Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

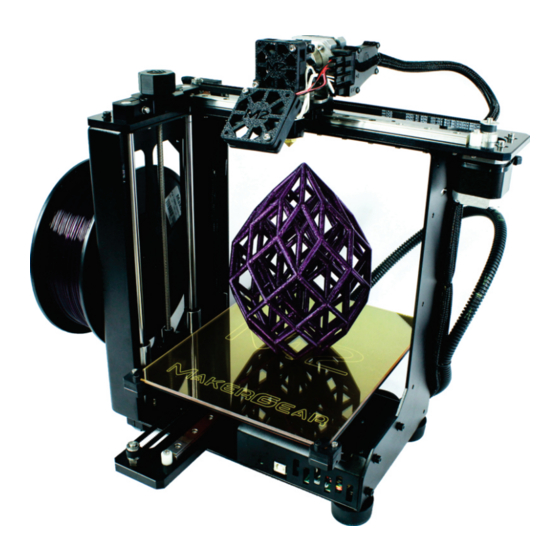

Summary of Contents for MAKERGEAR M2

- Page 2 MakerGear has not expressly forbidden it, but you’ll run the risk of ticking off a lot of people who think the M2 is the “bee’s knees”, and I’ll tell you up front, they’ll defend it. Final discretion rests with the moderators. If they cause a ruckus, or have the potential to do so, you can expect your posts to start disappearing, so keep it polite.)

-

Page 3: Table Of Contents

Calibrating the Z-Offset Calibrating the Tension on the Filament Drive Screw Calibrating the Extrusion Width Quick Start Guide – Dual Extruder M2 Getting Started with the Dual Extruder System Adjusting the Right Nozzle Gap ... -

Page 4: Tools List

Tools List Although you can get by without them, the tools below just make it easier to use a 3D printer. 1. Metric Feeler Gauges (Amazon) - They are invaluable in setting the Z-stop. 2. Calipers - Needed for calibrating the extrusion widths and heights. 3. -

Page 5: Setting Up The Machine/Installing Driver

(These things vibrate when they print.) Because the M2 changes slightly as improvements are incorporated into the base model: Carefully read through all of the current instructions provided by MakerGear (included in your box) before assembling. You can also direct download your RAMBo Windows Driver before assembly, to have it ready. It is available at the page linked here: http://makergear.wikidot.com/m2-firmware... -

Page 6: Adjusting The Level

Turn the Z-axis knob to finish bringing the bed up until it almost touches the nozzle. (You should still be able to see a small gap at eye level, about the thickness of the sheet of paper.) When the nozzle is close enough, use the masking tape to tape the Z-knob into place, to keep it from turning. - Page 7 Use the Front Adjustment Screw and Rear Adjustment Screw to adjust the size of the gap along the Y axis. (Front to back.) For example: Say the front of the bed is too low relative to the rear of the bed, (the gap is larger at the front of the machine than at the rear), you would position the nozzle at the area of the largest gap, watch it at eye level, and slightly loosen the Front Adjustment Screw to bring the plate up until the gap at the front is the same size as the gap at the rear of the plate.

-

Page 8: Preparing The Plate

Again, only close half of the gap. For more information: A more detailed description (with photos) of Setting the Z-Stop and Bed Leveling is available on the MakerGear Forum: http://forum.makergear.com/viewtopic.php?f=3&t=2783 And a video of the more expert leveling process is available at the link below: https://www.youtube.com/watch?v=R53wWwktH0s... -

Page 9: Establishing Communication With Your Slicer Software

G-code file with the instructions to an SD card, which is then inserted into the card reader on the printer. (In an assembled M2, the SD card is shipped inside the card reader on the machine.) The M2 can be used with the (recommended) Simplify3D slicer software, or the free open source option of Slic3r through a Printrun (aka: Pronterface) or Repetier interface. -

Page 10: Checking And Setting The Z-Endstop

But you want to get as close as you can to that ideal with the Z-Home. On a pre-assembled M2, the Z-stop is set once for you, using a Kapton-coated glass plate, and the cold-set method. (If the plates now come with the Kapton tape pre-applied, then the test was probably performed with your plate. -

Page 11: Checking The Z-Endstop Gap

Quickest method: Home Z while the M2 is turned on but not heated, center the print head, and slide a business card in and out of the gap between the nozzle and the bed. It should just fit under the nozzle without binding, while perfectly flat. - Page 12 4. Remove the spool of filament from the holder - it will be in the way. 5. Loosen the nut on the Z-stop bolt (counterclockwise) with a 7 mm wrench, or a pair of needle nose pliers. (It’s very hard to reach with your fingers.) 6.

-

Page 13: Hot Setting The Z-Endstop (V4 Style Nozzle)

Hot Setting the Z-EndStop: (V4 Style Nozzle) 1. Position the nozzle in the center of the bed. Make sure the heated bed plate is seated flat between the rubber corners. Clip the prepared glass plate to the bed. 2. Set the bed temperature to 60°C and the extruder temperature to 215°C, using the Jog Controls or Machine Control Panel. -

Page 14: Preparing To Print

(Do not let go of the end of the filament until you have fed it through the filament guide.) Video on the process here: MakerGear M2 Filament Feeding: https://www.youtube.com/watch?v=Ni7xN4616No 2. Attach your filament dust wiper*. The filament dust wiper prevents clogs from bits of dust that wind up on the spools during manufacturing, and it’s a good idea to always use one. -

Page 15: Printing

4. Send the model to be printed. The software will heat the nozzle, move it into position, and start extruding. Note: The M2 uses a pre-configured starting script in Simplify3D that moves the print head forward, back, then off to the right of the bed, extrudes 20 mm or so of filament to prime the nozzle, and then wipes itself off on the plate before starting the print. -

Page 16: Calibrations

Do this once for each type of filament. (PLA, ABS, PETG etc.) Calibrate the Z-Offset: http://forum.makergear.com/viewtopic.php?f=3&t=3124 2. Calibrate the Tension on your Filament Drive Screw: Do this once for each type of filament. (PLA, ABS, PETG, Flex, etc.) Having the incorrect tension on the filament drive screw also causes a lot of printing problems. -

Page 17: Quick Start Guide Dual Extruder M2

3. The Dual M2 comes with the V4 style nozzles. (When you set the Z-stop, you can use the second listed Hot-Set method, which does not require fiddling with the Z-stop bolt and nut. -

Page 18: Adjusting The Right Nozzle Gap

Adjusting the Right Nozzle Gap Set the height for the right side nozzle depending on how you plan to use it. Different Colors of the Same Filament If you plan to use the machine to print filaments that print within the same temperature range, (ex: dual color printing with PLA), do the following: 1. -

Page 19: Starter S3D Profiles For The Dual

Simplify3D Dual FFF Profiles for the M2: http://forum.makergear.com/viewtopic.php?f=13&t=2984 Additional handy resources for using the Dual M2 with Simplify3D are linked below: Dual Extrusion Wizard|Simplify3D: https://www.youtube.com/watch?v=qPufaJhyqME&list=PLogLRK5xzNdieu445p2O7wODJpQBVf-Ss And more discussions and modifications are available on the forum in the M2 Dual Extruder section. -

Page 20: Tips For Printing Pla

Tips for Printing PLA In order to get the best results with a filament, it helps to know a little something about the characteristics of that filament when printing. I’m going to list some tips for printing with PLA, but they are not going to work the same with other filaments. - Page 21 It’s always a good idea to print a Skirt around the object to be printed, 2-3 outlines, 1 layer, at a distance of from 2 to 4 mm from your print. It gets the nozzle well primed and can show gap problems before the print starts, giving you time to stop it before you waste a lot of plastic.

-

Page 22: Troubleshooting Tips

Troubleshooting Tips: Most of the problems that beginners see stem from only a handful of issues. Many of these can be spotted (with practice) by watching how the “critical-first-layer” is laid down. (You’ll quickly become an expert at spotting potential trouble just by watching that first layer go down.) The diagram shows what the profile of an extruded thread looks like based on the nozzle position relative to the bed. - Page 23 c. First layer is squashed enough to create a sharp skirt on the calibration square, and the first layer is shorter than the other layers, but otherwise the print is sticking everywhere – fine tune the gap using the Z-Offset Calibration and enter the values into the Z-Offset slot in the G-Code tab of Simplify3D or Slic3r.

- Page 24 Some of the issues you will see with failed bed adhesion are: a. The corners of your print will start to pull away from the bed – this causes the print to warp up and eventually the nozzle might actually hit the print – knocking the print loose, causing misalignment issues, or even sticking the nozzle into the print.

- Page 25 Check the forum for instructions for safely removing your hot end and disassembling it to clear the clog. V4 style: http://forum.makergear.com/viewtopic.php?f=3&t=2942 V3B style: http://makergear.wikidot.com/m2-hotend-assembly http://forum.makergear.com/viewtopic.php?f=3&t=2074 (Note: Jammed or stripped filament also causes no extrusion, and is the more likely candidate. Check for that first.)

- Page 26 5. Bed Leveling problem. After using the machine for a while, you might start to see problems that indicate the level needs to be adjusted. Some of the issues you will see with an un-level bed are: a. When laying down the first layer, you will see an extreme difference - between the printing on the right side of the bed versus printing on the left side, or between the front and the back.

Need help?

Do you have a question about the M2 and is the answer not in the manual?

Questions and answers