Summary of Contents for Nibe PELLUX 100

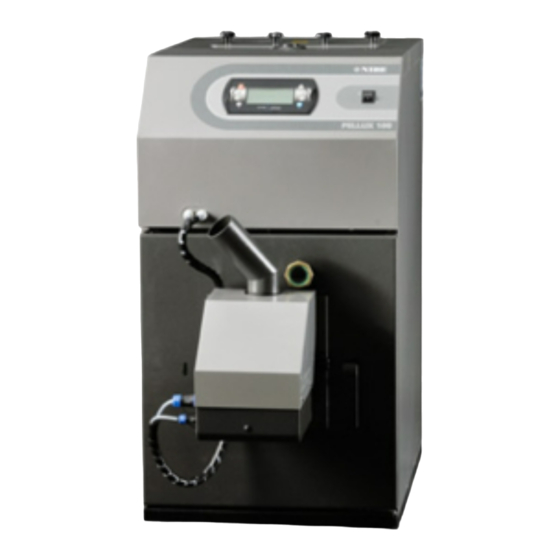

- Page 1 MOS GB 1248-1 INSTALLATION AND MAINTENANCE INSTRUCTIONS PELLUX 100 PELLUX 100 231259...

-

Page 3: Table Of Contents

Causes and actions in event of malfunctions Burner Component positions For the Installer Boiler General information for the installer Burner Electrical components Boiler room Chimney Dimensions and location coordinates Connection Technical specifications Pipe connections Enclosed kit Electrical connections Connection Accessories Internal fuse protection PELLUX 100... - Page 4 General General Thank you for relying on us to supply your boiler and congratulations on choosing PELLUX 100, a high quality pellet boiler with a long service life. In order to get the ultimate benefit from your PELLUX 100 you should read through these Installation and Maintenance Instructions.

-

Page 5: For Home Owners

The external circulation pump starts when the temperature PELLUX 100 has a top connection and is equipped with in the heater falls below the set values. automatic charging for preparation of domestic hot water. PELLUX 100 is also equipped with a climate controlled automatic shunt. -

Page 6: Front Panel

Escape. Moves up a level in the menus or erases a parameter setting. Arrow up. Makes it possible to navigate in the menus and to raise a set value. If you are on the start page you can move to the simplified menu by pressing arrow up. PELLUX 100... - Page 7 If you are on the start page you can move to the simplified menu by pressing arrow down. Enter. Press Enter to: open the menu that you have up at present. change to entered value. confirm an alarm. PELLUX 100...

-

Page 8: Start And Stop

If no flames are registered after 5 attempts an alarm Remember that the remaining fuel will not be extin- is given and the firing up attempt is stopped. guished but must burn out. PELLUX 100... -

Page 9: Control

Heating program Hot water program This is the menu that is displayed when PELLUX 100 is in its normal/start mode. The menu displays the boiler status, set temperature for the boiler and the present temperature. One can also see the date, time, whether the control computer... - Page 10 Manual start of fuel feed from the pellet hopper. Feed Fuel After filling an empty pellet hopper this function must be used until the fuel starts to come out of the fire proof hose from the pellet auger. PELLUX 100...

-

Page 11: Dealing With Malfunctions And Maintenance General

Before the sweep visits, the hatch for any draft limiter must be locked by turning the locking screw a quarter turn to the side of the hatch. This is to prevent soot from entering the boiler room when the chimney is swept. After sweeping the PELLUX 100... -

Page 12: Causes And Actions In Event Of Malfunctions

The temperature limiters break the power to the burner and pellet screw if the temperature exceeds 90 °C. Before the burner and the pellet screw are started again the tripped temperature limiter must be reset, see page 38. PELLUX 100... - Page 13 NOTE The product's serial number should always be stated with all correspondence with NIBE. 069 _ _ _ _ _ _ _ _ _ _ _ _ _ _ PELLUX 100...

-

Page 14: For The Installer

PELLUX 100 has an upward top connection with an internal If the heating system is equipped with an open expansion diameter of 125 mm and is intended for connection to a vessel, the distance between the highest radiator and the chimney with a minimum internal diameter of 125 mm. -

Page 15: Pipe Connections

Pipe connections This shows the outline diagram for pipe installation when one has a water heater, buffer tank or buffer tank with solar heating PELLUX 100 standard installation PELLUX 100 with buffer PELLUX 100 with buffer and solar heating PELLUX 100... -

Page 16: Electrical Connections Connection

PELLUX 100 must be installed via an isolator switch with a minimum breaking gap of 3 mm. Connecting the control computer The boiler requires 230 V NAC 50 Hz NOTE Voltage/supply is connected to terminal block X9. - Page 17 CAN-bus to prevent an echo. There must be a terminator on the CAN bus even if only one module is connected to it. The control computer is connected to the CAN bus and the power supply according to the image below. PELLUX 100...

- Page 18 Control grid cleaning in module L2 DO6, N Fresh air fan for the burner. AO1, N1 Pipe cleaning Control of turbulator cleaning AO2, N Pellet screw AO3, N1 Circulation pump hot water AO4, N Neutral conductor Protective earth PELLUX 100...

-

Page 19: Connection Burner

Output for external circulation pump External circulation pump is connected to CAN bus module, see table option. 16. The pump is operated using the set values in the control computer. PELLUX 100... -

Page 20: Installing The Boiler Burner

Pellet hopper and pellet screw 2. Install the pellet screw in the opened hole and to the PELLUX 100 fuel is fed from a pellet hopper of an external feed pipe in the bottom of the pellet hopper. pellet screw. The pellet screw should be inclined at a rising 3. -

Page 21: Draft Limiter

Upon delivery, the hatch is set at 10 Pa. At the correct setting, the hatch must open smoothly and Lock screws evenly when the burner is not in operation. PELLUX 100... -

Page 22: Service Menus

4. Scroll using the Up or Down arrows until the correct section is Central Heating displayed in the menu. Temperature 5. Press the Enter button to access the menu for the selected sec- Circuit No : 1 tion. Kitchen PELLUX 100... - Page 23 PELLUX 100...

- Page 24 Starts the mixing valve servo motor regardless of other set- tings. Circuit name States the name of the heating circuit. Flow temperature -20 °C 80 °C Flow temperature -0 °C 80 °C Flow temperature 10 °C 80 °C PELLUX 100...

- Page 25 HW 1 which section you have selected to check. Both by name and number. set value for the hot water. measured value for the hot water. source for preset temperatures. indication of whether the pump is operating or not. PELLUX 100...

- Page 26 Pump test Starts the circulation pump re- gardless of other settings. Circ. name States the name of the hot wa- ter circuit. For setting schedule see page 33. PELLUX 100...

- Page 27 5. Select what you require using Enter, in this case State. State 6. Here you can now see: 12:43 state. number of hours since the boiler last updated the informa- tion. time. boiler temperature over the last two hours. burner output in %. average output. PELLUX 100...

- Page 28 HWX cleaning start t. 15 Setting for what times the heat exchanger is to be cleaned. HWX cleaning stop t. XX Test Cleaning HWX Test operation of the heat ex- changer cleaning. For setting schedule see page 33. PELLUX 100...

- Page 29 1. In the start menu, press Enter to open the extended menu. 2. Scroll using the Up or Down arrows. 3. When you come to the settings menu, press Enter to access the Settings menu to select which values you wish to set or check. PELLUX 100...

- Page 30 Determines if the system has an external temperature sensor or not. (module 0) Return sensor Determines if the system has a return temperature sensor or not. (module 5) Solar heating Determines if the system has solar panels or not. PELLUX 100...

- Page 31 %. 11.5 kg total fuel consumption. present fuel consumption. 4.3 kg/h 4.6 kW present burner effect in kW. Oxygen content of smoke gases. brightness of flames. fan output. time to fill the fuel reservoir. PELLUX 100...

- Page 32 Oxygen level min. Set value for oxygen content of the smoke gas minimum 30 % burner output. PELLUX 100...

- Page 33 The boiler temperature has exceeded the highest permitted value. Processor reset. Damage to the control computer. Power failure. Temperature limiter Communication with module 0. Communication with module 1. Communication with module 2. Communication with module 3. Communication with module 4. PELLUX 100...

- Page 34 Short circuit in the hot water sensor. Open circuit in the hot water sensor. Short circuit in the room heating sensor. Open circuit in the room heating sensor. Extinguishing fault. Communication with lambda module. Over heating solar panels. Frost damage solar panels. PELLUX 100...

- Page 35 + the marker is scrolled forward a step. 16. When the day is programmed as you wish, press Enter. 17. When you have approved or denied the changes the name of the week day starts to flash again. PELLUX 100...

- Page 36 19. Follow points 6 to 18 until you have programmed all the days that you want. 20. When the last day that you want to program starts to flash again you have completed the programming. PELLUX 100...

- Page 37 4. Scroll to the Service menu using the Up or Down arrow. 5. Open the menu using Enter. Settings Service 6. Enter password CH 1 ***** Password A B C D E F G H I J K L M PELLUX 100...

- Page 38 Enter. System configuration 10. Find the Solar panels module and set it to yes. Solar Outside temp. sensor Return temp. sensor Solars 11. Solar heating is now active and controlled by the control com- puter. PELLUX 100...

-

Page 39: Resetting Temperature Limiter

3. Open the boiler door and unscrew the two screws holding the front panel in position. Screws 4. The front panel is also held in position by catches. Carefully pull the panel out backwards and be careful with the cables connected to it. PELLUX 100... - Page 40 2. Remove the 4 screws holding the protective panel in position. 3. Press in the metal catch on the temperature limiter. 4. Reinstall the protective panels. 5. Connect the power supply again. 6. Start the control computer and go to the alarm menu and reset the alarm. PELLUX 100...

-

Page 41: Sweeping

This is to prevent soot from entering the boiler room when the chimney is swept. After sweeping, the hatch must be relocked. PELLUX 100 swept by pulling through the channels in the boiler's convection section with the supplied soot brush and vacuuming the hearth. - Page 42 10. Check the condition of the fireproof hose between the burner and the pellet hopper. 11. Start the fuel feed to fill the pellet screw and the fire- proof hose with fuel as far as the burner. 12. Set the burner. PELLUX 100...

-

Page 43: Electrical Circuit Diagram Boiler

For the Installer Electrical circuit diagram Electrical circuit diagram Boiler PELLUX 100... -

Page 44: Burner

For the Installer Electrical circuit diagram Burner PELLUX 100... -

Page 45: Component Positions Boiler

Ceramic insert Ash box Burner 10 A miniature circuit breaker (MCB) Soot hatch Expansion terminal (G25) Control computer Main switch Lead-in for electrical cable to burner Inspection glass to check burner flame Hatch for combustion chamber with ash box PELLUX 100... -

Page 46: Burner

For the Installer Component positions Burner List of components burner Ignition pod Grid Glow coil Door frame switch Connection, power supply pellet screw Connection, power supply Connection, control computer Fan motor Photocell Temperature limiter Feed pipe Cover PELLUX 100... -

Page 47: Electrical Components

8. Capacitor 2. Control computer 9. Connection terminal for sweeping motor 3. Current and control cable to burner 10. Connection terminal main current 4. Door sensor 11. Cable gland 5. Motor control module 12. CAN-bus module 6. Cable gland PELLUX 100... -

Page 48: Dimensions And Location Coordinates

For the Installer Dimensions and location coordinates Dimensions and location coordinates ø 133 R25(x3) PELLUX 100... -

Page 49: Technical Specifications

Max available output pellet operation 20 kW Output range pellet operation 6 -20 kW Hearth, measurement, W x D 300 x 400 mm Hearth, volume 60 litres Ash box, volume 13 litres Part no. boiler 069 079 Part no. burner 067 223 PELLUX 100... -

Page 50: Enclosed Kit

Installation and Maintenance Instructions Soot brush with shaft Wing nut M8 Tapping valve Draft limiter with gasket kit Outdoor temperature sensor Angled flue pipe (vertical flue pipe supplied by special Plug (R6) 1/8" order) Plug 3/8" Adapter for angle flue PELLUX 100... - Page 51 Part no 08 97 32 pipe. Collar: Upper connection: Ø int 139 mm Ø int 159 mm Length without collar: 750 mm Ø ext 168 mm Part no. 08 98 50 Lower connector: Ø int 139 mm Part no. 08 91 59 PELLUX 100...

- Page 52 PELLUX 100...

- Page 53 PELLUX 100...

- Page 54 PELLUX 100...

- Page 56 Puh: 09-274 697 0 Fax: 09-274 697 40 E-mail: info@nibe.fi www.nibe.fi AIT France, 10 rue des Moines, 67500 Haguenau Tel : 03 88 06 24 10 Fax : 03 88 06 90 15 E-mail: info@nibe.fr www.nibe.fr NIBE Energy Systems Ltd, 3C Broom Business Park, Bridge Way, Chesterfield S41 9QG Tel: 0845 095 1200 Fax: 0845 095 1201 E-mail: info@nibe.co.uk www.nibe.co.uk...

Need help?

Do you have a question about the PELLUX 100 and is the answer not in the manual?

Questions and answers