Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Leybold vacuum TRIVAC S 4 B

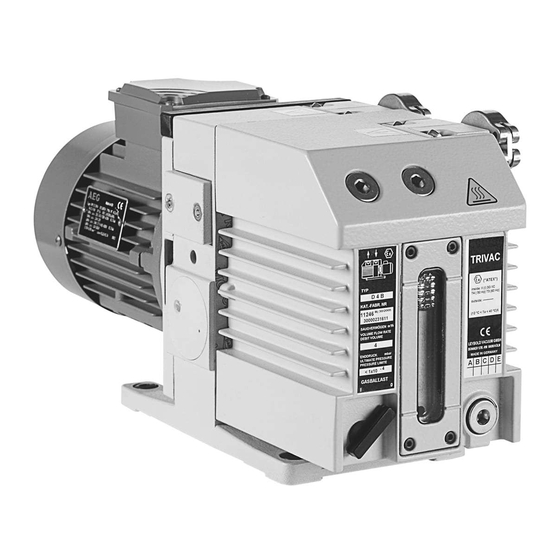

- Page 1 LEYBOLD VACUUM Vacuum Pumps Instrumentation Fittings and Valves GA 01.201/8.02 TRIVAC ® Rotary Vane Vacuum Pump S/D 4 / 8 B Cat. No. 102 45/46/55/56 103 01/02/03/04/05/06/07 103 11/12/13/14/15/16/17 112 45/46/55/56 113 01/02/03/04/05/06/07/08 113 11/12/13/14/15/16/17/18 Operating Instructions...

-

Page 2: Table Of Contents

Contents Contents Warning Indicates procedures that must be strictly observed to prevent hazards to persons. Page Description ......3 Function . -

Page 3: Description

TRIVAC-B pumps are oil-sealed rotary vane pumps. The housing (2/6) (pump chamber), has two radially sliding TRIVAC S 4 B and S 8 B are single-stage pumps, and vanes (2/5) which divide the pump chamber into several the TRIVAC D 4 B and D 8 B are dual-stage pumps. The compartments. - Page 4 Description Key to Fig. 2 Intake port Dirt trap Anti-suckback valve Intake channel Vanes Pump chamber Rotor Cover plate, connection for inert gas ballast Exhaust channel Exhaust valve Internal demister Spring buckles Cover plate, connection for oil filter Fig. 2 Sectional drawing of the TRIVAC-B The gas ballast stops condensation of vapours in the The vacuum is maintained by the TRIVAC-B through an pump chamber up to the limit of vapour tolerance as...

-

Page 5: Supplied Equipment

Description Key to Fig. 3 Accessories Bearings Non-return valve Pump chamber of the TRIVAC Oil reservoir Oil pump Fig. 3 Schematic of the lubricating system Key to Fig. 4 1 Oil reservoir 5 Valve seat 2 Spring 6 Valve disk 3 Control piston 7 Gas inlet 4 Anti-suckback piston... -

Page 6: Accessories

Description 1.3 Accessories 1.4 Spare Parts Cat. No. / Ref. No. Set of gaskets 197 20 Condensate trap AK 4-8, DN 16 KF ..188 06 Pump module, complete S 4 B 200 10 988 Exhaust filter AF 4-8, DN 16 KF . -

Page 7: Technical Data

Pressure with gas ballast without gas ballast Fig. 5 Pumping speed characteristics of the TRIVAC S 4 B to TRIVAC D 8 B, 50 Hz operation, SI units... - Page 8 Description...

-

Page 9: Operation

Operation Key to Fig. 7 Handle Intake port Exhaust port Oil-level glass Gas ballast knob Threaded connection M 16 x 1.5 for inert gas ballast Adapter Cover plate Cover plate; connection for oil filter Fig. 7 Connections and controls 2 Operation 2.1 Installation 2.2 Connection to the System... -

Page 10: Electrical Connection

Operation 2.3 Electrical Connections The maximum throughput of the pump is equivalent to the pumping speed of the pump (see Section 1.6). Warning Before wiring the motor or altering the Caution wiring, ensure that mains supply for the The cross-section of the intake and exhaust pump is off and that it can not be applied lines should be at least the same size as inadvertently. -

Page 11: Start-Up

Operation Star connection Delta connection Fig. 8 Connection diagram for TRIVAC-B with 50 Hz 3-phase motor Caution After connecting the motor and after every Warning The safety regulations which apply to the time you alter the wiring, check the direction application in each case must be observed. -

Page 12: Operation

Operation 2.5 Operation Once all vapours have been pumped off from a process (e.g. during drying), the gas ballast valve can be closed to improve the attainable ultimate pressure. TRIVAC-B pumps can pump condensable gases and vapours, provided that the gas ballast valve (7/5) is open and the pump has attained its operating temperature. -

Page 13: Shutdown Through Monitoring Components

Maintenance 3 Maintenance Drain the oil (see Section 3.2). Add clean oil until the oil-level is at the “min” mark (see Section 3.2) and let the pump operate for some time. Disconnect the electrical connections Warning Then drain the oil and add clean oil until the oil level is at before disassembling the pump. -

Page 14: Checking The Oil Level

Maintenance 3.1 Checking the Oil Level During operation of the TRIVAC-B the oil level must always remain between marks (9/2) and (9/3) on the oil- level glass. The amount of oil must be checked and topped up as required. Caution Fill in oil only after the pump has been switched off. -

Page 15: Cleaning The Dirt Trap

Maintenance Key to Fig. 10 Oil case Spring buckles Demister Frame for demister Hex. socket screws Silencing nozzle Gasket Fig. 10 Removal and fitting of the internal demister 3.3 Cleaning the Dirt Trap Periodically clean or replace the internal demister; the maintenance interval depends on the application. -

Page 16: Disassembly And Reassembly Of The Electric Motor

Maintenance Key to Fig. 11 Gasket Handle Coupling Threaded pin Only for USA motors: adapter flange Electric motor Hex. socket screws Intermediate flange Hex. socket screw Fig. 11 Disassembly and reassembly of the electric motor 3.5 Disassembly and Remove the handle (11/2). Loosen the threaded pin (11/4) and pull the coupling Reassembly of the (11/3) off the motor shaft. -

Page 17: Replacing The Outer Shaft Seal

Maintenance Key to Fig. 12 1 Coupling element 2 Hexagon socket screw 3 Spring washer 4 Coupling (one half) 5 Key 6 Compression disc 7 O-ring 8 Bushing 9 Shaft seal 10 Centering disk 11 Hexagon socket screws Position of the shaft seal Fig. -

Page 18: Removing And Remounting The Pump Module

Maintenance 3.7 Removing and Using a suitable plastic or aluminium cylinder (shaft seal driver) and a plastic hammer, force the shaft seal (12/9) Remounting the Pump carefully and without bending it into the centering disk (for position of shaft seal, see Fig. 12). Module If you do not have a shaft seal driver, place the shaft seal on the opening in centering disk and carefully force it in... -

Page 19: Remounting The Pump Module

Maintenance Key to Fig. 13 Hex. nuts Pump module Washer Gasket Coupling element Tie rods Fig. 13 Removing and remounting the pump module 3.7.2 Remounting the Pump Module When installing a new pump module, it is also advisable to use a new gasket (13/4). Check the coupling element (13/5) for damage;... -

Page 20: Leybold Service

Maintenance 3.8 Leybold Service 3.9 Storing the Pump If a pump is returned to Leybold, indicate whether the Caution Before putting a pump into operation once pump free of substances damaging to health or whether more it should be stored in a dry place it is contaminated. -

Page 21: Troubleshooting

Maintenance 3.10 Troubleshooting Fault Possible cause Remedy Repair* Pump does not Wiring is malfunctioning. Check and repair wiring. – start. Motor protection switch incorrectly set (3-phase motors only). Set motor protection switch properly. Operating voltage does not match motor. Replace the motor. Motor is malfunctioning. -

Page 22: Maintenance Plan

Maintenance 3.11 Maintenance Plan (Recommendation) Rotary vane pumps Measurement/test quantity Interval Remarks TRIVAC S/D 4 B Operating/auxiliary 6m a n-a VE VP Refer also to the Operating Instructions – Section: TRIVAC S/D 8 B materials individual components. Operate the pump for at least 0.8 Condensed water is thus removed from the oil. - Page 23 Maintenance Rotary vane pumps Measurement/test quantity Interval Remarks TRIVAC S/D 4 B Operating / auxiliary VE VP 6m a n-a Refer also to the Operating Instructions – Section: TRIVAC S/D 8 B materials individual components. Change the oil – Oil: N 62 or special and Oil change: alternative oils.

-

Page 24: Eec Declaration Of Conformity

EEC Declaration of Conformity We - LEYBOLD AG – herewith declare that the products The products conform to the following directives: defined below meet the basic requirements regarding • EEC Directive on Machinery (89/392/EWG) safety and health of the relevant EEC directives by and subsequent 91/368/EWG design, type and versions which are brought into circulation by us. - Page 25 Declaration of Contamination of Vacuum Equipment and Components The repair and/or service of vacuum equipment and components will only be carried out if a correctly completed declaration has been submitted. Non-completion will result in delay. The manufacturer could refuse to accept any equipment without a declaration.

- Page 26 We reserve the right to modify the design and the specified data. The illustrations are not binding. LEYBOLD AG Vakuum Bonner Straße 498 (Bayenthal) D-50968 Köln Telefon: (0221) 347-0 Telefax: (0221) 347-1250...

Need help?

Do you have a question about the TRIVAC S 4 B and is the answer not in the manual?

Questions and answers