Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for E Instruments AMI 300

- Page 1 Multifunctional IAQ Monitor Supplied Calibration AMI 300 with certificate...

-

Page 2: Table Of Contents

Table of contents I – Technical specifications.....................4 Technical features..........................4 Specifications............................4 II – Introduction........................6 Description..............................6 Connections..............................7 III – Browsing........................8 IV – Menus..........................9 Probe menu...............................9 Using wire probes and modules........................9 Using wireless probes............................9 Functions..............................9 Temperature...............................9 Hold - Min/Max............................9 Delta T................................9 Hygrometry................................10 Calculations..............................10 Air quality................................10 Audible alarm..............................11... -

Page 3: I - Technical Specifications

Pressure module Piezoresistive sensor Left side : Overpressure allowed ±500 Pa : 250 mbar 1 USB port for E Instruments cable only Overpressure allowed ±2,500 Pa : 500 mbar 1 power supply plug Overpressure allowed ±10,000 Pa : 1,200 mbar Overpressure allowed ±500 mbar : 2 bar... - Page 4 I – Technical specifications Measuring ranges Measuring units Accuracy* Resolutions From 0.15 to 3 m/s ±3% of reading ±0.03 m/s 0.01 m/s m/s, fpm, Km/h Air velocity From 3.1 to 30 m/s ±3% of reading ±0.1 m/s 0.1 m/s 0.1 °C °C, °F Temperature ±0.3% of reading ±0.3°C...

-

Page 5: Introduction

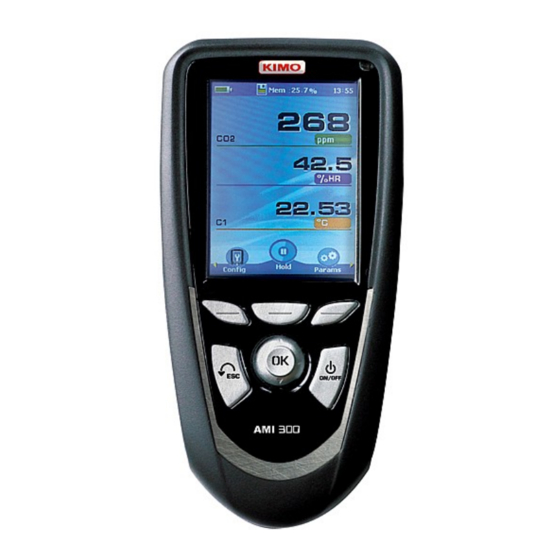

II – Introduction Description Top view Module connections Graphic display Battery level Memory status used Mini-Din C2 mini-Din C1 Hour connector connector Value Unit Side view Power supply connection Channel USB port for Instruments Circular cable menu Elastomer protection Keypad Access keys for circular menu Browsing joystick : 4 directions... -

Page 6: Connections

II – Introduction Connections Interchangeable measurement modules Interchangeable modules with Smart-plus system are automatically recognized when connected to the instrument. 1. Current / voltage module 2. Pressure module It allows differential pressure, air velocity or airflow measurements It allows current or voltage measurements on V/ with Pitot tube or Debimo on two pressure inputs (- and +) and A1 or VA/2 channels with current/voltage input thermocouple temperature measurement on Tc1 channel with wire... -

Page 7: Browsing

III – Browsing Power-up Enter key code with directional pad. (if the locking is activated) e Probe connection Probes display Select a connection with right and left keys Connections can be activated or deactivated with Info Measure Params... -

Page 8: Menus

IV – Menus Probe menu 1. Using wire probes and modules Probes display Wire probes and modules with Smart-plus system are automatically recognized from first connection. The ''Probe'' menu only appears when probes or module are connected. This menu allows to view probe information plugged to C2, Module, C1 or wireless connections. -

Page 9: Hygrometry

IV – Menus Hygrometry The following functions are enabled only if at least one probe is connected: - Hold (Hold – Min/Max) – see Temperature - Config (Configuration) - see Air velocity - ∆ T (Delta T) - Calc. (Calculation) - Alarms - see Air quality - Rec (Recording) - see Air velocity - Params (Parameters) - see Air velocity... -

Page 10: Audible Alarm

IV – Menus Alarms Select respectively ON or OFF with and in order to enable or disable the alarm. Choose your setpoint : CO Limit 1 (first CO setpoint), CO Limit 2 (second CO setpoint), low temperature setpoint and high temperature setpoint. Confirm with OK or . Select thresholds with OK or ... -

Page 11: Comax

IV – Menus CO max The CO mode is available when a CO/Temperature probe is connected. You can access this function selecting COmax with the access key CO max The CO is measured on an adjustable period, the maximum value measured in this period is called CO max . When CO peak is selected, the period is diplayed (30 seconds by default). -

Page 12: Units

This sub-function allows to modify the backlit. Click on OK or to enter. Select your backlit level (from 0 to 9 or AUTO) with and . Confirm wih OK. If you select AUTO, the AMI 300 adjuts automatically the backlit according to the room brightness. -

Page 13: Key Code

1. Create or launch a continuous dataset A continuous dataset can be carried out using AMI 300 and is composed of several dated measuring points. The operator can choose an automatic or a manual dataset, with an instant value or an average. This datasets can't be set using Datalogger-10 Software. -

Page 14: Downloading Data

IV – Menus 2. Launch a planned dataset A planned dataset is composed of several locations. For each location, the operator can enter a theorical value and a tolerance for the parameter to be controlled. Planification must be made via the software. a. -

Page 15: General Informations

4. Replace the front. Maintenance E Instruments performs calibration, adjustment and maintenance of all your instruments to guarantee a constant level of quality of your measurements. In regards of Quality insurance norms, we recommend that the instruments are checked once a year.

Need help?

Do you have a question about the AMI 300 and is the answer not in the manual?

Questions and answers