Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Essilor PRO-E 600

- Page 1 User Manual...

-

Page 2: Table Of Contents

> C ANUAL ONTENTS ONTENTS NTRODUCTION I. F -E 600 IRST STEPS WITH 1. Descriptive diagrams 2. Using the edger a. Turning on the edger b. Switching off the edger c. Using the touch screen and keypads d. Edging screen II. - Page 3 > C ANUAL ONTENTS 11. Perform a Retouching III. C ONFIGURING THE EDGER 1. Configure the edger a. Time, date and language b. Connections c. Screensaver 2. Adjusting the precision of the edger a. Adjusting the diameter of the finished lenses b.

-

Page 4: Introduction

> I ANUAL NTRODUCTION NTRODUCTION To take full advantage of the functions on you Pro-E 600 edger, we encourage you to consult the entire manual. You need to have at least memory version: V 1.0.0 Pro-E 600 > v1 -02.17... -

Page 5: First Steps With Pro -E

I. F -E 600 IRST STEPS WITH... -

Page 6: Descriptive Diagrams

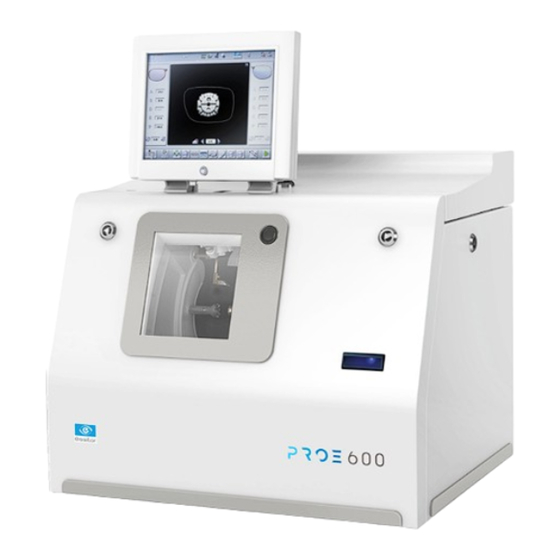

Using the device p.10) 1. D ESCRIPTIVE DIAGRAMS This section consists of descriptions and lists of accessories. USB plug Trough Screen ON/OFF button Cycle start button Barcode reader Screen tilt buttons Fans Manufacturer plate Main switch Connectors Pro-E 600 > v1 -02.17... - Page 7 220 V power cable • RJ45 cable for the tracer-edger connection • Essibox connection cable • Wastewater evacuation pipe with attachment ring • 2 connectors to clip onto two internal water pipes and connect to the rinsing kit Pro-E 600 > v1 -02.17...

-

Page 8: Using The Edger

Do not press the ON/OFF button for several seconds. This would result in a shut-down of the machine and a warningmessage would be displayed at the next switch-on. > A confirmation message is displayed on the screen. Press to confirm. > The edger will switch off. Pro-E 600 > v1 -02.17... -

Page 9: Using The Touch Screen And Keypads

The numeric keypad is displayed for entering values. • Reset the fields • Go back • Confirm • Cancel and go back to the work screen • The alphanumeric keypad is displayed to save or search for jobs. Pro-E 600 > v1 -02.17... -

Page 10: Edging Screen

• Job ID • Job reference (alphanumeric characters) • Job list & • Collection list (when the edger is connected to a Essilor range tracer) d. Edging screen Work screen indicator Tool wear indicators Settings Pro-E 600 > v1 -02.17... - Page 11 Job call: Tracer menu Actions available for the current screen Start the edging cycle Detailed functions For more information, consult the section Edging a lens > Work environment of the edger > Captioned screen. p.16) Pro-E 600 > v1 -02.17...

-

Page 12: Edging A Lens

II. E DGING A LENS... -

Page 13: Edger Working Environment

This section describes the edger working environment and the initial stages of the edging of a lens. • Description of the edging screen p.16) • Shape call-up procedure p.18) • Putting the lens in place p.19) a. Menu screen Lens material ◦ Plastic lens -index 1.5 & ◦ Polycarbonate lens Pro-E 600 > v1 -02.17... - Page 14 Trivex lens ◦ Tribrid lens The configuration of the edging cycles depends on the type of material. An incorrect choice may result in material damage. The Pro-E 600 edger does not edge glass lenses. Type of finish ◦ Bevel ◦...

-

Page 15: Calling Up A Shape

Calling up the number of a shape saved on the tracer: > Press for a few seconds to open the numeric keypad. > You can then call up a shape via the ID allocated to it. • Job call via a barcode: Pro-E 600 > v1 -02.17... -

Page 16: Lens Set-Up And Feeling

For an 18 × 14 mm posiblock Place the lens in the posiblock holder. Place the metal peg of the posiblock upwards and the positioner downwards: a magnet is used to hold the lens in position on the axis. Pro-E 600 > v1 -02.17... - Page 17 As the lens is felt, its shape appears on screen. The double tracing represents the profile of the front surface of the shape (inner shape) and its rear surface (outer shape). > In the case of edging mode selection: Pro-E 600 > v1 -02.17...

-

Page 18: Perform A Beveling

After the tracing of a rimmed frame: • The bevel finish is selected by default. • The automatic mode is selected by default. If you want to produce a bevel less than 0.75mm high, configure the bevel directly on the screen. Pro-E 600 > v1 -02.17... - Page 19 Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. > The edging screen for the second lens is displayed. All finishes chosen and the modifications made are kept. Pro-E 600 > v1 -02.17...

-

Page 20: Legend Screen For Customized Bevels

The cursor is represented by the green square along the shape. To move it, select it directly or use the buttons. Zoom window Represents the bevel profile and indicates the distance between the bevel crest and the front and rear surfaces of the lens at the cursor position. Pro-E 600 > v1 -02.17... -

Page 21: Customized Beveling

Particular groove Thin lens for which the base is Compliance with original shape. (groove with approximately equal to the Job using a specific frame. meniscus meniscus of the groove. & Pro-E 600 > v1 -02.17... - Page 22 All groove imperfections will be reproduced. Press to adjust the distribution value if required. Press > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Pro-E 600 > v1 -02.17...

-

Page 23: Modifying The Bevel Curve

Press the “cycle start” button (front face) or > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. Pro-E 600 > v1 -02.17... -

Page 24: Modifying The Bevel Curve At A Particular Point

Press the “cycle start” button (front face) or Press to go back to the customized bevel finish screen. > For the second lens, the customized bevel icon is pre-selected and the trajectory modification icon is displayed. Pro-E 600 > v1 -02.17... -

Page 25: Displacing The Bevel Curve

This section describes the procedures for the creation of a high-base bevel: • Description of the high-base bevel screens, p.29) • Produce a high-base bevel in “automatic trajectory” mode or “front surface tracking” mode. p.31) Pro-E 600 > v1 -02.17... -

Page 26: Captioned Screens

2: Width of the flat side of the bevel 3. Front surface tracking value a. Captioned screens High-base bevel “front surface tracking” screen Work area Image of the shape to be edged: Frame shape at bottom of groove Bevel trajectory on rear surface Pro-E 600 > v1 -02.17... - Page 27 Centre of the flat side of the bevel Front surface/rear surface of lens Number of shelf bevel values Transition from 4 to 8 shelf bevel values. Transition from 8 to 4 shelf bevel values. Navigation ◦ Stop the cycle Pro-E 600 > v1 -02.17...

-

Page 28: High-Base Beveling

> Perform a chamfering p.66) Press the “cycle start” button (front face) or > The door closes, the lens is clamped and then felt. > The high-base bevel finish screen “automatic trajectory” is displayed by default. Pro-E 600 > v1 -02.17... - Page 29 “automatic trajectory” mode, p.32) • produce a high-base bevel in “front surface tracking” mode. p.34) High-base bevel in “automatic trajectory” mode Press to select the bevel in “automatic trajectory ” mode. > The following screen will appear: Pro-E 600 > v1 -02.17...

- Page 30 The bevel trajectory on the rear surface is modified in the work screen. The result can be viewed in the zoom window. Press the “cycle start” button (front face) or > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Pro-E 600 > v1 -02.17...

- Page 31 The following screen will appear: Press the buttons on the right of your screen to modify the width of the flat side of the bevel. > The result can be viewed in the zoom window. Pro-E 600 > v1 -02.17...

- Page 32 > The result can be viewed in the zoom window and the display window of the bevel trajectory on the lens section. Press the “cycle start” button (front face) or > The edging cycle starts. Pro-E 600 > v1 -02.17...

-

Page 33: Perform A Step Bevel

Concerning the lens, the main constraint is the thickness of the nasal and temporal edges. • Concerning the frame, the crucial elements are the bridge and shape of the groove. The hinge is an additional factor in the case of a metal frame, the arms for a plastic frame. Pro-E 600 > v1 -02.17... -

Page 34: Install The Step Bevel Tool

Allen key Blocking key Tool for “wheel” removal Step wheel in its set-up tool From the working screen of your edger, press (tool wear indicator) for several seconds to access the screen for tool changes. Pro-E 600 > v1 -02.17... - Page 35 The GMD module moves to facilitate the operation. Press to receive more image information on the tool assembly/dismantling procedure. Press to cancel the action. > The following message appears: remove the chamfering wheel and replace it with the step wheel. Pro-E 600 > v1 -02.17...

- Page 36 (towards yourself) the wheel, using the Allen key. Remove the chamfering wheel and the spacer. Position the step bevel wheel with its mounting accessory on the axle. Tighten (towards yourself) the step bevel wheel using the Allen key. Pro-E 600 > v1 -02.17...

- Page 37 0. The icon appears, the statistics are cleared. Press to confirm the tool change, then to exit the menu. Pro-E 600 > v1 -02.17...

-

Page 38: Captioned Screens

Mid-lower (the value must be between 0.40 and 3 mm) Width of the flat side of the bevel The value of the flat side of the bevel must be between 0.1 mm and 2 mm. back chamfer of assembly aid Pro-E 600 > v1 -02.17... -

Page 39: Perform A Step Bevel

The customized mode is selected by default. In the step finish, you cannot polish your bevel. Nevertheless, the step wheel was designed to create a finish that is equivalent to polycarbonate lenses. Press to select the Step bevel. Pro-E 600 > v1 -02.17... - Page 40 In this mode, the trajectory of bevel follows the front surface lens base as closely as possible. Step bevel in “automatic trajectory” mode Press to select the bevel in “automatic trajectory ” mode. > The following screen will appear: Pro-E 600 > v1 -02.17...

- Page 41 4 or 8 areas: • Temporal • Mid-temporal • Upper • Mid-upper • Nasal • Mid-nasal • Lower • Mid-lower Move the cursor along the shape to see the bevel profile in the zoom window. Pro-E 600 > v1 -02.17...

- Page 42 The edging screen for the second lens is displayed. All finishes chosen and the modifications made are kept. Step bevel in “front surface tracking” mode Press to select the bevel in “front surface tracking” mode. > The following screen will appear: Pro-E 600 > v1 -02.17...

- Page 43 • Temporal • Mid-temporal • Upper • Mid-upper • Nasal • Mid-nasal • Lower • Mid-lower Move the cursor along the shape to see the bevel profile in the zoom window. Pro-E 600 > v1 -02.17...

- Page 44 > The result can be viewed in the zoom window and in the window showing the bevel trajectory on the lens section. Press to perform a back chamfer of the assembly aid. Pro-E 600 > v1 -02.17...

-

Page 45: Grooving

◦ a modification at a point of the groove curve p.54) ◦ a displacement of the groove curve p.55) • You can consult the description of the customized groove screen. Pro-E 600 > v1 -02.17... -

Page 46: Automatic Grooving

For more information, consult the section Edging a lens > Perform a polishing and Edging a p.65) lens > Perform a chamfering p.66) Press the “cycle start” button (front face) or > The door closes, the lens is clamped and then felt. Pro-E 600 > v1 -02.17... -

Page 47: Customized Groove Legend Screen

Rear surface tracking: the middle of the groove is positioned at a constant distance from the rear surface. ◦ Distributed groove: the middle of the groove is positioned in proportion to the thickness of the lens, with respect to the front surface. Pro-E 600 > v1 -02.17... -

Page 48: Customized Grooving

Back to the main edging screen ◦ Start the edging cycle c. Customized grooving The use of the customized groove depends on 2 parameters: the frame and the lens. Before starting your job, identify the major constraint. Pro-E 600 > v1 -02.17... - Page 49 Press the “cycle start” button (front face) or > The door closes, the lens is clamped and then felt. > The customized groove finish screen is displayed. Select the type of customized groove you want to do. Pro-E 600 > v1 -02.17...

-

Page 50: Modifying The Groove Curve

> The position of the groove as well as the distances between the center of the groove and the front & rear surfaces of the lens are displayed in the zoom window. Pro-E 600 > v1 -02.17... -

Page 51: Modifying A Point In The Groove Curve

> The position of the groove as well as the distances between the center of the groove and the front & rear surfaces of the lens are displayed in the zoom window. Pro-E 600 > v1 -02.17... -

Page 52: Displacement Of The Groove Curve

Press the “cycle start” button (front face) or > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Pro-E 600 > v1 -02.17... -

Page 53: Produce A Flat-Edge Finish

When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. Pro-E 600 > v1 -02.17... -

Page 54: Do A Mixed Job

Main screen for mixed jobs Modes available for a mixed finish ◦ Automatic mode: the position of the bevel or groove is automatically calculated according to the information acquired when tracing the frame and feeling the lens. Pro-E 600 > v1 -02.17... - Page 55 Settings for area 2 ◦ Bevel finish ◦ Groove finish ◦ Flat-edge finish Navigation ◦ Stop the cycle ◦ Return to the main edging screen without saving your changes ◦ Start the edging cycle Area definition screen Pro-E 600 > v1 -02.17...

-

Page 56: Configuring The Mixed Finish

Call up the desired shape located on the tracer or on the job management program. > The shape is displayed on the edger work screen. Select lens material. Press to select mixed job mode. Select your type of cycle. Pro-E 600 > v1 -02.17... - Page 57 The two points are then unlocked. Drag them with the stylus. If necessary, press to modify the position of the center of the groove or bevel using the buttons This value cannot be modified in automatic mode. Pro-E 600 > v1 -02.17...

-

Page 58: Perform A Drilled Job

Change the drill bit or modify the diameter of the drilling points. You can also create various combinations: • Drilled bevel Pro-E 600 > v1 -02.17... -

Page 59: Automatic Drilling

Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. > The edging screen for the second lens is displayed. All finishes chosen and the modifications made are kept. Pro-E 600 > v1 -02.17... -

Page 60: Legend Screen For Customized Drilling

(degrees) ◦ difference between the initial value and the modified value Cross-sectional view Cross-sectional view of the lens after the feeling cycle, showing the angle of the drill bit at the selected drilling point. Pro-E 600 > v1 -02.17... -

Page 61: Customized Drilling

The customized drilling screen is displayed. Select the type of drilling you want to do. If necessary, select the drilling point(s) you want to modify. If necessary, modify the diameter and/or angle of the selected drilling point. Pro-E 600 > v1 -02.17... -

Page 62: Perform A Polishing

Make sure you select the correct type of material for MHI (> 1.5) or Tribrid lenses and never polish a lens of this type without water. Otherwise, the polishing wheel could suffer irreversible damage. The polishing option is pre-selected. Not available Pro-E 600 > v1 -02.17... -

Page 63: Chamfering

1 and 1. 2 mm < 1 mm • Distance between the edge of the groove and the edge of the lens ISTANCE VAILABLE OPTIONS > 0.8 mm between 0.5 and 0.8 mm < 0.5 mm Pro-E 600 > v1 -02.17... -

Page 64: Perform A Retouching

Manual lens clamping Retouch launch Differences with the edging screen The edging screen is different to the retouch screen through: • the presence of the posiblock, • no frame thickness. When the first-lens edging cycle is finished: Pro-E 600 > v1 -02.17... - Page 65 The edging screen for the second lens is displayed. > All finishes chosen and the modifications made are kept. The retouch done on the first lens is automatically saved for the edging of the second lens. Pro-E 600 > v1 -02.17...

-

Page 66: Configuring The Edger

III. C ONFIGURING THE EDGER... -

Page 67: Configure The Edger

Date Use the arrows to set the date. Type of date display Select the type of display out of the available formats. Language Select the flag corresponding to your language. Other languages Pro-E 600 > v1 -02.17... -

Page 68: Connections

List of devices connected to the tracer Settings linked to the configuration of the serial port Settings linked to the configuration of the Ethernet port Reinitialization of communication ports Once the modification is made, press to return to the work screen. Pro-E 600 > v1 -02.17... -

Page 69: Screensaver

If lenses of a particular material always seem too small or too big after edging, you can adjust their diameter according to the type of frame. To access that menu from your edger work screen, select > > Pro-E 600 > v1 -02.17... -

Page 70: Adjusting The Position Of The Bevel And Groove

Adjusting the position of the bevel and groove After edging a lens, if the position of the bevel or groove always seems too close to the front or rear surface, you can adjust it. Pro-E 600 > v1 -02.17... -

Page 71: Adjusting The Diameter Of Drill-Holes

After drilling a lens, if the diameter of the holes always seems too small or too big, you can adjust it according to the diameter of the drill bit used and the lens material. To access that menu from your edger work screen, select > > The following screen is displayed: Pro-E 600 > v1 -02.17... -

Page 72: Adjusting The Chamfer

After edging a lens, if a chamfer always seems too small or too big, you can adjust its size according to the lens material. To access that menu from your edger work screen, select > > The following screen is displayed: Pro-E 600 > v1 -02.17... -

Page 73: Adjusting The Groove

After edging a lens, if the width or depth of the groove always seem too close too small or too big, you can adjust them. To access that menu from your edger work screen, select > > The following screen is displayed: Pro-E 600 > v1 -02.17... -

Page 74: Adjust The Position Of High-Base Bevel

After lens edging, if the position of high-base bevels seems consistently too far ahead or too far behind, you can adjust it. To access this menu from your edger work screen, select > > The following screen is displayed: Pro-E 600 > v1 -02.17... -

Page 75: Adjust The Position Of The Step Bevel

Adjust the position of the step bevel After the edging of a lens, if the position of high-base bevel or step bevel seems consistently too far ahead or too far behind, you can adjust it. Pro-E 600 > v1 -02.17... - Page 76 > The numeric keypad is displayed. b. Enter the new value. ◦ Negative value: the flat side of the bevel will be smaller ◦ Positive value: the flat side of the bevel will be larger. c. Press to confirm. Pro-E 600 > v1 -02.17...

-

Page 77: Maintenance & Servicing

IV. M & AINTENANCE SERVICING... -

Page 78: Carrying Out The Autotests

Edger autotests Initialisation and rotation of lens shafts Reproducer: lens shaft raising and lowering Right feeler movement Left feeler movement Closing of lens shafts Wheel rotation Rotation of Grooving/Milling/Drilling (GMD) module Pro-E 600 > v1 -02.17... -

Page 79: Calibrating The Touch Screen

Point precisely on each cross as they are displayed, holding the stylus perpendicular to the screen so as not to alter the calibration. > The settings menu is displayed automatically once the calibration is finished. Press to return to the work screen. Pro-E 600 > v1 -02.17... - Page 80 There are three wear-out thresholds: First wear-out threshold The icon appears beside the access button on the maintenance menu, press above to directly access the preventive maintenance menu of the “small tools” modiule: Pro-E 600 > v1 -02.17...

- Page 81 With each cycle launch: " Proper functioning of a component is no longer assured. This could impact the edging of your lenses. Continuing could also call into question your existing guarantees. Do you wish to continue?" Pro-E 600 > v1 -02.17...

-

Page 82: Changing Or Cleaning The Edger Tools

(drill bits) or clean them (mill bit and drill bit), • to replace them with new tools, You can replace: • The drill bit • The mill bit • Step bevel wheel Pro-E 600 > v1 -02.17... -

Page 83: Changing Or Cleaning The Drill Bit

• Always use tools recommended by Essilor. • Never use the edger if one of the tools is missing from the module. Never remove a used or broken tool if you cannot replace it. - Page 84 For cleaning, select the diameter of the drill bit in place. Press > The GMD module moves to facilitate the operation. Press to receive more image information on the tool assembly/dismantling procedure. Press to cancel the action. Block the axle with the blocking key. Pro-E 600 > v1 -02.17...

- Page 85 Put the adjustable wrench on the chuck The adjustable wrench must never touch the drill bit. Loosen the chuck with the adjustable wrench (two notches towards yourself). Remove the adjustable wrench then the drill bit. Pro-E 600 > v1 -02.17...

- Page 86 During the installation of a new drill bit, the statistics are automatically reset to zero by default. >The icon appears by default at the bottom of the screen. When replace a drill bit with a different diameter drill bit or when cleaning the machine, the statistics are saved by default. Pro-E 600 > v1 -02.17...

-

Page 87: Changing Or Cleaning The Mill Bit

600 MHI lenses have been edged: 600 × 2.5 = 1500 • 1,500 lenses made of other materials have been edged: On your edger work screen, select > > Prerequisite: You must have the following tools: Blocking key an adjustable wrench Press Pro-E 600 > v1 -02.17... - Page 88 Block the axle with the blocking key. Put the adjustable wrench on the chuck The adjustable wrench must never be in contact with the mill bit. Loosen the chuck with the adjustable wrench (two notches towards yourself). Pro-E 600 > v1 -02.17...

- Page 89 Remove the adjustable wrench then the mill bit. Inset the new mill bit all the way at the back. Put the adjustable key onto the chuck, then tighten (two notches towards the bottom of the trough). > The chuck tightens up. Pro-E 600 > v1 -02.17...

-

Page 90: Changing The Step Bevel Wheel

Press to select the step bevel wheel: CX3831. Press to confirm the tool. > The GMD module moves to facilitate the operation. Press to receive more image information on the tool assembly/dismantling procedure. Pro-E 600 > v1 -02.17... - Page 91 Step wheel in its tool for mounting/dismantling Position the blocking key on the back axle of the step bevel wheel and position the assembly aid tool on the wheel. Loosen (towards yourself) the step bevel wheel using the Allen key. Pro-E 600 > v1 -02.17...

- Page 92 Position the new step bevel wheel with its assembly accessory on the axle. Tighten (towards yourself) the step bevel wheel using the Allen key. Ensure that the tool is correctly fixed onto the axle. Remove the mounting tool and the Allen key Pro-E 600 > v1 -02.17...

-

Page 93: Changing The Chamfering Wheel

Prerequisite: You must have the following tools: • Blocking key • an Allen key Press > The GMD module moves to facilitate the operation. Press to receive more image information on the tool assembly/dismantling procedure. Pro-E 600 > v1 -02.17... - Page 94 Be careful to save the screw. Replace the old wheel with a new one. The blue part of the wheel must be oriented towards the outside of the module, and the gray part must be placed against the spindle. Pro-E 600 > v1 -02.17...

- Page 95 During the installation of a new tool, the statistics are automatically reset to zero by default. >The icon appears by default at the bottom of the screen. When replacing a chamfering wheel with a step bevel wheel, or cleaning the machine, the statistics will be saved. Pro-E 600 > v1 -02.17...

-

Page 96: Statistics And Technical Log

The replacement of a worn tool with a new one resets the partial counter(s) to zero. Total counter Edging operations Number of edging, drilling and finishing operations performed depending on the lens material: ◦ Roughing ◦ Milling ◦ Bevels ◦ Flat-edge finish ◦ Grooves Pro-E 600 > v1 -02.17... -

Page 97: Technical Log And Errors

Number of error messages displayed since the last reset to zero. You can sort the error codes generated by the machine by frequency of appearance. To sort the partial counters press , press again to define the sort direction (ascending, descending). Total counter Pro-E 600 > v1 -02.17... -

Page 98: Maintaining And Cleaning The Edger

Never clean the machine with chemical products (e.g.: petrol, thinners, solvents). • Never clean the machine elements (module, etc.) with a wet rag. • No additive should be added to the water in the edger tank. Do not add pyridine. Pro-E 600 > v1 -02.17... -

Page 99: Clean The Door, The "Small Tools" Module And The Wheels

1. Dismantle the wheel 2. Clean the wheel with a decalcifer such as white vinegar. Cleaning must be performed only when the wheels have been disassembled and are outside the trough. Pro-E 600 > v1 -02.17... -

Page 100: Dressing The Wheels

From the work screen of the edger, select > > to access the wheel dressing menu. You can access the dressing menu by pressing on the work screen. > The following screen is displayed. Polishing wheel Pro-E 600 > v1 -02.17... - Page 101 Once the cycle is finished, press to open the clamps and remove the dressing stone. If the dressing stone shows a residual ring, remove it in order not to disrupt subsequent dressing operations. Pro-E 600 > v1 -02.17...

-

Page 102: Technical Data

ECHNICAL DATA... -

Page 103: Edger

3 wheel versions (depending on material): plastics, polycarbonate, medium or high index, Trivex , polishing Precision adjustment: • Finished lens diameter of - 2 to + 2 mm • Drilling diameter of - 0.10 to + 0.10 mm Pro-E 600 > v1 -02.17... -

Page 104: Environment

Take care not to block the vents and to leave enough space above the device. Do not place any object on the device. Avoid exposing the device to vibrations or shocks. Pro-E 600 > v1 -02.17... - Page 105 > T ANUAL ECHNICAL DATA The back of your machine must be at least 20 cm away from a wall. Pro-E 600 > v1 -02.17...

-

Page 106: General Information

ENERAL INFORMATION... -

Page 107: Symbols

Essilor cannot be held responsible for any malfunction or loss of data resulting from such errors or omissions. -

Page 108: Declaration Of Conformity

All edgers obtain a final shape on a lens, by removing material. This process generates dust, which depends on the lens and the materials used. The materials used for coating the Essilor wheel and consumed during its use are not toxic or allergenic. Nevertheless, users must check that the ground materials are not toxic. -

Page 109: Electromagnetic Waves

Your system is an electrical appliance compliant with the applicable safety standards. In the event of malfunction, repairs must be carried out by qualified personnel approved by Essilor. Otherwise, user safety is likely to be compromised. In the event of a long period of non-use and before maintenance and/or replacement of certain accessories, you must unplug your system from the mains. -

Page 110: Glossary

LOSSARY... - Page 111 The indices vary according to the materials used for the lenses: • Plastic lens: 1.5 • Polycarbonate lens: 1.59 • Medium or High Index lens: > 1.5 • Trivex™ lens: 1.5 to 1.6 • Tribrid™ lens: 1.6 • Glass lens: 1.5 to 1.9 Pro-E 600 > v1 -02.17...

- Page 112 Essilor Instruments USA 8600 W. Catalpa Avenue, Suite 703 Chicago, IL 60656 Phone: 855.393.4647 Email: info@essilorinstrumentsusa.com www.essilorinstrumentsusa.com...

Need help?

Do you have a question about the PRO-E 600 and is the answer not in the manual?

Questions and answers