Table of Contents

Advertisement

Quick Links

OWNERS MANUAL

INSTALLATION, REPAIR, AND OPERATING INSTRUCTIONS

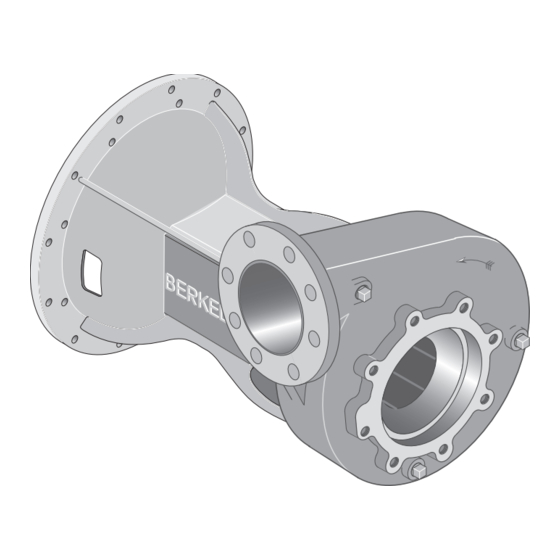

S.A.E. Engine-Mount

Centrifugal Pump

IMPORTANT

For best possible performance and continuous, satisfactory operation,

read these instructions before installing your new pump.

Should service be required, this manual can be a valuable guide.

It should be kept near the installation for ready reference.

Record nameplate data from pump on blank nameplate inside this

manual for future reference.

Berkeley Pumps / 293 Wright Street / Delavan, WI 53115

F00636 (Rev. 7/21/09)

Advertisement

Table of Contents

Summary of Contents for Berkeley S.A.E.

- Page 1 Should service be required, this manual can be a valuable guide. It should be kept near the installation for ready reference. Record nameplate data from pump on blank nameplate inside this manual for future reference. Berkeley Pumps / 293 Wright Street / Delavan, WI 53115 F00636 (Rev. 7/21/09)

-

Page 2: Table Of Contents

Table of Contents • SAFETY ...........................3 • INSTALLATION General Information ......................3,4,5 Flywheel Coupling ......................6,7 Pump to Engine Assembly....................8 Verify Rotation ........................9 Suction Connection .....................10,11 Discharge Connection ....................12,13 • START-UP Priming ........................14,15 Operation ..........................15 • MAINTENANCE General Information ......................16 Packing Ring Replacement ....................17 Impeller Removal......................18 Seal/Impeller Replacement ....................19 Shaft Maintenance/Replacement ..................20... -

Page 3: Safety

Safety First General Information READ AND FOLLOW SAFETY INSTRUCTIONS! This is the safety alert symbol. When you see this symbol on your pump or in this manual, look for one of the following signal words and be alert to the potential for personal injury: DANGER warns about hazards that will cause serious personal injury, death or major property... -

Page 4: General Information 3

When in System piping should be at least one commercial pipe size doubt, consult your nearest Berkeley Professional Dealer. larger than pump connections and flow velocity should not exceed eight (8) feet per second. -

Page 5: General Information 3

Installation General Information TABLE 1 Flywheel S.A.E. Flywheel Housing Size Housing Dimensions 20-1/8 17-5/8 16-1/8 14-1/4 12-3/8 20-7/8 18-3/8 16-7/8 13-1/8 ENGINE Size 7/16-14 3/8-16 3/8-16 3/8-16 3/8-16 Figure 2 SUCTION PIPING and/or the air temperature increases. When driving the pump at the RPM required to deliver water into the system piping, Refer to illustrations on Page 10 and 11 for recommended and the engine must operate within the engine manufacturers... -

Page 6: Flywheel Coupling

Dimension Form provided on the responsibility of the assembler. Berkeley Pumps will page 23, and send it to Berkeley for quotation of special supply data for the pump and coupling for use by the flywheel coupling. -

Page 7: Flywheel Coupling

Installation Flywheel Couplings Flywheels for Industrial Type Overcenter Clutch Engine Flywheel Coupling Spline Diameter -10T (Spline Count) Figure 3 TABLE IIA – WIDE RPM RANGE, ELASTOMER MOUNTED HUB Flywheel Dimensions Flywheel Coupling Clutch Catalog Shaft Spline Size Qty. Size (UNC) Number Diameter 6-1/2”... -

Page 8: Pump To Engine Assembly

DO NOT proceed with shaft bearings. Simply stated, Dimension “A” must be less assembly. Direct the problem to your nearest Berkeley than Dimension “B”. Professional Dealer. -

Page 9: Verify Rotation

Installation Verify Pump Rotation If Engine fan is rotating clockwise as viewed, a pump with clockwise rotation is required. View-"A" looking toward fan. View-"A" View-"B" DIESEL ENGINE Pump volute indicates View-"B" looking clockwise rotation as toward pump shaft. viewed from driver as shown. -

Page 10: Suction Connection

Installation Suction Connection Portable and Permanent Portable Installation is most common with this style pump. Companion Connection for remote hand primer Flange Kit or for manual priming. Connection for optional Engine Exhaust Primer. Locate at least one (1) pipe diameter from pump case. Eccentric Reducer flat side up. - Page 11 Installation Suction Connection Portable and Permanent Avoid suction hose that may collapse during operation due to insufficient strength. High spot in suction hose may result in air pocket. Vortex caused by insufficient submergence Concentric Reducer causes may cause pump to high spots along the suction line lose prime.

-

Page 12: Discharge Connection

Installation Discharge Connection NOTICE: All connections must be air tight. Isolation valve to permit servicing of check valve or pump. Discharge Priming Valve Use Concentric reducer to minimize friction losses. Support piping as required. Rigid Wall Flexible Discharge Hose with quick connect shown. - Page 13 Installation Discharge Connection Avoid undersized pipe / hose diameter Avoid check valves that cause hydraulic shock. Do not leave pipe unsupported Do not use Gate Valve to throttle flow. Avoid abrupt change in pipe size. 6050 0609 • Avoid excess friction loss caused by numerous fittings, insufficient pipe diameter, and sharp turns in pipe run.

-

Page 14: Start-Up

• Locate exhaust primer connection as shown above. escape. • For complete operation, refer to specific instructions in- • Close vent opening when water without air emerges. cluded with exhaust primer, or consult your nearest Berkeley Professional Dealer. Page 14 F00636... -

Page 15: Priming

When necessary to replenish the grease supply, use an NLGI No. 4 Water Pump Grease. Mechanically Sealed Pumps: Mechanically sealed pumps require no special procedures unless they are mounted vertically. In this case, call Berkeley Customer Service at 1-888-237-5353 for more information. F00636 Page 15... -

Page 16: Maintenance

DROPLET form (40 to 60 drops by Berkeley Pumps and are recommended for use in main- tenance operations. per minute). Water must not be streaming or spraying out. -

Page 17: Packing Ring Replacement

Maintenance Packing Ring Replacement Removal See Page 19 for Seal Replacement. Pump liquid end removed for pictorial clarity only. Packing Packing Packing Hooks Gland Ring Shaft Shaft 6052 0609 • Unfasten hardware holding packing gland in place and slide • Slide lantern ring (if used) back to expose any remaining back on shaft to expose packing rings. -

Page 18: Impeller Removal

Maintenance Impeller Removal Clockwise Rotation Volutes shown. 4041 0901 6054 0609 1. Remove the volute and the old gasket(s) and O-Ring(s). NOTE: Certain models, such as the B4EY, have a suction Discard the gaskets and O-rings. cover which is removed first to gain access to the impeller. On these models, remove the access cover, then remove •... -

Page 19: Seal/Impeller Replacement

Maintenance Seal/Impeller Replacement B4EY Series Seal Change Sequence Remove seal plate 6056 0609 If your pump has a bolted in balance ring, remove it; if it Compress the seal spring on the shaft sleeve and has a pressed in balance ring, leave it in place unless reinstall the seal retaining ring (if used). -

Page 20: Shaft Maintenance/Replacement

Maintenance Shaft Maintenance/Replacement Make sure bearings are clean; pack with grease as shown. Outer Bearing Cap with Grease Seal Outer Bearing Cap Water Slinger Water Slinger Oil Seal Procedure and parts may vary Procedure and parts may vary slightly depending on pump model. slightly depending on pump model. -

Page 21: General Pump Care

Maintenance General Pump Care ROUTINE MAINTENANCE WINTERIZING A well maintained pumping system will extend the life of the If pump is to be out of service for an extended period of time, unit and will require fewer repairs. This means less down time such as the winter months, the following storage procedures which can be very critical when a constant delivery of water is should be followed. -

Page 22: Routine Inspection Check List

Maintenance Routine Inspection Record I. QUARTERLY INSPECTION III. QUARTERLY INSPECTION Inspect all system piping connections for leakage Inspect all system piping connections for leakage or possible misalignment. or possible misalignment. Complete any lubrication requirements as dictated Complete any lubrication requirements as dictated by pump and driver owner’s manual. -

Page 23: Pump Nomenclature

General Information SAMPLE ONLY ORDERING REPLACEMENT PARTS: Locate the Berkeley nameplate on the pump, plate is normally BERKELEY PUMPS on the bearing bracket. Information found on this plate is shown below. To be sure of receiving correct parts, provide all MODEL S.N. -

Page 24: Parts Breakdown

Pump Nomenclature S.A.E. Engine Mount Single Row Seal Retainer Mechanical Bearing Seal Shoulder Ring Double Row Thrust Bearing SAE 1: 12 Holes on 20.88" Bolt Circle Oil Seal SAE 2: 12 Holes on 18.38" Bolt Circle O-Ring Slinger SAE 3: 12 Holes on 16.88" Bolt Circle or Gasket SAE 4: 12 Holes on 15.00"... - Page 25 Pump Nomenclature S.A.E. Engine Mount Grease Seal Bearing SAE 4: 12 Holes on 15.00" Bolt Circle SAE 5: 8 Holes on 13.12" Bolt Circle Retaining Ring Thrust Ring Sealed Bearing Bracket Shaft Gasket Shaft Grease Seal Sealed Slinger Bearing Packing Nut Packing Nut Seal Plate...

-

Page 26: Troubleshooting

Troubleshooting PROBABLE CAUSE SYMPTOM GROUP I GROUP II GROUP III ELECTRICAL MECHANICAL SYSTEM No water delivered Not enough water delivered Not enough pressure Engine heats excessively Abnormal noise and/or vibration CAUSE CORRECTIVE ACTION I. ENGINE A. Speed too low Refer to engine manufacturer’s manual. B. - Page 27 Your only remedy, and BERKELEY’s only duty, is that BERKELEY repair or replace defective products (at BERKELEY’s choice). You must pay all labor and shipping charges associated with this warranty and must request warranty service through the installing dealer as soon as a problem is discovered.

Need help?

Do you have a question about the S.A.E. and is the answer not in the manual?

Questions and answers