Table of Contents

Advertisement

Installation Instructions

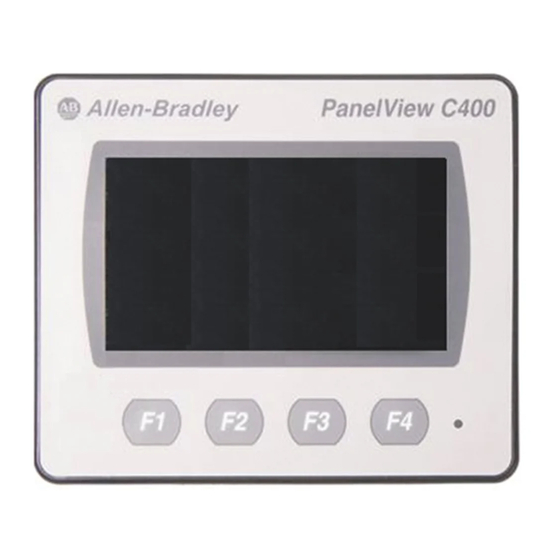

PanelView Component HMI Terminals

Catalog Numbers 2711C-F2M, 2711C-K2M, 2711C-T3M, 2711C-K3M,

2711C-T6M, 2711C-T4T, 2711C-T6C, 2711C-T6T, 2711C-T10C

Topic

About This Publication

This document provides instructions on how to install, wire, ground, and troubleshoot PanelView

Component HMI terminals. It does not provide information on how to configure or run applications on the

following devices:

2711C-F2M, 2711C-K2M, 2711C-T3M, 2711C-K3M, 2711C-T6M, 2711C-T4T, 2711C-T6C,

2711C-T6T, 2711C-T10C

Page

3

6

6

9

20

21

22

23

25

25

26

27

30

33

Advertisement

Table of Contents

Need help?

Do you have a question about the PanelView C200 and is the answer not in the manual?

Questions and answers