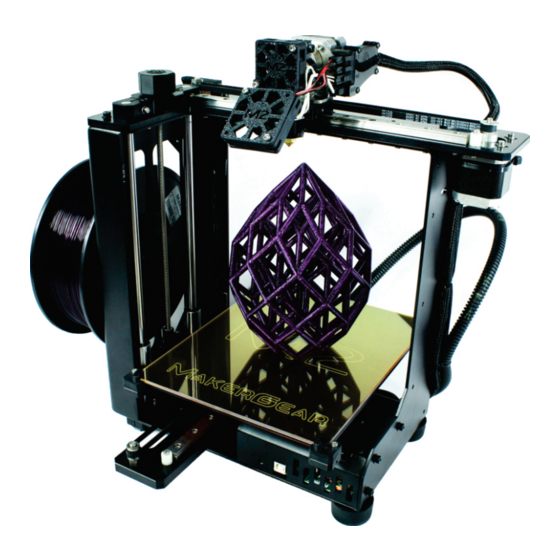

MAKERGEAR M2 User Manual

Rev g

Hide thumbs

Also See for M2:

- User manual (24 pages) ,

- User manual (24 pages) ,

- Beginner's manual (26 pages)

Summary of Contents for MAKERGEAR M2

- Page 1 USER GUIDE...

-

Page 2: Table Of Contents

4 - Hardware Setup 7 - A Note About Nozzles 8 - Slicing Files 9 - Changing Filament 10 - M2 Features 13 - What’s the Function? 14 - Filament Settings 15 - Maintenance & Storage 16 - Warranty & Support... -

Page 3: Welcome

Welcome Your MakerGear M2 3D Printer has arrived! Following minimal setup, your M2 is ready to print out-of-the-box. To ensure safety as well as high quality printing, carefully follow the setup instructions included in this User Guide. This printer was assembled at the MakerGear factory in Beachwood, Ohio, USA, and was tested for at least six hours to ensure that it was fully operational at the time of shipping. -

Page 4: Important Safeguards

Important Safeguards 1. The following safeguards exist to ensure the safety of users and to avoid potential risks. Ignoring these safeguards can cause damage to the printer and its environment. 2. Unplug the power cord when the printer is not in use. To unplug, grasp the plug and firmly pull it from power outlet. -

Page 5: What's Included

USB cord, feeler gauge, brush, and 4 extra build plate hold-down clips. 1 kg spool of 1.75 mm PLA (color may vary). Spool holder with screws which was printed on your M2 using the included SD card. -

Page 6: Hardware Setup

Hardware Setup 1. Carefully compress and remove the foam from the top of the printer and from inside the printer frame. 2. Remove foam from above and below the 4-legged “spider” inside the frame. Remove the heated build platform from its slot in the foam and place it on the spider with the glass build plate facing up, as shown on page 5. - Page 7 4. Remove the binder clip, and rotate the hold-down clips to point to- ward the front and back of the glass build plate in order to secure it in place. 5. Install the spool holder with the 4 included screws using the 3 mm allen key, ensuring that the longer side is facing up.

- Page 8 Done: click this to navigate to the “Advanced” tab, where you can find manual controls for your M2 as well as a real-time display of the temperatures and coordiantes of your extruder...

-

Page 9: A Note About Nozzles

Some of our users choose to print with nozzles that are either larger or smaller than the 0.35 mm nozzle included on the M2 in order to accommodate specific printing needs. If you plan to print with different-... -

Page 10: Slicing Files

If you try to dowload and print a file from the internet, you’ll notice its format is either .STL or .OBJ, which your M2 is unable to read. In order to print these files, you must use special software designed to “slice”... -

Page 11: Changing Filament

“hexa.g” sample that you printed, see the online resources offered by your slicing software provider in order to familiarize yourself with different slicing settings’ impact on various aspects of print quality. If you experience persistent issues, contact MakerGear support via: http://www.MakerGear.com/support Changing Filament 1. -

Page 12: M2 Features

M2 Features Front 1 Z Fine Adjust Knob 7 Z Axis Limit Switch 2 Heated Build Platform (HBP) 8 SD Card Reader 3 X Axis Linear Rail 9 Reset Button 4 X Axis Belt 10 USB Port 5 Z Axis Lead Screw... - Page 13 M2 Features Rear 12 X Axis Limit Switch 13 Filament Guide 14 Y Axis Linear Rail 15 Y Axis Belt 16 6-Position Power Connector 17 Y Axis Limit Switch...

- Page 14 M2 Features Extruder Assembly...

-

Page 15: What's The Function

RAMBo board. 40x15 mm Fan (24 V) cools printed layers (as needed). 6-Position Power Connector brings low voltage DC power to M2. Extruder Wire Mount locates and clamps connectors for extruder. Filament Drive pulls filament into extruder. -

Page 16: Filament Settings

Filament Settings The MakerGear M2, with its V4 hot end operable at 300 C, is capable of running a wide variety of materials. The table below recommends settings for a few of the most popular materials. Recommended Temperature, Extrusion Recommended... -

Page 17: Maintenance & Storage

Additionally, fully seal the filament spool in a bag, preferably with a new desiccant packet inside. • If you are storing the M2 for a period of 2 weeks or more, follow all above instructions, THEN cover the entire printer in order to protect it from the buildup of dust and other airborne particles. -

Page 18: Warranty & Support

Exceptions The M2 has an open design (no proprietary cartridges) and M2 owners are free to use third party filament. However, the MakerGear hot end is only covered when MakerGear filament and authentic MakerGear components are used. -

Page 19: About Us

USA using domestic and foreign parts. Yet despite countless improvements and advancements during the years since MakerGear’s humble beginnings, our dedication to quality and community remains unchanged. Our work revolves around providing three things: quality printers, excellent customer service, and a user-centric 3D printing experience. - Page 20 What are you making? Tag #madewithMAKERGEAR for a chance to be featured! @MakerGear ©2018 MakerGear. MakerGear LLC 23632 Mercantile Road Unit G Beachwood, Ohio, US 44122...

Need help?

Do you have a question about the M2 and is the answer not in the manual?

Questions and answers