Table of Contents

Advertisement

Industrial Standard

'IS13-5530'

Gas Engine

Air Compressor

Installation,

Maintenance,

And

Service Data

DV Systems Inc. - Canada

490 Welham Road

Barrie, ON

L4N 8Z4

Tele:

(705) 728-5657

Fax:

(705) 728-4974

Contents:

Web:

www.dvcompressors.com

Email: sales@dvcompressors.com

- 1 -

Please read this manual before

installing or using your Air

Compressor Unit. It contains

valuable information that will

help in the receiving,

installation, use, and

maintenance of the Unit.

Please keep this manual in a

safe place for future reference.

All of the information, policies, and

procedures in this reference manual apply

exclusively to DV Systems.

DV Systems Inc. - US

128-B Talbert Road

Mooresville, NC

28117

Tele:

Fax:

SDIG

Feb '15

Page:

2

3

4

5

6

7

8

9

9

10

11-14

14

15

(704) 799-0046

(704) 799-0355

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for DV Systems IS13-5530

-

Page 1: Table Of Contents

Please keep this manual in a safe place for future reference. All of the information, policies, and procedures in this reference manual apply exclusively to DV Systems. DV Systems Inc. - Canada DV Systems Inc. - US 490 Welham Road 128-B Talbert Road Barrie, ON... -

Page 2: Quick Start

SDIG Feb ‘15 Quick Start Mechanical Installation. (Refer to Page 7) These Units are used in applications where electrical power is not readily available. The most popular use of this type of Compressor is on service trucks, trailers, etc. As the airflow is from the Beltguard forward over and around the Pump, ensure that there is sufficient space behind the Beltguard to allow cooling of the Unit. -

Page 3: Safety Precautions

SDIG Feb ‘15 Safety Precautions In order to operate the Compressor Unit safely and correctly, we have opted to use the following symbols to make you aware of important points. These points relate to user safety and preventing equipment problems. Please pay close attention to these sections. -

Page 4: Preventative Maintenance Schedule

Noted below are general maintenance guidelines which must be followed and documented, this in accordance with the DV Systems Warranty. It is based on an approximate Compressor usage of 30 hours per week. If your particular application varies from this, please adjust accordingly. -

Page 5: Unpacking And Inspection

Shipments of DV Systems products are the property of the Consignee when the products leave our facility. DV Systems Inc. is not responsible for any damages or shortages caused to the product after it has left our shipping dock. -

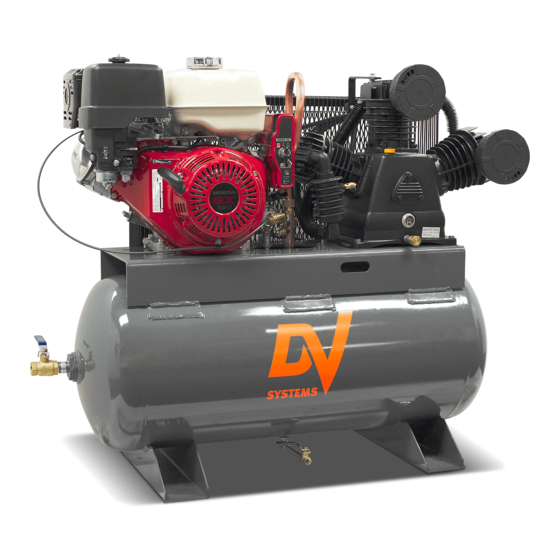

Page 6: Compressor Parts

SDIG Feb ‘15 Compressor Parts Please refer to the picture below, as it identifies the major components of the ‘IS13-5530’ style Air Compressor Unit and their function. (Base mounted Units do not have a Tank.) CT-9751 PB-21175003 Aftercooler Tube Air Filter Assembly... -

Page 7: Installation - Mechanical

Compressor. The Compressor must sit squarely on the floor. DV Systems has available a ‘UDH-9700-K4’ Kit consisting of (4) Vibration Isolator Pads to be placed under the Unit to absorb vibration. -

Page 8: Lubrication

Serious damage may result from use, however limited, without oil. Use only DV Systems Premium Compressor Oil. Also, do not mix the DV Systems oil with any other lubricant. Oil Changes. Drain the existing oil from the Unit. Running the Unit prior to draining the oil will ensure that the oil will drain relatively quickly. -

Page 9: Honda Engines

SDIG Feb ‘15 Honda Engines General Information. The 13 HP ‘TASE’ Gas Engine Compressor Units are As indicated below, the Honda Engine can be driven by means of a Honda Engine. The Engines have started by either: proven to be very reliable over the years and are a) a Recoil Starter (manual). -

Page 10: Start-Up Procedures

Unit to operate in this fashion for 30 minutes. This lubricates the Pistons, Bearings, and all internal surfaces. During the first few days of operation, check the Unit periodically to ensure it is running smoothly. Should you have any concerns, contact your DV Systems Distributor. - 10 -... -

Page 11: Trouble-Shooting Guide

Compressor Unit unless you are familiar with it, as there are many issues that may come into play, the most important being personal safety and the welfare of the Unit. Should you have any questions, or require servicing to your Unit, please contact your local DV Systems Distributor. - Page 12 Normal sound amplified through floor. Mount Unit on Vibration Pads. Improper level or grade of oil in Pump. Use correct DV Systems oil, and check that level is correct. Carbon or other foreign material on Piston Clean top of Piston. Check Cylinder walls for head.

- Page 13 SDIG Feb ‘15 Trouble Shooting Guide (cont’d) Condition: Cause: Suggested Correction: G. Compressor Over- Undersized Unit for air requirements. Maximum operating time, based on an 8 hour heating. day, is 60%, which relates to approximately 35 minutes per hour. Dirt accumulation on outside of Pump. Clean Pump.

-

Page 14: Check Valve / Unloader Calibration

SDIG Feb ‘15 Trouble Shooting Guide (cont’d) Condition: Cause: Suggested Correction: K. Oil Leaks or the Oil was spilled when filling the Pump. Use care when filling with oil. Wipe any spills Appearance of Oil on the immediately. Compressor. Over-filling of the Pump with oil. Drain oil until proper level is reached. -

Page 15: Dv Systems Limited Warranty

In order to make a claim under this Warranty, the customer must first call DV Systems Warranty Department at the number shown on this warranty.

Need help?

Do you have a question about the IS13-5530 and is the answer not in the manual?

Questions and answers