Isuzu 4LE2 Workshop Manual

Diesel engine

Hide thumbs

Also See for 4LE2:

- Owner's manual (107 pages) ,

- Instruction manual (48 pages) ,

- Workshop manual (121 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Isuzu 4LE2

- Page 1 4LE2 TIER 4/STAGE Ⅲ B EXHAUST EMISSION STANDARDS WORKSHOP MANUAL ENGINE...

- Page 2 FOREWORD This manual describes the service procedures for the 4LE2 diesel engine (Tier 4/Stage Ⅲ B compatible). The contents of this manual are current at the date of issue, but may differ slightly from your engine due to specification changes or other modifications made thereafter. This manual consists of the following sub-sections. Publication No. Publication Name Sub-sections IDE-2650 ENGINE Introduction Service Information Guide Maintenance Information Functional Inspection Sympton DTC Information Engine Control Mechanical Fuel System Cooling Lubrication Induction Exhaust Aux. Emission Control Devices Electrical – Wiring Diagram...

- Page 4 Introduction (All models) 0-1 Introduction Introduction (All models) Table of Contents Introduction................0-2 safety information............0-2...

- Page 5 0-2 Introduction (All models) Introduction safety information ・ Prepare the tools, instruments, and special tools in advance. Repair work safety information ・ Prepare the parts that require replacement and Warning: parts that cannot be reused in advance. ・ Workshop manuals are created for qualified ・...

- Page 6 Introduction (All models) 0-3 ・ Make sure the ground connection for the ・ When disconnecting the waterproof connector, welding machine is as close to the welding remove dust or moisture adhering to the area as possible. connector by blowing it with air, etc. If dust or moisture enters the connector, Replacement parts and parts number safety remove it before connecting the connector.

- Page 7 0-4 Introduction (All models) Warning: Caution: ・ If the fuse blows out, identify the cause and ・ When installing electronic parts, take care to replace with a known good fuse of the same ensure the harnesses do not get pinched and capacity.

- Page 8 Introduction (All models) 0-5 1. Clip 1. Existing harness (With protective material) 2. Protective tube 2. Additional harness 3. Band clip for securing harness Caution: 4. Prohibited area for securing band clip ・ For wiring between the engine and chassis, Commercial electronic products safety information give the wiring sufficient free length to prevent wear and damage caused by vibration.

-

Page 10: Table Of Contents

Service Information Guide (All models) 14A-1 Description General Information Service Information Guide (All models) Table of Contents Contents included in service information.....14A-2 Plastic gauge..............14A-4 Recommended liquid gasket.........14A-6 Thread locking adhesive agent........14A-8 Term................14A-9 Abbreviations .............14A-10 Standard bolts..............14A-14... -

Page 11: Contents Included In Service Information

14A-2 Service Information Guide (All models) Contents included in service information Contents included in service information Includes the maintenance precautions specific to each item. Removal Includes the removal procedure for repairing parts, Disconnection devices, etc. Includes the disconnection procedures for wiring, piping, etc. - Page 12 Service Information Guide (All models) 14A-3 1. Vehicle front 9. Gas or warm air 2. Upward 10. Mixing of outside air and gas or mixing of cold 3. Operating section or operating direction air and warm air 4. Detail of a particular part 11.

-

Page 13: Plastic Gauge

14A-4 Service Information Guide (All models) Plastic gauge Using the plasti-gauge Type Measurable range : 0.025 to 0.076 mm { 0.00098 PG-1 (Green) to 0.00299 in } : 0.051 to 0.152 mm { 0.00201 PR-1 (Red) to 0.00598 in } :... - Page 14 Service Information Guide (All models) 14A-5...

-

Page 15: Recommended Liquid Gasket

14A-6 Service Information Guide (All models) Recommended liquid gasket Using the thread liquid gasket Manufacturer Type Product name Area used (reference) name ThreeBond 1207B ThreeBond Engine oil seal retainer Silicon type ThreeBond 1207C ThreeBond Engine oil pan (Room temperature ThreeBond 1215 ThreeBond Timing gear case vulcanization process) - Page 16 Service Information Guide (All models) 14A-7 Caution: ・ If the workshop manual specifies an application method, follow that method.

-

Page 17: Thread Locking Adhesive Agent

14A-8 Service Information Guide (All models) Thread locking adhesive agent Using the thread locking adhesive agent Type Color Loctite 242 Blue Loctite 262 Loctite 271 Caution: ・ Thoroughly remove grime, moisture, oil, and grease from the bolts, bolt holes, and screw thread portion of the nuts to which thread locking adhesive agent will be applied. -

Page 18: Term

Service Information Guide (All models) 14A-9 Term Term Specified value Refers to specified values for inspection, adjustment, assembly, and installation. Limit Refers to a maximum or minimum value that should not be exceeded during maintenance work. If this value is exceeded, the relevant part must be replaced or repaired. -

Page 19: Abbreviations

14A-10 Service Information Guide (All models) Abbreviations Abbreviations... - Page 20 Service Information Guide (All models) 14A-11 Abbreviation Description Analog/Digital ABDC After bottom dead center Alternating current Accessory Alternating current generator Actuator American Petroleum Industry Assembly ATDC After top dead center Automatic transmission fluid Battery + terminal Battery BBDC Before bottom dead center Bracket Bearing BTDC...

- Page 21 HO2S Superheat O2 sensor Idle air control Intake air temperature Integrated circuit ID Plate Name plate (ID Plate) IDSS ISUZU Diagnostic Service System Intake manifold temperature Intake Injection International Organization for Standardization Intake shutter position Intake throttle position Joint connector...

- Page 22 Service Information Guide (All models) 14A-13 Right side Relay Random access memory Reference Read-only memory Rail pressure Rear Rear Rear Society of Automotive Engineers Slow blow fuse FRP regulator Signal Shield Starter/Start Standards Switch Top dead center TEMP Temperature Throttle position Battery voltage VGS Turbo Variable geometry system turbo...

-

Page 23: Standard Bolts

14A-14 Service Information Guide (All models) Standard bolts List of standard bolt and nut tightening torques Note: ・ The tightening torque values in the following table apply to locations where no tightening torque is specified. - Page 24 Service Information Guide (All models) 14A-15 Strength category Bolt head Hex bolt Flange bolt Hex bolt Flange bolt shape : 3.9 to 7.8 N・m { 0.4 to : 4.6 to 8.5 N・m { 0.5 to : 4.9 to 9.8 N・m { 0.5 to :...

- Page 25 14A-16 Service Information Guide (All models) : 358.9 to 539.4 N・m : 430.5 to 711.0 N・m M24 x 2 { 36.6 to 55.0 kgf・m / ― { 43.9 to 72.5 kgf・m / ― 265 to 398 lb・ft } 318 to 524 lb・ft } :...

- Page 26 Service Information Guide (All models) 14A-17 Strength category Bolt head Hex bolt Flange bolt Hex bolt Flange bolt shape : 5.6 to 11.2 N・m { 0.6 : 6.6 to 12.2 N・m { 0.7 M6 x 1 to 1.1 kgf・m / 50 to 99 to 1.2 kgf・m / 58 to 108 ―...

- Page 27 14A-18 Service Information Guide (All models) : 490.8 to 810.5 N・m : 554.1 to 830.6 N・m M24 x 2 { 50.0 to 82.6 kgf・m / ― { 56.5 to 84.7 kgf・m / ― 362 to 598 lb・ft } 409 to 613 lb・ft } :...

- Page 28 Service Information Guide (All models) 14A-19 Flare nut width across Tightening torque for middle- and large-sized flats Pipe diameter vehicles : 12.8 to 18.6 N・m { 1.3 to 1.9 kgf・m / 9 to : 14 mm : 14 mm : 4.6 mm { 0.181 in } 14 lb・ft } { 0.55 in } { 0.55 in }...

- Page 30 Maintenance Information (4LE2) 15B-1 Description Engine Maintenance Information (4LE2) Table of Contents Maintenance precautions..........15B-2 Primary specifications...........15B-5 Function, Structure, Operation........15B-8 Introduction to the trouble diagnosis......15B-48...

-

Page 31: Maintenance Precautions

15B-2 Maintenance Information (4LE2) Maintenance precautions Maintenance precautions Important precautions for handling the engine The holes and gaps in the fuel system, including inside Precautions on maintenance the injector where the fuel passes through, are To prevent the engine from being damaged and to ensure manufactured with high precision. - Page 32 Maintenance Information (4LE2) 15B-3 Aftermarket electronic equipment refers to commercially ・ To prevent damage due to electrostatic available electronic equipment attached to the machine discharge, do not open the packaging of a after it has been shipped from the factory. Be careful, as...

- Page 33 15B-4 Maintenance Information (4LE2) Items to check before programming When performing programming, check the ECM part No. as necessary. When performing programming, check the engine type as necessary. When performing programming, check the engine No. as necessary. When performing programming, check the injector ID code as necessary.

-

Page 34: Primary Specifications

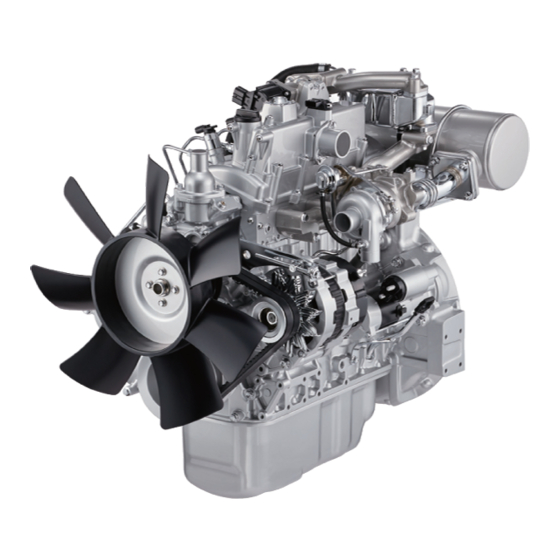

Maintenance Information (4LE2) 15B-5 Primary specifications Primary specifications Engine main specifications... - Page 35 15B-6 Maintenance Information (4LE2) Item Engine model 4LE2 Type Diesel/4-cycle/water-cooled, inline 4 cylinder overhead valve Shape of combustion chamber Direct injection type Cylinder liner type No liner Cylinder bore x stroke 85 mm {3.35 in} × 96 mm {3.78 in} Displacement 2.179 L {133 cu in}...

- Page 36 Maintenance Information (4LE2) 15B-7 Primary specifications of cooling system Item Specifications Water pump Centrifugal impeller method Thermostat Wax pellet type : 82 ℃ { 180 °F } With jiggle valve Open valve temperature : 95 ℃ { 203 °F } With jiggle valve...

-

Page 37: Function, Structure, Operation

15B-8 Maintenance Information (4LE2) Function, Structure, Operation Engine number 1. Engine type stamping 2. Engine number stamping Function, Structure, Operation Crankshaft Do not reuse the crankshaft by grinding, as it has a Description of functions and operations tufftriding surface treatment applied. If a problem is Engine electronic control found, replace with a new one. - Page 38 Maintenance Information (4LE2) 15B-9 pressure fuel, and the fuel injector that injects the fuel in water, and notifies the operator through the indicator the form of a fine mist. Each of these is controlled by the when it becomes full of water.

- Page 39 15B-10 Maintenance Information (4LE2) 1. FRP sensor 2. Pressure limiter Fuel supply pump...

- Page 40 Maintenance Information (4LE2) 15B-11 1. Fuel temperature sensor 4. Camshaft key 2. Suction control valve 3. High pressure pipe Caution: ・ There is a gauze filter assembled inside the union of the fuel supply pump, but the union should not be removed so as to prevent any...

- Page 41 15B-12 Maintenance Information (4LE2) 1. ID plate 2. 2D barcode 3. Injector 4. Fuel inlet Fuel filter 1. Union 2. Gauze filter 3. Supply pump 4. Strainer 5. Joint bolt Injector 1. Priming pump 2. Plug 3. Case 4. Drain plug...

- Page 42 Maintenance Information (4LE2) 15B-13 1. Thermostat 6. Water pump 2. Oil cooler 7. Radiator 3. EGR cooler 8. Bypass pathway 4. Cylinder head 5. Cylinder block Water pump The water pump is a centrifugal impeller type pump and is driven by the engine fan belt.

- Page 43 15B-14 Maintenance Information (4LE2) 1. Fan center 4. Bearing unit 2. Impeller 3. Seal unit Thermostat of 82°C {180°F}, and it is assembled inside the The thermostat is a wax pellet type. The unit is the thermostat housing unit. bottom bypass type with an initial open valve temperature...

- Page 44 Maintenance Information (4LE2) 15B-15 1. Valve 3. Jiggle valve 2. Piston Lubrication type A full-flow bypass integrated filter element, water cooling oil cooler, and piston coolant oil jet are adopted for the lubrication system.

- Page 45 15B-16 Maintenance Information (4LE2) Exhaust system...

- Page 46 Maintenance Information (4LE2) 15B-17 1. Integrated oxidation catalyst silencer Emission control device The EGR operates when the engine speed, engine coolant temperature, intake temperature, and barometric pressure satisfy certain criteria. Then, the valve opening angle is The EGR system recirculates a part of the exhaust gas to...

- Page 47 15B-18 Maintenance Information (4LE2) 1. EGR cooler 5. ECM 2. Coolant outlet 6. Boost pressure sensor/boost temperature sensor 3. Coolant inlet 4. EGR valve Electrical system In addition, 3 small diodes that are referred to as trio- diode are used to supply the field current.

- Page 48 Maintenance Information (4LE2) 15B-19 Generator (12 V - 35 A) regulator, the bearing, and the pulley. The moving parts The regulator is an integrated solid state type. It is are the roller and the pulley. installed together with the brush holder assembly to the The IC regulator cannot be disassembled, so it should be rear end cover and is embedded in the generator.

- Page 49 15B-20 Maintenance Information (4LE2) Starter system than the pinion, the pinion is caused to turn in reverse, The starter is 24 V/3.2 kW or 12 V/2.0 kW and is a but the pinion just idles due to the one-way clutch reduction type.

- Page 50 Maintenance Information (4LE2) 15B-21 Fuel injection correction The ECM calculates the basic injection quantity based on the signals from the accelerator position sensor, boost sensor, CKP sensor, CMP sensor, etc. At this time, the open or close timing of the SCV and the energizing time...

- Page 51 15B-22 Maintenance Information (4LE2) The ECM calculates the current altitude using signals If the ECM is equipped with an emergency stop function from the barometric pressure sensor. by a high engine coolant temperature, it stops the engine According to conditions such as the current altitude, the when the temperature reaches a set temperature.

- Page 52 Maintenance Information (4LE2) 15B-23 Decrease in engine oil pressure Overrun When the engine oil pressure drops below the specified When the engine speed reaches a specified value, an value, an alarm for the engine oil pressure decrease is alarm for overrun is issued and the engine is stopped.

- Page 53 15B-24 Maintenance Information (4LE2) Injection pressure control second injection is performed when ignition is made. The injection pressure is controlled by regulating the fuel This control for injection timing and injection amount is pressure inside the common rail (fuel rail). The proper performed by regulating the injector.

- Page 54 Maintenance Information (4LE2) 15B-25 1. Electromagnetic pump 9. Various sensors (Accelerator, boost, water 2. Fuel filter temperature) 3. Supply pump 10. CKP sensor 4. FRP sensor 11. CMP sensor 5. Common rail (fuel rail) 12. Fuel tank 6. Pressure limiter 13.

- Page 55 15B-26 Maintenance Information (4LE2) 1. Electromagnetic pump 6. Fuel tank 2. Fuel filter 7. Fuel return pipe 3. Supply pump 8. Pre-fuel filter 4. Common rail (fuel rail) 5. Fuel injector Fuel filter clog warning function and engine speed maintaining the restricted engine speed at that time.

- Page 56 Maintenance Information (4LE2) 15B-27 1. Supply pump 6. Pre-fuel filter 2. Warning light 7. Electromagnetic pump 3. Monitor 8. Fuel filter pressure sensor 4. Monitor (CAN communication) 9. Main filter 5. Fuel tank 1. First stage 2. Second stage Removing air from the fuel system Wait for approx.

- Page 57 15B-28 Maintenance Information (4LE2) 1. Pre-fuel filter 5. Supply pump 2. Electromagnetic pump 6. Fuel tank 3. Electromagnetic pump equipment machine 4. Fuel filter Darker portions in the diagram represent large valve lift The EGR system recirculates a part of the exhaust gas to...

- Page 58 Maintenance Information (4LE2) 15B-29 1. EGR cooler 5. ECM 2. Coolant outlet 6. Boost pressure sensor/boost temperature sensor 3. Coolant inlet 4. EGR valve Engine operation control There are the following 4 types of operation control instructions, and the selection varies depending on each specification.

- Page 59 15B-30 Maintenance Information (4LE2) Mode map switch control Outer switch Operation mode Control MAP0 MAP1 MAP2 OFF Basic control OFF Fixed rotation control 1 OFF Fixed rotation control 2 Fixed rotation control 3 OFF ON OFF Maximum engine speed restriction control 1...

- Page 60 For verification and questions regarding the The engine speed upper limit varies depending specifications, contact an Isuzu service-related person. on the engine type, the machine specifications, Idle manual control and the engine warm-up condition.

- Page 61 15B-32 Maintenance Information (4LE2) If a CAN controller exists on the machine side Engine speed output to tachometer The ECM outputs the engine speed pulse to the tachometer as a tachometer output. The tachometer displays the engine speed based on the engine speed pulse sent from the ECM.

- Page 62 Maintenance Information (4LE2) 15B-33 The ECM is designed to maintain regulation levels of About ECM functions exhaust gases while obtaining excellent performance and The ECM constantly monitors the information sent from fuel efficiency. The ECM monitors various engine various sensors, and controls the various systems of the functions via sensors such as the CKP sensor.

- Page 63 15B-34 Maintenance Information (4LE2) circuit tests, make sure to use digital multimeter 5-8840-2691-0. Note: ・ Use the ECM with the part No. corresponding to the machine. When performing welding work on the machine, start the work after disconnecting the negative terminal of the battery.

- Page 64 Maintenance Information (4LE2) 15B-35 1. EGR valve 8. Engine speed sensor 2. Boost pressure sensor/boost temperature sensor 9. CKP sensor 3. Engine coolant temperature sensor 10. FRP sensor 4. CMP sensor 11. Glow plug 5. Suction control valve 12. IMT sensor 6.

- Page 65 15B-36 Maintenance Information (4LE2) supply pump, etc. The voltage becomes lower when the resistance is lower, and it becomes higher when the resistance is higher. Note: ・ Do not replace the fuel temperature sensor. When a malfunction is found, replace the supply pump assembly.

- Page 66 Maintenance Information (4LE2) 15B-37 The pressure limiter is activated when the pressure in the to apply it to the injector, and uses it for fuel injection common rail (fuel rail) becomes unusually high so as to quantity control and injection timing control by release the pressure inside the common rail (fuel rail).

- Page 67 15B-38 Maintenance Information (4LE2) are 56 notches spaced 6° apart and a 30° section without notches. Top dead center of cylinder No. 1 can be detected through this section without notches, and a pulse signal is generated. By detecting the section without...

- Page 68 Maintenance Information (4LE2) 15B-39 Note: ・ For the installation position of the accelerator position sensor, refer to the manual of the machine. Barometric pressure sensor The barometric pressure sensor is installed on the machine side, and it replaces the barometric pressure with a voltage signal.

- Page 69 15B-40 Maintenance Information (4LE2) signal. The ECM calculates the vacuum in the fuel filter based on the voltage signal to determine clogging in the fuel filter. Diagnosis light By turning ON the diagnostic switch, the DTC is indicated by flashing.

- Page 70 Maintenance Information (4LE2) 15B-41 Note: The operation can be performed at the engine speed specified for each mode by switching the mode change ・ For the installation position and shape of the switch. diagnostic switch, refer to the manual of the machine.

- Page 71 15B-42 Maintenance Information (4LE2)

- Page 72 Maintenance Information (4LE2) 15B-43 ECM pin assignment...

- Page 73 15B-44 Maintenance Information (4LE2) 81 pin connector...

- Page 74 Maintenance Information (4LE2) 15B-45 Pin No. Pin name Connection PG-POWER ECM power source GND PS-+B Battery power source PG-POWER ECM power source GND PG-POWER ECM power source GND PS-+B Battery power source OS-DIAGL Diagnosis light OS-BOOSTL Boost temperature sensor pilot light...

- Page 75 15B-46 Maintenance Information (4LE2) IS-LOAD Load advance switch signal IS-START Ignition switch start signal IS-MDMAP0 Mode map switch 0 signal IS-MDMAP1 Mode map switch 1 signal IS-MDMAP2 Mode map switch 2 signal IS-DIAG Diagnostic switch signal IS-MEMCL Memory clear switch...

- Page 76 Maintenance Information (4LE2) 15B-47 Pin No. Pin name Connection IA-PFUEL FRP sensor signal IA-THL Fuel temperature sensor signal IA-THW Engine coolant temperature sensor signal SP-5V5 CMP sensor, fuel pressure sensor, EGR position sensor power source OS-OVRL Engine overrun light IA-SCVLO...

-

Page 77: Introduction To The Trouble Diagnosis

15B-48 Maintenance Information (4LE2) Introduction to the trouble diagnosis Introduction to the trouble diagnosis cannot be reproduced. However, the ECM may have recorded the failure. About trouble diagnosis Past malfunctions, past failures The following trouble diagnosis procedure is extremely important to resolve problems of all Middle stage of failure electric/electronic systems. - Page 78 Maintenance Information (4LE2) 15B-49 ・The check sheet assists in onboard diagnosis, repair, 1. Failure symptoms and repair verification at the vehicle servicing station. 2. Failure frequency/failure conditions...

- Page 79 15B-50 Maintenance Information (4LE2) Preliminary inspection When implementing the diagnostic procedures, Visual inspection of engine room carefully make a visual inspection of the engine...

- Page 80 Maintenance Information (4LE2) 15B-51 room. This inspection can often lead to solving a About the diagnostic test performed on the machine problem without taking extra steps. Past failures ・The diagnostic tests of the previous ignition cycle have ・Visually inspect all air hoses for punched holes, cuts, been completed.

- Page 81 15B-52 Maintenance Information (4LE2) Input components ・Turn the ignition switch ON, but the engine OFF. Check the input components to inspect whether there is ・Connect the diagnostic switch. For a machine with an open circuit in the circuit and whether the values are no diagnostic switch, short No.

- Page 82 Maintenance Information (4LE2) 15B-53 procedure. It is also possible to perform the inspection by Check by testing under the conditions given by the referring to the functional diagnosis. customer. When a DTC is diagnosed, verify that the malfunction When the appropriate symptom is not found has been repaired by reproducing the condition that Investigate the complaint in detail.

- Page 83 15B-54 Maintenance Information (4LE2) Item Item Objective Method Clear the previous DTCs. Keep the engine idling Verification of the DTC display to sufficiently warm it up, then perform a racing DTC check after the repair operation with the engine speed raised up to No Load Max., and secure the test conditions.

- Page 84 Maintenance Information (4LE2) 15B-55 Caution: Factory shipment settings Based on the engine serial number, data such as the ECM ・ When conditions such as the running state of injector QR code can be downloaded to the ECM. the machine or the engine, water temperature,...

- Page 85 15B-56 Maintenance Information (4LE2) Data Display Items Unit Reference values Battery Voltage Target Engine Speed Engine Speed Accelerator Pedal Position Sensor 1 (APP1) Accelerator Pedal Position Sensor 2(APP2) Accelerator Pedal Position (APP) % Fuel Rail Pressure Sensor Fuel Rail Pressure Feedback Engine Coolant Temperature Sensor ℃...

- Page 86 Maintenance Information (4LE2) 15B-57 Fuel Filter Pressure Sensor kPa {psi} Turbochager Drive Duty % Target Fuel Injection Quantity mm3/st Start Of Pilot Injection °CA Target Fuel Rail Pressure mPa {psi} Target Turbocharger Position % Target EGR Valve Position % Target Manifold Absolute Pressure...

- Page 88 Functional Inspection (4LE2) 15C-1 Description Engine Functional Inspection (4LE2) Table of Contents Engine compression pressure inspection.......15C-2 Fuel system check............15C-4 Air intake system check..........15C-5 Exhaust system check............15C-6 EGR control system check..........15C-7 Starting system check............15C-8 Glow control system check...........15C-9 OBD system check............15C-11 Inspection of the diagnostic light warning light illumination circuit system...............15C-12...

-

Page 89: Engine Compression Pressure Inspection

15C-2 Functional Inspection (4LE2) Engine compression pressure inspection Engine compression pressure inspection inspection Start the engine. Note: ・ Warm up the engine. Turn OFF the ignition switch. Disconnect the battery ground cable from the battery. Remove the harness connector from the injector. - Page 90 Functional Inspection (4LE2) 15C-3 13. Connect the harness connector to the injector. 14. Connect the battery ground cable to the battery.

-

Page 91: Fuel System Check

15C-4 Functional Inspection (4LE2) Fuel system check Fuel system check description of function The fuel system consists of the fuel tank, fuel filter, supply pump, common rail (fuel rail), and injectors, with each component being connected by the fuel pipe. -

Page 92: Air Intake System Check

Functional Inspection (4LE2) 15C-5 Air intake system check Air intake system check description of function Caution: ・ If the air intake system parts were installed by the machine manufacturer, refer to the machine manual. The air intake system consists of the air cleaner, air intake pipe, turbocharger, and other components. -

Page 93: Exhaust System Check

15C-6 Functional Inspection (4LE2) Exhaust system check Exhaust system check description of function The exhaust system consists of the exhaust pipe, tail pipe, etc. Exhaust system check inspection Inspection when there may be a malfunction in the exhaust system Inspect the exhaust pipe and the tail pipe. -

Page 94: Egr Control System Check

Functional Inspection (4LE2) 15C-7 EGR control system check EGR control system check description of function Refer to "1.Engine 1H.Aux. Emission Control Devices(4LE2) EGR valve installation". The ECM controls the EGR valve based on the engine speed, engine coolant temperature, intake air temperature, fuel injection quantity, and barometric pressure. -

Page 95: Starting System Check

No air should be mixed into the fuel when performing assembly. this diagnostic. The air cleaner element should be clean when performing Refer to "1.Engine 1C.Fuel System(4LE2) Common this diagnostic. rail assembly removal". The fuel filter should be clean when performing this Refer to "1.Engine 1C.Fuel System(4LE2) Common... -

Page 96: Glow Control System Check

Functional Inspection (4LE2) 15C-9 Glow control system check Glow control system check description of function values: 6 Ω At room temperature Caution: Note: ・ For both the starter ECM control specification ・ If the reading is not the specified value, inspect and the safety relay specification, the QOS the applicable glow plug. - Page 97 15C-10 Functional Inspection (4LE2) 21. After replacing the ECM, set the injector ID code.

-

Page 98: Obd System Check

Functional Inspection (4LE2) 15C-11 OBD system check OBD system check description of function ・ If the diagnostic light does not flash, inspect the diagnostic light flashing circuit system. The OBD system check is a systematic method for checking problems caused by a malfunction in the engine... -

Page 99: Inspection Of The Diagnostic Light Warning Light Illumination Circuit System

15C-12 Functional Inspection (4LE2) Inspection of the diagnostic light warning light illumination circuit system Inspection of the diagnostic light warning light illumination circuit system description of function Power supply voltage is provided to the diagnostic light via the ignition switch, and the light illuminates based on the signal from the ECM. -

Page 100: Inspection Of The Diagnostic Light Warning Light Blinking Circuit System

Functional Inspection (4LE2) 15C-13 Inspection of the diagnostic light warning light blinking circuit system Inspection of the diagnostic light warning light 13. Replace the ECM. blinking circuit system description of function Refer to "1.Engine 1J.Electrical(4LE2) Power supply voltage is provided to the diagnostic light ECM removal". -

Page 101: Inspection Of The Starter Circuit System

START position. When the starter 14. Inspect the starter. relay is turned ON, the starter is activated to start the Refer to "1.Engine 1J.Electrical(4LE2) Starter engine. motor inspection". Inspection of the starter circuit system inspection 15. - Page 102 Symptom (4LE2) 15D-1 Description Engine Symptom (4LE2) Table of Contents Engine start failure............15D-2 Engine stalling...............15D-4 Engine hunching, rough idling........15D-6 Excessive white smoke in the exhaust gas....15D-7 Excessive black smoke in the exhaust gas....15D-8 Abnormal noise.............15D-9 Large fuel consumption..........15D-10 Large oil consumption..........15D-12...

-

Page 103: Engine Start Failure

Charges for supply pump replacement due to use of oil blends of fuel after long storage periods and biofuel Isuzu genuine pre-filters have no air removal plug, so containing organic substances will be incurred. check whether the layout may cause air to accumulate. - Page 104 Symptom (4LE2) 15D-3 r/min or less, and the absolute pressure is 15 MPa {153 Decrease in system performance due to a failure kgf/cm2 / 2175 psi} or less, for 3 seconds or more. Malfunctions in the engine body such as seizure,...

-

Page 105: Engine Stalling

Whether structures in the layout of the fuel filter, pre- filter, and electromagnetic pump may cause air to accumulate. Isuzu genuine pre-filters have no air removal plug, so check whether the layout may cause air to accumulate. Also, check whether the layout of the electromagnetic pump inlet and outlet is appropriate. - Page 106 Symptom (4LE2) 15D-5 Malfunctions of the common rail (fuel rail) such as activation of the pressure limiter or internal sealing deterioration Malfunctions in the injector, failure to inject fuel Decrease in system performance due to a failure Malfunctions in the engine body such as seizure,...

-

Page 107: Engine Hunching, Rough Idling

Check for poor connections at the connector and for Isuzu genuine pre-filters have no air removal plug, so malfunctions such as abrasion or bends at the harness. check whether the layout may cause air to accumulate. -

Page 108: Excessive White Smoke In The Exhaust Gas

Symptom (4LE2) 15D-7 Excessive white smoke in the exhaust gas Excessive white smoke in the exhaust gas description Engine body failure such as insufficient compression of symptom pressure, piston related failure, turbocharger failure, or a decrease or increase in oil Heavy white smoke is produced during operation. -

Page 109: Excessive Black Smoke In The Exhaust Gas

15D-8 Symptom (4LE2) Excessive black smoke in the exhaust gas Excessive black smoke in the exhaust gas description of symptom Heavy black smoke is produced during operation. Excessive black smoke in the exhaust gas diagnostics ・Preliminary inspection Before using this section, perform functional inspections or OBD system checks to check the following. -

Page 110: Abnormal Noise

Symptom (4LE2) 15D-9 Abnormal noise Abnormal noise description of symptom and control, etc., of each part. Repair if a malfunction is detected. The engine combustion sound is abnormal. Abnormal noise diagnostics ・Preliminary inspection Before using this section, perform functional inspections or OBD system checks to check the following. -

Page 111: Large Fuel Consumption

15D-10 Symptom (4LE2) Large fuel consumption Large fuel consumption description of symptom Whether the ECM ground is clean and securely installed to the correct position. Fuel consumption is significantly greater than described Cracks and twists in the pipes and hoses related to fuel, in the manual for the machine. - Page 112 Symptom (4LE2) 15D-11 1. Integrated oxidation catalyst silencer 5. From air cleaner 2. Exhaust pipe 6. EGR valve 3. From intercooler 7. EGR cooler 4. To intercooler...

-

Page 113: Large Oil Consumption

15D-12 Symptom (4LE2) Large oil consumption Large oil consumption description of symptom Perform functional diagnostic inspections, and check the operation, control, etc., of each part. Repair if a Oil consumption is significantly greater than described in malfunction is detected. the manual for the machine. -

Page 114: Insufficient Engine Output

Symptom (4LE2) 15D-13 Insufficient engine output Insufficient engine output description of symptom Malfunctions in the fuel system such as no fuel, fuel freezing, air in the fuel pipe, filter malfunctions, pipe The engine output is below the predicted output, the... - Page 116 DTC Information (4LE2 (12V)) 15E-1 Description Engine DTC Information (4LE2 (12V)) Table of Contents DTC P0016 (Flash Code 16) Crankshaft Position - Camshaft DTC P0219 (Flash Code 543) Engine Overspeed Condition Position Correlation............15E-3 ..................15E-24 DTC P0087 (Flash Code 225) Fuel Rail/System Pressure - DTC P0237 (Flash Code 32) Turbocharger Boost Sensor Too Low................15E-4...

- Page 117 15E-2 DTC Information (4LE2 (12V)) DTC P0687 (Flash Code 416) ECM/PCM Power Relay Control Circuit High............15E-46 DTC P0697 (Flash Code 57) Sensor Reference Voltage 3 Circuit................15E-47 DTC P06AF (Flash Code 277) EDU Injector Custom IC,Check Sum,Communication Line......15E-48 DTC P1093 (Flash Code 227) Fuel Rail Pressure (FRP) Too Low................15E-49...

-

Page 118: Position Correlation

DTC Information (4LE2 (12V)) 15E-3 DTC P0016 (Flash Code 16) Crankshaft Position - Camshaft Position Correlation DTC P0016 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The sensor rotor is fixed on the crankshaft. -

Page 119: Dtc P0087 (Flash Code 225) Fuel Rail/System Pressure - Too Low

15E-4 DTC Information (4LE2 (12V)) DTC P0087 (Flash Code 225) Fuel Rail/System Pressure - Too Low DTC P0087 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side between the fuel tank and the supply pump, and a high pressure side between the supply pump and the injectors. -

Page 120: Dtc P0089 (Flash Code 151) Fuel Pressure Regulator Performance

DTC Information (4LE2 (12V)) 15E-5 DTC P0089 (Flash Code 151) Fuel Pressure Regulator Performance DTC P0089 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side between the fuel tank and the supply pump, and a high pressure side between the supply pump and the injectors. -

Page 121: Dtc P0091 (Flash Code 247) Fuel Pressure Regulator Control Circuit Low

15E-6 DTC Information (4LE2 (12V)) DTC P0091 (Flash Code 247) Fuel Pressure Regulator Control Circuit Low DTC P0091 description of DTC The suction control valve is installed on the supply pump and controls the fuel amount sucked into the common rail (fuel rail). -

Page 122: Dtc P0092 (Flash Code 247) Fuel Pressure Regulator Control Circuit High

DTC Information (4LE2 (12V)) 15E-7 DTC P0092 (Flash Code 247) Fuel Pressure Regulator Control Circuit High DTC P0092 description of DTC The suction control valve is installed on the supply pump and controls the fuel amount sucked into the common rail (fuel rail). -

Page 123: Dtc P0093 (Flash Code 227) Fuel System Leak Detected

15E-8 DTC Information (4LE2 (12V)) DTC P0093 (Flash Code 227) Fuel System Leak Detected DTC P0093 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side between the fuel tank and the supply pump, and a high pressure side between the supply pump and the injectors. -

Page 124: Sensor Circuit Low

DTC Information (4LE2 (12V)) 15E-9 DTC P0097 (Flash Code 214) Intake Manifold Temperature Sensor Circuit Low DTC P0097 description of DTC The IMT sensor is installed to the intake chamber. The IMT sensor is a thermistor type sensor and it measures the temperature of the intake air mixed with EGR gas. -

Page 125: Sensor Circuit High

15E-10 DTC Information (4LE2 (12V)) DTC P0098 (Flash Code 214) Intake Manifold Temperature Sensor Circuit High DTC P0098 description of DTC The IMT sensor is installed to the intake chamber. The IMT sensor is a thermistor type sensor and it measures the temperature of the intake air mixed with EGR gas. -

Page 126: Dtc P0112 (Flash Code 22) Intake Air Temperature Sensor Circuit Low

DTC Information (4LE2 (12V)) 15E-11 DTC P0112 (Flash Code 22) Intake Air Temperature Sensor Circuit Low DTC P0112 description of DTC The boost temperature sensor is a thermistor type sensor and it measures the temperature of the air flowing into the engine. -

Page 127: Dtc P0113 (Flash Code 22) Intake Air Temperature Sensor Circuit High

15E-12 DTC Information (4LE2 (12V)) DTC P0113 (Flash Code 22) Intake Air Temperature Sensor Circuit High DTC P0113 description of DTC The boost temperature sensor is a thermistor type sensor and it measures the temperature of the air flowing into the engine. -

Page 128: Sensor Circuit Low

DTC Information (4LE2 (12V)) 15E-13 DTC P0117 (Flash Code 23) Engine Coolant Temperature Sensor Circuit Low DTC P0117 description of DTC The engine coolant temperature sensor is installed in the thermostat housing. The engine coolant temperature sensor is a thermistor type sensor and measures the temperature of the engine coolant. -

Page 129: Sensor Circuit High

15E-14 DTC Information (4LE2 (12V)) DTC P0118 (Flash Code 23) Engine Coolant Temperature Sensor Circuit High DTC P0118 description of DTC The engine coolant temperature sensor is installed in the thermostat housing. The engine coolant temperature sensor is a thermistor type sensor and measures the temperature of the engine coolant. -

Page 130: Dtc P0182 (Flash Code 211) Fuel Temperature Sensor Circuit Low

DTC Information (4LE2 (12V)) 15E-15 DTC P0182 (Flash Code 211) Fuel Temperature Sensor Circuit Low DTC P0182 description of DTC The fuel temperature sensor is installed on the supply pump. The fuel temperature sensor is a thermistor type sensor and measures the temperature of the fuel entering the supply pump. -

Page 131: Dtc P0183 (Flash Code 211) Fuel Temperature Sensor Circuit High

15E-16 DTC Information (4LE2 (12V)) DTC P0183 (Flash Code 211) Fuel Temperature Sensor Circuit High DTC P0183 description of DTC The fuel temperature sensor is installed on the supply pump. The fuel temperature sensor is a thermistor type sensor and measures the temperature of the fuel entering the supply pump. -

Page 132: Dtc P0192 (Flash Code 245) Fuel Rail Pressure Sensor Circuit Low

DTC Information (4LE2 (12V)) 15E-17 DTC P0192 (Flash Code 245) Fuel Rail Pressure Sensor Circuit Low DTC P0192 description of DTC The barometric pressure sensor changes the signal voltage according to changes in the barometric pressure. The sensor has the following circuits. -

Page 133: Dtc P0193 (Flash Code 245) Fuel Rail Pressure Sensor Circuit High

15E-18 DTC Information (4LE2 (12V)) DTC P0193 (Flash Code 245) Fuel Rail Pressure Sensor Circuit High DTC P0193 description of DTC The common rail (fuel rail) pressure sensor is installed to the common rail (fuel rail) and detects the fuel pressure in the common rail (fuel rail) and converts the pressure into a voltage signal. -

Page 134: Dtc P0201 (Flash Code 271) Injector Circuit - Cylinder 1

DTC Information (4LE2 (12V)) 15E-19 DTC P0201 (Flash Code 271) Injector Circuit - Cylinder 1 DTC P0201 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 135: Dtc P0202 (Flash Code 272) Injector Circuit - Cylinder 2

15E-20 DTC Information (4LE2 (12V)) DTC P0202 (Flash Code 272) Injector Circuit - Cylinder 2 DTC P0202 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 136: Dtc P0203 (Flash Code 273) Injector Circuit - Cylinder 3

DTC Information (4LE2 (12V)) 15E-21 DTC P0203 (Flash Code 273) Injector Circuit - Cylinder 3 DTC P0203 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 137: Dtc P0204 (Flash Code 274) Injector Circuit - Cylinder 4

15E-22 DTC Information (4LE2 (12V)) DTC P0204 (Flash Code 274) Injector Circuit - Cylinder 4 DTC P0204 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 138: Dtc P0217 (Flash Code 542) Engine Coolant Over Temperature Condition

DTC Information (4LE2 (12V)) 15E-23 DTC P0217 (Flash Code 542) Engine Coolant Over Temperature Condition DTC P0217 description of DTC The engine coolant temperature sensor is installed on the thermostat housing. The engine coolant temperature sensor is a thermistor type and measures the temperature of the engine coolant. -

Page 139: Dtc P0219 (Flash Code 543) Engine Overspeed Condition

15E-24 DTC Information (4LE2 (12V)) DTC P0219 (Flash Code 543) Engine Overspeed Condition DTC P0219 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The ECM calculates the engine speed and accurate crankshaft position based on the signal pulse from the CKP sensor. -

Page 140: Dtc P0237 (Flash Code 32) Turbocharger Boost Sensor Circuit Low

DTC Information (4LE2 (12V)) 15E-25 DTC P0237 (Flash Code 32) Turbocharger Boost Sensor Circuit Low DTC P0237 description of DTC The boost pressure sensor is located in the air intake pipe. This sensor changes the signal voltage in accordance with changes in air pressure in the air intake pipe. -

Page 141: Dtc P0238 (Flash Code 32) Turbocharger Boost Sensor Circuit High

15E-26 DTC Information (4LE2 (12V)) DTC P0238 (Flash Code 32) Turbocharger Boost Sensor Circuit High DTC P0238 description of DTC The boost pressure sensor is located in the air intake pipe. This sensor changes the signal voltage in accordance with changes in air pressure in the air intake pipe. -

Page 142: Dtc P0335 (Flash Code 15) Crankshaft Position Sensor Circuit

DTC Information (4LE2 (12V)) 15E-27 DTC P0335 (Flash Code 15) Crankshaft Position Sensor Circuit DTC P0335 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The sensor rotor is fixed on the crankshaft. There are 56 notches spaced 6° apart and a 30°... -

Page 143: Circuit Range/Performance

15E-28 DTC Information (4LE2 (12V)) DTC P0336 (Flash Code 15) Crankshaft Position Sensor Circuit Range/Performance DTC P0336 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The sensor rotor is fixed on the crankshaft. -

Page 144: Dtc P0340 (Flash Code 14) Camshaft Position Sensor Circuit

DTC Information (4LE2 (12V)) 15E-29 DTC P0340 (Flash Code 14) Camshaft Position Sensor Circuit DTC P0340 description of DTC The CMP sensor is installed on the gear case cover. The CMP sensor detects 5 protrusions in total per 1 engine rotation. -

Page 145: Dtc P0380 (Flash Code 66) Glow Plug Circuit

15E-30 DTC Information (4LE2 (12V)) DTC P0380 (Flash Code 66) Glow Plug Circuit DTC P0380 description of DTC The glow relay stops providing power supply voltage to the glow plug, and ON is displayed if the signal from the ECM is entered. The ECM recognizes the ignition switch ON signal, and outputs the ON signal to the glow relay. -

Page 146: Control Circuit Range/Performance

DTC Information (4LE2 (12V)) 15E-31 DTC P0404 (Flash Code 45) Exhaust Gas Recirculation 1 Control Circuit Range/Performance DTC P0404 description of DTC The ECM controls the opening and closing of the EGR valve based on the driving condition of the engine by controlling the EGR solenoid. -

Page 147: Dtc P0409 (Flash Code 44) Exhaust Gas Recirculation 1 Sensor Circuit

15E-32 DTC Information (4LE2 (12V)) DTC P0409 (Flash Code 44) Exhaust Gas Recirculation 1 Sensor Circuit DTC P0409 description of DTC The EGR position sensor is on the EGR valve together with the control solenoid. This sensor is made up of 3 individual sensors within 1 housing. -

Page 148: Dtc P0521 (Flash Code 294) Engine Oil Pressure Sensor Performance

DTC Information (4LE2 (12V)) 15E-33 DTC P0521 (Flash Code 294) Engine Oil Pressure Sensor Performance DTC P0521 description of DTC The oil pressure sensor detects the engine oil pressure. The oil pressure sensor is installed near the oil cooler of the cylinder block. -

Page 149: Dtc P0522 (Flash Code 294) Oil Pressure Sensor Circuit Low Input

15E-34 DTC Information (4LE2 (12V)) DTC P0522 (Flash Code 294) Oil Pressure Sensor Circuit Low Input DTC P0522 description of DTC The oil pressure sensor detects the engine oil pressure. The oil pressure sensor is installed near the oil cooler of the cylinder block. -

Page 150: Dtc P0523 (Flash Code 294) Oil Pressure Sensor Circuit High Input

DTC Information (4LE2 (12V)) 15E-35 DTC P0523 (Flash Code 294) Oil Pressure Sensor Circuit High Input DTC P0523 description of DTC The oil pressure sensor detects the engine oil pressure. The oil pressure sensor is installed near the oil cooler of the cylinder block. -

Page 151: Dtc P0563 (Flash Code 35) System Voltage High

15E-36 DTC Information (4LE2 (12V)) DTC P0563 (Flash Code 35) System Voltage High DTC P0563 description of DTC The ECM monitors the ignition voltage on the ignition feed terminal to verify that the voltage stays within the proper range. If the ECM detects that the voltage of the ignition power source is abnormally high, the DTC is set. -

Page 152: Memory Check Sum Error

DTC Information (4LE2 (12V)) 15E-37 DTC P0601 (Flash Code 53) Internal Control Module Memory Check Sum Error DTC P0601 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P0601 condition for setting the DTC The ECM detects that the calculated checksum does not agree with the ROM internal registered checksum. -

Page 153: Dtc P0602 (Flash Code 154) Control Module Programming Error

15E-38 DTC Information (4LE2 (12V)) DTC P0602 (Flash Code 154) Control Module Programming Error DTC P0602 description of DTC The injector ID code and the fuel delivery rate data is stored in the EEPROM within the ECM. If no injector ID... -

Page 154: Random Access Memory (Ram)

DTC Information (4LE2 (12V)) 15E-39 DTC P0604 (Flash Code 153) Internal Control Module Random Access Memory (RAM) DTC P0604 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P0604 condition for setting the DTC The battery voltage is 8 V or more. -

Page 155: Dtc P0606 (Flash Code 51) Ecm/Pcm Processor

15E-40 DTC Information (4LE2 (12V)) DTC P0606 (Flash Code 51) ECM/PCM Processor DTC P0606 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P0606 condition for setting the DTC The battery voltage is 8 V or more. -

Page 156: Processing Performance

DTC Information (4LE2 (12V)) 15E-41 DTC P060B (Flash Code 36) Internal Control Module A/D Processing Performance DTC P060B description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P060B condition for setting the DTC The ECM detects a malfunction of the internal A/D converter. -

Page 157: Dtc P0615 (Flash Code 19) Starter Relay Circuit

15E-42 DTC Information (4LE2 (12V)) DTC P0615 (Flash Code 19) Starter Relay Circuit DTC P0615 description of DTC The starter cut switch is provided to prevent the starter from operating when the engine is running. The starter cut relay is a normal closed relay and is positioned between the main relay and starter relay. -

Page 158: Dtc P0641 (Flash Code 55) Sensor Reference Voltage 1 Circuit

DTC Information (4LE2 (12V)) 15E-43 DTC P0641 (Flash Code 55) Sensor Reference Voltage 1 Circuit DTC P0641 description of DTC The ECM supplies 5 V power to the following sensors through power supply circuit 1. Accelerator position sensor Fuel filter pressure sensor... -

Page 159: Dtc P0651 (Flash Code 56) Sensor Reference Voltage 2 Circuit

15E-44 DTC Information (4LE2 (12V)) DTC P0651 (Flash Code 56) Sensor Reference Voltage 2 Circuit DTC P0651 description of DTC The ECM supplies 5 V power to the following sensor through 5 V power supply circuit 2. Barometric pressure sensor The ECM also supplies 5 V power to the following sensors through 5 V power supply circuit 5. -

Page 160: Control Circuit/Open

DTC Information (4LE2 (12V)) 15E-45 DTC P0685 (Flash Code 416) ECM/PCM Power Relay Control Circuit/Open DTC P0685 description of DTC The ECM main relay is applied to supply the battery power to the ECM through the relay switch side when the ECM receives an ignition switch ON signal. -

Page 161: Dtc P0687 (Flash Code 416) Ecm/Pcm Power Relay Control Circuit High

15E-46 DTC Information (4LE2 (12V)) DTC P0687 (Flash Code 416) ECM/PCM Power Relay Control Circuit High DTC P0687 description of DTC The ECM main relay is applied to supply the battery power to the ECM through the relay switch side when the ECM receives an ignition switch ON signal. -

Page 162: Dtc P0697 (Flash Code 57) Sensor Reference Voltage 3 Circuit

DTC Information (4LE2 (12V)) 15E-47 DTC P0697 (Flash Code 57) Sensor Reference Voltage 3 Circuit DTC P0697 description of DTC The ECM supplies 5 V power to the following sensors through power supply circuit 3. Oil pressure sensor The ECM monitors the voltage of 5 V power supply circuit 3, and if it detects that the voltage is abnormally low or high, the DTC is set. -

Page 163: Ic,Check Sum,Communication Line

15E-48 DTC Information (4LE2 (12V)) DTC P06AF (Flash Code 277) EDU Injector Custom IC,Check Sum,Communication Line DTC P06AF description of DTC This diagnosis applies to the injector IC inside the ECM. DTC P06AF condition for setting the DTC Note: ・ Injector IC malfunction The engine is running. -

Page 164: Dtc P1093 (Flash Code 227) Fuel Rail Pressure (Frp) Too Low

DTC Information (4LE2 (12V)) 15E-49 DTC P1093 (Flash Code 227) Fuel Rail Pressure (FRP) Too Low DTC P1093 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side... -

Page 165: Dtc P1097 (Flash Code 213) Boost Temperature Sensor Circuit Low

15E-50 DTC Information (4LE2 (12V)) DTC P1097 (Flash Code 213) Boost Temperature Sensor Circuit Low DTC P1097 description of DTC The boost temperature sensor is installed in the intake chamber. The boost temperature sensor changes its resistance according to the temperature in the intake chamber. -

Page 166: Dtc P1098 (Flash Code 213) Boost Temperature Sensor Circuit High

DTC Information (4LE2 (12V)) 15E-51 DTC P1098 (Flash Code 213) Boost Temperature Sensor Circuit High DTC P1098 description of DTC The boost temperature sensor is installed in the intake chamber. The resistance changes according to the temperature in the intake chamber. The resistance becomes lower when the intake air temperature is high, and higher when the intake air temperature is low. -

Page 167: Dtc P1261 (Flash Code 34) Fuel Injector Group 1 Supply Voltage Circuit

15E-52 DTC Information (4LE2 (12V)) DTC P1261 (Flash Code 34) Fuel Injector Group 1 Supply Voltage Circuit DTC P1261 description of DTC The charge voltage circuit inside the ECM increases the voltage applied to the injector. The charge voltage circuit is divided into two banks: common power supply 1 and common power supply 2. -

Page 168: Dtc P1262 (Flash Code 34) Fuel Injector Group 2 Supply Voltage Circuit

DTC Information (4LE2 (12V)) 15E-53 DTC P1262 (Flash Code 34) Fuel Injector Group 2 Supply Voltage Circuit DTC P1262 description of DTC The charge voltage circuit inside the ECM increases the voltage applied to the injector. The charge voltage circuit is divided into two banks: common power supply 1 and common power supply 2. -

Page 169: Closed Position Performance

15E-54 DTC Information (4LE2 (12V)) DTC P1404 (Flash Code 45) Exhaust Gas Recirculation 1 Closed Position Performance DTC P1404 description of DTC The ECM controls the opening and closing of the EGR valve based on the driving condition of the engine by controlling the EGR solenoid. -

Page 170: Dtc P1606 (Flash Code 51) Sw-Ic 1 Internal

DTC Information (4LE2 (12V)) 15E-55 DTC P1606 (Flash Code 51) SW-IC 1 Internal failure,Communication line failure DTC P1606 description of DTC This diagnosis applies to the SW-IC1 inside the ECM. DTC P1606 condition for setting the DTC Note: ・ SW-IC internal malfunction A malfunction in the SW-IC circuit was detected. -

Page 171: Dtc P160B (Flash Code 36) Ad-Ic Failure

15E-56 DTC Information (4LE2 (12V)) DTC P160B (Flash Code 36) AD-IC failure DTC P160B description of DTC This diagnosis applies to the AD-IC inside the ECM. DTC P160B condition for setting the DTC The battery voltage is between 8 - 16 V. -

Page 172: Memory Performance

DTC Information (4LE2 (12V)) 15E-57 DTC P1621 (Flash Code 54) Control Module Long Term Memory Performance DTC P1621 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P1621 condition for setting the DTC The ignition switch is ON. -

Page 173: Dtc P1655 (Flash Code 59) Sensor Reference Voltage 4 Circuit

15E-58 DTC Information (4LE2 (12V)) DTC P1655 (Flash Code 59) Sensor Reference Voltage 4 Circuit DTC P1655 description of DTC The ECM supplies 5 V power to the following sensors through power supply circuit 4. CKP sensor The ECM monitors the voltage of 5 V power supply circuit 4, and if it detects that the voltage is abnormally low or high, the DTC is set. -

Page 174: Dtc P2146 (Flash Code 158) Fuel Injector Group 1 Supply Voltage Circuit

DTC Information (4LE2 (12V)) 15E-59 DTC P2146 (Flash Code 158) Fuel Injector Group 1 Supply Voltage Circuit DTC P2146 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from various sensors. The injector... -

Page 175: Dtc P2149 (Flash Code 159) Fuel Injector Group 2 Supply Voltage Circuit

15E-60 DTC Information (4LE2 (12V)) DTC P2149 (Flash Code 159) Fuel Injector Group 2 Supply Voltage Circuit DTC P2149 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector charge... -

Page 176: Dtc P2228 (Flash Code 71) Barometric Pressure Circuit Low

DTC Information (4LE2 (12V)) 15E-61 DTC P2228 (Flash Code 71) Barometric Pressure Circuit Low DTC P2228 description of DTC The barometric pressure sensor changes the signal voltage according to changes in the barometric pressure. The sensor has the following circuits. -

Page 177: Dtc P2229 (Flash Code 71) Barometric Pressure Circuit High

15E-62 DTC Information (4LE2 (12V)) DTC P2229 (Flash Code 71) Barometric Pressure Circuit High DTC P2229 description of DTC The barometric pressure sensor changes the signal voltage according to changes in the barometric pressure. The sensor has the following circuits. -

Page 178: Circuit Or Up/Down Switch Error

DTC Information (4LE2 (12V)) 15E-63 DTC P256A (Flash Code 31) Idle Up Volume Sensor Circuit Or Up/Down Switch Error DTC P256A description of DTC The idling control switch is a switch for adjusting the idling rpm speed during warm-up and can be used when the idling control selector switch is set to "manual". -

Page 179: Dtc U0073 (Flash Code 84) Can-Bus Malfunction (J1939)

15E-64 DTC Information (4LE2 (12V)) DTC U0073 (Flash Code 84) CAN-Bus Malfunction (J1939) DTC U0073 description of DTC The ECM communicates with the control unit of the machine via the CAN communication circuit. The ECM outputs data via the CAN-High circuit and inputs data from other ECUs via the CAN-Low circuit. -

Page 180: Dtc Mapping Table

DTC Information (4LE2 (12V)) 15E-65 DTC mapping table DTC mapping table... - Page 181 15E-66 DTC Information (4LE2 (12V)) SPN-FMI P code 636-7 P0016 Crankshaft position - camshaft position correlation error 633-7 P0087 Fuel rail system pressure low pressure malfunction 157-15 P0089 Fuel rail pressure regulator control characteristic malfunction 1347-4 P0091 Fuel rail pressure regulator system low input...

- Page 182 DTC Information (4LE2 (12V)) 15E-67 1485-6 P0687 ECM main relay control system high input 10009-2 P0697 Sensor voltage system malfunction (Reference 3) 10050-2 Injector IC malfunction 10052-2 P06AF Injector IC checksum malfunction 10051-2 Injector IC communication malfunction 1239-17 P1093 Fuel rail pressure low pressure malfunction...

- Page 184 DTC Information (4LE2 (24V)) 15E-1 Description Engine DTC Information (4LE2 (24V)) Table of Contents DTC P0016 (Flash Code 16) Crankshaft Position - Camshaft DTC P0238 (Flash Code 32) Turbocharger Boost Sensor Position Correlation............15E-3 Circuit High..............15E-24 DTC P0087 (Flash Code 225) Fuel Rail/System Pressure - DTC P0335 (Flash Code 15) Crankshaft Position Sensor Too Low................15E-4...

- Page 185 15E-2 DTC Information (4LE2 (24V)) DTC P0687 (Flash Code 416) ECM/PCM Power Relay Control Circuit High............15E-46 DTC P0697 (Flash Code 57) Sensor Reference Voltage 3 Circuit................15E-47 DTC P06AF (Flash Code 277) EDU Injector Custom IC,Check Sum,Communication Line......15E-48 DTC P1093 (Flash Code 227) Fuel Rail Pressure (FRP) Too Low................15E-49...

-

Page 186: Position Correlation

DTC Information (4LE2 (24V)) 15E-3 DTC P0016 (Flash Code 16) Crankshaft Position - Camshaft Position Correlation DTC P0016 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The sensor rotor is fixed on the crankshaft. -

Page 187: Dtc P0087 (Flash Code 225) Fuel Rail/System Pressure - Too Low

15E-4 DTC Information (4LE2 (24V)) DTC P0087 (Flash Code 225) Fuel Rail/System Pressure - Too Low DTC P0087 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side between the fuel tank and the supply pump, and a high pressure side between the supply pump and the injectors. -

Page 188: Dtc P0089 (Flash Code 151) Fuel Pressure Regulator Performance

DTC Information (4LE2 (24V)) 15E-5 DTC P0089 (Flash Code 151) Fuel Pressure Regulator Performance DTC P0089 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side between the fuel tank and the supply pump, and a high pressure side between the supply pump and the injectors. -

Page 189: Dtc P0091 (Flash Code 247) Fuel Pressure Regulator Control Circuit Low

15E-6 DTC Information (4LE2 (24V)) DTC P0091 (Flash Code 247) Fuel Pressure Regulator Control Circuit Low DTC P0091 description of DTC The suction control valve is installed on the supply pump and controls the fuel amount sucked into the common rail (fuel rail). -

Page 190: Dtc P0092 (Flash Code 247) Fuel Pressure Regulator Control Circuit High

DTC Information (4LE2 (24V)) 15E-7 DTC P0092 (Flash Code 247) Fuel Pressure Regulator Control Circuit High DTC P0092 description of DTC The suction control valve is installed on the supply pump and controls the fuel amount sucked into the common rail (fuel rail). -

Page 191: Dtc P0093 (Flash Code 227) Fuel System Leak Detected

15E-8 DTC Information (4LE2 (24V)) DTC P0093 (Flash Code 227) Fuel System Leak Detected DTC P0093 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side between the fuel tank and the supply pump, and a high pressure side between the supply pump and the injectors. -

Page 192: Dtc P0112 (Flash Code 22) Intake Air Temperature Sensor Circuit Low

DTC Information (4LE2 (24V)) 15E-9 DTC P0112 (Flash Code 22) Intake Air Temperature Sensor Circuit Low DTC P0112 description of DTC The boost temperature sensor is a thermistor type sensor and it measures the temperature of the air flowing into the engine. -

Page 193: Dtc P0113 (Flash Code 22) Intake Air Temperature Sensor Circuit High

15E-10 DTC Information (4LE2 (24V)) DTC P0113 (Flash Code 22) Intake Air Temperature Sensor Circuit High DTC P0113 description of DTC The boost temperature sensor is a thermistor type sensor and it measures the temperature of the air flowing into the engine. -

Page 194: Sensor Circuit Low

DTC Information (4LE2 (24V)) 15E-11 DTC P0117 (Flash Code 23) Engine Coolant Temperature Sensor Circuit Low DTC P0117 description of DTC The engine coolant temperature sensor is installed in the thermostat housing. The engine coolant temperature sensor is a thermistor type sensor and measures the temperature of the engine coolant. -

Page 195: Sensor Circuit High

15E-12 DTC Information (4LE2 (24V)) DTC P0118 (Flash Code 23) Engine Coolant Temperature Sensor Circuit High DTC P0118 description of DTC The engine coolant temperature sensor is installed in the thermostat housing. The engine coolant temperature sensor is a thermistor type sensor and measures the temperature of the engine coolant. -

Page 196: Dtc P0182 (Flash Code 211) Fuel Temperature Sensor Circuit Low

DTC Information (4LE2 (24V)) 15E-13 DTC P0182 (Flash Code 211) Fuel Temperature Sensor Circuit Low DTC P0182 description of DTC The fuel temperature sensor is installed on the supply pump. The fuel temperature sensor is a thermistor type sensor and measures the temperature of the fuel entering the supply pump. -

Page 197: Dtc P0183 (Flash Code 211) Fuel Temperature Sensor Circuit High

15E-14 DTC Information (4LE2 (24V)) DTC P0183 (Flash Code 211) Fuel Temperature Sensor Circuit High DTC P0183 description of DTC The fuel temperature sensor is installed on the supply pump. The fuel temperature sensor is a thermistor type sensor and measures the temperature of the fuel entering the supply pump. -

Page 198: Dtc P0192 (Flash Code 245) Fuel Rail Pressure Sensor Circuit Low

DTC Information (4LE2 (24V)) 15E-15 DTC P0192 (Flash Code 245) Fuel Rail Pressure Sensor Circuit Low DTC P0192 description of DTC The barometric pressure sensor changes the signal voltage according to changes in the barometric pressure. The sensor has the following circuits. -

Page 199: Dtc P0193 (Flash Code 245) Fuel Rail Pressure Sensor Circuit High

15E-16 DTC Information (4LE2 (24V)) DTC P0193 (Flash Code 245) Fuel Rail Pressure Sensor Circuit High DTC P0193 description of DTC The common rail (fuel rail) pressure sensor is installed to the common rail (fuel rail) and detects the fuel pressure in the common rail (fuel rail) and converts the pressure into a voltage signal. -

Page 200: Dtc P0201 (Flash Code 271) Injector Circuit - Cylinder

DTC Information (4LE2 (24V)) 15E-17 DTC P0201 (Flash Code 271) Injector Circuit - Cylinder 1 DTC P0201 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 201: Dtc P0202 (Flash Code 272) Injector Circuit - Cylinder

15E-18 DTC Information (4LE2 (24V)) DTC P0202 (Flash Code 272) Injector Circuit - Cylinder 2 DTC P0202 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 202: Dtc P0203 (Flash Code 273) Injector Circuit - Cylinder

DTC Information (4LE2 (24V)) 15E-19 DTC P0203 (Flash Code 273) Injector Circuit - Cylinder 3 DTC P0203 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 203: Dtc P0204 (Flash Code 274) Injector Circuit - Cylinder

15E-20 DTC Information (4LE2 (24V)) DTC P0204 (Flash Code 274) Injector Circuit - Cylinder 4 DTC P0204 description of DTC The ECM calculates the optimum fuel injection ON time based on the data sent from sensors. The injector power supply circuit supplies high voltage, while the ECM grounds the injector solenoid control circuit and drives the injectors of each cylinder. -

Page 204: Dtc P0217 (Flash Code 542) Engine Coolant Over Temperature Condition

DTC Information (4LE2 (24V)) 15E-21 DTC P0217 (Flash Code 542) Engine Coolant Over Temperature Condition DTC P0217 description of DTC The engine coolant temperature sensor is installed on the thermostat housing. The engine coolant temperature sensor is a thermistor type and measures the temperature of the engine coolant. -

Page 205: Dtc P0219 (Flash Code 543) Engine Overspeed Condition

15E-22 DTC Information (4LE2 (24V)) DTC P0219 (Flash Code 543) Engine Overspeed Condition DTC P0219 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The ECM calculates the engine speed and accurate crankshaft position based on the signal pulse from the CKP sensor. -

Page 206: Dtc P0237 (Flash Code 32) Turbocharger Boost Sensor Circuit Low

DTC Information (4LE2 (24V)) 15E-23 DTC P0237 (Flash Code 32) Turbocharger Boost Sensor Circuit Low DTC P0237 description of DTC The boost pressure sensor is located in the air intake pipe. This sensor changes the signal voltage in accordance with changes in air pressure in the air intake pipe. -

Page 207: Dtc P0238 (Flash Code 32) Turbocharger Boost Sensor Circuit High

15E-24 DTC Information (4LE2 (24V)) DTC P0238 (Flash Code 32) Turbocharger Boost Sensor Circuit High DTC P0238 description of DTC The boost pressure sensor is located in the air intake pipe. This sensor changes the signal voltage in accordance with changes in air pressure in the air intake pipe. -

Page 208: Dtc P0335 (Flash Code 15) Crankshaft Position Sensor Circuit

DTC Information (4LE2 (24V)) 15E-25 DTC P0335 (Flash Code 15) Crankshaft Position Sensor Circuit DTC P0335 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The sensor rotor is fixed on the crankshaft. There are 56 notches spaced 6° apart and a 30°... -

Page 209: Circuit Range/Performance

15E-26 DTC Information (4LE2 (24V)) DTC P0336 (Flash Code 15) Crankshaft Position Sensor Circuit Range/Performance DTC P0336 description of DTC The CKP sensor is installed on the right rear of the cylinder block. The sensor rotor is fixed on the crankshaft. -

Page 210: Dtc P0340 (Flash Code 14) Camshaft Position Sensor Circuit

DTC Information (4LE2 (24V)) 15E-27 DTC P0340 (Flash Code 14) Camshaft Position Sensor Circuit DTC P0340 description of DTC The CMP sensor is installed on the gear case cover. The CMP sensor detects 5 protrusions in total per 1 engine rotation. -

Page 211: Dtc P0380 (Flash Code 66) Glow Plug Circuit

15E-28 DTC Information (4LE2 (24V)) DTC P0380 (Flash Code 66) Glow Plug Circuit DTC P0380 description of DTC The glow relay stops providing power supply voltage (24 V) to the glow plug, and ON is displayed if the signal from the ECM is input. The ECM recognizes the ignition switch ON signal, and outputs the ON signal to the glow relay. -

Page 212: Control Circuit Range/Performance

DTC Information (4LE2 (24V)) 15E-29 DTC P0404 (Flash Code 45) Exhaust Gas Recirculation 1 Control Circuit Range/Performance DTC P0404 description of DTC The ECM controls the opening and closing of the EGR valve based on the driving condition of the engine by controlling the EGR solenoid. -

Page 213: Dtc P0409 (Flash Code 44) Exhaust Gas Recirculation 1 Sensor Circuit

15E-30 DTC Information (4LE2 (24V)) DTC P0409 (Flash Code 44) Exhaust Gas Recirculation 1 Sensor Circuit DTC P0409 description of DTC The EGR position sensor is on the EGR valve together with the control solenoid. This sensor is made up of 3 individual sensors within 1 housing. -

Page 214: Sensor Circuit High

DTC Information (4LE2 (24V)) 15E-31 DTC P041C (Flash Code 52) Intake Manifold Temperature Sensor Circuit High DTC P041C description of DTC The IMT sensor is installed to the intake chamber. The IMT sensor is a thermistor type sensor and it measures the temperature of the intake air mixed with EGR gas. -

Page 215: Sensor Circuit Low

15E-32 DTC Information (4LE2 (24V)) DTC P041D (Flash Code 52) Intake Manifold Temperature Sensor Circuit Low DTC P041D description of DTC The IMT sensor is installed to the intake chamber. The IMT sensor is a thermistor type sensor and it measures the temperature of the intake air mixed with EGR gas. -

Page 216: Dtc P0521 (Flash Code 294) Engine Oil Pressure Sensor Performance

DTC Information (4LE2 (24V)) 15E-33 DTC P0521 (Flash Code 294) Engine Oil Pressure Sensor Performance DTC P0521 description of DTC The oil pressure sensor detects the engine oil pressure. The oil pressure sensor is installed near the oil cooler of the cylinder block. -

Page 217: Dtc P0522 (Flash Code 294) Oil Pressure Sensor Circuit Low Input

15E-34 DTC Information (4LE2 (24V)) DTC P0522 (Flash Code 294) Oil Pressure Sensor Circuit Low Input DTC P0522 description of DTC The oil pressure sensor detects the engine oil pressure. The oil pressure sensor is installed near the oil cooler of the cylinder block. -

Page 218: Dtc P0523 (Flash Code 294) Oil Pressure Sensor Circuit High Input

DTC Information (4LE2 (24V)) 15E-35 DTC P0523 (Flash Code 294) Oil Pressure Sensor Circuit High Input DTC P0523 description of DTC The oil pressure sensor detects the engine oil pressure. The oil pressure sensor is installed near the oil cooler of the cylinder block. -

Page 219: Dtc P0563 (Flash Code 35) System Voltage High

15E-36 DTC Information (4LE2 (24V)) DTC P0563 (Flash Code 35) System Voltage High DTC P0563 description of DTC The ECM monitors the ignition voltage on the ignition feed terminal to verify that the voltage stays within the proper range. If the ECM detects that the voltage of the ignition power source is abnormally high, the DTC is set. -

Page 220: Memory Check Sum Error

DTC Information (4LE2 (24V)) 15E-37 DTC P0601 (Flash Code 53) Internal Control Module Memory Check Sum Error DTC P0601 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P0601 condition for setting the DTC The ECM detects that the calculated checksum does not agree with the ROM internal registered checksum. -

Page 221: Dtc P0602 (Flash Code 154) Control Module Programming Error

15E-38 DTC Information (4LE2 (24V)) DTC P0602 (Flash Code 154) Control Module Programming Error DTC P0602 description of DTC The injector ID code and the fuel delivery rate data is stored in the EEPROM within the ECM. If no injector ID... -

Page 222: Random Access Memory (Ram)

DTC Information (4LE2 (24V)) 15E-39 DTC P0604 (Flash Code 153) Internal Control Module Random Access Memory (RAM) DTC P0604 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P0604 condition for setting the DTC The battery voltage is 16 V or more. -

Page 223: Dtc P0606 (Flash Code 51) Ecm/Pcm Processor

15E-40 DTC Information (4LE2 (24V)) DTC P0606 (Flash Code 51) ECM/PCM Processor DTC P0606 description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P0606 condition for setting the DTC The battery voltage is 18V or more. -

Page 224: Processing Performance

DTC Information (4LE2 (24V)) 15E-41 DTC P060B (Flash Code 36) Internal Control Module A/D Processing Performance DTC P060B description of DTC This diagnosis applies to the microprocessor inside the ECM. DTC P060B condition for setting the DTC The ECM detects a malfunction of the internal A/D converter. -

Page 225: Dtc P0615 (Flash Code 19) Starter Relay Circuit

15E-42 DTC Information (4LE2 (24V)) DTC P0615 (Flash Code 19) Starter Relay Circuit DTC P0615 description of DTC The starter cut switch is provided to prevent the starter from operating when the engine is running. The starter cut relay is a normal closed relay and is positioned between the main relay and starter relay. -

Page 226: Dtc P0641 (Flash Code 55) Sensor Reference Voltage 1 Circuit

DTC Information (4LE2 (24V)) 15E-43 DTC P0641 (Flash Code 55) Sensor Reference Voltage 1 Circuit DTC P0641 description of DTC The ECM supplies 5 V power to the following sensors through power supply circuit 1. Accelerator position sensor Fuel filter pressure sensor... -

Page 227: Dtc P0651 (Flash Code 56) Sensor Reference Voltage 2 Circuit

15E-44 DTC Information (4LE2 (24V)) DTC P0651 (Flash Code 56) Sensor Reference Voltage 2 Circuit DTC P0651 description of DTC The ECM supplies 5 V power to the following sensor through 5 V power supply circuit 2. Barometric pressure sensor The ECM also supplies 5 V power to the following sensors through 5 V power supply circuit 5. -

Page 228: Control Circuit/Open

DTC Information (4LE2 (24V)) 15E-45 DTC P0685 (Flash Code 416) ECM/PCM Power Relay Control Circuit/Open DTC P0685 description of DTC The ECM main relay is applied to supply the battery power to the ECM through the relay switch side when the ECM receives an ignition switch ON signal. -

Page 229: Dtc P0687 (Flash Code 416) Ecm/Pcm Power Relay Control Circuit High

15E-46 DTC Information (4LE2 (24V)) DTC P0687 (Flash Code 416) ECM/PCM Power Relay Control Circuit High DTC P0687 description of DTC The ECM main relay is applied to supply the battery power to the ECM through the relay switch side when the ECM receives an ignition switch ON signal. -

Page 230: Dtc P0697 (Flash Code 57) Sensor Reference Voltage 3 Circuit

DTC Information (4LE2 (24V)) 15E-47 DTC P0697 (Flash Code 57) Sensor Reference Voltage 3 Circuit DTC P0697 description of DTC The ECM supplies 5 V power to the following sensors through power supply circuit 3. Oil pressure sensor The ECM monitors the voltage of 5 V power supply circuit 3, and if it detects that the voltage is abnormally low or high, the DTC is set. -

Page 231: Ic,Check Sum,Communication Line

15E-48 DTC Information (4LE2 (24V)) DTC P06AF (Flash Code 277) EDU Injector Custom IC,Check Sum,Communication Line DTC P06AF description of DTC This diagnosis applies to the injector IC inside the ECM. DTC P06AF condition for setting the DTC Note: ・ Injector IC malfunction The engine is running. -

Page 232: Dtc P1093 (Flash Code 227) Fuel Rail Pressure (Frp) Too Low

DTC Information (4LE2 (24V)) 15E-49 DTC P1093 (Flash Code 227) Fuel Rail Pressure (FRP) Too Low DTC P1093 description of DTC A typical common rail (fuel rail) system is composed of the following 2 fuel pressure sections. A suction side... -

Page 233: Dtc P1112 (Flash Code 295) Boost Temperature Sensor Circuit Low Input

15E-50 DTC Information (4LE2 (24V)) DTC P1112 (Flash Code 295) Boost Temperature Sensor Circuit Low Input DTC P1112 description of DTC The boost temperature sensor is installed in the intake chamber. The boost temperature sensor changes its resistance according to the temperature in the intake chamber. -

Page 234: Dtc P1113 (Flash Code 295) Boost Temperature Sensor Circuit High Input

DTC Information (4LE2 (24V)) 15E-51 DTC P1113 (Flash Code 295) Boost Temperature Sensor Circuit High Input DTC P1113 description of DTC The boost temperature sensor is installed in the intake chamber. The resistance changes according to the temperature in the intake chamber. The resistance becomes lower when the intake air temperature is high, and higher when the intake air temperature is low. -

Page 235: Dtc P1261 (Flash Code 34) Fuel Injector Group 1 Supply Voltage Circuit

15E-52 DTC Information (4LE2 (24V)) DTC P1261 (Flash Code 34) Fuel Injector Group 1 Supply Voltage Circuit DTC P1261 description of DTC The charge voltage circuit inside the ECM increases the voltage applied to the injector. The charge voltage circuit is divided into two banks: common power supply 1 and common power supply 2. -

Page 236: Dtc P1262 (Flash Code 34) Fuel Injector Group 2 Supply Voltage Circuit

DTC Information (4LE2 (24V)) 15E-53 DTC P1262 (Flash Code 34) Fuel Injector Group 2 Supply Voltage Circuit DTC P1262 description of DTC The charge voltage circuit inside the ECM increases the voltage applied to the injector. The charge voltage circuit is divided into two banks: common power supply 1 and common power supply 2. -

Page 237: Dtc P1293 (Flash Code 221) Fuel Filter Pressure Sensor Circuit Low

15E-54 DTC Information (4LE2 (24V)) DTC P1293 (Flash Code 221) Fuel Filter Pressure Sensor Circuit Low DTC P1293 description of DTC The fuel filter pressure sensor detects the vacuum in the fuel filter. The fuel filter pressure sensor is installed on the fuel filter. -

Page 238: Dtc P1294 (Flash Code 221) Fuel Filter Pressure Sensor Circuit High

DTC Information (4LE2 (24V)) 15E-55 DTC P1294 (Flash Code 221) Fuel Filter Pressure Sensor Circuit High DTC P1294 description of DTC The fuel filter pressure sensor detects the vacuum in the fuel filter. The fuel filter pressure sensor is installed on the fuel filter. -

Page 239: Closed Position Performance