Subscribe to Our Youtube Channel

Summary of Contents for Hillyard TRIDENT XM13SC

-

Page 1: Service Manual

SERVICE MANUAL TRIDENT XM13SC Version: AB Date: October 4, 2017 Document Number:10055555... -

Page 2: Table Of Contents

Contents I Product Introduction 1 Serial Number and Technical Support 1.1 The Serial Tag ....... . . 1.2 Serial Tag location . - Page 3 7 Drying System 7.1 Structure ........43 7.2 Description .

-

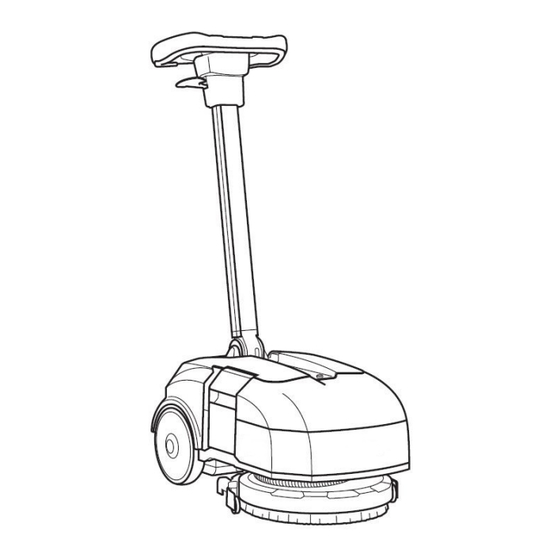

Page 4: I Product Introduction

Part I Product Introduction... -

Page 5: Serial Number And Technical Support

Chapter 1 Serial Number and Technical Support The Serial Tag Serial Tag location To have access to the Serial Tag it is sufficient to remove both tanks. The Serial Number is an extremely important information which has to be provided each time a Technical Support is required or is necessary to buy spare parts or accessories. -

Page 6: Main Technical Features

Chapter 2 Main Technical Features Technical Data TECHNICAL DESCRIPTION XM13SC Working Width Working Capacity, up to 9687 Brush Diameter/Revolutions in-rpm 11-150 Brush Motor Voltage/Power 36-90 Max Weight on brush Total Power Squeegee Width 12,8 Solution Tank Recovery Tank Vacuum Motor Voltage/Power 36-150 Machine Length 21,8-35,2... -

Page 7: Anomalies Resolution Guide

Part II Anomalies Resolution Guide... -

Page 8: Troubleshooting Guide

Chapter 3 Troubleshooting Guide Basic Guide 3.1.1 Electrical system: what to do if. . . The machine doesn’t switch on 1. The main switch is not pushed Push the main switch. 2. The battery doesn’t work properly Refer to the proper section (see section 3.1.1 at page 8) - Page 9 The battery charger doesn’t work 1. The battery charger is not con- Connect the charger to a supplied nected to the power supply electric socket. 2. The charger has the power switch Move the power switch in position 1. in position 0 3.

- Page 10 3.1.2 Mechanical scrubbing system: what to do if. . . The machine doesn’t clean well 1. The machine is switched off Switch on the machine. 2. The machine doesn’t switch on Refer to the proper section (see section 3.1.1 at page 8) 3.

- Page 11 3.1.3 Drying system: what to do if. . . The machine doesn’t dry well The machine is switched off Switch on the machine. The machine doesn’t switch on Refer to the proper section (see section 3.1.1 at page 8) The vacuum motor doesn’t work Refer to the Advanced Guide (see section 3.2.6...

- Page 12 3.1.4 Solution delivery system: what to do if. . . The delivered solution is not correct or not enough 1. The machine is switched off Switch on the machine. 2. The machine doesn’t switch on Refer to the proper section (see section 3.1.1 at page 8)

-

Page 13: Advanced Guide

Advanced Guide 3.2.1 Electric Cards Overview Main Card Handle Control Card Motor Control Card... - Page 14 3.2.2 The Display doesn’t switch ON Point 2 Check the battery Replace the voltage battery Point 3 Check the voltage on Replace the the connector J2 cables Point 4 Check the voltage Replace the J6-Pink / J2-Black main card Point 5 Check the voltage Replace the J6-Pink / J2-Black...

- Page 15 On the Handle card, Point 9 check the voltage on the connector J4 Point 11 Yellow & Brown On the Handle card, Replace the check the voltage on handle card the connector J4 Point 12 Yellow & White Replace the On the Main card, cables check the voltage on...

- Page 16 3.2.4 The Display doesn’t show the battery level All the other devices of the machine are functioning properly Point 2 Check the voltage J5-Gray / J2-Black Point 3 Replace the Check the voltage main card J5-Violet / J2-Black Point 4 Replace the cables Check the battery...

- Page 17 Check the voltage in Replace the AC on the connector Y motor Yellow & Red (with Point 4 running machine) Check the voltage Replace the on the connector X motor card Red & Black (with Point 5 running machine) Check the voltage Point 6 on the connector W Replace the...

- Page 18 3.2.6 The suction Motor doesn’t work All the other devices of the machine are functioning properly Replace the Check the voltage on motor the faston (with running machine) Point 2 Replace the Check the voltage on cables the connector J1 Gray &...

-

Page 19: Disassembling Procedures

Chapter 4 Disassembling Procedures ARNING EFORE TO PERFORM ANY OPERATION DESCRIBED BELOW VERIFY THAT THE MACHINE TANKS ARE COMPLETELY EMPTY THE MACHINE HAS TO BE TURNED OFF EMOVE THE BATTERY FROM THE MACHINE T LAST VERIFY THAT THE MACHINE IS IN A TOTALLY SAFE CONDITION... -

Page 20: Electrical Installation

Electrical Installation Remove the lifting handle from the handlebar stem by unscrewing the Put the machine in safe conditions. screws (see fig. 4.1.0-1) Turn the handlebar forward in hori- Release the lock levers of the tanks, zontal position. and remove them (see fig. - Page 21 Lift up the upper carter and slide it Disconnect the connectors from the along the handlebar stem. brush motor Control Card remove the screws securing the plate to the upper frame and remove the card. Disconnect the connectors from the Main Card, remove the screws and Remove the screws of the Main remove the card.

-

Page 22: Mechanical Friction System

Mechanical Friction System Put the machine in safe conditions. Remove the Brush from the Brush deck. 4.2.0-5 4.2.0-6 Unscrew the lower shaft from the shaft of the gearmotor as indicated by the arrow and remove the Brush retainer Bell (see fig. 4.2.0-5) Remove the Upper Carter (see fig. -

Page 23: Drying System

Drying System Put the machine in safe conditions. Remove the recovery tank Cover by releasing the latch handles (see fig. 4.3.0-15 4.3.0-16 4.3.0-15) Remove the recovery Tank by re- leasing the locking levers. Unscrew the rear screws of the suc- tion motor grid. -

Page 24: Frame And Traction System

Frame Traction System Put the machine in safe conditions. 4.4.0-18 4.4.0-19 Remove the screws that hold the handle to the handlebar tube (see fig. 4.4.0-18) Disconnect the cable from the Main card and release the cable from the fastening clamp. 4.4.0-20 Remove the Cover Carter (see section... -

Page 25: Solution Delivery System

Solution Delivery Sys- Put the machine in safe conditions. Release the locking levers. Remove the Recovery tank and then the solution Tank. Unscrew the screws and remove the housing and the clean water Filter. Disconnect the power cables from the pump and remove the water pipes. -

Page 26: Machine Description

Part III Machine Description... -

Page 27: Electrical System

Chapter 5 Electrical System Structure Description 1. Main Card A main card runs all the functions of the machine, brush base, suction and water. 2. Handle Control Card The main card receive as input, all the 3. Brush Motor control Card information from the control card. -

Page 28: Location Of Electrical Components

Location of Electrical components... - Page 29 List of Components 1 Battery 2 ON/OFF Switch 3 Handle Card 9 Main Card 10 Brush Motor control Card M1 Water Pump MBR Brush Motor MVA Suction Motor...

- Page 30 5.3.1 Main Card 5.3.2 Handle and Control card The Main Card is the heart of the ma- Functions of the handle chine and, depending of the input infor- Manage and set up the main func- mation, decides how to use the devices tions and command of the machine of the machine during normal work.

- Page 31 5.3.4 ON/OFF Switch Functions of the control card During the normal working, the dis- The machine is provided with a ON/OFF play shows the hourmeter and the bat- switch positioned at the base of the tery residual charge (in percentage). handlebar joint comfortably activated by When the charge of the battery goes pedal.

-

Page 32: Maintenance And Checks

5.3.6 ECO Function A correct Charging cycle follows the be- low series of illumination stages of the Once activated the ECO function (with Red LED. the proper button), let the brush motor and the suction motor work. With the Phase LED Description ECO mode activated, check if the noise Battery charging of the suction motor is reduced. -

Page 33: Programming

Programming 5.5.2 How to access the Opera- tor Menu 5.5.1 Entry into Operator Menu and Advanced Menu To enter to the Operator Menu go ahead as follow: The dashboard could be used like a pro- With the machine off, press at the gramming console. - Page 34 5.5.3 How to Change a Pa- 5.5.4 For example, to modify the rameter (in the Operator language from IT to EN Menu) Turn OFF the machine. To change the value of a parameter pro- With the machine off, press at the ceed as follows: same time button 2, 3 and 4.

- Page 35 5.5.5 How to access the Ad- 5.5.6 Use of the Check/Monitor vanced Menu Function The Check / Monitor function allows to The Advanced Menu can be reached check from the Operator Menu by accessing - The battery status the Password parameter and setting the - The motors absorption value 60.

-

Page 36: Alarm Table

Alarm Table 5.6.1 Alarms Alarms of Overcurrent and Temperature Id Alarm Meaning Solution AL 1: Function Brush Amperometric Protection Check consumption of the brush motor. Detected high current Brushes Ammeter on brush motor. AL 2: Function Suction Amperometric Protec- Check consumption of the suction motor. Detected high cur- Vacuum Ammeter tion rent on suction motor. -

Page 37: Menu Tables

Menu tables 5.7.1 Menu scheme Make sure the machine is turned off. Press simultaneously the buttons 2,3,4. Turn on the machine while holding down the buttons. Wait the loading of the Operator Menu. For the submenu of the Advanced Menu, refer to the specific tables. -

Page 38: Working Menu

5.7.2 Working Menu MENU DEFAULT CHOICES DESCRIPTION General Setup: IT - EN - FR - Setup language Language: ## SP - DE General Setup: GENIE XS . . . Setup type of machine Mod: ####### General Setup: Reset partial hourmeter Reset Cnt: # General Setup: KEY - BR -... -

Page 39: Pumps Sets

Brushes Sets Parameter Default Description Brushes Sets: 15.0 Maximum current from the main card to the brush motor. I Max: ## [Amp] Brushes Sets: 15.0 Rated current; with T Nom manages the amperometric protection I Nom: ## [Amp] (alarm + stop brush motor). Brushes Sets: Rated timer;... -

Page 40: Mechanical Rubbing System

Chapter 6 Mechanical Rubbing System Structure Description: 1. Gearmotor The washing function of the machine is obtained by the interaction of the 2. Gearmotor Support cleaning solution with the dirt present on the floor. 3. Brushdeck Body To facilitate and enhance this inter- 4. -

Page 41: Maintenance And Checks

Maintenance 6.3.2 Motor checks Check (to perform every 150h) Remove the brush. 6.3.1 Brush Deck Access the Check/Monitor Menu, and select the parameter I Br, pressing the The brush deck must be free to lean button 2. evenly to the ground and properly carry Lift the brush deck so that it does not out its function. - Page 42 6.3.3 Brass bushings 6.3.4 Scrubdeck Body Check Check (to perform every 150h) (to perform every 50h) The brass bushings allow a fluid ro- The brush base must be kept clean tational movement of the gearmotor and intact. A ruined brush base may support.

-

Page 43: Drying System

Chapter 7 Drying System Structure Description 1. Squeegee The machine dries the floor using an integrated Drying System. 2. Squeegee Support After the washing, the solution used, 3. Suction Hose with the mechanical action of the brush to remove the dirt, is collected by a 4. -

Page 44: Adjustments

Adjustments Maintenance Checks 7.3.1 Squeegee 7.4.1 Squeegee The Squeegee has to be adjusted when removed from the machine. The goal Check (to perform every 2h) of the adjustment is to let the squeegee To have a good performance blade be angled 45 degrees to the floor The squeegee chamber have to be clean for its whole length. - Page 45 7.4.4 Suction Cover Maintenance (to perform every 150h) Replacing Squeegee Wheels Floaters Put the machine in safe conditions. Check (to perform every 2h) The suction cover have to be clean to Place the machine vertically. allow the full passage of water and air through its conveyor compartments.

- Page 46 7.4.6 Vacuum Motor Successively with compressed Air, clean the air conveyor compartment Check (to perform every 150h) of the suction motor. Access the Check/Monitor Menu, and select the parameter I Vac, pressing the button 2. The vacuum motor with hose discon- nected from the squeegee has to absorb less than 2,8 Amps.

-

Page 47: Machine Frame And Traction System

Chapter 8 Machine Frame and Traction System Structure Description 1. Wheels The frame It is a single structure in alu- minum on which rest the tanks. 2. Frame The machine traction is ensured by the mechanical friction system. The wheels are directly fixed to the frame. -

Page 48: Cleaning Solution Supply System

Chapter 9 Cleaning Solution Supply System Structure Description: 1. Solution Tank The Cleaning Solution Supply System is made by a tank commonly called 2. Solution Filter solution tank or clean water tank. 3. Hoses In this tank the clean water is mixed with the detergent to create the cleaning 4. -

Page 49: Maintenance And Checks

Maintenance Checks 9.3.1 Solution Tank Check (to perform every 50h) 9.3.3-2 The solution tank has to be clean and intact. It has not to have cracks or any other kind of damage. Verify, when the 9.3.4 Water Pump tank is completely filled up, that there are not leakage. -

Page 50: Consumable & Recommended Spare Parts

Chapter 10 Consumable & Recommended Spare Parts 10.1 Consumable Spare Parts 10.1.1 Mechanical Rubbing System Description (in) Bristle Bristle (in) Colour 439929 BRUSH PPL 0,3 0,012 Black 441041 BRUSH PPL 0,2 0,024 Black 439930 PAD HOLDER 10.1.2 Drying System Description Dimensions 439839 FRONT RUBBER... -

Page 51: Recommended Spare Parts

10.2 Recommended Spare Parts The following table refers to the Recommended Spare Parts, and reports the amount suggested by the number of purchased machines. Machines Parts 10.2.1 Electrical System Description 439802 MAIN CARD CFSS000 440029 HANDLE CONTROL CARD 440247 BRUSH MOTOR CONTROL CARD 439605 SERIAL CABLE FOR CONTROL CARD 439524... - Page 52 Hillyard, Inc. Service Manual TRIDENT XM13SC Hillyard, Inc. 302 North 4th Street - P .O. Box 909 St. Joseph, Missouri 64501 - USA Tel. 1-800-365-1555 - Fax 1-800-881-3840 Edition: October 4, 2017...

Need help?

Do you have a question about the TRIDENT XM13SC and is the answer not in the manual?

Questions and answers

how do we remove brush to replace with drive block to use scrubbing pad?