Table of Contents

Advertisement

R

V

R

V

D

i

g

i

t

a

l

D

i

g

i

t

a

2

1

0

-

1

1

2

1

0

-

1

1

I

n

s

t

r

u

c

t

i

o

n

I

n

s

t

r

u

c

t

i

o

n

Ver. 23/10/2011

S

-

D

X

S

-

D

X

S

o

f

t

S

t

a

r

t

e

l

S

o

f

t

S

t

a

r

t

e

0

0

A

,

2

0

8

-

6

0

0

0

A

,

2

0

8

-

6

M

a

n

u

a

l

M

a

n

u

a

l

M

M

r

w

i

t

h

I

n

t

e

r

r

w

i

t

h

I

n

t

e

r

0

V

0

0

V

n

a

l

B

y

P

a

s

s

n

a

l

B

y

P

a

s

s

Advertisement

Table of Contents

Summary of Contents for Solcon RVS-DXM

- Page 1 Ver. 23/10/2011...

-

Page 2: Table Of Contents

2 Table of content RVS-DXM Instruction Manual TABLE OF CONTENT Table of content ........................2 Safety & Warnings ........................4 2.1 Safety ............................4 2.2 Attention ............................4 2.3 Warnings ............................. 4 Technical Data .......................... 5 3.1 Introduction ..........................5 3.2 Rating and frames sizes ...................... - Page 3 3 Table of content 7.6.2 Display Mode page 0 ....................31 7.6.3 Main Parameters page 1 .................... 32 7.6.3.1 Tripping Curves of the Integrated Overload Protection .......... 35 7.6.4 Start Parameters page 2 .................... 36 7.6.4.1 Soft start parameters ....................39 7.6.5 Stop Parameters page 3 ....................

-

Page 4: Safety & Warnings

DXM is connected to mains. This voltage is extremely dangerous and will cause death or severe injury if contacted. When RVS-DXM is connected to mains, even if control voltage is disconnected and motor is stopped, full vo The starter must be grounded to ensure correct operation, safety and to prevent damage. -

Page 5: Technical Data

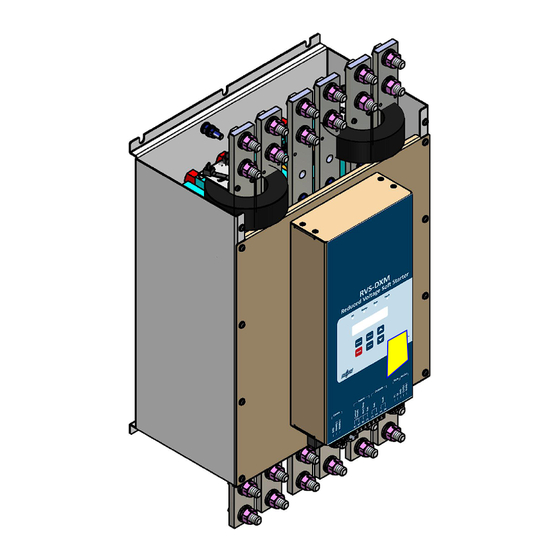

5 Technical Data TECHNICAL DATA Introduction The RVS-DXM is a third generation, highly sophisticated and reliable starter designed for use with standard three-phase, three-wire, squirrel cage, induction motors. It provides the best method of reducing current and torque during motor starting. -

Page 6: Mains Voltage (Line To Line)

Two voltage levels are available: 230VAC + 10%-15%, 50/60 Hz 115VAC+ 10%-15%, 50/60 Hz 3.3.4 Bus bars arrangement The RVS-DXM can be delivered in 4 different options thus makes its installation in the cabinet more flexible: RVS-DXM RVS-DXM RVS-DXM RVS-DXM... -

Page 7: Ordering Information

Front Panel Specify Description Standard Example: RVS-DXM rated 840A, mains voltage- 230V, control voltage- 115V, Modbus communication card, Analog card, Harsh environment treatment and standard front panel: RVS-DXM 840 - 400 - 115 - 3M+5+8 - 66 - S ________________________________________________________________________________________... -

Page 8: Recommended Wiring Scheme

8 Recommended Wiring Scheme RECOMMENDED WIRING SCHEME Mains and Control Description Refer to drawing on page 11 Indication Description Remarks 1L1, 3L2, 5L3 Connection to mains voltage up to 600V defines two voltage levels: 400V for 208-400V +10%/ -15% 50/60Hz 600V for 440-600V +10% /-15% 50/60Hz 2T1, 4T2, 6T3 Connection to motor... - Page 9 When the FAULT function is selected, the relay is energized upon fault. The contact returns to its original position when one of the following occurs: The fault has been removed and RVS-DXM was reset Disconnection of Control Supply When the FAULT-FAIL SAFE function is selected, the...

- Page 10 10 Recommended Wiring Scheme Indication Description Remarks Terminal NC No connection (optional) Standard RS485, half duplex with Modbus protocol, baud rate 1200, 2400, 4800, 9600 BPS. Terminal (-) RS-485 communication (-) Twisted shielded pair should be used. (optional) Connect shield to ground on the PLC/Computer side. Terminal (+) RS-485 communication Up 32 units can be connected for Modbus RS485...

-

Page 11: Input/Output Indication

11 Recommended Wiring Scheme Input/Output Indication 4.2.1 Bottom View of the Control Module Terminals T1, T2 Gnd, Out Terminals (-), (+) - Modbus (-), Out(+) - Analog out connection terminals (optional) and thermistor in (optional) Terminals A1, A2, B1, Profibus D9 connector C1, 13, 14, 23, 24 (optional) Terminals F1, F2... -

Page 12: Typical Wiring Diagram

12 Recommended Wiring Scheme Typical wiring diagram Notes: (1) - Use fuses for type 2 coordination. Refer to section 4.5.1 on page 14 (2) - For Aux. input programming refer to section 7.6.9 on page 47 Close auxiliary contact between F1 to F2 when fan control is required. Only possible when fan option is installed. -

Page 13: Power Wiring Scheme For Inside-Delta Connection

Reverse speed with RVS-DXM connected INSIDE DELTA. Notes: When installing the RVS-DXM INSIDE DELTA. it is highly recommended to use a line contactor (C1) or INSIDE DELTA. contactor (C2) in order to avoid a destruction of the motor in case of a shorted SCR in the RVS- DXM. -

Page 14: Wiring Notes

(1) Fuse rated voltage: Choose minimum fuse rated voltage which is above the rated voltage of the mains. (2) Fuse rated current: Select a fuse which is able to carry 7 times the rated RVS-DXM current for 30 seconds (this is double the maximum RVS-DXM current for the maximum acceleration time). - Page 15 Wrong connection of the starter or the Motor, will seriously damage the motor. 1. It is highly recommended to use a contactor in series to the RVS-DXM or upstream (after motor protection) in order to avoid a destruction of the motor in case of a shorted SCR in the RVS-DXM.

-

Page 16: Dimensions

16 Dimensions DIMENSIONS RVS-DXM 210A, 240A, 310A _____________________________________________________________________________________... - Page 17 17 Dimensions RVS-DXM 360A, 414A, 477A ________________________________________________________________________________________...

- Page 18 18 Dimensions RVS-DXM 515A _____________________________________________________________________________________...

- Page 19 19 Dimensions RVS-DXM 590 ________________________________________________________________________________________...

- Page 20 20 Dimensions RVS-DXM 720A 840A _____________________________________________________________________________________...

- Page 21 21 Dimensions RVS-DXM 960A 1100A ________________________________________________________________________________________...

-

Page 22: Installation

It is recommended to mount the starter directly on the rear metal plate for better heat dissipation. Note: Do not mount the RVS-DXM directly on the rear metal plate in case a ventilation fan or ventilation opening is on the back side of the RVS-DXM. -

Page 23: Calculating The Enclosure Size, For Non-Ventilated Metallic Enclosure

The total heat dissipation of the starter and other control devices in the enclosure. If starter is frequently started, average power should be used. 6.3.2 Additional Ventilation Use the following arrangement for forced ventilation of the RVS-DXM Outlet Inlet Inlet 6.3.3... - Page 24 24 Installation 3 x 50 + 25 N2XY 3 x 70 + 35 N2XY 3 x 95 + 50 N2XY 3 x 150 + 70 N2XY 3 x 185 + 95 N2XY 3 x 240 + 120 N2XY 2 x (3x 150 + 70)N2XY 3 x (3x 185+ 95) N2XY 1100 _____________________________________________________________________________________...

-

Page 25: Control Keypad

SAVED OK will display. Note: Pressing this button at any other time has no effect. Resets the RVS-DXM after a fault has been dealt with and the start command has been Reset removed. This cancels the fault displayed and allows you to restart the motor. -

Page 26: Status Leds

26 Control Keypad Status LEDs. Green Lights when Control Supply voltage is connected to the RVS-DXM. Lights during soft start and soft stop process, indicating that motor supply voltage is Yellow Ramp ramping up or down. Lights after completion of starting process, indicating that motor is receiving full Green voltage. -

Page 27: Obtain Default Parameters

Note: It is especially important to reprogram the FLC (as shown on the label of the RVS-DXM), FLA and RATED LINE VOLT. value again. 7.5.4 Reset Statistical Data Press the Mode and keys simultaneously. -

Page 28: Calibrate Voltage, Current And (Factory Use Only!)

- **** - START PARAMETERS - **** - STOP PARAMETERS - **** - DUAL ADJUSTMENT These pages are skipped if RVS-DXM is programmed to PARAMETERS (Refer to section 7.6.3 on page 32 for information on changing SPECIAL FEATURES PARAMETERS FAULT PARAMETERS... -

Page 29: Overview Of All Mode Pages And Factory Defaults

OVERVOLT. TRIP 120 % OVERVOLT. DELAY 2 SEC. DISPLAY MODE MINIMIZED PARAMETERS LOCK NOT LOCKED STORE ENABLE MAIN PARAMETERS (1) - Refer to section 7.6.3 on page 32 (2) POWER and POWER FACTOR readings available in RVS-DXM 58A and up. ________________________________________________________________________________________... - Page 30 COMM. PARAMETERS 5% OF FLC POWER FACTOR 0.71 - Refer to section 7.6.3 on page 32 - Refer to section 7.5 on page 26 for entering TEST/MAINTENANCE mode. TOTAL ENERGY and POWER FACTOR readings available in RVS-DXM 58A and up. _____________________________________________________________________________________...

-

Page 31: Display Mode

Following the delay, the LCD returns to AMP. VOLT Displays Motors current and mains voltage. OPTION CARD Displays whether option cards are installed in the RVS-DXM. Not Installed INSTALLED/ INSTALLED POWER When power metering option is installed, displays active POWER 30kw drawn by the motor. -

Page 32: Main Parameters

50-100% of 58 AMP. STARTER FLA (Full load name plate. Ampere) Note: When the RVS-DXM is installed Inside Delta set MOTOR FLA = <rated motor current>/1.73. RATED POWER 1-3000KW Rated motor power is used for analog output 30KW POWER reference. When analog card is installed, full... - Page 33 35. The OVERLOAD protection incorporates a THERMAL CAPACITY register that calculates heating minus dissipation of the motor. The RVS-DXM trips when the register fills up. (THERMAL CAPACITY=100%) The time constant, in seconds, for cool down after overload trip is:...

- Page 34 34 Control Keypad MAIN PARAMETERS Displays in MINIMIZED MODE and MAXIMIZED MODE - **** - (Refer below for changing modes) Display and default Range Description Remarks values UNDERVOLT. DELAY 1 10sec. Sets Note: 5 SEC. UNDERVOLT Becomes operational only after Start signal. TRIP DELAY.

-

Page 35: Tripping Curves Of The Integrated Overload Protection

35 Control Keypad 7.6.3.1 Tripping Curves of the Integrated Overload Protection The RVS-DXM allows motor protection according to IEC class 10 or 20 OR according to NEMA class 10, 20, or 30. NEMA & IEC Class OVERLOAD curves NEMA Class 10... -

Page 36: Start Parameters

Refer to section 7.6.4.1 on page 39. 0(STANDARD) 3 !! SOFT START 2 !! CURVE. Note: 1 !! When RVS-DXM 0 (STANDARD) PULSE TIME 1.0 SEC. Intended to start high friction loads, 0 SEC. PULSE START requiring high starting torque for a short TIME. - Page 37 37 Control Keypad START PARAMETERS Displays in MINIMIZED MODE and MAXIMIZED MODE - **** - (refer to section 7.6.3 on page 32 for changing mode) SETTING as Note: described in When INITIAL VOLTAGE is set above section 7.6.7 page 43. changes to INITIAL CURRENT.

- Page 38 38 Control Keypad START PARAMETERS Displays in MINIMIZED MODE and MAXIMIZED MODE - **** - (refer to section 7.6.3 on page 32 for changing mode) extended to 1- motor. It is recommended to set 90sec. by using ACCELERATION TIME to the minimum the WIDER acceptable value (approx.

-

Page 39: Soft Start Parameters

39 Control Keypad 7.6.4.1 Soft start parameters The RVS-DXM Start Curve 0 Standard curve (Default). The most stable and suitable curve for the motor, preventing prolonged starting and motor overheating. Note: When RVS-DXM Start curves 1-3 - - Induction motors produce peak torque of up to 3 times the rated torque towards the end of starting process. -

Page 40: Stop Parameters

STOP PARAMETERS PARAMETERS on page 34. 7.6.5.1 Soft stop parameters The RVS-DXM Stop Curve 0 Standard curve (Default) voltage is linearly reduced from nominal to zero. The most stable and suitable curve for the motor, preventing prolonged stopping and motor overheating. - Page 41 Curve 4 - Torque Curve - Provides linear deceleration of the torque. In certain loads, linear torque deceleration can result in close to linear speed deceleration. The RVS-DXM Torque Control does not require any external torque or speed sensor (tacho-gen. etc.). ________________________________________________________________________________________...

-

Page 42: Dual Adjustment Parameters

42 Control Keypad 7.6.6 Dual Adjustment Parameters page 4 DUAL ADJUSTMENT Displays in MAXIMIZED MODE only PARAMETERS (refer to section 7.6.3 on page 32 for changing mode) Display and default Description Remarks values When selecting GEN. START/STOP in mode I/O PROGRAMMING PARAMETERS on page PROG. -

Page 43: Special Features Parameters

Display and default Range Description Remarks values SLOW SPEED TORQ. 1(MIN.) Sets SLOW Note: 10(MAX.) SPEED When RVS-DXM TORQUE. SLOW SPEED TORQUE is not available. MAX SLOW SP TIME 1 30sec. Sets 30 SEC. Note: maximum time Range can for SLOW... -

Page 44: Wider Settings Parameters

WARNING! phase loss exists and PHASE LOSS protection is activated. This situation can occur in rare cases when there is no real fault but the RVS-DXM recognizes responsibility! unusual behaviour like when THDV (Total Harmonic Distortion in Voltage) in the network is high. -

Page 45: Fault Parameters

Note: LOSS trip when 1 or 2 phases are missing. Range can Notes: be extended If RVS-DXM trips on PHASE LOSS do the to YES/NO following: by using the (1) Verify that phase voltages are within the WIDER required range of the voltages. - Page 46 46 Control Keypad FAULT PARAMETERS Displays in MAXIMIZED MODE only - **** - (refer to section 7.6.3 on page 32 for changing mode) Display and default Range Description Remarks values CURRENT page 32 for details on adjusting UNDER RESET time CURRENT TRIP) delay.

-

Page 47: I/O Programming Parameters

47 Control Keypad 7.6.9 I/O Programming Parameters page 7 I/O PROGRAMMING Displays in MAXIMIZED MODE only (refer to section 7.6.3 on page 32 for changing mode) PARAMETERS Display and default Range Description Remarks values PROG. INPUT C1 START/STOP; Sets Refer to section 7.6.9.1 on page REMOTE RESET;... -

Page 48: Prog. Input C1

The RESET command will take affect only if START command is stopped. EXTERNAL FAULT C1 is used as an input to the RVS-DXM enabling the user to stop the motor in case of an external fault. When C1 is closed motor will stop and Fault LED will lit. - Page 49 MODBUS TIME OUT 0.1-60 Sets MODBUS TIME OUT. If no valid Modbus SEC., OFF communication during MODBUS TIME OUT, the RVS-DXM will trip. Trip occurs only if the following conditions exist: SER. LINK CONTROL is set to ENABLE SERIAL LINK NO. is not set to OFF If MODBUS TIME OUT is set to OFF protection is disabled.

-

Page 50: Comm. Parameters Page 8- Applicable With Optional Modbus & Devicenet Comm. 49 7.6.11 Comm. Parameters Page 8 - Applicable With Optional Profibus Comm

Display and default Range Description values COMM. PROTOCOL PROFIBUS Sets RVS-DXM communication PROTOCOL. PROFIBUS Applicable when the optional communication card is installed. BAUD RATE User can not change BAUD RATE value. AUTO (PROFIBUS) Max. rate is 12 mega bit per second (MBPS). -

Page 51: Statistical Data

51 Control Keypad 7.6.12 Statistical Data page 9 STATISTICAL DATA Displays in MINIMIZED MODE and MAXIMIZED MODE - **** - (refer to section 7.6.3 on page 32 for changing mode) Display and default Range Description values TOTAL ENERGY Displays total energy drawn by the motor in KWH. 0 KWH Note: Reading available in RVS-DXM58A and up. -

Page 52: Phase Sequence

If Aux. Input contact - C1 is programmed as an External Fault (Refer to section 7.6.9.1 on page 48 for details on programming Input C1), the RVS-DXM will trip if contact closes for more than 2 sec. External Fault becomes operational when starter is energized. -

Page 53: Timing Occurrence Table

53 Control Keypad Timing Occurrence Table Active During Timing And Occurrence Soft Start Stop Stop Too many starts with Start Inhibit period Electronic Overload with Curve selection O/C Shear Pin (Jam) Starter Protection trip immediately at 850% FLC Motor Protection trip function During Start factory set at 850% FLA in less than 1 cycle (*). -

Page 54: Starting Procedure

66 are ordered CTL1 and CTL3 should be installed When either RVS-DXM by the cabinet builder upstream the RVS-DXM. The CTs are delivered with a holding bracket which enables installation with either cable or busbar running through the CTs: CT installation on a busbar... - Page 55 Dip-Sw. S402B No use No use No use * Factory default setting Notes: It is important that the RVS-DXM is properly grounded and control module is tightly fastened to the power section. Use twisted shielded cable for thermistor connection. ________________________________________________________________________________________...

-

Page 56: Standard Starting Procedure

56 STARTING PROCEDURE Standard starting procedure Connect Control Supply. On LED will lit. Review all parameters with Mode and Select keys Set parameters as required. Motor starts to turn shortly after Start Initial inrush current or mechanical shock is too high? Speed accelerates Current during Motor speed... -

Page 57: Examples Of Starting Curves

Voltage and current increase until current reaches CURRENT LIMIT. The voltage is held at this value until motor is close to nominal speed, then current will begin to decrease. The RVS-DXM continues to ramp-up the voltage until reaching nominal. Motor speed smoothly accelerates to full speed. -

Page 58: Special Starting Using Dual Adjustment

58 STARTING PROCEDURE 8.4.3 Special starting Using Dual Adjustment For using DUAL ADJUSTMENT automatically, connect AUX. RELAY in series to Aux. Input as shown in section 8.4.3.1 on page 59. Program PROG. AUX. RELAY to IMMEDIATE and program RELAY ON DELAY to tx. Program PROG. -

Page 59: Special Starting Using Dual Adjustment Wiring Scheme

59 STARTING PROCEDURE 8.4.3.1 Special starting Using Dual Adjustment wiring scheme Notes: (1) - Program PROG. INPUT C1 to DUAL ADJUST (2) - Program PROG. AUX. RELAY to IMMEDIATE and program RELAY ON DELAY to tx. Refer to section 7.6.9 on page 47 for details on I/O programming. 8.4.4 Choosing a suitable Pump Curve (centrifugal Pumps) 8.4.4.1... -

Page 60: Stopping Curve

60 STARTING PROCEDURE 8.4.4.2 Stopping Curve Adjust MAIN PARAMETERS as necessary (FLA, FLC, etc..) Set STOP CURVE and DECELERATION TIME, to their default values (curve 0, 10 sec., respectively). Stop the pump, watching the pressure gauge and check valve as the pump stops. Look for overshooting ( Select STOP CURVE 1, increase DECELERATION TIME to 15 seconds. -

Page 61: 61 Trouble Shooting

SHEAR PIN refer to section 7.6.3 on page 32 (MAIN PARAMETERS). O/C or WRONG Trips the soft RVS-DXM when connected Inside Delta and Wrong connection or if CON. over current is detected by the RVS-DXM. Verify that the motor is not stalled or shorted and check cables and wiring. - Page 62 62 TROUBLE SHOOTING Fault Massage Cause and trouble shooting UNDER Trips the starter when line current drops below the preset level for the preset time. CURRENT Check UNDER CURRENT TRIP and TIME DELAY settings, check line currents through L1, L2, L3. For more information on UNDER CURRENT settings refer to section 7.6.3 on page 32 (MAIN PARAMETERS).

- Page 63 EPROM with a new software version or after power up. ously. By doing that, you are loading factory defaults to the RVS-DXM. Now program all parameters into the RVS-DXM like in a first start-up procedure. (If Fault LED is on, press Reset after WRONG PARAMETERS).

-

Page 64: Blank Rma Form

65 TECHNICAL SPECIFICATIONS: TECHNICAL SPECIFICATIONS: Supply Voltage Line to Line 208-600V (to be specified) + 10%-15% for all models Frequency 65 Hz (Fixed or variable frequency source) Control Supply 115V or 230V (to be specified) +10% - 15% Load Three phases, three wires, squirrel cage induction motor. Start-Stop Parameters: Starter FLC Motor FLA... -

Page 65: 66 Technical Specifications

Normal Service Conditions: Altitude Up to 1000m. For equipment to be used at higher altitudes consult Factory. Humidity Control Power Consumption The approx. consumption of RVS-DXM soft starters is as follows: Model Before bypass Inrush During After bypass Optional fan...

Need help?

Do you have a question about the RVS-DXM and is the answer not in the manual?

Questions and answers