Summary of Contents for Jungheinrich AMX Inox

- Page 1 AMX/-E 10 INOX/INOX PRO AMX 10 INOX PRO Ex 12.05 - Operating instructions 51021985 07.08...

- Page 2 Used to indicate standard equipment. Used to indicate optional equipment. Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the truck. No guarantee of particular features of the truck should therefore be inferred from the present operating instructions.

-

Page 4: Table Of Contents

Index Correct Application Truck Description Application ................... B 1 Materials ....................B 1 Assemblies and Functional Description ..........B 2 Standard Version Specifications ............B 4 Performance data for standard trucks ..........B 4 Dimensions ..................B 4 EN norms .................... B 7 Conditions of use ................ - Page 5 Industrial Truck Maintenance Operational safety and environmental protection ........ F 1 Maintenance Safety Regulations ............F 1 Servicing and inspection ..............F 3 Maintenance Checklist AMX ............... F 4 AMX-E Maintenance Checklist: ............F 5 Lubrication Schedule ................F 6 Consumables ..................

-

Page 6: A Correct Application

A Correct Application The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are supplied with the truck. The guidelines form part of these operating instructions and must be observed. National regulations apply in full. The truck described in the present operator manual is an industrial truck designed for lifting and transporting load units. -

Page 8: B Truck Description

AMX/AMX-E Inox AMX/AMX-E Inox Pro AMX Inox Pro Ex Acid resistant steel (AISI 316) t t t t t t t t t Stainless steel (AISI 303/304) Hot galvanized Electro-galvanized + yellow chromate AMX-E Inox Pro AMX Inox Pro/Inox Pro Ex... -

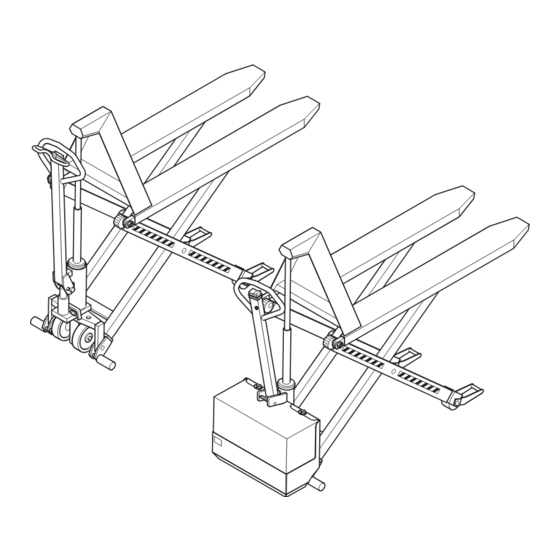

Page 9: Assemblies And Functional Description

Assemblies and Functional Description AMX Inox/Inox Pro/Inox Pro Ex Item Description Load fork Scissors Bearing thrust strap Load wheels Steer wheels Support leg Hydraulic cylinder Control handle “Lift/lower load fork” handle t = Standard equipment o = Optional equipment... - Page 10 AMX-E Inox/Inox Pro Item Description Load fork Scissors Bearing thrust strap Load wheels Battery connector Support leg Steer wheels Hydraulic unit Hydraulic cylinder Control handle “Lift/lower fork” button t = Standard equipment o = Optional equipment...

-

Page 11: Standard Version Specifications

Standard Version Specifications Technical data specified in accordance with VDI 2198. Technical modifications and additions reserved. Performance data for standard trucks Description AMX 10 Inox/ AMX-E 10 Inox Pro/ Inox/Inox Pro Inox Pro Ex Drive unit: Manual Electric (lift) Rated capacity 1000 1000 Load centre of gravity... - Page 12 AMX Inox/Inox Pro/Inox Pro Ex...

- Page 13 AMX-E Inox/Inox Pro...

-

Page 14: En Norms

Ambient temperature AMX Inox/Inox Pro - at temperatures from -35 °C to 40 °C Ambient temperature AMX-E Inox/Inox Pro - at temperatures from 5 to 40 °C Ambient temperature AMX Inox Pro Ex - at temperatures from -20 to 40 °C... -

Page 15: Identification Points And Data Plates

Identification points and data plates AMX Inox/Inox Pro AMX-E Inox/Inox Pro Item Description Warning decals: “Do not stand under the load handler” / “Do not stand on the load handler” Capacity Q “Load centre of gravity” decal Truck data plate “Correct operation/loading”... - Page 16 II 2G IIB T4 XXX XX ATEX XXXXXX X AMX Inox Pro Ex Item Description Warning decals: “Do not stand under the load handler” / “Do not stand on the load handler” Capacity Q “Load centre of gravity” decal Truck data plate “Correct operation/loading”...

-

Page 17: Data Plate

Type Year of manufacture Net weight in kg Manufacturer Manufacturer’s logo Rated capacity (kg) Serial no. XXX XX ATEX XXXXXX X AMX Inox Pro Ex Item Description Type Reference (ATEX) Year of manufacture Net weight in kg Manufacturer Manufacturer’s logo Rated capacity (kg) Serial no. -

Page 18: C Transport And Commissioning

C Transport and Commissioning Lifting by crane Only use lifting gear with sufficient capacity. (AMX-E: Transport weight = net weight + battery weight; see truck data plate) Strap points are provided for transporting the truck with crane lifting gear. – Park the truck securely (see Chapter E). -

Page 19: Using The Truck For The First Time

Using the truck for the first time To prepare the truck after delivery or transport the following tasks must be carried out: – Check the truck for completeness and satisfactory condition of the equipment. – Install battery (where required). Do not damage battery cables (only AMX-E). –... -

Page 20: D Battery Maintenance, Charging & Replacement

D Battery Maintenance, Charging & Replacement Safety regulations for handling acid batteries Park the truck securely before carrying out any work on the batteries (see Chapter E). Maintenance personnel: Batteries may only be charged, serviced or replaced by trained personnel. The present operator manual and the manufacturer’s instructions concerning batteries and charging stations must be observed when carrying out the work. -

Page 21: Battery Types

Battery types The truck is equipped with the following battery types: 12 volt battery 60AhC5 The battery weight is indicated on the battery data plate. When replacing/installing the battery make sure the battery is securely located in the battery compartment of the truck. Charging the Battery When the green LED (100%) on the battery discharge indicator is lit, the battery is fully charged. -

Page 22: Battery Discharge Indicator

Battery discharge indicator The battery discharge status is indicated by the LED. Charge Colour Status 100% Green Truck operational Green Truck operational Green Truck operational Yellow Charge battery <25% Charge battery, truck not operational For light applications (load < 300 kg) charge the battery when the LED is flashing yellow. -

Page 23: Battery Replacement

Battery Replacement The truck must be parked on level ground. To prevent short circuits, batteries with exposed terminals or connectors must be covered with a rubber mat. Place the battery connector or the battery cable in such a way that they will not get caught on the truck when the battery is removed. -

Page 24: E Operation

E Operation Safety Regulations for the Operation of Forklift Trucks Driver’s rights, obligations and responsibilities: The driver must be informed of his duties and responsibilities and be instructed in the operation of the truck and shall be familiar with the operator manual. The driver shall be afforded all due rights. Unauthorised Use of Truck: The driver is responsible for the truck during the time it is in use. -

Page 25: Additional Clause To The Safety Regulations For Operating An Explosion-Proof Industrial Truck ( )

Additional clause to the safety regulations for operating an explosion-proof industrial truck ( Explosion-proof trucks are indicated as follows: II 2G IIB T4 Trucks with this reference can be used in zone 1 areas at risk from explosion due to gas, steam or fog of explosion group IIB and temperature group T4. -

Page 26: Controls

Controls AMX Inox/Inox Pro/Inox Pro Ex Item Control / Display Function t Moves and steers the truck. Control handle t Manually lifts / lowers load fork. “Lift/lower load fork” handle AMX-E Inox/Inox Pro Item Control / Display Function t Indicates the battery charge status Battery discharge indicator (see Chapter D). -

Page 27: Starting Up The Truck

Starting up the truck Before the truck can be commissioned, operated or a load unit lifted, the driver must ensure that there is nobody within the hazardous area. Checks and operations to be performed before starting daily work – Inspect the entire truck (especially the wheels and the load handler) for visible signs of damage. -

Page 28: Industrial Truck Operation

Industrial truck operation Safety regulations for truck operation Travel routes and work areas:Only use lanes and routes specifically designated for truck traffic. Unauthorised third parties must stay away from work areas. Loads must only be stored in places specially designated for this purpose. Driving conduct:The driver must adapt the travel speed to local conditions. -

Page 29: Travel, Steering, Braking

Travel, Steering, Braking Never carry passengers. Travel Do not drive the truck unless the panel is closed and properly locked. – Start up the truck (refer to section 3).. AMX tiller AMX-E tiller: – The truck can be pulled or pushed from the tiller (8) handle (11). AMX: When moving a laden truck, the handle (9) must be in the “neutral”... -

Page 30: Lifting And Depositing Loads

Lifting and depositing loads Before picking up a load, the driver must ensure that it is correctly palletised and that the capacity of the truck is not exceeded. Do not lift long loads at an angle. – AMX: Lower the fork if necessary by pressing the AMX-E tiller: handle in the “Lower”... -

Page 31: Parking The Truck Securely

Stability at Height Risk of trapping from moving parts! The support legs (13) and bearing thrust strap (12) combine to stabilise the truck. When the forks are above a height of 400 mm, the support legs and bearing thrust strap automatically lower to prevent the scissor lift truck from travelling. The support legs are eccentric, so that they can be adjusted according to their gradual state of wear. -

Page 32: Troubleshooting

Troubleshooting This chapter is designed to help the user identify and rectify basic faults or the results of incorrect operation. When locating a fault, proceed in the order shown in the table. Fault Probable Cause Action Load cannot be lifted –... - Page 33 E 10...

-

Page 34: F Industrial Truck Maintenance

F Industrial Truck Maintenance Operational safety and environmental protection The servicing and inspection duties contained in this chapter must be performed in accordance with the intervals indicated in the maintenance checklists. Any modification to the forklift truck assemblies, in particular the safety mechanisms, is prohibited. - Page 35 Electrical System: Only suitably trained personnel may operate on the truck’s electrical system. Before working on the electrical system, take all precautionary measures to avoid electric shocks. For battery-operated trucks, also de-energise the truck by removing the battery connector. Welding: To avoid damaging electric or electronic components, remove these from the truck before performing welding operations.

-

Page 36: Servicing And Inspection

The application conditions of an industrial truck have a considerable impact on the wear of the service components. We recommend that a Jungheinrich customer service adviser carries out an application analysis on site to work out specific service intervals to prevent damage due to wear. -

Page 37: Maintenance Checklist Amx

Maintenance Checklist AMX Maintenance intervals Standard W A B C Cold Store Chassis/ 1.1 Check all load bearing components for damage Design: 1.2 Check screw connections Wheels: 2.1 Check wheels for wear and damage 2.2 Check suspension and attachment Steering: 3.1 Check the steering play Hydraulic 5.1 Test operation... -

Page 38: Amx-E Maintenance Checklist

AMX-E Maintenance Checklist: Maintenance intervals Standard W A B C Cold Store Chassis/ 1.1 Check all load bearing components for damage Design: 1.2 Check screw connections Wheels: 2.1 Check wheels for wear and damage 2.2 Check suspension and attachment Steering: 3.1 Check the steering play Hydraulic 5.1 Test operation... -

Page 39: Lubrication Schedule

Lubrication Schedule g Contact surfaces Hydraulic oil filler neck Grease nipple Cold Store Application... -

Page 40: Consumables

Consumables Handling consumables: Consumables must always be handled correctly. Follow the manufacturer’s instructions. Improper handling is hazardous to health, life and the environment. Consumables must only be stored in appropriate containers. They may be flammable and must therefore not come into contact with hot components or naked flames. Only use clean containers when filling up with consumables. -

Page 41: Replacing The Hydraulic Oil (Amx)

Replacing the Hydraulic Oil (AMX) Draining the oil: – Fork must be in lowered position. – Tilt pallet truck to the side and remove tank stopper. – The oil now flows out of the filling hole. Filling the oil: – Align pallet truck again and add about 0,7 litres of hydraulic oil. –... -

Page 42: Checking Electrical Fuses

Checking electrical fuses – Prepare the truck for maintenance (see Chapter 7.1). – Check all fuse ratings in accordance with the table; replace if necessary. Item Description To protect: Pump motor 80 A 2 F1 Overall control circuit fuse... -

Page 43: Recommissioning

Recommissioning The truck may only be restored to service after cleaning or repair work, once the following operations have been performed. – Lubricate the truck in accordance with the lubrication schedule. – Bleed the hydraulic system by pumping the pallet truck up completely. –... -

Page 44: Returning The Truck To Operation After Decommissioning

Returning the truck to operation after decommissioning – Thoroughly clean the truck. – Lubricate the truck in accordance with the lubrication schedule (see Chapter F). – Check hydraulic oil for condensed water and replace if necessary. – Start up the truck (see Chapter E). AMX-E only: –... -

Page 45: Safety Checks To Be Performed At Regular Intervals And Following Any Unusual Incidents

Carry out a safety check in accordance with national regulations. Junheinrich recommends checks in accordance with FEM Guideline 4.004. Jungheinrich has a special safety department with trained personnel to carry out such checks. The truck must be inspected at least annually (refer to national regulations) or after any unusual event by a qualified inspector.

Need help?

Do you have a question about the AMX Inox and is the answer not in the manual?

Questions and answers