Table of Contents

Advertisement

Quick Links

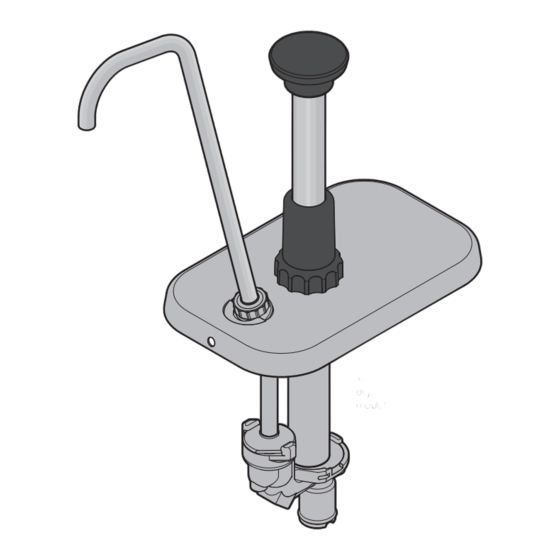

Stainless Steel Pump

for use with remote

dispensing systems

MODEL:

CP-RP

Thank You

...for purchasing our Stainless Steel Pump.

This quality NSF listed pump delivers precise portions

and lasts for years of service.

CONSISTENT PORTIONS—SERVE BETTER

Your pump may vary

depending on specific

model number.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Server Serve Better CP-RP

- Page 1 Stainless Steel Pump for use with remote dispensing systems MODEL: CP-RP Your pump may vary depending on specific model number. Thank You ...for purchasing our Stainless Steel Pump. This quality NSF listed pump delivers precise portions and lasts for years of service. CONSISTENT PORTIONS—SERVE BETTER...

-

Page 2: Pump Parts

Pump model, P/N (part number) and 82027 other identification are stamped on lid: MODEL SERIES XXXX ##X ##X O-RING, 1" 05127 ##### CYLINDER* For additional details about your pump, GASKET 88554 visit www.Server-Products.com VALVE BODY 85891 Enter your P/N into the search bar. Page 2... -

Page 3: Pump Cleaning

Be aware of the product you are serving and the NSF International lists this pump as temperature the product is required to maintain. “Not acceptable for dispensing potentially Server Products, Inc. cannot be responsible for the hazardous foods.” serving of potentially hazardous product. PUMP CLEANING FLUSH &... -

Page 4: Clean-In-Place

CLEAN-IN-PLACE PROCEDURE FOR PUMPS CLEAN • Pump out all (if any) remaining food product from inside pump body. • Wash and rinse off outside of pump body. • Flush out and rinse inside of pump. • Place lower end of pump into container full of water and operate pump until all (if any) remaining product is expelled and only warm water flows from discharge... - Page 5 DISASSEMBLY If pump has been in use, first rinse and flush pump. See PUMP CLEANING on page 3. During disassembly, collect small parts in a container to prevent loss. REMOVE PLUNGER & LID Turn locking collar and discharge tube nut counterclockwise to loosen and remove.

- Page 6 ASSEMBLY WASH ALL PARTS PROPERLY BEFORE EVERY USE. See page 3. PREPARE PISTON INSTALL SMALL O-RING into seal. INSTALL SEAL onto piston head. Apply food equipment lubricant to outside of seal. TIP: Flared end of seal should face away from piston head. SLIDE WASHER onto piston.

- Page 7 INSTALL GASKET into valve body. Apply food equipment lubricant on gasket. TIP: Flat side of gasket should face up. INSTALL CYLINDER onto valve body. TILT wide edge of cylinder under nub on rim of valve body. FIT TABS on cylinder into corresponding notches in valve body.

-

Page 8: Troubleshooting

Server Products customer service to request a Return Authorization Number. Merchandise must be sent to Server Products with this number. Service is extremely prompt. Typically, units are repaired Server Products equipment is backed by a and ship out within 48 hours of receipt.

Need help?

Do you have a question about the Serve Better CP-RP and is the answer not in the manual?

Questions and answers