Advertisement

Quick Links

SFo _ u_h_

'_e"_r"unle

_

SWA/_S

owner's

manual

CATALOG NO.

9-29012

9-29013

FITS THE FOLLOWING

MODEL NUMBERS:

113.197110,

113.197111

113.197150,

113.197151

113.197210,

113.197211

113.197250,

113_197251

113.197410,

113.197411

113.197510,

113.197511

113.197610,

113.197611

113.197180,

113.197181

FOR YOUR

SAFETY:

SEA/A_S/ I:RRFT$ M gN_

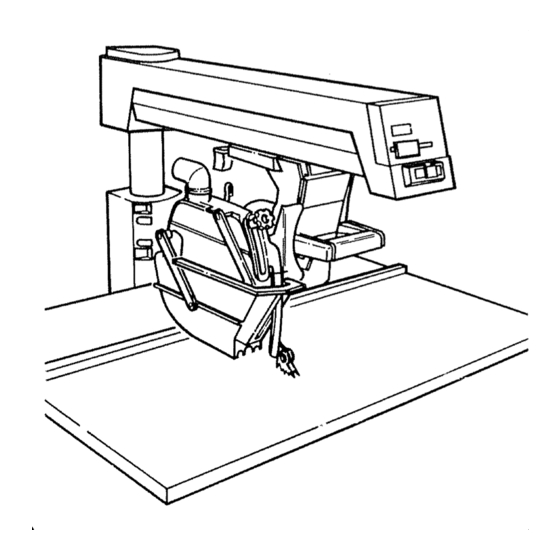

10-INCH RADIAL SAW

GUARD KIT

• assembly

• operating

• repair parts

READ ALL

INSTRUCTIONS

CAREFULLY

Sold by SEARS, ROEBUCK

AND

CO.,

Chicago,

IL 60684

U.S.A.

Part No. SP5623

Printed in USA

Advertisement

Summary of Contents for Craftsman 9-29012

- Page 1 113.197510, 113.197511 113.197610, 113.197611 113.197180, 113.197181 FOR YOUR SAFETY: READ ALL INSTRUCTIONS CAREFULLY Sold by SEARS, ROEBUCK Part No. SP5623 SEA/A_S/ I:RRFT$ M gN_ 10-INCH RADIAL SAW GUARD KIT • assembly • operating • repair parts CO., Chicago, IL 60684 U.S.A.

- Page 2 This warranty gives you specific which vary from state to state. SEARS, ON CRAFTSMAN RADIAL this Craftsman Sears will repair it, free of IS AVAILABLE BY SIMPLY CENTER/DEPARTMENT UNITED STATES. legal rights and you may also have other rights ROEBUCK AND CO.

-

Page 3: Major Hazards

Read and follow all safety information and instructions. Major Hazards Three major hazards are associated with using the radial arm saw for ripping, They are ouffeed zone hazard, kickback, and wrong way feed. from This section only briefly explains these haz- workpiece ards. - Page 4 Safety Kickback Hazard Kickback is the uncontrolled p_opelling of the workpiece back toward the user' during ripping° The cause of kickback is the binding or pinching of the blade in the workpiece° Several conditions can cause the blade to bind or pinch. When a workpiece kicks back, it could hit hard enough to cause internal organ injury,...

-

Page 5: Safety Instructions

4. Keep floors clean and flee of sawdust, wax and other slippery materials. 5. Keep work area well lighted and unclut- tered, 6. Use saw only in dry area. Do not use in wet or damp areas. Dust Mask Ear Proleclors... - Page 6 10. Keep saw table clean. 11. Store items away from saw. Do not climb on saw or stand on saw table to reach items because saw can tip over. to be cut and nec-...

- Page 7 6o Do not turn saw on and off in rapid sequence because blade can loosen. cutting 7. Blade should stop within 15 seconds after saw is switched off. If blade takes longer, the saw needs repair. Contact Sears Service Center. Safety blade nut because...

-

Page 8: Identify Parts

Do not throw away bcjbre palts contacting Sears, Use the list to identij], the nuntber #9-29012 If you ate missing at O, part, part. Sonlethnes snlall any packaging until guar'd is put A COnlplete parts... - Page 9 Using the rear screw holes as a drill guide, drill a .5/16" hole in the saw base for each of the two rear screws. Remove the front table. The U-Clips that were used as nuts for...

- Page 10 Assembly 7, Rotate the saw to the negative 45 degree l_'cx,_c! position. Remove and discmd ttle oflmr lmndle retaining screw, Discard tile old handle, 8. Using the two #1(1 x 3/4 flat head screws provided, altach the new h;mdle in tile same...

- Page 11 Align Riving Knife to Blade The goa! of this adjustment is to position the riving knife directly in line with the blade. Riving knife alignment is an important safe- ty factor, The riving knife rides in the kerf of the cut work_iece during ripping to keep the two sides of the workpiece from pinching on the blade.

- Page 12 0 °, 45°L, 45°R Turns motor on!off On-Off Switch Allows saw to be switched on Yellow Key Bevel Lock Frees motor to rotate; locks in any desired position; pre-set indexed positions at 0°, 45 °, - 45°, 90°, -90°...

- Page 13 Function Control Frees carriage to move along Rip Lock radial tuna; locks in position Tell distance between blade and Rip Scale & Rip fence when saw is in in-rip or Indicators (Non- Electronic Models) out-rip position Swivel Lock Frees blade carriage to rotate between rip and crosscut posi- tions;...

- Page 14 Notch in guard fits securely into matching on motor Clear guard is moveable: raise over fence at start of crosscut; See Saw Handle; most work- pieces will automatically raise clear guard during ripping; See Guard Tab Turn counterclockwise...

- Page 15 Pawls Riving Knile Knob Pawls Riving Knife Function Control Provides manual way to raise G u ard Tab clear plastic guard during rip- ping when workq_iece fails to raise it Pawls!Riving Frees pawls and riving knife to Knife Knob independently down Pawls During ripping, slow or stop...

- Page 16 Notes...

- Page 17 PARTS LIST CRAFTSMAN CATALOG 9-29012 & 9-29013 Always order by Part Number - Not by Key Number Part Description 818922-1 Screw, Flat Hd Ptastite #10 x3/4 820520 Handle, Yoke 820534 Spring 820533 Trigger * Washer, 3/16 x 3/8 x 1/32...

- Page 18 PARTS LIST CRAFTSMAN 10" RADIAL GUARD CATALOG 9-29012 & 9-29013 Always order by Part Number - Not by Key Number el=l= FIGURE 2...

- Page 19 Ho/der, AKB 824159 Screw, Flat Hd Type 'q-F' 1/4 - 20 x 9/16 c£) 10" RADIAL SAW GUARD KIT CATALOG 9-29012 & 9-29013 Always order by Part Number - Not by Key Number FIGURE 2 - GUARD Description 820519 STD551225 820530...

- Page 20 • Product Type • Model Number • Part Number • Part Description Sold by SEARS, ROEBUCK AND CO., Chicago, Part No, SP5623 10-1NCH RADIAL SAW GUARD KIT For the repair or replacement parts you need Call 7 am -7 pro, 7 days a week...

Need help?

Do you have a question about the 9-29012 and is the answer not in the manual?

Questions and answers