Table of Contents

Advertisement

Quick Links

- 1 Figure 2.1 - B320 Bevel Gear Operator

- 2 Installing an Operator with a Threaded Stem Nut

- 3 Disassembly and Reassembly of B320-10 through -80

- 4 Figure 6.1 - B320-10 and 20 Parts Diagram

- 5 Figure 6.2 - B320-30 and -40 Parts Diagram

- 6 Figure 6.3 - B320-50 and -70 Parts Diagram

- 7 How to Order Parts

- Download this manual

Advertisement

Table of Contents

Summary of Contents for Flowserve Limitorque B320 series

- Page 1 USER INSTRUCTIONS Limitorque B320 Series Installation ® Operation FCD LMENIM3201-02 – 01/15 Maintenance Experience In Motion...

- Page 2 Limitorque B320 Series FCD LMENIM3201-02 – 01/15 This page is left intentionally blank.

-

Page 3: Table Of Contents

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Contents Introduction Purpose User Safety Product Capabilities and Features Initial Inspection and Storage Instructions Product Identification Inspection and Recording Storage Procedure Operator Weights Installation Instructions Safety Precautions Safety Practices Installation 4.3.1 Installing an Operator with a Threaded Stem Nut 4.3.2... - Page 4 Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figures Figure 2.1 – B320 Bevel Gear Operator Figure 2.2 – B320 Nameplate Figure 6.1 – B320-10 and 20 Parts Diagram Figure 6.2 – B320-30 and -40 Parts Diagram Figure 6.3 – B320-50 and -70 Parts Diagram Figure 6.4 –...

-

Page 5: Introduction

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Introduction 1.1 Purpose This Installation, Operation and Maintenance Manual (IOM) explains how to install and maintain the B320 bevel gear operator. Information on installation, disassembly, lubrication, and spare parts is provided. 1.2 User Safety Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury and damage to the equipment. -

Page 6: Product Capabilities And Features

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Product Capabilities and Features The B320 gear operator makes it easier to both Designed to make operation of multi-turn valves easier manually operate multi-turn valves and convert to a motorized service. The B320 offers torque ranges up to Built for reliable valve control —... -

Page 7: Product Identification

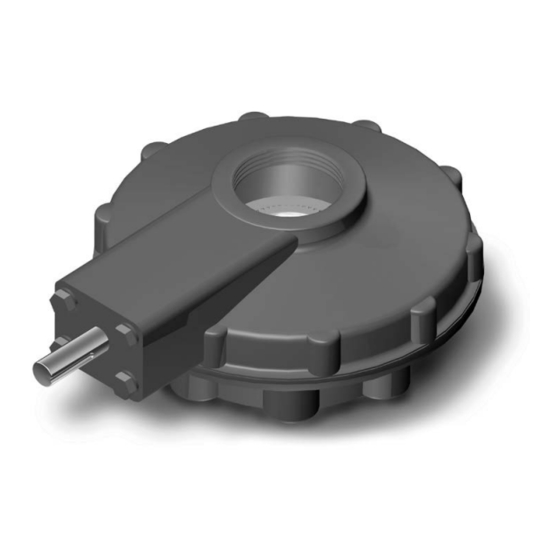

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 2.2 Product Identification Figure 2.1 – B320 Bevel Gear Operator Nameplate Input Shaft Mounting Base Housing 2.3 Inspection and Recording Upon receipt of the gear operator, inspect the condition of the equipment and record nameplate information. -

Page 8: Storage Procedure

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figure 2.2 – B320 Nameplate 2.4 Storage Procedure NOTE: The following is the recommended storage procedure to retain maximum product integrity during storage. Failure to comply with recommended procedure will void the warranty. -

Page 9: Operator Weights

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Operator Weights The approximate weights of the gear operators, with and without spur gear attachments, are provided below: Table 3.1 – Operator Weights Operator Without SGA With SGA B320-10 B320-20 B320-30 B320-40 B320-50... -

Page 10: Installation Instructions

CAUTION: Do not use replacement parts that are not genuine Flowserve Limitorque parts, as serious personal injury and/or damage to the operator and valve may result. -

Page 11: Safety Practices

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 4.2 Safety Practices The following check points should be performed to maintain safe operation of the B320 gear operator: • Set up a periodic operating schedule on infrequently used valves. • Ensure that the limit and/or torque switches on any electric actuator fitted to the bevel gear operator are correctly and appropriately adjusted. -

Page 12: Installing An Operator With A Blank Stem Nut (B320-90, Two-Piece)

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 6. Using the specified lubricant, grease the thrust base assembly through the grease fitting. See Section 5 Lubrication, and Figure 6.1, 6.2, 6.3, 6.4 and 6.5 for grease fitting location. 7. Mount the operator on the valve as detailed in Section 4.3.1, Installing an Operator with a Threaded Stem Nut. -

Page 13: Lubrication

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Lubrication The B320 bevel gear operators have a sealed gear case, factory-lubricated with grease. No seal can remain absolutely tight at all times. Therefore, it is not unusual to find a very small amount of weeping around shaft seals —... -

Page 14: Minimum Lubricant Qualities Required

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Table 5.1 – Lubricant Quantities Operator Without SGA With SGA B320-10 B320-20 B320-30 B320-40 B320-50 B320-70 B320-80 B320-90 5.3 Minimum Lubricant Qualities Required The standard lubricants used by Limitorque have been proven to be extremely reliable over years of service. -

Page 15: Disassembly And Reassembly

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Disassembly and Reassembly No special tools are required for assembly/disassembly of the B320 series bevel gear operators. c WARNING: Valve must be in fully opened position with no pressure in the line to perform work on the gear operator. -

Page 16: Disassembly And Reassembly Of B320-10 Through -80

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 6.1 Disassembly and Reassembly of B320-10 through -80 6.1.1 Disassembly (Piece numbers refer to Figures 6.1, 6.2, 6.3, and 6.4). 1. Remove Thrust Ring (piece #5). Pull out Stem Nut (piece #4), Washers (piece #7) and Bearings (piece #6). -

Page 17: Figure 6.1 - B320-10 And 20 Parts Diagram

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figure 6.1 – B320-10 and -20 Parts Diagram Figure 6.2 – B320-30 and -40 Parts Diagram flowserve.com... -

Page 18: Figure 6.3 - B320-50 And -70 Parts Diagram

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figure 6.3 – B320-50 and -70 Parts Diagram 25 24 20 16 15 Figure 6.4 – B320-80 Parts Diagram... -

Page 19: Table 6.2- Common Parts List

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Table 6.2– Common Parts List Piece Quantity Description Housing Base Bevel Gear Stem Nut Thrust Ring Needle Bearing Thrust Washer Ball Bearings O-ring O-ring O-ring Lockwasher Hex Head Cap Screw Grease Fitting Plain Washer Flat Head Mach. -

Page 20: Disassembly And Reassembly Of B320-90

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 6.2 Disassembly and Reassembly of B320-90 6.2.1 Disassembly (Piece numbers refer to Figure 6.5). 1. Remove Thrust Plate (piece #118) followed by Stem Nut (piece #392, two-piece) and Drive Sleeve (piece #117, 2-piece; piece #394, one-piece) and Roller Bearings (piece #115 and 116). -

Page 21: Disassembly And Reassembly Of Spur Gear Attachments

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Table 6.3 – B320-90 Parts List Piece Quantity Description Bevel Housing Torque Drive Sleeve Bevel Cap Input Shaft/Pinion Bevel Gear Threaded Collar Quad Ring O-ring Ball Bearing Roller Bearing Cone Roller Bearing Cup... -

Page 22: Reassembly Of 3:1 Spur Gear Attachment For B320-10 Through -40

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 3. Remove the Snap Ring (piece #29). 4. Remove the Hex Head Cap Screw (piece #28) and Lockwasher (piece #27). 5. Remove the Spur Gear Housing (piece #30). 6. Continue disassembly as detailed in Section 6.1. Disassembly and Reassembly – 320-10 through -80. -

Page 23: Disassembly Of 6.3:1, 10.3:1, And 10.8:1 Spur Gear Attachments For B320-50, -70, And -80

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Table 6.4 – 3:1 SGA Parts List for B320-10 through -40 Piece Quantity Description Lockwasher Hex Head Cap Screw Snap Ring Spur Gear Housing Spur Gear Cover Bushing Dowel Pin Hex Head Cap Screw... -

Page 24: Figure 6.7 - 6.3:1, 10.3:1, And 10.8:1 Sga Parts Diagram For B320-50 Through -80

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figure 6.7 – 6.3:1, 10.3:1, and 10.8:1 SGA Parts Diagram for B320-50 through -80 Table 6.5 – 6.3:1 , 10.3:1, and 10.8:1 SGA Parts List for B320-50 through -80 Piece Quantity Description Spur Pinion... -

Page 25: Disassembly Of 5:1 Spur Gear Attachment For B320-90

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 6.3.5 Disassembly of 5:1 Spur Gear Attachment for B320-90 (Piece numbers refer to Figure 6.8 and Table 6.6). 1. Remove the Socket Head Cap Screws (piece #217) and Lockwashers (piece #216) to remove the Housing (piece #201). -

Page 26: Figure 6.8 - 5:1 Sga Parts Diagram For B320-90

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figure 6.8 – 5:1 SGA Parts Diagram for B320-90 Section "B-B" Thru Idler Gear Section "A-A" Table 6.6 – 5:1 SGA Parts List for B320-90 Piece Quantity Description Adapter Plate Housing Input Shaft and Pinion... -

Page 27: Disassembly Of 17.5:1 Spur Gear Attachment For B320-90

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 6.3.7 Disassembly of 17.5:1 Spur Gear Attachment for B320-90 (Piece numbers refer to Figure 6.9 and Table 6.7). 1. Remove Socket Head Cap Screws (piece #220) and Lockwashers (piece #221) to remove the Housing Cover (piece #201). -

Page 28: Figure 6.9 - 17.5:1 Sga Parts Diagram For B320-90

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Figure 6.9 – 17.5:1 SGA Parts Diagram for B320-90 221 201... -

Page 29: Table 6.7 - 17.5:1 Sga Parts List For B320-90

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 Table 6.7 – 17.5:1 SGA Parts List for B320-90 Piece Quantity Description Housing Housing Cover 1st Set Input Shaft/Pinion 1st Set Output Gear 2nd Set Input Shaft 2nd Set Input Gear 2nd Set Output Gear... -

Page 30: How To Order Parts

Limitorque B320 Series FCD LMENIM3201-02 – 01/15 How to Order Parts To order parts or obtain further information for your Limitorque B320 gear operators, contact your local Limitorque distributor sales office, or: Flowserve Flow Control Limitorque Actuation Systems 5114 Woodall Road P.O. - Page 31 Limitorque B320 Series FCD LMENIM3201-02 – 01/15 This page is left intentionally blank. flowserve.com...

- Page 32 Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide Whitefield, Bangalore –...

Need help?

Do you have a question about the Limitorque B320 series and is the answer not in the manual?

Questions and answers