Table of Contents

Advertisement

Quick Links

1

Overview ............................................................................................................................ 1

Safety features .................................................................................................................... 3

Operator Safety ................................................................................................................. 3

2

Assembly procedure ........................................................................................................... 6

Glass jar installation ........................................................................................................... 6

Inserting viscometer tubes/thermometers ........................................................................... 9

Filling the bath .................................................................................................................. 10

Draining the Bath ............................................................................................................. 11

3

Applying power ................................................................................................................ 13

Cold Start .............................................................................................................. 13

Warm Start ............................................................................................................ 14

Self-test sequence ............................................................................................................. 14

Front panel operations ...................................................................................................... 16

Using the keypad .................................................................................................. 17

Setting bath temperature ................................................................................................... 18

Calibrating the CT-2000 ................................................................................................... 18

MENU options .................................................................................................................. 20

Change to (C/F) .................................................................................................... 20

Bath temperature offsets ....................................................................................... 20

Communication options .................................................................................................... 21

Full duplex (point-to-point) connections .............................................................. 23

Half duplex and polled (multi-drop) operations ................................................... 23

Commands, queries & responses .......................................................................... 23

®

CT-2000 Constant Temperature Bath

CANNON

Revision 1.0g-February, 2012; CANNON

2139 High Tech Road • State College, PA 16803 • USA

CONTENTS

1

5

13

®

Instrument Company

i

Advertisement

Table of Contents

Summary of Contents for Cannon CT-2000

-

Page 1: Table Of Contents

Self-test sequence ......................14 Front panel operations ...................... 16 Using the keypad ....................17 Setting bath temperature ....................18 Calibrating the CT-2000 ....................18 MENU options ........................20 Change to (C/F) ....................20 Bath temperature offsets ..................20 Communication options ....................21 Full duplex (point-to-point) connections .............. - Page 2 APPENDIX A — MODEL CT-2000 PROBLEM ANALYSIS APPENDIX B — CORRECTING SHAFT & IMPELLER MISALIGNMENT Shaft run-out correction ....................31 APPENDIX C — CHOOSING A TEMPERATURE BATH LIQUID APPENDIX D — CT-2000 SPARE PARTS LIST APPENDIX E — WARRANTY/RETURN INFORMATION Products limited warranty....................

-

Page 3: Introduction

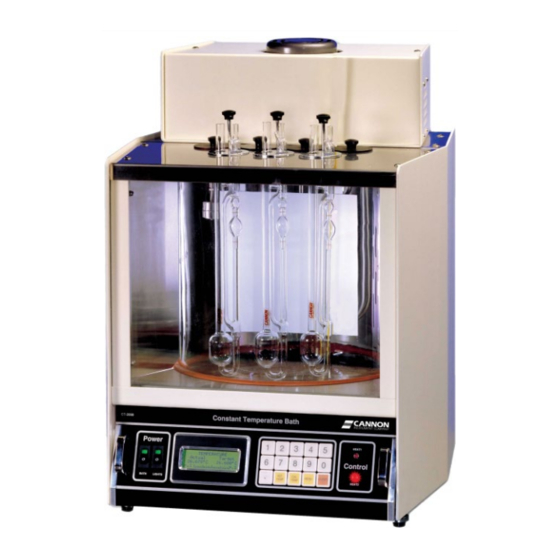

The CT-2000 The CANNON ® CT-2000 Constant Temperature Bath is designed to maintain precise temperatures at a wide range of settings for accurate viscosity measurements. Because of its temperature stability and ease of use, it is also suitable for any other application where temperatures must be maintained within hundredths of one degree Celsius. - Page 4 Temperature selection The CT-2000 offers convenient keypad entry of temperature settings up to three decimal places over the entire temperature range of the instru- ment. The bath temperature will remain stable within hundredths of one degree of the temperature setting.

-

Page 5: Safety Features

Follow instructions in this manual regarding use and maintenance of the CT-2000. Do not place the CT-2000 system on an unstable cart or stand. The CT-2000 should be placed on a stable laboratory table or bench. If any liquids are spilled into the electronic components of the CT- 2000, remove power from the unit and contact CANNON ®... - Page 6 This page intentionally left blank. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

-

Page 7: Unpacking And Assembly

Instrument Company immediately. Damaged items Retain all packing materials until the instrument is connected and func- tioning properly. If any component(s) must be returned to CANNON ® Instrument Company, the damaged item(s) should be packaged in the original shipping container. Refer to APPENDIX E of this manual for instructions on returning defective equipment. -

Page 8: Assembly Procedure

Figure 2: Detaching top cover float switch) from the upper rear panel of the CT-2000. 4. Remove the front top cover and rear top cover (see Figures 3 and 4). Use caution when removing the rear top cover because the tempera- ture control probes and heating elements are attached to it. - Page 9 13. When the drawer is removed, locate the four ¼-20 set screws visible at the top of the drawer opening underneath the bath. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ®...

- Page 10 3. Connect all plugs and probes to the correspondingly labeled sockets at the rear of the CT-2000 bath unit as follows (see Figure 10): ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012;...

-

Page 11: Inserting Viscometer Tubes/Thermometers

5. Adjust the four feet on the bottom of the bath housing to level the bath jar. This should be done prior to filling the bath with fluid. 6. Plug the CT-2000 main power cord at the back of the electronics drawer into an outlet with electrical specifications matching the label on the rear of the instrument. -

Page 12: Filling The Bath

Different bath fluids expand at different rates. Do not overfill the bath! WARNING Monitor the level of bath liquid closely when operating the CT-2000 at higher temperatures (100-150°C). The bath liquid will expand as the temperature increases. The CT-2000 bath jar is not designed to contain liquid under pressure. -

Page 13: Draining The Bath

WARNING Always use a rubber bulb or similar device to apply suction to a tube containing bath liquids. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA... - Page 14 This page intentionally left blank. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

-

Page 15: Bath Operation

Cold Start The Cold Start is the normal start-up mode for the CT-2000. During the Cold Start process, the CT-2000 will perform several diagnostics (see Self-Test Sequence, next page). At the conclusion of a successful test procedure, the results will be briefly displayed on the LCD screen. -

Page 16: Warm Start

100.000 C HEATING To Cold Start the CT-2000, toggle the power BATH switch up. The POWER lamp should light when bath power has been activated. The five LED’s in the lower row of keys will blink on and then off, and the instrument will emit a short “beep”... - Page 17 Testing Voltage Levels ..Positive Supply..OK Negative Supply..OK Diagnostic Report All tests PASSED Entering Normal Operation ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

-

Page 18: Front Panel Operations

The ENTER key will flash in a repeating pattern and the heating LED will not light (see Warm Start information, page 12). In the event of a FAILED test, turn off the CT-2000 power for at least five seconds and restart the unit. -

Page 19: Using The Keypad

1 2 ) . Figure 12: The CT-2000 front panel Using the keypad The keypad on the front panel of the CT-2000 consists of fifteen keys: white numbers 0 through 9 a white decimal point (.) key a yellow SET TEMP (set temperature) key... -

Page 20: Setting Bath Temperature

NOTE If a temperature is entered which is outside of the operational tempera- ture range of the CT-2000, you will receive a RANGE ERROR message on the LCD screen. To correct this error, press ENTER and follow the screen prompts to enter appropriate data. -

Page 21: Calibrating The Ct-2000

The instrument stores calibration corrections for every temperature integer. Procedure Use the CAL TEMP keypad option to calibrate the CT-2000 to your ASTM thermometer for a given temperature. NOTE Before you calibrate, make sure that the bath has stabilized at the desired test temperature. -

Page 22: Menu Options

MENU options The MENU selection from the CT-2000 keypad permits the user to access three functions: Change to (C/F) Changes screen display to alternate temp. scale Bath Temp Offsets Globally adjusts calibration data COM Setup Sets computer communication options Change to (C/F) The Change to (Celsius or Fahrenheit) option is essentially a toggle between two temperature scales. -

Page 23: Communication Options

General Bath Offset The General Bath Offset is a protected function of the CT-2000. This option is a global adjustment which is made at the factory by CANNON ® . In rare instances when this setting may need to be altered, the adjustment should be made in consultation with an authorized CAN- ®... - Page 24 If the CT-2000 was previously configured to operate in a polled (RS-485) environment, the following will appear on the LCD: COMMUNICATION MODE 1. Polled 2. Point to Point (Reports Disabled):1 The last line on the LCD indicates that timed reports are disabled and the present mode is polled.

-

Page 25: Full Duplex (Point-To-Point) Connections

Full duplex (point-to-point) connections The RS-232 interface is furnished for a direct connection between the CT-2000 and one computer. A DB-25 connector on the rear panel of the CT-2000 is configured as Data Communication Equipment (DCE). This configuration permits a direct connection (straight through cable--pins 1- 8, 20). - Page 26 A “download” push button is located on the rear panel of the CT-2000. Pressing and holding this button for several seconds places the CT-2000 instrument in the “download”...

- Page 27 , l a h t i : s i ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

- Page 28 , e l t f i s i h h t i : s i ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

- Page 29 ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

- Page 30 This page intentionally left blank. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

- Page 31 APPENDIX A — MODEL CT- 2000 PROBLEM ANALYSIS A successful CT-2000 self-test is an indicator that there are no detectable errors and checked components are functional . There are certain condi- tions, however, that cannot be verified by these automatic tests. These include: 1.

- Page 32 • Stirring impeller may be on shaft with the wrong orientation. See APPENDIX B. • Bath fluid may be too viscous for operation at this temperature. Replace with appropriate fluid. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company...

- Page 33 Shaft run-out correction The following procedure is suggested to correct shaft run-out: 1. Remove the motor-stirrer from the CT-2000 bath. 2. Grasp the motor firmly with the left hand. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012;...

- Page 34 When the crayon makes a line at least two-thirds of the way around the shaft, the run-out has diminished to an acceptable level. A uniform line completely around the shaft would indicate no run-out detectable by this procedure. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company...

- Page 35 ° 5 ° 0 ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

- Page 36 IBF Bath Oil IBF Bath Oil contains an oxidation inhibitor which reduces tendency to darken at higher temperatures. Viscosity is 36 cSt at 40°C, 5.6 cSt at 100°C. This oil is available from CANNON ® (catalogue # 9726-L20). Silicone fluids Silicone fluids are available in a wide range of viscosities and can be used over a wide range of temperatures.

- Page 37 CHAPTER APPENDIX D — CT-2000 SPARE PARTS LIST Following is a list of parts for the CT-2000 which may be ordered from CANNON ® Instrument Company. Part Number Description P20.1 PYREX JAR 12 X 12 P20.22 THERMOMETER HOLDER (RUBBER) P22.26 JAR TOP GASKET P22.39...

- Page 38 This page intentionally left blank. ® CT-2000 Constant Temperature Bath CANNON Revision 1.0g—February, 2012; CANNON ® Instrument Company 2139 High Tech Road • State College, PA 16803 • USA...

- Page 39 CHAPTER APPENDIX E — WARRANTY/ RETURN INFORMATION Products limited warranty In addition to other manufacturers’ warrantees, CANNON ® Instrument Company (“the Company”) warrants all products (other than reagents and chemicals) delivered to and retained by their original purchasers to be free from defect in material and workmanship for one year from the date of the Company’s invoice to the purchaser.

- Page 40 Shipping notification Products returned without prior notification (by either telephone or fax), or without Cannon’s authorization, will not be accepted. The customer may be billed a testing fee if a product is returned to ® CANNON and found to be working properly.

Need help?

Do you have a question about the CT-2000 and is the answer not in the manual?

Questions and answers