Table of Contents

Advertisement

Quick Links

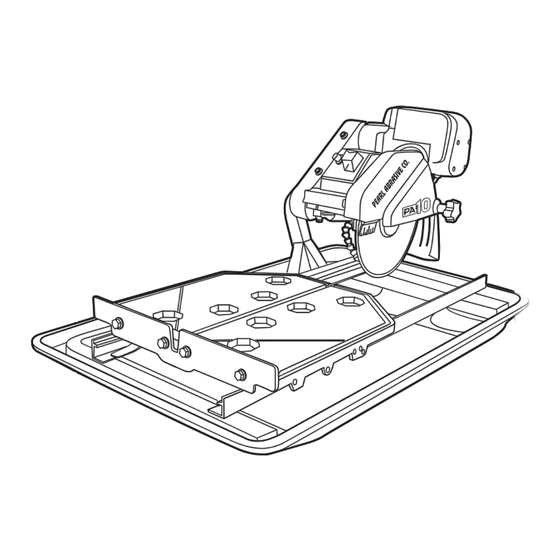

MODEL PA-10™ TILE SAW

OWNER'S/OPERATOR'S MANUAL

Caution!

Read Safety and General Instructions carefully before using saw for the first time.

REV. 3

serial

number -

You should record the Serial Number of your Tile Saw on this

Owner's/Operator's Manual and on the Warranty Card. The Warranty

Card must be sent back with all the required pertinent information

for the warranty to take effect.

Covered by one or more of the following US Patents:

7302947, 7394031 and 6752139

™

Advertisement

Table of Contents

Summary of Contents for Pearl PA-10

- Page 1 ™ MODEL PA-10™ TILE SAW OWNER’S/OPERATOR’S MANUAL serial number - You should record the Serial Number of your Tile Saw on this Owner’s/Operator’s Manual and on the Warranty Card. The Warranty Card must be sent back with all the required pertinent information for the warranty to take effect.

-

Page 2: Table Of Contents

TABLE OF CONTENTS PAGE GENERAL SAFETY RULES FOR ALL POWER TOOLS....... . 3 SYMBOLS . -

Page 3: General Safety Rules For All Power Tools

i. GENERAL SAFETY RULES FOR ALL POWER TOOLS W RNING! Read all instructions. As with all machinery there are certain hazards involved with operation and use of the machine. The following basic safety precautions should be followed at all times to reduce the risk of fire, electric shock and serious personal injury to you or others. -

Page 4: Symbols

21. Extension cords. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. Extension cord tables (refer to page 21) show the correct size to use depending on cord length and nameplate ampere rating. -

Page 5: Features

iii. FEATURES CARBON BRUSH MOTOR Generates more torque and is physically smaller and lighter than similarly rated induction motors. CUTTING TABLE Features an injection mold rubber mat that provides a THERMAL OVERLOAD PROTECTION fi rm, durable work surface Prevents the motor from overheating and while the ball bearing protects the saw from power surges. -

Page 6: Unpacking

v. UNPACKING Open the container and carefully lift the saw by the foam packaging and place it on a flat, level working area. Be sure that you have the following items before you discard the container: • Saw • Stainless steel water tray •... - Page 7 Figure 4 W TER PUMP INST LL TION 1. Remove the water pump from the box and check that it is not damaged. 2. Slide the pump onto the U-shaped bracket located at the bottom of the frame. The pump Side should be oriented such that the water outlet is Extension...

-

Page 8: Proper Blade Use

SETTING THE CUTTING DEPTH The recommended cutting depth is 1/4" below the cutting table surface. To adjust the cutting depth, loosen the cutting depth control knob and set the cutting head such that the lowest point of the blade is 1/4"... -

Page 9: Safe Operating Practices For Tile Saw

Do not operate any saw without safety guards in place or with a blade diameter Blade dressing stones are available from your local Pearl larger than the maximum saw blade capacity. Warehouse. 8. Before mounting a blade on the saw clean and 14. - Page 10 See Figure 6(D). If a Ground Fault Circuit Interrupter 19. Grounding Instructions outlet is not available, Pearl Abrasive Co. has it available as an accessory item. A plug-in Ground Fault Circuit • In the event of a malfunction or...

- Page 11 Cover of Grounding grounded Means outlet box (Lug) Metal Screw Grounding pin Grounding pin Figure 6 Grounding Methods receptacle to prevent water from dripping * Ground Fault Circuit Interrupter (GFCI) onto the receptacle or plug. The user protection should be provided on the should arrange a “drip loop”...

-

Page 12: Care And Maintenance

ix. CARE AND MAINTENANCE W RNING! For your safety before performing any maintenance on the saw turn off the power switch and unplug the power cord. GENER L RULES prevent the water pump from clogging with residual dirt. • Always clean the machine before performing any After wet cleaning and before using the machine maintenance/ repair. - Page 13 W TER PUMP M INTEN NCE RE LIGNMENT When the machine has not been used for a long period of time, Method 1: hard packed dirt may begin to build up inside the pump and This procedure deals with the most common source of block the pump wheel.

- Page 14 Figure 10 1. Lift the saw up from within the water tray and place it on a flat level surface. Use the universal wrench to loosen (but do not remove) the fasteners from either end of both guide rails. Move each rail away from the other, so that the horizontal rollers are clear of the right guide rail.

-

Page 15: Electrical Motor Specifications

2. Loosen the socket bolts on the flat roller plate so that the Figure 15 roller can swing freely about one bolt. See Figure 16. Do Flat this for both flat roller plates. Roller Guide Roller 3. Hold the table against the guide rails. The flat rollers should reposition themselves to maintain contact with the Shim guide rails. - Page 16 xi.TROUBLESHOOTING – 16 –...

- Page 17 For your safety and the safety of others, turn the power switch off and always remove the W RNING! plug from power source before troubleshooting. Repairs performed by unauthorized personnel could cause serious hazard. We recommend that service to this tool be performed by a qualified service technician with original equipment replacement parts.

-

Page 18: Replacement Parts List

11 Male 3╱8 - 16 UNC x 32L Star type knob PA100021 5╱8 - 11 UNC Nut PSV00004 12 VX10.2XL/PA10 Water tray V35012SSXL PA-10 BLADE GUARD ASSEMBLY PART NAME PART NUMBER Blade guard assembly PA100204 M6 Spring lock washer V3911090... - Page 19 PA-10 CUTTING HEAD ASSEMBLY PART NAME PART NUMBER PART NAME PART NUMBER Motor Mounting Plate PA100201 19 M8 x 1.25 x 70L x 22S Socket head cap hex screw (4) PA0329 Motor tension bracket PA100074 20 M8 Spring Lock Washer (6)

- Page 20 PA-10 LIQUID BEARING HOUSING ASSEMBLY PART NAME PART NUMBER PART NAME PART NUMBER 10" Variant LCBH ver2 (black) - Complete PA100202 M4 x 0.7 x 8L Cross Screw PA1374 Blade Shaft PA100112 10 D40 d17 6203LLB Radial Bearing PA100120 Rubber Gasket...

- Page 21 PA-10 CUTTING TABLE ASSEMBLY PART NAME PART NUMBER PART NAME PART NUMBER Cutting table (only) PA100095 11 M8 Spring Lock Washer PA0121 Guide roller complete (2) PA100097 12 M6 Spring Lock Washer V3911090 Horizontal roller assembly (3) PA100098 13 M8 x 1.25 Nut...

- Page 22 xiii. ACCESSORIES & PARTS Name (Qty.) Name (Qty.) Stainless Steel Water Tray (1) (Optional) Complete Drain plug is not included Miter Block with Part Number Knob (1) V35012SS-XL Part Number S1000-34 Knob Only (1) V35016 Name (Qty.) (Optional) Side Extension Table (1) Part Number V100102 Name (Qty.)

-

Page 23: How To Order Parts

Pearl reserves the right to discontinue products at any time without notice. All illustrations displayed in this manual are the property of Pearl Abrasive Co. and shall not be duplicated or reproduced without the express written consent of Pearl Abrasive Co. - Page 24 CORPORATE OFFICE: SO. CALIFORNIA • USA 4900 ZAMBRANO ST., COMMERCE, CA 90040-0031 562-927-5561 • FAX 562-928-3857 Toll Free: 800-969-5561 www.pearlabrasive.com GEORGIA • USA ONTARIO • CANADA 3950 STEVE REYNOLDS BLVD., 375-2 PIDO ROAD NORCROSS, GEORGIA 30093 PETERBOROUGH, ONTARIO K9J-6X7 Part No. PA10MAN • 07/17...

Need help?

Do you have a question about the PA-10 and is the answer not in the manual?

Questions and answers