Summary of Contents for Varian Turbo-V70

- Page 1 INSTRUCTION MANUAL Turbo-V70 controller Eurocard Model 969-9514 87-900-879-01 (A) APRIL 2002...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Section Page Safety summary Description General Turbo-V70 controller eurocard description Controller specifications Controller outline Installation General J2 connector J3 connector J4 connector J5 RS-232 interface connector RS-232 communication description Operation General Switching on/off the pump Low speed activation/deactivation... -

Page 5: Safety Summary

WARNING! Warning are used when failure to observe instructions or precautions could result in injury or death. CAUTION! Cautions are used when failure to observe instructions could result in damage to equipment, whether Varian supplied or other associated equipment. NOTE Infomation to aid the operatr in obtaining the best performance from the equipment. -

Page 6: General

The controller can be operated via remote signals 1-1 General through an RS-232 connection. The RS-232 signals are The Turbo-V70 controller eurocard is a microprocessor- available on J5 connector. controlled, solid-state, frequency converter with self- The controller can be operated in local mode through diagnosis and protection features. -

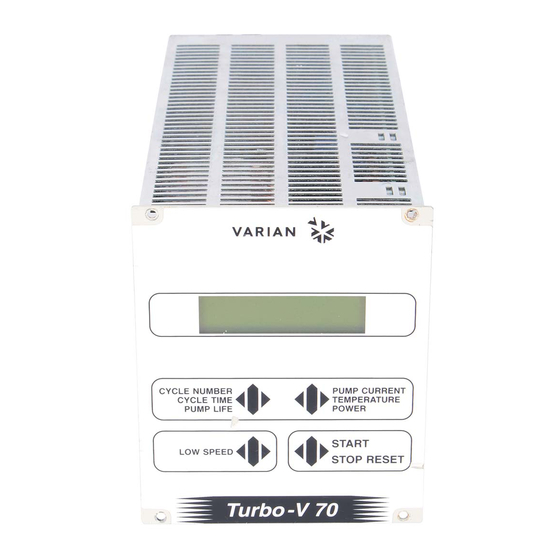

Page 7: Controller Outline

SECTION I - DESCRIPTION 1-4 Controller outline The outline dimension for the controller are shown in Fig. 1-1. Figure 1-1 Controller outline 87-900-879-01 (A) -

Page 8: General

SECTION II - INSTALLATION 2-1 General 2-4 J4 connector Inspect the controller for any shipping damage. The signals of J4 connector are the following: • The controller is designed to be installed into a rack. Pin 3 Failure. When a fault condition is detected, the pump is stopped and a signal is present on this All the connections are fitted to J2, J3, J4 and J5 pin. -

Page 9: Rs-232 Communication Description

SECTION II - INSTALLATION • 2-6 RS-232 communicafion description Data Field Lenght: it points out the next field lenght in characters. In this protocol the possible Communication format: combinations are: 02 = parameter reading request • 8 data bit 06 = parameter, writing •... - Page 10 SECTION II - INSTALLATION • in the case of a string with a lenght greater than 40 characters, with: PARAMETER TYPE DESCRIPTION NUMBER X0002 Low speed ON/OFF Controller address X0003 Pump ON/OFF • X0008 Remote ON/OFF in the case of a wrong checksum, with: 10009 Error acknowledgment: error status clearing...

-

Page 11: General

SECTION III - OPERATION 3-1 General 3-3 Low speed activation/deactivation Make all vacuum manifold and electrical connections To activate the Low Speed status it is necessary to and refer to Turbo-V pump instruction manual prior to connect pin 13 of J4 connector to pin 15 (ground) of the operating the Turbo-V controller. -

Page 12: General

SECTION IV - MAINTENANCE Error Code Table 4-1 General Replacement controllers are available on an advance DESCRIPTION exchange basis through Varian. necessary, BLINKING information is provided to aid the operator in NUMBER determining malfunctions and corrective steps to be taken. No error Output current>... - Page 13 NOTE: If a product is received at Varian which is contaminated with a toxic or hazardous material that was not disclosed, the customer will be held responsible for all costs incurred to ensure the safe handling of the product, and is liable for any harm or injury to Varian employees as well as to any third party occurring as a result of exposure to toxic or hazardous materials present in the product.

- Page 14 Request for Return FAILURE REPORT TURBO PUMPS and TURBOCONTROLLERS POSITION PARAMETERS Power: Rotational Speed: Does not start Noise Vertical Current: Inlet Pressure: Does not spin freely Vibrations Horizontal Temp 1: Foreline Pressure: Does not reach full speed Leak Upside-down Mechanical Contact Overtemperature Other: Temp 2:...

- Page 15 Tel: (39) 011 997 9111 Tel: (39) 011 997 9111 Fax: (39) 011 997 9350 Brazil Fax: (39) 011 997 9350 Varian Industria e Comercio Ltda. Japan Avenida Dr. Cardoso de Mello 1644 Internet Users: Varian Vacuum Technologies Vila Olimpia Customer Service &...

Need help?

Do you have a question about the Turbo-V70 and is the answer not in the manual?

Questions and answers