SoundTraxx Tsunami2 TSU-2200 Installation Manual

Digital sound decoder

Hide thumbs

Also See for Tsunami2 TSU-2200:

- User manual (81 pages) ,

- User manual (76 pages) ,

- User manual (80 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for SoundTraxx Tsunami2 TSU-2200

- Page 1 Tsunami2 and Econami Digital Sound Decoder Installation Guide Rev.D 05/10/2017...

-

Page 2: Table Of Contents

The information in this document is subject to change without notice. SoundTraxx (Throttle Up! Corp.) shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or consequential damage resulting from the furnishing, performance or use of this material. -

Page 3: All Aboard

Refer to the Sound Selection References for a quick guide of CV values to adjust sound effects in each version. Refer to the SoundTraxx Guide to Successful Soldering for soldering tips and recommendations. To download all user documentation, visit www.soundtraxx.com/manuals.php. -

Page 4: Pre-Installation Considerations

All Aboard! Pre-Installation Considerations Carefully read the instructions that are printed on the decoder’s packaging. Then, finish reading this installation guide. While installing the decoder, keep these precautions in mind: Handle the decoder carefully in a Do not exceed the output ratings for static-free environment. -

Page 5: Tsunami2 And Econami Installation Guide

Drill bit assortment We have a variety of accessories to aid your installation. For more information about our full line of installation accessories, visit www.soundtraxx.com/access/index.php. Miniature Speakers, Baffles, and Gaskets: We have a variety of miniature speakers, baffles, and gasket kits for use with our digital sound decoders;... -

Page 6: Installation

Installation Installation Step 1. Test the Motor Stall Current Test the locomotive’s stall current to ensure that it is compatible with the decoder that you have chosen: 1. Place the locomotive on a section of track powered by a conventional DC powerpack set to the same track voltage as your command station (typically 12-14 volts). -

Page 7: Step 2. Plan The Installation

1” x 1” x 1” enclosure. Note: Employing a proper speaker enclosure cannot be emphasized enough; the absence of an effective enclosure is almost always the cause of poor sound SoundTraxx Speaker Baffle Kit quality. Tsunami2 and Econami Installation Guide... - Page 8 Installation Steam Locomotive Considerations Sound quality is greatly affected by speaker placement, which depends on the size and type of locomotive. The speaker will produce higher quality sound when fixed within an airtight enclosure with the front of the speaker facing open air. Most steam engines have a tender that can be used as an enclosure.

-

Page 9: Step 3. Isolate Motor And Lights From The Frame

Installation Step 3. Isolate Motor and Lights from the Frame Note: If you have a DCC-ready model with an NMRA 8-pin connector, NMRA 9-Pin “JST” connector, or 21-Pin “NEM” connector, proceed to page 15. To ensure only the decoder’s motor outputs are driving the two motor connections, isolate the motor connections from the locomotive frame, left rail, and right rail pickups. -

Page 10: Step 4. Modify The Tender Or Body Shell

Installation Step 4. Modify the Tender or Body Shell A certain amount of “bodywork” may be necessary to accommodate the speaker and sound system. This typically includes removing weights, mounting brackets, and internal bracing, as well as modifying other structural features. Steam Modification Installing a decoder in a steam locomotive often involves modifying the tender and tender floor. - Page 11 Installation Modify the Tender Floor Speakers can be located on the tender floor in many instances. Consider the following when mounting the speaker to the tender floor: 1. Determine the exact speaker location within the tender and verify that there is clearance between the tender body and speaker magnet.

-

Page 12: Step 5. Mount The Speaker

Fix the gasket to the speaker, and fix the speaker to the desired surface. Take care not to fix the gasket to the speaker cone. Figure 10: SoundTraxx Speaker Gasket Installation Tsunami2 and Econami Installation Guide... -

Page 13: Step 6. Install And Wire The Decoder

Note: Do not use SoundTraxx Digital Sound Decoders with speakers with a total impedance less than 8 ohms. Doing so may result in erratic operation, or even cause component failure. - Page 14 Refer to the wiring diagrams on page 21 for more information. Wire the decoder to LEDs SoundTraxx decoders support the use of LEDs wired in-series using 1K (1000) OHM, 1/4 watt resistors. Unlike incandescent bulbs, LEDs are sensitive to polarity: The negative (−) LED cathode (shorter lead) connects to...

- Page 15 9-pin plug. 3. Pull gently with even force applied to all 9 wires to remove the SoundTraxx wire harness from the decoder. 4. Plug the decoder into the NMRA 9-pin “JST” wire harness located in the model.

-

Page 16: Step 7. Test The Istallation

Installation Step 7. Test the Installation At this point, you should be ready for the test track. We recommend your test track be equipped with a fast-blow fuse appropriately rated for your decoder (1-amp decoder = 1-amp fuse). Test the installation according to the following: 1. -

Page 17: Wiring Diagrams

The TSU-1100 and ECO-100 both include an optional 220µF, 25V capacitor or may be used with a SoundTraxx CurrentKeeper to maintain performance during momentary power losses. To install a CurrentKeeper, remove the connector and trim the blue and black wires to about 3”. -

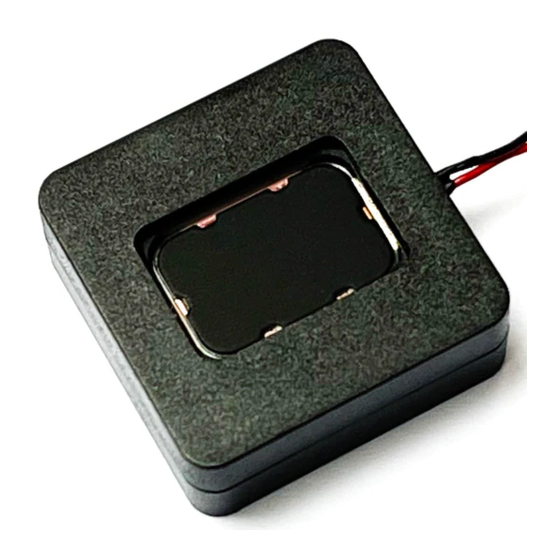

Page 18: Tsu-2200/Eco-200

Wiring Diagrams TSU-2200/ECO-200 The TSU-2200 and ECO-200 are considered to be “universal” style decoders for installation in a variety of models. These decoders are equipped with a NMRA 9-Pin “JST” plug for easy installation in many DCC ready models. Wires are color-coded according to the NMRA Standard (where applicable): Power, Motor, Headlight, and Backup Light Wires: Black: Left Rail Pickup Blue: Function Common (12V) -

Page 19: Tsu-21Pnem/Eco-21Pnem

In most cases, a CurrentKeeper may be soldered to the locomotive's factory-installed board to help maintain performance during momentary power interruptions. Please contact our Customer Support at (970) 259-0690 or support@soundtraxx.com for assistance with determining the correct soldering locations. Figure 22: TSU-21PNEM/ECO-21PNEM Wiring Diagram... -

Page 20: Tsu-Pnp/Eco-Pnp

Wiring Diagrams TSU-PNP/ECO-PNP Designed as a factory board replacement format decoder, the TSU-PNP and ECO-PNP both provide mounting points for many Athearn, Atlas, Bowser, Kato, and Intermountain Railway Co. HO scale models. Current Keeper Installation Plug the CurrentKeeper wire harness directly into the 2-pin socket located next to the motor connections on the decoder. -

Page 21: Tsu-4400/Eco-400

Wiring Diagrams TSU-4400/ECO-400 Wiring the TSU-4400 and the ECO-400 is done by way of two terminal blocks on the circuit board. Use a small flathead screwdriver to loosen the screws on the top of the block. If necessary, trim any excess length from the wires to prevent them from interfering with installation. - Page 22 Tsunami2 and Econami Installation Guide...

Need help?

Do you have a question about the Tsunami2 TSU-2200 and is the answer not in the manual?

Questions and answers