / 2000 / 2700. Provide a drain connection (minimum DN 50) to discharge the concentrate. -

Page 27: How To Connect The System

Mount CO trap to vent the diluate tank Limit of supply Drinking water filter BOXER K 1" Reverse osmosis system GENO-OSMO-X Electrodeionisation system GENO-EDI-X System separator DK 2 (Optionally with integrated GENO membrane Grünbeck degassing system MEC) by others... -

Page 28: Electrical Wiring

4 | Electrical wiring Note: The pertinent electric circuit diagrams are located separately in the switch cabinet of the GENO-EDI-X system. The power feed line dimensions can be found there. 1. For the electrical connection, a supply line to the system must be provided on site according to the electric circuit diagram. -

Page 29: Ecommissioning

Calculation according to the following formula: FCE = conductivity + (ppm CO x 2.79) + (ppm SiO x 1.94) e) The required current value for GENO-EDI-X 100 / 180 / 360 is then calculated as follows: Q x FCE Diluate flow Q in l/h Feed Conductivity Equivalent FCE in µS/cm... -

Page 30: Start Edi-Xsystem Operation

Operating current/voltage Switching off the GENO-EDI-X system The GENO-EDI-X system is switched off in the control electronics using the “0-ON” button. After a brief run-down time, the GENO-EDI-X comes to a stop. Order no. 024 770 901-inter Edited by: rreh/bkop G:\BA-770901-inter_024_GENO-EDI-X.docx... -

Page 31: Foperation

2 | Brief description of GENO-EDI-tronic 2.1 Field of application GENO-EDI-tronic constitutes the control electronics for all Grünbeck electrodeionisation systems GENO-EDI-X. GENO-EDI-tronic controls the operation of the 2.2 Function electrodeionisation system in connection with optional pressure booster systems. -

Page 32: Switch Cabinet

Electrodeionisation System GENO-EDI-X 3 | Switch cabinet The switch cabinet contains the terminals for all connecting line, the power supply unit for the EDI module, the control transformers for the voltage supply, the fuses and the protective motor switch and the MK200 module, which controls the system in conjunction with the control panel. -

Page 33: Operating The Control Unit

Electrodeionisation System GENO-EDI-X 4 | Operating the control unit Fig. F-2: Control panel “Display” function in the respective menu “Entry” function in the respective menu Access to the “EDI System” menu Access to the “PB System” menu or Exit Access to the system menu... -

Page 34: Operating The Control Unit

Electrodeionisation System GENO-EDI-X 5 | Operating the control unit The menu contains a few items that are not explained here. These include adjusting values for expansion modules. The documentation of these points is provided only together with these modules. In the basic version, the items have no function. - Page 35 Electrodeionisation System GENO-EDI-X 5.2.1 Overview of the inputs and outputs Input Function Output Function P9 Low pressure switch for RO system release pre-feed pump (option) L4a switch-off level Supply of power supply system unit GENO-EDI-X L4b switch-on level Solenoid valve Y11...

- Page 36 Electrodeionisation System GENO-EDI-X Continuation Overview of inputs and outputs Input Function Output Function Error in power supply unit 1 (option) Error in power supply unit 2 (option) Error in power supply unit 3 (option) Reserve Programmable input Table F-4: Overview of inputs and outputs 5.2.2 Input Logic...

-

Page 37: System Configuration

Electrodeionisation System GENO-EDI-X 5.2.4 System In this submenu, the existing system components can be Configuration defined. This submenu has the following parameters: Menu Setting range Basic setting Level System Config. Language: GERMAN GERMAN Code ENGLISH 0095 PB system Definition of pressure... -

Page 38: I/O Display

Electrodeionisation System GENO-EDI-X 5.2.5 I/O Display In this submenu, the current states of the inputs/outputs are displayed. This submenu has the following parameters: Menu Setting range Basic setting Level I/O Display Inputs Input states of the individual ------ Code E16 – E01:... -

Page 39: Messages And Signals

Electrodeionisation System GENO-EDI-X 5.3 Messages and signals 5.3.1 Errors Errors generally lead to the deactivation of at least part of the overall system. Message text Description ERROR This message appears in case of voltage POWER FAILURE recovery when the system has been switched on and the parameter “Restart: NO”... - Page 40 Electrodeionisation System GENO-EDI-X Message text Description ERROR This message appears when the flow volume of ELEKTR. FLOW the electrolyte for the set time is too low ERROR This message appears when the flow volume of DILUATE FLOW the diluate for the set time is too low and the...

-

Page 41: Warnings

Electrodeionisation System GENO-EDI-X Message text Description ERROR This message appears when the measured value SENS.PRESS. of the pressure sensor/concentrate lies outside of CONC. a plausible range. (E.g., cable breakage) ERROR This message appears when input 16 is E16 (text can be... -

Page 42: Electrodeionisation (Geno-Edi-X System)

5.4 Electrodeionisation (GENO-EDI-X system) This menu includes the adjusting values related to the GENO-EDI-X system. The EDI main menu is called by pressing the F3 button on any visualisation system view. On the next screen, the only choices still available are the display function (F2 button) and the entry function (F1 button). -

Page 43: User

Table F-13: Customer user level 5.4.2 Parameters This submenu contains the general parameters of the GENO-EDI-X system. This submenu has the following parameters: Menu Description Basic setting Level EDI System EDI system:... - Page 44 Display of the conductivity µs/cm dil.: measurement in: µS/cm megaohm Flow Disp.Dil.: Flow display of the diluate in the flow chart of the GENO-EDI-X sys- tem: - l/h: Display in litres per hour Display in m hour - NO: No display...

- Page 45 Electrodeionisation System GENO-EDI-X Conc.Cond. Conductivity measurement in pres. concentrate The conductivity measurement is not present YES: The conductivity measurement is present Press.Perm. Pressure measurement in pres. permeate Pressure measurement is not present YES: Pressure measurement is present Press.Dil. Pressure measurement in diluate pres.

-

Page 46: Times

Electrodeionisation System GENO-EDI-X 5.4.3 Times This submenu contains the time parameters of the GENO-EDI-X system. This submenu has the following parameters: Menu Setting range Basic setting Level EDI Times Rinsing time: EDI module rinsing time: 20 sec. Setting range: 0 – 999 seconds E-Perm. -

Page 47: Errors

GENO-EDI-X system days Setting range: 0...365 days Table F-15: Times 5.4.4 Errors This submenu contains the parameters for the errors of the GENO-EDI-X system. This submenu has the following parameters: Menu Setting range Basic setting Level EDI Errors Err.M8 delay: Delay time for a malfunction 5 sec. - Page 48 Electrodeionisation System GENO-EDI-X Max. Dil. Delay time for monitoring the 600 sec. Cond. Del.: diluate conductivity Setting range: 0...999 seconds Max. Perm. Limit value for the 20 µS/cm Cond.: conductivity of permeate Setting range: 5 – 40 µS/cm Max. Perm.

- Page 49 Electrodeionisation System GENO-EDI-X Min. Perm. Delay time for monitoring the Cond. Del: minimum permeate conductivity sec. Setting range: 0...999 seconds Max. Perm. Limit value for the permeate 30°C Temp.: temperature Setting range: 0 - 40°C Perm. Temp. Deactivation in case permeate Deact.:...

-

Page 50: Service Data

Setting range: 0 - 999 seconds Table F-16: Errors 5.4.5 Service Data This submenu contains the parameters for the service information of the GENO-EDI-X system. These parameters can only be displayed and not changed. This submenu has the following parameters: Menu Description... -

Page 51: Reference Data

Electrodeionisation System GENO-EDI-X 5.4.6 Reference Data This submenu contains the parameters for calibrating the water meters and conductivity. This submenu has the following parameters: Note: These values must be entered during production! Menu Description Basic setting Level RO Reference Diluate Ref.:... -

Page 52: Basic Setting

Setting range: 0...500 µS/cm Table F-18: Reference Data 5.4.7 Basic Setting This submenu contains the parameters for the basic settings of the GENO-EDI-X system. This submenu has the following parameters: Menu Description Basic setting Level EDI Basic Setting Default values: When “1”... -

Page 53: Pressure Booster (Pb System) If Activated In System Menu

Electrodeionisation System GENO-EDI-X 5.5 Pressure booster (PB system) if activated in system menu This menu includes the adjusting values related to the pressure booster. The PB main menu is called by pressing the F4 button on the visualisation system of the PB system. On the next screen, the only choices still available are the display function (F1 button) and the entry function (F2 button). -

Page 54: User

Electrodeionisation System GENO-EDI-X 5.5.1 User This submenu contains the customer parameters. This submenu has the following parameters: Menu Setting range Basic setting Level PB User Operating OFF: The PB system is AUTO Code mode: not active 0095 MANUAL: The pressure booster... -

Page 55: Errors

Electrodeionisation System GENO-EDI-X 5.5.3 Errors This submenu contains the parameters for the errors of the PB system. This submenu has the following parameters: Menu Setting range Basic setting Level PB Errors M6/M7 prot. Pressure booster pumps with mot. sw.: protective motor switch... -

Page 56: Gtroubleshooting

Electrodeionisation System GENO-EDI-X G Troubleshooting 1 | Basic information Even carefully designed and manufactured technical systems that are operated properly may experience malfunctions. Table G-1 provides an overview of possible problems that may occur during the operation of the systems and indicates the causes and their elimination. -

Page 57: Troubleshooting

Check the RO system or permeate feed pump. Malfunction Flow capacity of the Water temperature Check of temperature GENO-EDI-X system too too low Readjust adjusting valve V4, Incorrect setting of V5, V6, V7 adjusting valve V4, V5, V6, ... -

Page 58: Hmaintenance

Electrodeionisation System GENO-EDI-X H Maintenance 1 | Basic information In order to guarantee the reliable function of the systems over a long period of time, some maintenance work has to be performed at regular intervals. All regulations and guidelines which apply at the installation site must be strictly adhered to. -

Page 59: Maintenance

Electrodeionisation System GENO-EDI-X 3 | Maintenance According to DIN 1988 part 8 / A 12, maintenance work at the systems may only be performed by Grünbeck’s technical service/authorised service company or an approved specialist company. For this kind of systems, an operation log - a checklist has to be kept.

Need help?

Do you have a question about the GENO-EDI-X and is the answer not in the manual?

Questions and answers