Summary of Contents for Bubble 1 MARINE OIL STOVE

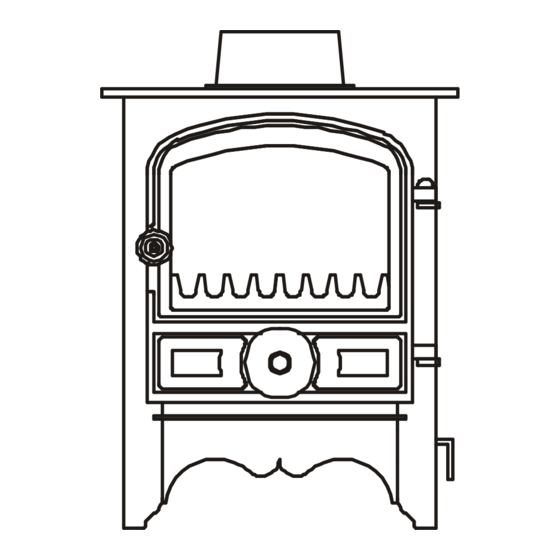

- Page 1 BUBBLE 1 MARINE OIL STOVE © USER INSTRUCTIONS ISSUE 4 @10-09-13 Draught copy needs finishing www.oilstoves.co.uk...

-

Page 2: Table Of Contents

INDEX WARNINGS...................................... 4 INTRODUCTION ..............................4 FIREGUARDING....................................4 DOOR GLASS....................................4 STOVE EXTERIOR ..................................5 BURNER POT ....................................5 FASTENING DOWN..................................5 HOW IT WORKS ..............................5 CONTROLS ....................................... 5 THE OPTIONAL COAL KIT ................................6 STOVE COMPONENTS .................................. 6 RUNNING THE STOVE ............................ - Page 3 OIL TRIP WILL NOT RESET ..............................12 BURNER WILL NOT COME TO HIGH FIRE .......................... 12 OIL WILL NOT FLOW INTO THE POT ..........................12 OIL SMELLS ....................................12 BURNER RUNS SOOTY................................12 BURNER DOES NOT LIGHT EASILY ............................12 OIL WILL NOT ENTER THE POT ............................

-

Page 4: Warnings

The stove can also be supplied with or without a coal ARNINGS kit. 1. Never try to relight a hot stove; wait until it has Just like a solid fuel stove, coal effect will only be cooled down, hot oil vapour is explosive. available when the stove is running at maximum or near 2. -

Page 5: Stove Exterior

After cleaning wipe it dry. With the increased flow of oil, extra heat is generated, which in turn stimulates the chimney to TOVE XTERIOR work harder and consequently draw more air into the To clean the stove externally pot to maintain an adequate fuel air ratio. Let it go out and simply brush away any dust with a ONTROLS very soft brush. -

Page 6: The Optional Coal Kit

water flow through it may cause damage. the coals making routine leaning and servicing very Make sure that the boiler has been vented of all air easy. BEFORE ATTEMPTING TO LIGHT THE STOVE. To remove it, turn the stove off and when it is cooled Lighting the stove takes a little time and patience;... -

Page 7: Lighting And Adjusting

It is possible to fit different makes of oil control door. valves to Bubble Stoves, make sure that you have the Wait for approx 1 minute until the pool of oil is alight relevant separate valve document and that you are and then turn the oil on to minimum setting no 1. -

Page 8: Excess Flames During Ignition

Watch the appliance for a few minutes until it settles After a few minutes, the flame will die down and down into blue flame combustion. eventually extinguish itself. Allow the burner to run for a further 10 minutes DO NOT TOUCH THE STOVE UNTIL IT HAS before turning the appliance up to the higher settings. -

Page 9: Fault Finding

Under changing and fluctuating wind conditions To try and ensure satisfactory performance from the downdraghting will occur. BUBBLE stove chimneys must be capable of maintaining a constant steady vacuum of not less than If you have to moor in situations where the above- .04"... -

Page 10: Chimney Heights

OOR OIL FLOW PROBLEMS INIMUM EIGHT UNNING Bubble stoves have a very accurate oil flow control valve, which is set up to give a precise oil flow at high MINIMUM HEIGHT FOR LOW FIRE RUNNING IS and low fire. 1.8 METERS. (Short extension) -

Page 11: Oil Line

If the burner does not run well check that the seals in the stove are good and that there is no ingress of air If the bubble stove is fitted up to the first bulkhead into the appliance flue ways. -

Page 12: Oil Smells

If the appliance is running and there is an oil smell, • Damaged oil feed pipe. turn the appliance off and investigate or call a service • Height of oil control valve has been engineer. disturbed. The descaling device has adjustable packing, which may need to be tightened up after first undoing the RIP WILL NOT ESET... -

Page 13: Oil Smells

(STOVES WITH BOILERS) to splash around and leak through the air holes in the side of the pot. Has the oil trip lever tripped off? Has the boiler stat tripped off? Operating oil flow rates OIL Flow rates in cc per minute. 10cc Oil Flow Rates In litres per hour. -

Page 14: Fault Finding Heating System

VERY WEEKS FAULT FINDING HEATING SYSTEM If the system does not perform well check the Tighten up the gland nut on the descaling device to following-: stop oil smells. THE CIRCUIT DESIGN. VERY MONTHS AIR LOCKED CIRCULATING PUMP. Have your service man replace or clean all the filters in the oil supply line. - Page 16 PARTS LIST PART NO DESCRIPTION STOVE SPECIFIC PARTS DRY STOVE 87-01-450-B DRY STOVE FIREBRICK KIT COMPRISING OF :- DRY STOVE SIDE BRICKS 87-04-501-B1 DRY STOVE BACK BRICK 87-04-501-B1-2 BAFFLE PLATE ASSEMBLY (means including fastener) DRY STOVE OIL VALVE ASSEMBLY 78-01-008DRY REAR HEAT SHIELD FOR B1 DRY 87-01-501-8 SPECIFIC PARTS SMALL BOILER STOVE...

- Page 17 SMALL BOILER STOVE FIREBRICK KIT 87-01-501BRICK REAR HEAT SHIELD FOR SMALL BOIER STOVE SPECIFIC PARTS LARGE BOILER STOVE LARGE BOILER ASSEMBLY 92-20-105A TOBY VALVE TO ACCEPT AQUASTAT 35 SEC 4/13 78-01-008WET AQUASTAT ZW12 (3904011) 78-01-008C SLEEVE (FOR AQUASTAT) ZW12 (3904012) 78-01-008D REAR HEAT SHIELD FOR LARGE BOILER STOVE 87-01-501-8B...

- Page 18 DOOR KNOB (BRASS) BRASS026 M8 NUT 77-02-072 COMMON OIL FLOW CONTROL ROD ASSEMBLY COMPRISING :- SPLIT PIN 77-02-044 OIL TRIP ROD (ALLUMINIUM) 87-01-501TCR OILTRIP SWITCH BLACK KNOB RS686-008 FLOW RATE STICKER PRINT011 COMMON OIL VALVE COMPONENTS COMPRISING :- OIL CONTROL VALVE SUPPORT BRACKET 87-01-501-16 OIL CONTROL VALVE INLET FITTING FIT403...

Need help?

Do you have a question about the 1 MARINE OIL STOVE and is the answer not in the manual?

Questions and answers