Table of Contents

Advertisement

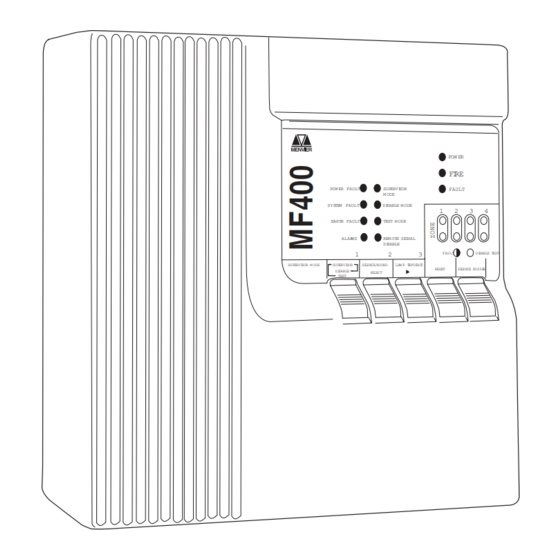

MENVIER FIRE SYSTEM

MF200/400 MF200-72/400-72

For service

please call:

Service agreement number

Cooper Lighting and Security Ltd.

Wheatley Hall Road, Doncaster, South Yorkshire, DN2 4NB, United Kingdom

Sales

Tel:

+44 (0)1302 - 303303

Fax:

+44 (0)1302 - 367155

E-mail: sales@cooper-ls.com

PLEASE PASS THIS BOOKLET TO THE USER,

AFTER INSTALLATION KEEP WITH PANEL.

General

+44 (0)1302 - 321541

+44 (0)1302 - 303220

technical@cooper-ls.com

POW ER FAULT

SUPERVI SOR

M ODE

SYS TEM FAULT

DI SABLE M ODE

EART H FAULT

TEST M ODE

ALAR MS

REM OTE SI GNAL

DI SABLE

1

2

SUPERVI SOR M ODE

SUPERVI SOR

SI LENCE/ SOUND

DI SABLE

SELECT

TEST

Tel:

Export

+44 (0)1302 - 303250

+44 (0)1302 - 303251

export@cooper-ls.com

PINST MF4/V

POW ER

FI RE

FAULT

1

2

3

4

3

FAULT

DI SABLE T EST

LAM P T EST/ EXI T

RESET

SI LENCE BUZZE R

Lighting and Security

www.cooper-ls.com

Advertisement

Table of Contents

Summary of Contents for Cooper MENVIER MF200

-

Page 1: Service Support Number

For service Tel: please call: Service agreement number PLEASE PASS THIS BOOKLET TO THE USER, AFTER INSTALLATION KEEP WITH PANEL. Cooper Lighting and Security Ltd. Lighting and Security Wheatley Hall Road, Doncaster, South Yorkshire, DN2 4NB, United Kingdom Sales General Export... -

Page 2: Table Of Contents

CONTENTS SERVICE SUPPORT NUMBER ......................1 SYSTEM INFORMATION ........................2 PANEL CONTROLS AND INDICATORS ....................3 PANEL OPERATION ...........................4 GENERAL ............................ 4 NORMAL OPERATION ........................ 4 SUPERVISOR MODE ........................4 PANEL INTERFACE CONNECTIONS AND PANEL CONTROLS ........... 6 INPUTS ............................6 OUTPUTS ............................ -

Page 3: Panel Controls And Indicators

PANEL CONTROLS AND INDICATORS Visual DESIGNED TO EN54 PART 2&4 1997 DESIGNED TO EN54 PART 2&4 1997 POWER POWER FIRE FIRE SUPERVISOR SUPERVISOR POWER FAULT POWER FAULT FAULT FAULT MODE MODE SYSTEM FAULT SYSTEM FAULT DISABLE MODE DISABLE MODE EARTH FAULT EARTH FAULT TEST MODE TEST MODE... -

Page 4: Panel Operation

PANEL OPERATION General The panel has 2 levels of operation. Normal Mode and Supervisor Mode. Normal Operation Silence Buzzer (key 5) The user can silence the PANEL buzzer by pressing the 'SILENCE BUZZER' key (at any time), the buzzer will then give a beep approximately every 10 seconds. Note:- This does not silence the alarms only the panel buzzer. - Page 5 PANEL OPERATION - continued 2. Release and repress (key 3) to toggle through LED's representing each function. 3. When you highlight the LED representing each function to be enabled/disabled press 'key select’ to enable/disable this function. 4. To exit Disable Mode and leave the panel in the disable state press 'key 1' to toggle to Supervisor Mode LED and press ‘key 3’...

-

Page 6: Panel Interface Connections And Panel Controls

PANEL INTERFACE CONNECTIONS AND INTERFACE CONTROLS Inputs Class Change A pair of terminals are provided for class change. By shorting these terminals together (e.g. switch, time clock) the alarms will sound. The panel will not indicate a fire. The alarms will cancel when the short circuit is removed. -

Page 7: Wiring Diagrams

WIRING DIAGRAMS CABLE SCN CABLE SCN CABLE SCN CABLE SCN CABLE SCN CABLE SCN CABLE SCN CABLE SCN PAGE 7... -

Page 8: Installation Instructions

INSTALLATION INSTRUCTIONS General All cables entering the panel must be via the cable entries provided or the aperture in the rear face. All cables must be tested for earth fault before connecting to the panel. Do not use a High Voltage Tester (Megger) on any cable after connection to any equipment including the panel. -

Page 9: Installing The Panel

INSTALLATION INSTRUCTIONS - continued Installing the Panel Read all the installation instructions before commencing with the installation. Installation of this panel must be done by a suitably qualified/trained person. The installation must comply with IEE wiring regulations and with BS5839 part 1 1988. The electronic components within the Fire Panel are Static Sensitive. -

Page 10: Faults

FAULTS General All fault conditions on the fire panel will be indicated by the 'FAULT' LED flashing, the panel buzzer beeping and at least one other fault specific LED flashing. The auxiliary fault output will de-activate. All faults indications will be cleared automatically if the fault is removed unless stated. CAUTION ELECTRIC SHOCK HAZARD :- BEFORE REMOVING THE PANEL COVER THE MAINS SUPPLY MUST BE TURNED OFF. -

Page 11: Technical Specification

TECHNICAL SPEC Standards Design to comply with EN54 Part 4 1996 and Part 2 1996 Electromagnetic Compatibility EN 50130-4 1996 Alarm Systems Part 4 EN50081-1 1992 EN61000-2-2-1994 Number of Zones 4(MF400) 2(MF200) Number of alarm Lines Mains Input Voltage 240Vac +10%-15% Standby Duration 24Hr System operating Voltage...

Need help?

Do you have a question about the MENVIER MF200 and is the answer not in the manual?

Questions and answers