Table of Contents

Advertisement

Quick Links

Operating Instructions

General Information ................................................. 5

Symbols ................................................................... 5

Use of tilt handle ..................................................... 5

Safety ....................................................................... 5

Operating conditions ............................................... 5

EMC ......................................................................... 6

Warranty .................................................................. 6

Maintenance ............................................................ 6

Protective Switch-Off .............................................. 6

Power supply ........................................................... 6

Type of signal voltage .............................................. 7

Amplitude Measurements ....................................... 7

Total value of input voltage ..................................... 8

Time Measurements ............................................... 8

Connection of Test Signal ........................................ 9

First Time Operation .............................................. 10

Trace Rotation TR .................................................. 10

Probe compensation and use ............................... 11

Adjustment at 1kHz ............................................... 11

Adjustment at 1MHz ............................................. 11

amplifiers in Yt mode. ........................................... 12

X-Y Operation ......................................................... 12

Phase comparison with Lissajous figures ............ 13

in DUAL mode ....................................................... 13

Measurement of an ............................................... 13

amplitude modulation ............................................ 13

Triggering and time base ....................................... 14

Automatic Peak-Triggering .................................... 14

Normal Triggering .................................................. 15

Slope ...................................................................... 15

Trigger coupling ...................................................... 15

Line triggering (~) .................................................. 16

Alternate triggering ................................................ 16

External triggering ................................................. 16

Trigger indicator ..................................................... 16

Holdoff-time adjustment ....................................... 16

Delay / After Delay Triggering ............................... 17

AUTO SET .............................................................. 18

SAVE/RECALL ........................................................ 19

Component Tester ................................................. 19

Using the Component Tester ................................ 19

Test Procedure ....................................................... 19

Test Pattern Displays ............................................. 19

Testing Resistors ................................................... 20

Testing Capacitors and Inductors .......................... 20

Testing Semiconductors ........................................ 20

Testing Diodes ....................................................... 20

Testing Transistors ................................................. 20

In-Circuit Tests ....................................................... 20

Subject to change without notice

Oscilloscope

HM304

GB

General ................................................................... 23

Astigmatism Check ............................................... 23

Symmetry and Drift of the Vertical Amplifier ....... 23

Calibration of the Vertical Amplifier ....................... 23

Vertical Amplifier .................................................... 23

Triggering Checks .................................................. 24

Timebase ................................................................ 24

Holdoff time ........................................................... 25

Component Tester ................................................. 25

Trace Alignment ..................................................... 25

General ................................................................... 25

Instrument Case Removal ..................................... 25

Operating Voltages ................................................ 26

Maximum and Minimum Brightness .................... 26

Astigmatism control .............................................. 26

Trigger Threshold ................................................... 26

Trouble-Shooting the Instrument .......................... 26

Adjustments ........................................................... 26

RS232 Interface - Remote Control ....................... 27

Baud-Rate Setting .................................................. 27

Data Communication ............................................. 27

Command definition .............................................. 27

Command Chart: ................................................... 27

Short instruction for HM304 ................................. 29

Switching on and initial setting ............................. 29

Vertical amplifier mode .......................................... 29

Triggering mode ..................................................... 29

Measurements ...................................................... 29

Component tester mode ....................................... 29

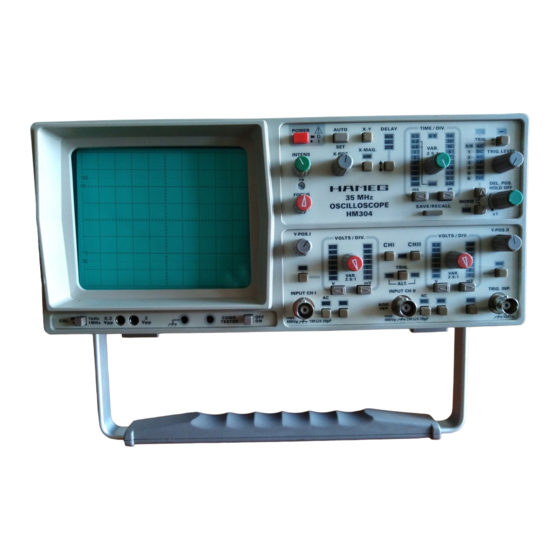

(Brief Description - Front View) ............................. 30

Table of contents

1

Advertisement

Table of Contents

Summary of Contents for Hameg HM304

-

Page 1: Table Of Contents

Component Tester ..........19 Instrument Data Field with Single Commands ..28 Using the Component Tester ........ 19 Short instruction for HM304 ......... 29 Test Procedure ............19 Switching on and initial setting ......29 Test Pattern Displays ..........19 Testing Resistors ........... - Page 2 HAMEG instruments fulfill the regulations of the EMC directive. The conformity test made by HAMEG is based on the actual generic- and product standards. In cases where different limit values are applicable, HAMEG applies the severer standard. For emission the limits for residential, commercial and light industry are applied.

- Page 3 5, av de la République F - 94800 Villejuif Die HAMEG GmbH / HAMEG S.a.r.l bescheinigt die Konformität für das Produkt The HAMEG GmbH / HAMEG S.a.r.l herewith declares conformity of the product HAMEG GmbH / HAMEG S.a.r.l déclare la conformite du produit...

-

Page 4: Oscilloscope Data Sheet With Technical Details

'delay' and 'automatic General Information trigger after delay' modes by a factor of up to 1,000 times. The HM304 is CRT: D14-364GY/123 or ER151-GH/-,rectangular equipped with a built-in Component Tester, dual frequency (1 kHz / 1 MHz) -

Page 5: General Information

General Information contains important information and warnings which have to be followed by the user to ensure safe operation and to retain This oscilloscope is easy to operate. The logical arrangement the oscilloscope in a safe condition. of the controls allows anyone to quickly become familiar with the operation of the instrument, however, experienced users The case, chassis and all measuring terminals are are also advised to read through these instructions so that all... -

Page 6: Emc

The fuse(s) can then be replaced and pressed in until locked HAMEG warrants to its Customers that the products it on both sides. manufactures and sells will be free from defects in materials and workmaship for a period of 2 years. -

Page 7: Type Of Signal Voltage

The minimum signal voltage which must be applied to the Y input for a trace of 1div. height is 1mVpp when the 1mV LED With the HM304, most repetitive signals in the frequency is lit and the vernier is set to CAL by turning the fine range up to at least 35MHz (-3dB) can be examined. -

Page 8: Total Value Of Input Voltage

With the designations = displayed wave length in div. of one period, With the above listed exceptions HAMEG 10:1 probes can = time in seconds for one period, be used for DC measurements up to 600V or AC voltages = recurrence frequency in Hz of the signal, Tc = time coefficient in s/div. -

Page 9: Connection Of Test Signal

When using a 50Ω cable such as the HZ34, a 50Ω through termination type HZ22 is available from HAMEG. When = √ transmitting square signals with short rise times, transient... -

Page 10: First Time Operation

DC voltage (e.g. for hum voltage measurement). The HM304 accepts all signals from DC (direct voltage) up to a frequency of at least 35MHz (-3dB). For sinewave voltages With all attenuator probes, the maximum AC input voltage the upper frequency limit will be 50MHz (-6dB). -

Page 11: Probe Compensation And Use

1kHz and 1MHz from two output sockets below the CRT screen. Using the probes HZ51, 52 and 54, the full bandwidth of the HM304 can be utilized without risk of unwanted waveform As the squarewave signals are used for probe compensation distortion. -

Page 12: Operating Modes Of The Vertical Amplifiers In Yt Mode

Providing these essential features, as well as switch- by simultaniously depressing both pushbuttons marked with selectable output-frequencies, the calibrator of the HM304 < and > arrows in the TIME/DIV sector. Any change in the can, under certain conditions, replace expensive squarewave... -

Page 13: Phase Comparison With Lissajous Figures

• Do not use a too high test frequency. The phase shift of ϕ the two oscilloscope amplifiers of the HM304 in the X-Y mode can exceed an angle of 3° above 120kHz. ϕ π... -

Page 14: Triggering And Time Base

The time base The internal trigger threshold of the HM304 is given as ≤ is set so that several cycles of the modulation frequency are 5div. When the trigger voltage is externally supplied, it can visible. -

Page 15: Normal Triggering

coupling mode. In this case the automatic is still present, but automatic (peak-value) triggering was in use, the peak a wrong TRIG. LEVEL setting causes an untriggered display. value detection is then switched off automatically. Automatic triggering is practicable with internal and external trigger voltage. -

Page 16: Line Triggering (~)

Line triggering (~) The maximum input voltage of the input circuit is 100V (DC+peak AC). A voltage originating from mains/line (50 to 60Hz) is used for triggering purposes if the trigger coupling (TRIG.) is set to ~. It must be noted that a different phase angle between the This trigger mode is independent of amplitude and frequency measuring and the triggering signal may cause a display not of the Y signal and is recommended for all mains/line... -

Page 17: Delay / After Delay Triggering

Photo 1 (composite video signal) MODE: undelayed TIME/DIV: 5ms/div Trigger coupling: TV-F Trigger slope: falling ( - ) Depressing the DELAY pushbutton once for a short time, lights the SEA (SEARCH) LED on the DELAY scale. In all delay modes, the DEL. POS. knob assumes the function of DEL. -

Page 18: Auto Set

DTR mode was higher than the actual value in SEA (search) no LED on the DELAY scale is lit. The instrument then is set mode, the time coefficient in DEL or DTR mode is automatically to the operating conditions used before automatically set to the value used during SEA (search) switching over to DEL. -

Page 19: Save/Recall

Observe oscilloscope display. Component Tester Only discharged capacitors should be tested! The HM304 has a built-in electronic Component Tester Test Pattern Displays (COMP. TESTER), which is used for instant display of a test pattern to indicate whether or not components are faulty. -

Page 20: Testing Resistors

Testing Resistors 7V, their Z-breakdown, forms a second knee in the opposite direction. A Z-breakdown voltage of more than 6.8V can not If the test object has a linear ohmic resistance, both deflecting be displayed. voltages are in the same phase. The test pattern expected from a resistor is therefore a sloping straight line. -

Page 21: Subject To Change Without Notice

In-circuit tests are possible in many cases. However, they Another way is a test pattern comparison to an identical circuit are not well defined. This is caused by a shunt connection of which is known to be operational (likewise without power real or complex impedances - especially if they are of relatively and any external connections). -

Page 22: Subject To Change Without Notice

Subject to change without notice... -

Page 23: Test Instructions General

Differences of up to 1div. are permissible (input coupling should be set to AC). Normally, the CRT of the HM304 has very good brightness. Any reduction of this brightness can only be judged visually. -

Page 24: Triggering Checks

Of course, the quality of the transmission performance is It should be approx. 0.3-0.5div. for the HM304. An increased not only dependent on the vertical amplifier. The input trigger sensitivity creates the risk of response to the noise attenuators, located in the front of the amplifier, are level in the trigger circuit. -

Page 25: Holdoff Time

If a precise marker signal is not available for checking the graticule. With the HM304 in its closed case, an angle of Timebase time coefficients, then an accurate sine-wave rotation ±0.57° (0.1div. difference in elevation per 10div. -

Page 26: Operating Voltages

Trouble-Shooting the Instrument Handling of the CRT needs utmost caution. The glass bulb must not be allowed under any circumstances to come into contact with hardened tools, nor should it undergo local For this job, at least an isolating variable mains/line transformer superheating (e.g. -

Page 27: Rs232 Interface - Remote Control

RS232 Interface - Remote Control Command definition The oscilloscope is supplied with a serial interface for Kommand: Rückgabe Beschreibung control purposes. The interface connector (9 pole D- SUB PC→ → → → → Scope Scope→ → → → → PC female) is located on the rear of the instrument. -

Page 28: Instrument Data Field With Single Commands

the PC to the oscilloscope, otherwise it results in a buffer overflow. The setting of the oscilloscope is made via the In- strument Data Field (Device Data Field = DDF) as a binary array. Each byte of the data field can also be called-up by a single command. -

Page 29: Short Instruction For Hm304

Short instruction for HM304 Switching on and initial setting Case, chassis and all measuring terminals are connected to the safety earth conductor (Safety Class I). Connect instrument to power outlet, depress red POWER button. LED‘s indicating operating condition. Instrument is set as it was before switching off. -

Page 30: Front Panel Elements Hm304 (Brief Description - Front View)

Front Panel Elements HM 304 (Brief Description - Front View) Element Function Element Element Element Element Element Function Function Function Function Function POWER Turns scope on and off. Trigger Coupling Indicates trigger coupling: (pushbutton) I = ON; O = OFF (LED scale) AC: <20Hz - 100MHz DC: 0 - 100MHz... - Page 31 Element Function Element Function CH I & CH II Pushbuttons for Mono CH I and CH II, DUAL and GD (LED lit) = signal disconnected from input, (pushbuttons + ADD selection. Mode indication by LED(s) deflecti- (pushbutton Y amplifier input grounded. „ADD“...

Need help?

Do you have a question about the HM304 and is the answer not in the manual?

Questions and answers