ITT Hydrovar Installation, Operation And Maintenance Manual

Pump control

Hide thumbs

Also See for Hydrovar:

- Operating instructions manual (20 pages) ,

- Quick start manual (2 pages)

Subscribe to Our Youtube Channel

Summary of Contents for ITT Hydrovar

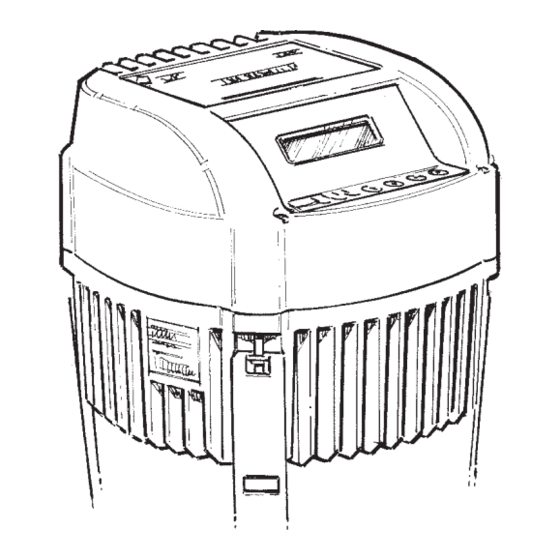

- Page 1 IM223 IT T Commercial Water Goulds Pumps Hydrovar Pump Control Installation, Operation and Maintenance Goulds Pumps is a brand of ITT Corporation. www.goulds.com Engineered for life...

-

Page 2: Table Of Contents

INDEX 1 Important Safety Instructions ...................... 4 2 System Design ..........................5 2.1 Pressure tank ........................... 6 3 Product Overview ......................... 7 3.1 Hardware configurations ......................7 3.2 Operation modes ........................7 3.2.1 Actuator (for single pump operation only!) ..............7 3.2.2 Controller ........................ - Page 3 INDEX 9 Programming ..........................35 9.1 Display – Control panel of the Master / Single Inverter ............35 9.2 Function of the push buttons ....................35 9.3 Basic Drive Display ....................... 36 9.4 Software parameters ......................36 00 MAIN MENU ......................... 37 20 SUBMENU STATUS ......................

-

Page 4: Important Safety Instructions

When in operation, the motor and pump could start unexpectedly and cause serious injury. Hazardous Pressure Section 1A Review Hydrovar components and ensure that all parts are included. Inspect all components supplied for shipping damage. Included Hydrovar components: 1. Hydrovar motor mount variable 4. -

Page 5: System Design

System Design Section 2 The following diagrams show typical single and multi-pump systems using the HYDROVAR Variable Speed Drive. Connect directly to water supply. Use of a low suction pressure switch is recommended. NOTE Systems MUST be designed by qualified technicians only and meet all applicable state and local code requirements. -

Page 6: Pressure Tank

System Design Pressure Tank, Pressure Relief Valve and Discharge Piping Use only “pre-charged” tanks on this system. Do not use galvanized tanks. Select an area that is always above 34º F (1.1º C) in which to install the tank, pressure sensor and pressure relief valve. If this is an area where a water leak or pressure relief valve blow-off may damage property, connect a drain line to the pressure relief valve. -

Page 7: Product Overview

In its basic configuration (consisting of only the power unit) the HYDROVAR can be used as a Basic Inverter. In that configuration the HYDROVAR can be used as a sequence pump in a multi pump system, or as a simple soft starter for single pump applications. -

Page 8: Cascade Serial/Synchron

Application Example Booster sets up to 6 pumps where only one pump is speed controlled by the HYDROVAR and the others are fixed speed (1 HYDROVAR Master Inverter+5 fixed speed). This should be the standard configuration when the additional Relay Card is used. - Page 9 This configuration allows each pump to become the lead pump. This also ensures a proper operation if one Master controller fails. In this case another HYDROVAR takes control. This ensures that the operating hours of each pump will be the same to ensure even wear of the pumps.

-

Page 10: Model Number

Model Number Code Section 4 Hydrovar Variable Speed Drive Type and Catalog Number Hydrovar Example Product Code Filter (optional): Standard = 0, (no filter) Residential = B HP Rating: 02 = 2 03 = 3 05 = 5 07 = 7.5... - Page 11 Model Number Code Section 4 (continued) Hydrovar Product Numbering Chart Voltage Phase Normal Duty HP Drive Type Model Number MASTER HVM1202 BASIC HVB1202 SINGLE HVS1202 230 V MASTER HVM1203 BASIC HVB1203 SINGLE HVS1203 MASTER HVM3403 BASIC HVB3403 SINGLE HVS3403 MASTER...

-

Page 12: Technical Data

Technical Data Section 5 Hydrovar Power Supply Rated Input Recommended Maximum Rated Output Voltage Limits 48-62 HZ Current Line Protection Wire Size Cat #* Amps Amps HVM1202 1 Ph, 220-240V -10%, +15% HVM1203 HVM3403 HVM3405 11.4 3 Ph, 380-460V HVM3407 15.1... -

Page 13: General Technical Data

At higher temperatures reduce the output current as shown below or upsize to the next largest HYDROVAR. Maximum Ambient Temperature (ºC) The enclosure rating of the HYDROVAR is IP55 however, please note the following: • Protect the HYDROVAR from direct sunlight! •... -

Page 14: Emc Requirements (Electromagnetic Compatibility)

Caution: The relevant EMC regulations for which the HYDROVAR was tested in class B environments is based on the restricted use of the product and the following limitations:1) the drive voltage is less than 1000 V;... -

Page 15: Dimensions And Weights

Dimensions and Weights Section 6 HVM1202, HVM1203, HVM3403, 3405 All dimensions in inches! Drawings are not to scale! Dimensions are nominal Weight [lbs] Type Basic Master / Single 2, 3 HP 1 Ph 3, 5 HP 3 Ph a … minimum center-distance between HYDROVARs 12"... - Page 16 Dimensions and Weights HVM3407, HVM3410, HVM3415 10.9 10.2 10.2 All dimensions in inches! Drawings are not to scale! Dimensions are nominal Weight [lbs] Type Basic Master / Single 7.5, 10, 15 HP 16.9 17.8 3 Ph a … minimum centre-distance between HYDROVARs 17"...

-

Page 17: Additional Components

To remove the HYDROVAR cover, loosen the 4 fastening screws. • Verify that there is no liquid on the unit before you open the cover. • The HYDROVAR is installed on the motor fan cover using the mounting brackets, the four screws and the relevant washers. -

Page 18: Assembly Instructions - All Models

Additional Components 7.2 Assembly Instructions – All models (continued) -

Page 19: Electrical Installation And Wiring

• Bussman T-tron type JJN and JJS fuses are acceptable (or equal) Internal equipment protection: • The Hydrovar has internal protections against the following malfunctions: short circuit; under and over- voltage, overload and the overheating of the electronic components. External protective devices: •... - Page 20 Bussman KTK-R-20 600V HFD534E2 460/3/60 OT40F3 3 HP / 40A #18-8AWG 7 IN/LB Bussman KTK-R-30 600V NOTE: Recommended protection (not included with drive only). This fused disconnect is available as part of the PHV series packaged Hydrovar, see price book.

-

Page 21: Emc- Electromagnetic Compatibility

Use shielded wires only if the total length exceeds 6 feet.) Line Reactors Line reactors are available as an option and should be mounted between the HYDROVAR and the main fuse. The Line reactor should be as close to the HYDROVAR as possible, (max. 12"). -

Page 22: Recommended Wire Types

8.4 Wiring and Connections Remove the screws holding the top cover of the HYDROVAR. Lift off the top cover. The following parts can be seen on a HYDROVAR Master / Single Drive: 1 Ph 2, 3 HP 3 Ph 3, 5 HP 3 Ph 7.5, 10, 15 HP... -

Page 23: Input Voltage Terminals

Electrical Installation and Wiring 8.4.1 Input Voltage Terminals The power supply is connected to the power section: Terminal L + N (230 VAC, single-phase) Terminal L1+ L2 + L3 (460 VAC, three-phase) 2, 3 HP / 1Ø 3, 5 HP / 3Ø 7.5, 10, 15 HP / 3Ø... -

Page 24: Motor Connection

Electrical Installation and Wiring 8.4.2 Motor Connection Attaching the Thermistor Method A : Method B : 1. Remove conduit box cover 2. Attach the thermistor (Method A or B) 3. Replace the terminal block, if necessary 4. Wire the motor according to the motor manufacturer's instructions. NOTE! The thermistor must be attached to the motor. -

Page 25: Solo Run (Hand Mode)

PTC. This input can also be attached to an external ON / OFF switch when using the HYDROVAR as a Basic drive. Either the thermistor or on/off switch must be closed between X1/PTC or the drive will stop running! A low water switch or other protective device can... -

Page 26: Addressing

Low water switch X3/11-12 When the HYDROVAR is used as a Basic drive in a multi-pump system, the X2 terminals on the power unit are used for the serial RS-485 connection to the other HYDROVAR units in the system. (Note: Internal interface is not available on Single Inverters!) X2 RS485-Interface –... - Page 27 Master drive – The address of the Master drive is set using the Hydrovar software. Dip switches are used to program the Basic drives to a specific address. On all Master drives the dip switches must be set to address 1 (default setting, see below).

-

Page 28: Control Unit

Switch 4 not used! Address 8 Setting the correct address on Basic drives: • The HYDROVAR must be disconnected from power supply for at least 5 minutes before removing the top cover! • Use the dip-switch on the power unit. (See picture above!) •... - Page 29 Electrical Installation and Wiring X3 Digital and Analogue I/O 1 GND, electronic ground 2 Actual value current input sensor 1 0-20mA / 4-20mA [Ri=50Ω] 3 Power supply for external sensors 24VDC, ** max. 100mA 4 Actual value current input sensor 2 0-20mA / 4-20mA [Ri=50Ω] 5 Actual value voltage input sensor 2 *DI 2...

- Page 30 Electrical Installation and Wiring Additional power supply ** max. 100 mA +24V Current signal input (required val. 2) 0-20mA / 4-20mA [Ri=50Ω] To determine the required value or the offset Analogue output 2 4-20mA Analogue output 1 0-10 VDC +10V Current signal input (required val.

- Page 31 Electrical Installation and Wiring Connection Examples: • Sensor–Actual-value-signal Input Connecting a 3-wire transducer Connecting an active actual-value-signal (e.g. standard pressure transducer) 4-20mA 4-20mA Possible Connections: Standard Pressure Transducer: Actual-value-signal input 0/4-20mA X3/4 … Sensor 2 +24VDC sensor supply X3/3 brown Actual-value-signal input 0/4-20mA X3/2 …...

- Page 32 Electrical Installation and Wiring • Switching between two different required values External switching between two connected required value signals (e.g.: between voltage and current signal input) by closing digital input 1 (X3/9-10). In ACTUATOR mode the drive can switch between two different frequencies from the digital inputs.

- Page 33 SIO - SIO - Using the RS-485 – User interface on the control card, one or more HYDROVAR can communi- cate by standard Modbus-protocol with an external control device (e.g. PLC). This interface can be used for controlling the HYDROVAR with external devices. Also available on HYDROVAR Single drives.

- Page 34 Electrical Installation and Wiring X5 Status-Relays Status Relay 1 [Max. 250VAC] [250mA] [Max. 220VDC] [250mA] [Max. 30VDC] [2A] Status Relay 2 Status Relay 1 Status Relay 2 Notice: Do not transmit any voltage 3 NO 6 NO or electronic noise on these 2 NC 5 NC contacts.

-

Page 35: Programming

All programming must be completed by qualified technicians! 9.1 Display – Control Panel of the Master / Single Drive 9.2 Function of the Push Buttons Start the HYDROVAR ▲ Stop the HYDROVAR ▼... -

Page 36: Basic Drive Display

The general parameter description is written for the HYDROVAR Master Inverter (Full featured HYDROVAR including the high level control card which also supports the optional modules like the optional Relay Card and all... -

Page 37: Main Menu

Programming When using a HYDROVAR Single drive there are fewer software features available than with the HY- DROVAR Master drive. All parameters which are not active for the HYDROVAR Single drive are marked with the following symbol: … Parameter not available for HYDROVAR Single drive Parameters which are available on all HYDROVAR drives are marked with the following symbol: …... - Page 38 If parameter MODE [0105] is set to Actuator, the parameter REQUIRED VALUE [02] will change to ACTUAL. FREQ. and is equivalent to parameter [0830]. This allows the HYDROVAR to run to up to two pre-selected frequencies to manually control the drive.

- Page 39 80 % --> 40.0 PSI If the pump system has reached the required pressure of 50.0 PSI and meets demand the HYDROVAR shuts off the pump. When demand increases, and the pressure drops the pump starts. If a START VALUE [04] of 80% has been selected the pump won’t start until the pressure drops below 40 PSI, (80% of 50 PSI).

-

Page 40: Submenu Status

Select ON with ▲ or OFF with the ▼ button. If AUTO-START = ON the HYDROVAR starts automatically after reconnecting power following interruption. If AUTO-START = OFF the HYDROVAR will not start automatically after reconnecting power following interruption. After reconnection of the power supply the following message is shown: AUTO START = OFF XX.X Hz... - Page 41 [105]. Select desired unit by pressing ▲ or ▼. CASCADE SERIAL/SYNCHRON: The selection specifies the address of the HYDROVAR units E.g. Device 1 -> Master Inverter with pre-selected address 1 Device 2 -> Basic Inverter with pre-selected address 2 Device 3 ->...

- Page 42 Programming Mode CASCADE SERIAL/SYNCHRON: running -> Pump is running stopped -> Pump is stopped disabled -> Pump is disabled by an external input. (Stopped with buttons or disabled with parameter ENABLE DEVICE [24]) or by external on/off contact open preparing -> A new unit is connected to the multi-pump system and Data is being transferred solo run ->...

-

Page 43: Submenu Diagnostics

43 TEMP . INVERTER Temperature of the selected unit XX % XX°C The current value determines the temperature inside the selected HYDROVAR and is shown in °C and also in percent of the maximum allowed temperature. 44 CURR. INVERTER Current of the selected unit... -

Page 44: Submenu Settings

Improper settings can cause the drive to malfunction. These parameters can be changed during operation. Therefore they should be changed only by trained and qualified technicians. It is recommended to stop the HYDROVAR by pressing ▼ in the main menu before changing parameters in submenues. -

Page 45: 0100 Submenu Basic Settings

In this mode, the HYDROVAR does not control the set value but runs the connected motor at a frequency proportional to the input signal from the analogue input, or is programmed on the HYDROVAR. The follow-... - Page 46 Programming In actuator mode the drive can work with pre-selected frequencies for manual control of the HYDROVAR. Two different frequencies can be set in the submenu REQUIRED VALUES [0800]. Switch between these frequencies using parameter SW REQ. VAL [0815]. f[Hz] fmax [0255] f ->min...

-

Page 47: 0200 Submenu Conf Inverter

ON: If the LOCK FUNCTION is activated, no changes can be made in any parameter without first entering the password. The HYDROVAR can be started and stopped with the up/down arrows. To change the set value, the LOCK FUNCTION must be set to OFF. - Page 48 Possible settings: ALL, 1-8 If several HYDROVAR Master Inverters and even Basic Inverters are connected via the RS-485 interface, the parameters in SUMBENU [200] can be entered on one unit and will be carried over to the other units in the group.

- Page 49 Programming set rated REQUIRED VALUE [02] Set HYSTERESIS [0315] in % WINDOW [0310] setting in % of the required Set HYSTERESIS [0315] in % FMIN TIME [0260] MIN FREQ [0250] Time RA: Ramp F acceleration Actual Value RD: Ramp F deceleration Output Frequency R1: Ramp 1 –...

- Page 50 Minimum frequency 20.0 Hz Possible settings: 0.0 – f At operation below MIN. FREQUENCY (0250) the HYDROVAR operates with the fast ramps F A and D, (0235/0240). The pump type and application should be considered when setting MIN. FREQ. For...

- Page 51 Possible settings: 30.0 – 90.0 Hz This parameter determines the frequency at which the HYDROVAR generates its maximum output voltage (value of the connected input voltage). For standard applications this frequency should be set to MAX. FRQ. [0245] (Default Setting 60Hz).

- Page 52 Auto, 8 kHz, 4 kHz • Auto (default setting) In standard operation the HYDROVAR works with a switching frequency of 8 kHz in order to reduce the noise level. At rising temperature inside the HYDROVAR the switching frequency is decreased to 4 kHz automatically.

-

Page 53: 0300 Submenu Regulation

Both the current output frequency and actual value are shown. X.XX PSI • By pressing ▲ or ▼ in this menu, the internal controller of the HYDROVAR is deactivated and it changes to manual mode. • Using the ▲ and ▼ buttons any constant speed can be set without further control to achieve the set point! •... - Page 54 Programming 0325 FRQ. LIFT 0325 Frequency limit for required lift value 30.0 Hz Possible settings: 0.0 Hz – 70.0 Hz Control according to a system curve (increase of the set pressure, depending on the flow rate/speed to cover friction losses). The setting determines the output-frequency where the set pressure starts to be increased.

-

Page 55: 0400 Submenu Sensor

0400 SENSOR In this submenu all actual value sensors which are connected to the HYDROVAR can be configured, (up to two transducers with current output or voltage signal output). Two different transducer types can not be used because the configuration is the same for all connected sensors. - Page 56 Programming 0415 SENSOR TYPE 0415 Selection of the sensor type and input terminal 4 – 20mA Possible settings: - analog I 4-20mA - analog I 0-20mA - analog U 0-10V For choosing the correct sensor input. Sensor type: Terminals: - analog I 4-20mA X3/2 ->...

-

Page 57: 0500 Submenu Sequence Cntr

Programming 0435 SENS 1 CAL X 0435 Sensor 1 upper range value calibration 0% = actual value Possible settings: - 10% up to +10% To set the calibration for the upper range value of sensor 1. After setting the dimension unit and sensor range, the upper range value can be adjusted between -10 and +10%. - Page 58 Programming Calculations of the new required value for multi pump applications: k ... number of active pumps (k >1) p = p + (k-1)*[lift value – fall value] • Lift value = Fall value ⇒ Pressure constant independent of how many pumps are in operation •...

- Page 59 If three pumps are running (1 Master Inverter + 2 fixed speed pumps) and a system pressure of 100 PSI is reached, one after another assist pump is switched off. This parameter prevents the system against overpressure in case the HYDROVAR has been parameterized incorrectly.

- Page 60 This parameter allows an automatic change over of the master pump and the assist pumps, to provide even wear and achieve even operating hours of the pumps. The switch interval is used for HYDROVAR Master Inverters only (connected via the RS-485 interface) by using operation mode Cascade Serial or Cascade Synchron.

-

Page 61: 0600 Submenu Errors

Possible settings: 1 – 100 sec Delay time to switch-off the HYDROVAR if the actual value drops below the minimum threshold limit or a connected external low water protection at terminals X3/11-12 has been opened. Notice: The minimum threshold function is also active during start up of the pump! Therefore the delay... -

Page 62: 0700 Submenu Outputs

ON: Allows an automatic restart for 5 times in case of a failure. If the failure is still active after the 5th restart, the HYDROVAR will shut off and the appropriate error message is shown. The internal counter of the automatic error reset is decreased by 1 after each operating hour, so if an error could be reset after 3 restarts, there are 3 further restarts possible after one hour, 4 after two hours and 5 automatic restarts after 3 operating hours. -

Page 63: 0800 Submenu Required Values

Pump is manually turned off or E-stop activated, Relay 1: X5/ 1-3 closed StandBy no error/warning is indicated and HYDROVAR doesn’t run Relay 2: X5/ 4-6 closed If Parameter ERRORRESET [0615] is activated and a Relay 1: X5/ 1-3 closed Errorreset Warning occurs 5 times ->... - Page 64 Programming 0810 C.REQ.VAL 2 0810 Configuration required value 2 Possible settings: - OFF - digital - analog U 0-10V - analog I 0-20mA - analog I 4-20mA Required value 2 is not used. The internal required value 2 is used. digital Setting in the main menu in Parameter 02 or Parameter [0825].

-

Page 65: 0900 Submenu Offset

Programming This pre-selected required value is active in all modes except Actuator if parameter C.REQ.VAL.1 [0805] or C.REQ.VAL.2 [0810] is set to digital, and parameter SW REQ.VAL. [0815] is set to setpoint 1/2 or the REQUIRED VALUE 1/2 is selected via digital input. This pre-selected required value could also be taken over in the main menu with parameter REQUIRED VAL. - Page 66 Programming 0910 LEVEL 1 0910 Offset active between 0 and LEVEL 1 Possible settings: 0 – OFFSET RANGE 0912 OFFSET X1 0912 Offset signal value Possible settings: 0 – LEVEL 1 Designation of the x – coordinate as absolute value. 0913 OFFSET Y1 0913 Desired value...

- Page 67 Programming Example for using the Offset function: Constant pressure system with required value of 70 PSI. Additionally a flow sensor is connected to the Offset input. Parameter [907] - Offset Range = 300 (maximum range of flow sensor = 70 GPM) System requirement 1: 5 bar constant pressure while the flow rate is between 20 GPM and 50 GPM.

-

Page 68: 1000 Submenu Test Run

Test Run Time, Frequency and Boost can be selected in the parameters below. To disable the automatic test run, press ▼ until “OFF” appears on the display. The test run is only active when the HYDROVAR is stopped because of low/no demand and external ON/OFF (E-stop) contact (X3/7-8) is closed! 1010 TESTRUN FRQ. -

Page 69: 1100 Submenu Setup

1135 CLR OPERAT. 1135 Clear operation time Press 3 sec. The operation time indicates the total time the HYDROVAR is already connected to power supply. For reset the operation time of the current HYDROVAR press button till “RESET” appears. -

Page 70: 1200 Submenu Rs485-Interface

Internal Interface If several Master Inverters are connected via the internal RS-485 interface (maximum 8 / using cascade se- rial mode) each HYDROVAR needs its own allocated pump-address number (1-8). Each address may only be used once! 1220 PUMP ADDR. -

Page 71: Failure Messages

• Errors are indicated on the HYDROVAR display and by the red failure LED on the control panel. In case of an error the connected motor is stopped immediately. All errors are shown in plain text and saved in the error memory including date and time when the failure occurred. -

Page 72: Master / Single Inverter

If a Master Inverter is used in such a system, the errors which occurred on the Basic Inverter can be reset by the Master without interfering with the operation of the other HYDROVAR units in the system (also valid for automatic Error-reset). - Page 73 Probable Cause Measure • Check Parameter RAMP 1/2 [0215 / 0220] (too short) and BOOST [0265] (too low) OVERLOAD Power limit of the HYDROVAR • Check motor connection, cable and ERROR 12 is exceeded power supply • Pump blocked • Motor turns in the wrong direction •...

- Page 74 Failure Messages • Incoming pressure or minimum level too low Low water contact • Bridge X3/11-12, if there is no ext. LACK OF WATER (X3/11-12) is opened low water protection ERROR 21 (only active if motor is running) • Adjust Parameter DELAY TIME [0610] if the failure happens only for a short time Reset:...

-

Page 75: Internal Errors

• Check earth/ground. • Install additional inductances for the signal-cables (e.g. ferrites). Examples: Booster Unit Problem: HYDROVAR will not stop Cause: Check: • Demand exceeds pump capacity • check pipes and valves • Pre-charge pressure in pressure tank •... -

Page 76: Maintenance

Disconnecting: The HYDROVAR must be disconnected from the power supply for at least 5 minutes before any work can be carried out. Consider pump and motor instructions. Always wear your personal protection equipment. For further information, please contact your distributor! -

Page 77: Programming Flow Chart

Programming Flow Chart Section 12... - Page 78 Programming Flow Chart Section 12 (continued)

- Page 79 Programming Flow Chart Section 12 (continued)

-

Page 80: Goulds Pumps Limited Warranty

THIS WARRANTY EXTENDS TO THE DEALER ONLY. Goulds Pumps and the ITT Engineered Blocks Symbol are registered trademarks and tradenames of ITT Corporation.

Need help?

Do you have a question about the Hydrovar and is the answer not in the manual?

Questions and answers