Isuzu 4LE2 Owner's Manual

Tier 4/stage 3b

Hide thumbs

Also See for 4LE2:

- Instruction manual (48 pages) ,

- Workshop manual (121 pages) ,

- Workshop manual (872 pages)

Table of Contents

Summary of Contents for Isuzu 4LE2

- Page 1 BLACK DIC252 4 mm (0.08 mm) PICTORIAL INDEX INFORMATION 4LE2 IMPORTANT INFORMATION TIER 4/STAGE 3B OWNER’S MANUAL HANDLING OF ENGINE HANDLING IN COLD SEASON INSPECTION AND MAINTENANCE IN CASE OF EMERGENCY MAIN DATA INDEX No.IDE-6450A Printed in Japan IDE-6450A_4500781_Cover.indd 1 IDE-6450A_4500781_Cover.indd 1...

- Page 2 We recommend that you also read the separate instructions for the equipment on your vehicle that was installed by your Isuzu Distributor. • Your Isuzu Distributor will be glad to answer any questions you may have about the information in this manual. Notes on Reading This Manual •...

- Page 3 Symbols Used in This Manual DANGER Failure to follow these instructions identified by this symbol could result in death or serious injury to you and/or other people. WARNING Failure to follow these instructions identified by this symbol could result in death or severe injury/engine fire.

- Page 4 IDE-6450A_4500781_ALL.indd 2 IDE-6450A_4500781_ALL.indd 2 2014/04/18 14:19:46 2014/04/18 14:19:46...

- Page 5 HOW TO USE THIS MANUAL AND HOW TO FIND A SPECIFIC TOPIC ● HOW TO USE THIS MANUAL ● HOW TO FIND A SPECIFIC TOPIC ● CHAPTER DESCRIPTION ● PICTORIAL INDEX IDE-6450A_4500781_ALL.indd 0-1 IDE-6450A_4500781_ALL.indd 0-1 2014/04/18 14:19:46 2014/04/18 14:19:46...

- Page 6 HOW TO USE THIS MANUAL Chapter index tab Chapter/section titles Use this for quick access to These titles are useful for getting the gist of the your desired chapter. content at a glance. IMPORTANT INFORMATION Before Operating the Engine Perform Daily (Pre-Operating) Inspections Before Operation Daily (Pre-Operating) Inspection Refer to Page...

- Page 7 HOW TO FIND A SPECIFIC TOPIC Use chapter/section titles as keys Page 0-5 Search for the page describing the specific topic by using the general table of contents under CHAPTER DESCRIPTION, the CHAPTER INDEX, and/or the TABLE OF CONTENTS on the first page of each chapter.

- Page 8 IDE-6450A_4500781_ALL.indd 0-4 IDE-6450A_4500781_ALL.indd 0-4 2014/04/18 14:19:46 2014/04/18 14:19:46...

-

Page 9: Table Of Contents

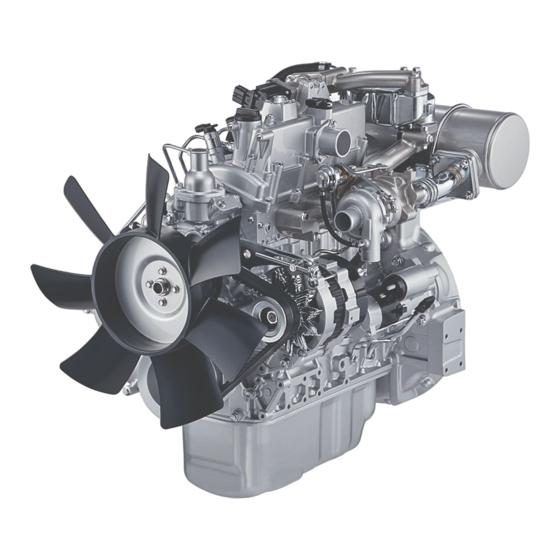

CHAPTER DESCRIPTION PICTORIAL INDEX ····································· 0-6 INFORMATION ··············································· 1 IMPORTANT INFORMATION ························ 2 Describes what you should know before you operate the engine safely and smoothly. HANDLING OF ENGINE ································ 3 Explains how to start and stop the engine and describes various switches. HANDLING IN COLD SEASON ····················... - Page 10 PICTORIAL INDEX Exterior Reference Reference Equipment Equipment Page Page Turbocharger Water drain plug 5-19 Starter 5-31 Oil drain plug 5-10 Oil dipstick Generator 5-31 Some equipment and part shapes may vary depending on engine model and specification. IDE-6450A_4500781_ALL.indd 0-6 IDE-6450A_4500781_ALL.indd 0-6 2014/04/18 14:19:46 2014/04/18 14:19:46...

- Page 11 PICTORIAL INDEX Reference Reference Equipment Equipment Page Page EGR valve ― Crank pulley ― Injector ― Supply pump ― Common rail ― Supply pump strainer 5-25 Some equipment and part shapes may vary depending on engine model and specification. IDE-6450A_4500781_ALL.indd 0-7 IDE-6450A_4500781_ALL.indd 0-7 2014/04/18 14:19:46 2014/04/18 14:19:46...

- Page 12 PICTORIAL INDEX IDE-6450A_4500781_ALL.indd 0-8 IDE-6450A_4500781_ALL.indd 0-8 2014/04/18 14:19:47 2014/04/18 14:19:47...

- Page 13 INFORMATION ● Isuzu Genuine Parts ● Warranty ● Engine Number/Emission Label/Special Vehicle Labels ● Exhaust Emission Regulation Related Parts IDE-6450A_4500781_ALL.indd 1-1 IDE-6450A_4500781_ALL.indd 1-1 2014/04/18 14:19:47 2014/04/18 14:19:47...

- Page 14 Isuzu. For parts and oils required for maintenance and service, use "Isuzu genuine parts". Isuzu shall not be responsible for any failure or accident that is caused by use of parts other than "Isuzu genuine parts".

- Page 15 INFORMATION Engine Number/Emission Label/Special Vehicle Labels • If any of these labels is smudged, damaged, or peeled, contact an Isuzu Distributor. • For the labels on the machine side, refer to the instruction manual from the relevant manufacturer. • Some examples of these labels are indicated below, but there are many others not shown.

- Page 16 INFORMATION Emission Labels It is attached to the intake chamber. The emission labels on the engine indicate very important instructions and information that you should respect to ensure safe and proper use of the engine. Be sure to read them before using the engine.

- Page 17 ● Staying Safe 2-11 ● Preventing Engine Failure 2-12 ● When to Visit an Isuzu Distributor 2-13 As this chapter contains information and cautions that should be observed in order for safe and problem-free engine operation, be sure to read it before operating the engine.

-

Page 18: Using Fuel Other Than Extra-Low-Sulfur Diesel Fuel (With Sulfur Content Of

IMPORTANT INFORMATION Before Operating the Engine Perform Daily (Pre-Operating) Inspections Before Operation Daily (Pre-Operating) Inspection → Refer to Page Fuel, Lubricant and Coolant Use the Specified Fuel CAUTION • Using fuel other than extra-low-sulfur diesel fuel (with sulfur content of 15 ppm or lower) may have a harmful effect on the engine, possibly resulting in a breakdown. -

Page 19: Important Information

IMPORTANT INFORMATION ADVICE • For fuel of diesel engine, the following characteristics are required. Use a type of extra-low-sulfur diesel fuel designated for general diesel vehicles which satisfies these requirements. No fine dust is contained. Appropriate degree of viscosity is provided. High in cetane value. - Page 20 The use of un esterified bio-oils blended into diesel fuel at any concentration is not approved by Isuzu and could damage your fuel system and engine.

- Page 21 IMPORTANT INFORMATION Handling the Fuel WARNING • Be sure to place the starter switch in the "OFF" position to shut down the engine before refueling the machine because refueling while the engine is running may cause a fire. • When refueling, putting any flame nearby is strictly prohibited. Do not place a lighted cigarette or something similar nearby which may result in a fire.

- Page 22 Replace the engine coolant periodically. In the cold season, to prevent the engine damage or accident due to freezing of the coolant, the Isuzu genuine long-life coolant (LLC) is available at Isuzu Distributors. Take advantage of this product. Replacing the Coolant →...

- Page 23 IMPORTANT INFORMATION Operating the Engine Keep Flammable Material Away from the Engine CAUTION • While the engine is running or immediately after engine operation, the exhaust pipe is extremely hot. Make sure that there is no flammable item such as plants, dried grass, paper waste, oil or old tire nearby.

- Page 24 IMPORTANT INFORMATION If the Engine Has not Been Used for a Long Period ADVICE • Perform a thorough inspection before starting an engine that has not been run for a long period of time (one month or longer). Also, confirm that there is no oil leakage and the oil has been sufficiently added to the specified level.

- Page 25 When abnormalities such as holes or cracks caused by corrosion and damaged joints are found on the exhaust pipe, have it inspected/serviced at the nearest Isuzu Distributor. Continuous use of the exhaust pipe without having the defect repaired is dangerous as the exhaust gas may leak, causing carbon monoxide poisoning.

- Page 26 2-10 IMPORTANT INFORMATION Do not Turn Off the Engine While the Machine is Running WARNING • Do not place the starter switch to any position other than the "DRIVE" position while running the machine. If the engine is stopped while running the machine, the engine may be damaged.

- Page 27 2-11 IMPORTANT INFORMATION When the Warning Light Comes On ADVICE • Continuing to operate the engine while ignoring any warning lights that have come on is dangerous and may result in engine damage or failure. Always perform the necessary inspections. Staying Safe When the Engine Coolant is Hot WARNING...

- Page 28 2-12 IMPORTANT INFORMATION If the Battery Goes Flat CAUTION • When charging the battery from an external power source, remove the battery cables to protect the generator. When the Battery Goes Flat → Refer to Page Preventing Engine Failure Do not Climb onto the Engine ADVICE •...

- Page 29 Attaching a part that is not suitable for the performance or function of the machine may lead to an unexpected breakdown or accident. Please consult the Isuzu Distributor for adjustment of the engine or installation of the equipments. Ask an Isuzu Distributor for Engine Adjustment CAUTION •...

- Page 30 Isuzu Distributor. ADVICE • in the "Corrective Action" column indicates that the failure requires a repair or adjustment, so contact the nearest Isuzu Distributor. Reference Symptom Cause Corrective Action...

-

Page 31: Handling Of Engine

HANDLING OF ENGINE ● Starting the Engine ● Inspection Method After the Engine Started ● Stopping the Engine ● Handling the Engine with Turbocharger IDE-6450A_4500781_ALL.indd 3-1 IDE-6450A_4500781_ALL.indd 3-1 2014/04/18 14:19:52 2014/04/18 14:19:52... - Page 32 HANDLING OF ENGINE Starting the Engine Starting Preparation 1. Before starting the engine, confirm that the DRIVE DRIVE machine is not set to the operation/driving START START mode and each switch such as for the windshield wiper, lighting, and air conditioner AUTO RETURN AUTO RETURN on the machine side is turned to "OFF".

- Page 33 HANDLING OF ENGINE CAUTION • Do not perform the starting operation while the preheat indicator light is on. 3. After confirming that the preheat indicator light has gone out, turn the starter switch to the "START" position to start the engine. 4.

- Page 34 HANDLING OF ENGINE Inspection Method After the Engine Started Avoid a quick increase of engine speed or load immediately after the engine is started. First, idle the engine for about 10 minutes, and then check the operating status of instruments and warning lights. Also, check for abnormal vibration from the engine, noise, and the conditions of smell and color in the exhaust gas.

- Page 35 The oil pressure warning light flashes or comes on • When the oil level is normal and no oil leak is found, a failure in the hydraulic system can be suspected. Promptly consult an Isuzu Distributor. Engine Warning Light/Engine Failure Code CAUTION •...

- Page 36 • If an abnormality is found in the engine sound or the color of exhaust smoke, immediately contact an Isuzu Distributor. Abnormal Noise of Engine • Listen to the engine sound carefully, and if an abnormal noise is heard, check the engine and identify the possible cause.

- Page 37 HANDLING OF ENGINE Coolant Temperature Both too high and too low temperatures of the coolant can cause an engine malfunction. The temperature in the range of approx. 75 - 90°C (167 - 194°F) is suitable. When the engine coolant temperature gauge reads an value exceeding the appropriate temperature, or when the coolant temperature warning light comes on, an dangerous condition of substantially heated engine can be suspected.

- Page 38 HANDLING OF ENGINE Stopping the Engine 1. Confirm that the machine is not set to the operation/driving mode. 2. Before stopping the engine, decrease the engine speed to the idling speed to cool down for approx. 3 minutes. During this cooling down period, check for an abnormality in the engine sound, oil pressure, etc.

- Page 39 HANDLING OF ENGINE Handling the Engine with Turbocharger Starting the Engine For the engine starting operation, refer to "Starting the Engine". ADVICE • When the engine is cold, do not rev the engine while in the neutral position. Starting the Engine →...

- Page 40 3-10 HANDLING OF ENGINE IDE-6450A_4500781_ALL.indd 3-10 IDE-6450A_4500781_ALL.indd 3-10 2014/04/18 14:19:56 2014/04/18 14:19:56...

-

Page 41: Handling In Cold Season

HANDLING IN COLD SEASON ● Cautions for Use in Cold Regions and Seasons IDE-6450A_4500781_ALL.indd 4-1 IDE-6450A_4500781_ALL.indd 4-1 2014/04/18 14:19:56 2014/04/18 14:19:56... - Page 42 • When the coolant temperature does not rise after the engine is warmed up, have the thermostat inspected at the nearest Isuzu Distributor. • In an area with heavy snow, the snow accumulated around the machine may cause bad ventilation.

- Page 43 HANDLING IN COLD SEASON Replacing the Engine Oil Use an engine oil with a viscosity adequate to the outside temperature as engine oils will thicken with low outside temperatures, resulting in starting difficulties. Selecting the Engine Oil → Refer to Page Replacing the Engine Oil →...

- Page 44 HANDLING IN COLD SEASON ADVICE • Do not use home heating oil or gasoline in your diesel engine; either may cause engine damage. The addition of kerosene will not unplug a filter plugged with wax. Warming a "waxed" filter to a temperature of 0°C to 10°C (32°F to 50°F) will return the wax to solution. Filter replacement is not normally required.

- Page 45 HANDLING IN COLD SEASON Storage in Cold Regions When storing the engine in cold regions, make sure that coolant and engine oil are in conditions suitable to the environment. Also, when starting the engine after it has been stored, make sure that there is no snow or foreign matter that could interfere with engine startup, and that rotating parts are not frozen.

- Page 46 HANDLING IN COLD SEASON IDE-6450A_4500781_ALL.indd 4-6 IDE-6450A_4500781_ALL.indd 4-6 2014/04/18 14:19:57 2014/04/18 14:19:57...

-

Page 47: Inspection And Maintenance

INSPECTION AND MAINTENANCE ● Precautions for Inspections and Adjustments ● Discarded Parts, Oils and Other Liquids ● Isuzu Genuine Oils and Grease ● Daily (Pre-Operating) Inspection ● Inspecting Components that Showed Abnormalities During Previous Operation ● Engine Conditions ● Engine Oil ●... -

Page 48: California Proposition 65 Warning

INSPECTION AND MAINTENANCE Precautions for Inspections and Adjustments WARNING • Select a place with flat and firm ground for performing maintenance. Otherwise, unpredictable injuries may occur. • Make sure to stop the engine and pull out the starter key. • When performing works with the electrical system, make sure to disconnect the negative (-) battery terminal. - Page 49 • Discarded parts, oil, grease and fluids could have an adverse effect on the environment. It is difficult to dispose of these properly, so have an Isuzu Distributor handle all inspections and replacements. When changing the oil, filter, or coolant, prepare a pan in which to discharge any fluids.

- Page 50 When an inspection reveals an abnormality or when an abnormality was found while operating the engine on the previous day or time, have the machine repaired at an Isuzu Distributor before the next operation. Daily (Pre-Operating) Inspection List [1. Inspecting components that showed abnormalities during the previous...

- Page 51 Inspecting Components that Showed Abnormalities During Previous Operation Check the components that showed abnormalities during the previous operation. Have the location with the abnormality repaired at the nearest Isuzu Distributor before the next operation. Engine Conditions Periodic Inspection and Maintenance List →...

-

Page 52: Engine Oil Viscosity

Selecting the Engine Oil As for the engine oil, use the Isuzu genuine low-ash engine oil or those equivalent to the oils specified below. When planning to use any other engine oil, contact the machine manufacturer or an Isuzu Distributor. - Page 53 INSPECTION AND MAINTENANCE Oil Identification Logo (for United States and Canada Only) A logo (symbol) is used on most oil containers to help you select the oil you should use. The top portion of the logo shows the oil quality by API designations such as CJ-4 or others.

- Page 54 INSPECTION AND MAINTENANCE ADVICE • Insert the oil dipstick while being careful not to use excessive force. Failure to do so may cause deformation of the oil dipstick. Adding the Engine Oil WARNING • When adding oil, be careful not to spill any, but keep a workshop rag handy just in case there are any spills.

- Page 55 INSPECTION AND MAINTENANCE Replacing the Engine Oil WARNING • When adding oil, be careful not to spill any, but keep a workshop rag handy just in case there are any spills. If any oil should spill onto the engine, carefully wipe it away as it may cause a fire.

- Page 56 5-10 INSPECTION AND MAINTENANCE 6. Remove the oil dipstick and carefully fill the specified engine oil into the oil filler. 7. Install the oil dipstick and the oil filler cap, and start the engine 5 minutes after refueling, and then let it idle. At this time, check whether any oil leak is found around the oil filter and oil drain cock.

- Page 57 The engine oil filter has the function of removing the dirt, dust and other impurities mixed into the engine oil. The engine filter has a significant impact on the performance and service life of the engine, so use of the "Isuzu genuine parts" is recommended.

- Page 58 5-12 INSPECTION AND MAINTENANCE 1. Clean around the oil filler cap so that foreign matter does not enter. Remove the oil filler cap. 2. Place a container for receiving the oil beneath the oil pan and the oil filter. 3. Remove the oil drain plug to discharge the oil.

- Page 59 When a bad quality belt is used as a replacement, a trouble such as abnormal noise generation, engine stop and insufficient battery charging may be caused due to belt rapid wear or belt breakage. When replacing the generator drive belt, it is recommended to use the "Isuzu genuine parts". Periodic Inspection and Maintenance List →...

- Page 60 5-14 INSPECTION AND MAINTENANCE Inspecting the Generator Drive Belt Press the center of the belt with a hand, and check whether the belt deflects only slightly. Also, check the belt for a damage. Measurement of Deflection Amount and Vibration Frequency Press the middle of the belt with a force of 98 N (approx.

- Page 61 5-15 INSPECTION AND MAINTENANCE Mounting bolt tightening torque 8M bolt 23.5 N·m (2.4 kgf·m/17 lb·ft) 10M bolt 48.0 N·m (4.9 kgf·m/35 lb·ft) 4. After the adjustment, run the engine at the idling speed for approx. 5 minutes, and then stop the engine to recheck the belt tension. Replacing the Generator Drive Belt 1.

- Page 62 Handling the Long-life Coolant To prevent the engine damage due to freezing of the coolant and to protect the cooling system from corrosion, mix the Isuzu specified long-life coolant (LLC) and tap water with an appropriate ratio. Long-life coolant...

- Page 63 As for the long-life coolant (LLC), make sure to use either BESCO LLC SUPER TYPE E or BESCO LLC SUPER TYPE AS. • When the long-life coolant which is specified by Isuzu is not used, the engine, radiator or heater core may be damaged. ADVICE •...

- Page 64 Inspect the radiator and radiator hose for a crack, damage and water leakage. Also, check whether water leakage stains have been left on the ground surface where the machine is set. When a crack, damage or water leakage is found, contact an Isuzu Distributor.

-

Page 65: Draining The Cooling System

5-19 INSPECTION AND MAINTENANCE Draining the Cooling System 1. Remove the radiator cap. 2. Open the coolant drain cock on the radiator to discharge the coolant. 3. Loosen the water drain plug located on the left side of the cylinder block, and discharge the coolant inside the engine. -

Page 66: Filling The Cooling System

5-20 INSPECTION AND MAINTENANCE Filling the Cooling System 1. Close the radiator drain cock and the engine Air bleeder plug Air bleeder plug water drain plug. 2. From the radiator water inlet, slowly add the coolant up to the filler opening. To avoid air intrusion, the coolant should be supplied slowly. - Page 67 The fuel filter has the function of removing debris or moisture in the fuel. The fuel filter has a significant impact on the performance and service life of the engine and fuel economy, so use of the "Isuzu genuine parts" is recommended. Also, depending on the machine, an electromagnetic fuel pump which incorporates a fuel filter may be equipped.

- Page 68 5-22 INSPECTION AND MAINTENANCE Draining Water from the Fuel Filter The fuel filter has the structure of that the internal float floats up when water is deposited inside. When the float floats up to the bottom of the cartridge, make sure to remove the water.

- Page 69 5-23 INSPECTION AND MAINTENANCE Bleeding the Fuel System When air mixes into the fuel system, this can cause a difficulty in engine starting or engine malfunction. When the fuel tank is emptied, or when water removal from fuel or filter element replacement is performed, make sure to carry out air removal. 1.

- Page 70 5-24 INSPECTION AND MAINTENANCE Changing the Fuel Filter ADVICE • When replacing the filter, also replace Air bleeder Air bleeder the O-ring with the one supplied with the plug plug element kit. • Disposal and treatment of the replaced Filter body Filter body filter must be conducted in accordance with the specified procedure.

- Page 71 5-25 INSPECTION AND MAINTENANCE 3. Replace the O-ring of the case and drain plug with new ones, place the new element in the case, thinly apply the fuel on the O-ring, and screw in the element. When the O-ring contacts the seal surface, tighten with the special filter wrench.

- Page 72 5-26 INSPECTION AND MAINTENANCE Electromagnetic Fuel Pump Replacing or Cleaning the Filter The electromagnetic fuel pump may be equipped depending on the machine. The filter inside the pump is either paper type or steel mesh type. When filter replacement is required, contact the machine manufacturer. Also, for the replacement or cleaning periods of each type, refer to the periodic inspection and maintenance list.

- Page 73 5-27 INSPECTION AND MAINTENANCE • As for the paper type, replace the filter and gasket with new ones. • For the steel mesh type, clean the removed filter with clean diesel fuel, and blow off the dirt and other impurities using high-pressured air.

- Page 74 The following items are the inspection and maintenance items that enable smooth and long-term use of the engine and require specialized maintenance techniques. In accordance with the periodic inspection and maintenance list, consult the machine manufacturer or the nearest Isuzu Distributor periodically for inspection and adjustment. ADVICE •...

- Page 75 5-29 INSPECTION AND MAINTENANCE Adjusting the Valve Clearance Perform periodic inspections and cleanings in accordance with the periodic inspection and maintenance list. Also, perform an inspection and maintenance when the sound of rocker arm is loud or when the engine is not working well without a failure in the fuel system.

- Page 76 5-30 INSPECTION AND MAINTENANCE No. 1 cylinder top dead center of the compression stroke Exhaust Intake Exhaust Intake Exhaust Intake Exhaust Intake No. 4 cylinder top dead center of the compression stroke Exhaust Intake Exhaust Intake Exhaust Intake Exhaust Intake 4.

- Page 77 5-31 INSPECTION AND MAINTENANCE Measuring the Engine Compression Pressure This should be performed at periodic inspections or when the engine output has dropped. Periodic Inspection and Maintenance List → Refer to Page 5-36 Compression pressure* 3.04 MPa (31.0 kgf/cm²/441 psi) * Measurement should be taken under the conditions of cranking speed 250 rpm and coolant temperature 70 - 85°C (158 - 185°F).

- Page 78 5-32 INSPECTION AND MAINTENANCE Battery The battery has the function to operate the various lights and many electric accessories including the engine startup. For inspection and replacement, consult the machine manufacturer. Periodic Inspection and Maintenance List → Refer to Page 5-36 Battery Handling Precautions Keep the battery always clean.

- Page 79 5-33 INSPECTION AND MAINTENANCE WARNING • Make sure to stop the engine when inspecting the battery. • The battery fluid is diluted sulfuric acid. Be extremely careful not to let the fluid get on your hands, clothes, or metals. If it happens, wash the fluid away with water immediately.

- Page 80 Especially in winter, the battery fluid may freeze causing a damage to the battery case. • If reduction in the battery fluid is drastic, immediately have it inspected at an Isuzu Distributor. IDE-6450A_4500781_ALL.indd 5-34 IDE-6450A_4500781_ALL.indd 5-34 2014/04/18 14:20:07...

- Page 81 5-35 INSPECTION AND MAINTENANCE Inspecting the Specific Gravity of Battery Fluid Check the specific gravity of the battery fluid using a hydrometer. When the specific gravity is low, then charge the battery. Hydrometer Hydrometer Specific gravity of fluid (When the fluid temperature is 20°C (68°F)) 1.270 - 1.290 Conversion of Specific Gravity Measurement of specific gravity should be taken...

- Page 82 5-36 INSPECTION AND MAINTENANCE Periodic Inspection and Maintenance List In order to maintain safe and economical engine operation, performance of periodic inspection and maintenance is recommended. ADVICE • After 1500 hours, perform inspection and maintenance for every 250 hours or 500 hours in accordance with this table.

- Page 83 5-37 INSPECTION AND MAINTENANCE Fuel System Inspection/Maintenance 1000 1250 1500 Daily Remarks Item hours hours hours hours hours hours Fuel leak Water removal from fuel Replacing the fuel filter Every 500 hours element Inspecting and cleaning Every 500 hours the supply pump strainer Replacing the electromagnetic pump Every 500 hours...

- Page 84 As specified by maintenance the cooling the machine system manufacturer Inspecting the As specified by functionality of radiator the machine cap* manufacturer * : When performing inspection or maintenance, consult an Isuzu Distributor. IDE-6450A_4500781_ALL.indd 5-38 IDE-6450A_4500781_ALL.indd 5-38 2014/04/18 14:20:09 2014/04/18 14:20:09...

- Page 85 (blower cleaning as turbocharger necessary) Inspecting and cleaning Every 3000 hours the EGR valve Inspecting and cleaning Every 1500 hours the EGR cooler * : When performing inspection or maintenance, consult an Isuzu Distributor. IDE-6450A_4500781_ALL.indd 5-39 IDE-6450A_4500781_ALL.indd 5-39 2014/04/18 14:20:09 2014/04/18 14:20:09...

- Page 86 As specified by Inspecting the wiring and the machine connections manufacturer Preheating status Inspection the engine Every 3000 hours controller (ECM) * : When performing inspection or maintenance, consult an Isuzu Distributor. IDE-6450A_4500781_ALL.indd 5-40 IDE-6450A_4500781_ALL.indd 5-40 2014/04/18 14:20:09 2014/04/18 14:20:09...

- Page 87 Every 1000 hours 0.40 mm (0.016 in) Inspecting and adjusting for both intake and the valve clearance* exhaust (in cold engine) * : When performing inspection or maintenance, consult an Isuzu Distributor. IDE-6450A_4500781_ALL.indd 5-41 IDE-6450A_4500781_ALL.indd 5-41 2014/04/18 14:20:09 2014/04/18 14:20:09...

- Page 88 5-42 INSPECTION AND MAINTENANCE IDE-6450A_4500781_ALL.indd 5-42 IDE-6450A_4500781_ALL.indd 5-42 2014/04/18 14:20:09 2014/04/18 14:20:09...

- Page 89 IN CASE OF EMERGENCY ● Cause of Failure and Corrective Action ● When the Battery Goes Flat ● When the Fuel Runs Out IDE-6450A_4500781_ALL.indd 6-1 IDE-6450A_4500781_ALL.indd 6-1 2014/04/18 14:20:09 2014/04/18 14:20:09...

- Page 90 Isuzu Distributor. ADVICE • in the "Corrective Action" column indicates that the failure requires a repair or adjustment, so contact the nearest Isuzu Distributor. Reference Symptom Cause Corrective Action...

- Page 91 IN CASE OF EMERGENCY Reference Symptom Cause Corrective Action Page Remove moisture and 5-22 Clogging of the fuel filter replace the element 5-24 Clogging of the pre-fuel Clean or replace the ― filter element The engine starts, Failure of the engine ―...

- Page 92 IN CASE OF EMERGENCY Reference Symptom Cause Corrective Action Page No coolant Refill ― Front of the radiator is Perform cleaning 5-21 clogged with debris Tighten it securely or Reserve tank cap not fully replace the cap with a ― tightened new one Overheat occurs...

- Page 93 When connecting the jumper cables, the clips should not be put in contact with one another. • Ask an Isuzu Distributor to recharge the battery. • Do not disconnect a battery terminal with the engine running. Doing so could cause a failure in the electrical system.

- Page 94 IN CASE OF EMERGENCY For 12V Disabled machine Machine with booster batteries Use the machine frame as the ground Negative side jumper cable Positive side jumper cable For 24V Disabled machine Machine with booster batteries Use the machine frame as the ground Negative side jumper cable Positive side jumper cable WARNING...

- Page 95 IN CASE OF EMERGENCY When the Fuel Runs Out Since air enters in the fuel system when the fuel filter is replaced or the fuel runs out, simply supplying the fuel cannot start the engine. Remove the air from the fuel system.

- Page 96 IN CASE OF EMERGENCY IDE-6450A_4500781_ALL.indd 6-8 IDE-6450A_4500781_ALL.indd 6-8 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 97 MAIN DATA ● Main Data and Specifications IDE-6450A_4500781_ALL.indd 7-1 IDE-6450A_4500781_ALL.indd 7-1 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 98 MAIN DATA Main Data and Specifications Engine AP-4LE2 Specifications 4-cycle, Water-cooled type, In-line four-cylinder, Overhead valve type, Intercooler specification, Turbocharger equipped engine Number of cylinders - Inner diameter x Travel mm (in) 4 - 85 × 96 (3.35 × 3.78)

-

Page 99: Index

Fuel, Lubricant and Coolant Warranty When the Battery Goes Flat When the Fuel Runs Out Generator Drive Belt 5-13 When to Visit an Isuzu Distributor 2-13 Handling the Engine with Turbocharger 3-9 IDE-6450A_4500781_ALL.indd 8-1 IDE-6450A_4500781_ALL.indd 8-1 2014/04/18 14:20:10 2014/04/18 14:20:10... - Page 100 MEMO IDE-6450A_4500781_ALL.indd 8-2 IDE-6450A_4500781_ALL.indd 8-2 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 101 MEMO IDE-6450A_4500781_ALL.indd 8-3 IDE-6450A_4500781_ALL.indd 8-3 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 102 MEMO IDE-6450A_4500781_ALL.indd 8-4 IDE-6450A_4500781_ALL.indd 8-4 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 103 MEMO IDE-6450A_4500781_ALL.indd 8-5 IDE-6450A_4500781_ALL.indd 8-5 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 104 MEMO IDE-6450A_4500781_ALL.indd 8-6 IDE-6450A_4500781_ALL.indd 8-6 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 105 MEMO IDE-6450A_4500781_ALL.indd 8-7 IDE-6450A_4500781_ALL.indd 8-7 2014/04/18 14:20:10 2014/04/18 14:20:10...

- Page 106 MEMO IDE-6450A_4500781_ALL.indd 8-8 IDE-6450A_4500781_ALL.indd 8-8 2014/04/18 14:20:10 2014/04/18 14:20:10...

Need help?

Do you have a question about the 4LE2 and is the answer not in the manual?

Questions and answers