Table of Contents

Advertisement

Quick Links

Bedienungsanleitung / Handbuch / Datenblatt

Sie benötigen einen Reparaturservice für Ihren Etikettendrucker

oder suchen eine leicht zu bedienende Etikettensoftware?

Wir helfen Ihnen gerne weiter.

Ihr Partner für industrielle Kennzeichnungslösungen

Drucksysteme Janz & Raschke GmbH

Röntgenstraße 1

D-22335 Hamburg

Telefon +49(0)40 – 840 509 0

Telefax +49(0)40 – 840 509 29

kontakt@jrdrucksysteme.de

www.jrdrucksysteme.de

Advertisement

Chapters

Table of Contents

Summary of Contents for Novexx Solutions ALX 92x

- Page 1 Bedienungsanleitung / Handbuch / Datenblatt Sie benötigen einen Reparaturservice für Ihren Etikettendrucker oder suchen eine leicht zu bedienende Etikettensoftware? Wir helfen Ihnen gerne weiter. Ihr Partner für industrielle Kennzeichnungslösungen Drucksysteme Janz & Raschke GmbH Röntgenstraße 1 D-22335 Hamburg Telefon +49(0)40 – 840 509 0 Telefax +49(0)40 –...

- Page 2 Bedienungsanleitung / Handbuch / Datenblatt Maßgeschneiderte Lösungen für den Etikettendruck und die Warenkennzeichnung Seit unserer Gründung im Jahr 1997, sind wir erfolgreich als Partner namhafter Hersteller und als Systemintegrator im Bereich der industriellen Kennzeichnung tätig. Unser Motto lautet: So flexibel wie möglich und so maßgeschneidert wie nötig. Ich stehe mit meinem Namen für eine persönliche und kompetente Beratung.

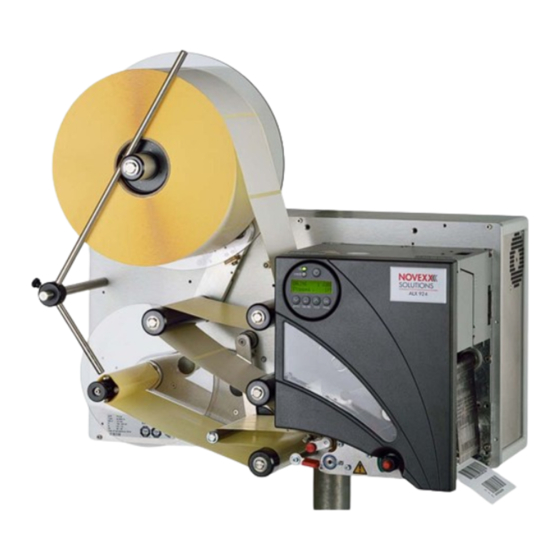

- Page 3 SERVICE MANUAL ALX 92x Print & Apply system Release 3 - 6/2016...

-

Page 4: Table Of Contents

06/15 Rev. 6.01-01 All devices Using the Documentation Copyright ............2 Text appearance ........10 Documentation structure ........ 3 Title page ..........11 Datapool, documentation object ....3 Abbreviations ..........12 Documentation concept......3 Printer names..........12 Documentation format ........ 6 Parameters ..........12 Printing the documentation ......7 Index .............13 Navigation aids .......... -

Page 5: Copyright

/Using the Documentation All devices Copyright © 2015 by Novexx Solutions GmbH. All rights reserved. Reprinting and reproduction of these documents, including extracts, is only allowed with the express permission of the manufacturer. More detailed information is available from your supplier. -

Page 6: Documentation Structure

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Documentation structure Datapool, documentation object The overall documentation is a part of the datapool, which is provided for the printer user and the service personnel on CD or other electronic media. Datapool This datapool includes: –... -

Page 7: Using The Documentation

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Subject section Thematically-related subject contents are described in each topic section. A topic section is the smallest unit of information with its own – page numbering, – header bar, –... - Page 8 64-06 Dispenser Commissioning and Operation 64-08 64-08 Dispenser Setup USER MANUAL Release 1 - 06/2015 Advanced Applications © 2015, Novexx Solutions GmbH, Ohmstraße 3, 85386 Eching, Germany. Maintenance and Cleaning Topic All rights reserved. sections Info-Printouts and Parameters Copyright Symbols...

-

Page 9: Documentation Format

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Start page The start page is also only an organisational component and is displayed when the CD starts, or on the Internet on the link to the printer datapool. The following features characterize a start page: –... -

Page 10: Printing The Documentation

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Printing the documentation In order to make the documentation readable without a PC, the documents can be printed in A4 as well as in Letter format. For printing, the Acrobat Reader uses the print capabilities of the platform it is run on. -

Page 11: Navigation Aids

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Navigation aids Info search The following options are available for quickly searching for information in the paper documentation: – The title page of each manual with a list of contents of the topic section –... -

Page 12: Symbols And Note Signs

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Symbols and note signs Warning notes Warning notes warn of a possibly dangerous situation. Personal injury, material damage or data loss are possible, if care is not taken. Depending on the dimension of possible damages, the warning notes look different: •... -

Page 13: Symbols

Lefthand version (LH version): Symbol marking a text section which refers to the LH version of a device. (Only important for DPM, PEM and ALX 92x) Righthand version (RH version): Symbol marking a text section which refers to the RH version of a device. -

Page 14: Title Page

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Title page Link Black text in the blue frame: link to topic sections which occur several times in different manuals (click). Link Purple text in the blue frame: link to a topic section which only occurs once and belongs specifically to the manual (click). -

Page 15: Abbreviations

64-xx Tabletop printer with 64bit electronics 64-04, 64-05, 64-06, 64-08 ALX 92x Print-Dispenser of the ALX 92x series ALX 924, ALX 925, ALX 926 Tab. 2 Abbreviated spelling of printers. Parameters The notation of parameters is done as follows: MENU >... -

Page 16: Index

06/15 Rev. 6.01-01 USER + SERVICE MANUAL /Using the Documentation All devices Index Abbreviations ..........12 Link page ............ 5 Alterations, technical ........2 Paper documentation ........7 Copy ............2 Patents ............2 Copyright ............. 2 Pinch Point ..........10 Datapool ............ - Page 17 06/16 Version 04 SERVICE MANUAL ALX 92x Please note General information ........2 Validity of this manual and required compliance ..........2 How information is represented ....3 Notes on installation and repair work ..4 Safety instructions ......... 7 Information and qualifications ....

- Page 18 Copyright All rights to this operating manual are assigned to NOVEXX Solutions. Transmission, reprinting or any other means of reproduction of this manual, whether whole or in part, are not allowed without prior written permission. Third parties, in particular competi- tors, are not to be allowed access to information derived from this manual.

- Page 19 06/16 Rev. 03 SERVICE MANUAL General information ALX 92x How information is represented Explanation of To enhance readability and make information easier to find, different types of informa- symbols tion are identified: Instruction with no order of tasks assigned 1.

- Page 20 06/16 Rev. 03 SERVICE MANUAL General information ALX 92x Notes on installation and repair work General information Before performing any maintenance or repair work: Block access to the working area of the machine to unauthorised persons. Post a notification sign, which calls attention to the work.

- Page 21 06/16 Rev. 03 SERVICE MANUAL General information ALX 92x Rules for electromag- Connect all metallic parts to each other via large surfaces, ensuring electric netic compatibility conductivity. Only polished metal surfaces are electrically conductive. Painted or oxidised sur- faces are unsuitable. Aluminium which appears to be polished still has an invisible oxidation layer on the surface.

- Page 22 06/16 Rev. 03 SERVICE MANUAL General information ALX 92x Lay all lines as close as possible to metal parts, even reserve cables Freely hanging lines act as transceiver antennas. Ground all reserve cables and unused wires in the cables at least at one end.

- Page 23 06/16 Rev. 6.01-00 SERVICE-HANDBUCH ALX 92x Safety instructions Information and qualifications Ensuring the Let the installation, setup and repair of the machine only be accomplished by ap- necessary qualification propriately qualified personnel. Let intallation and service work at the machine only be accomplished by qualified electricians.

-

Page 24: Machine Operating Safety

Improper usage of the machine can lead to accidents, material damage and loss of production! When installing the labeller, check for visible shipment damage. Immediately in- form Novexx Solutions of any damage. When installing the machine on a support stand, make sure that it can not tip over. - Page 25 06/16 Rev. 6.01-00 SERVICE-HANDBUCH ALX 92x Protection measures in applicator mode WARNING! Danger of crushing between dispenser edge and applicator pressure plate due to applicator movement ! Prevent personnel from reaching between dispensing edge and applicator by installing higher-level protective guards...

- Page 26 06/16 Rev. 6.01-00 SERVICE-HANDBUCH ALX 92x If the machine must be switched on while the Never touch energised components. This also applies to components with low voltages. casing is open for re- pair or inspection: Ensure the flawless Regularly check the electrical equipment.

- Page 27 07/15 Rev. 06 SERVICE MANUAL ALX 92x Installation/Deinstallation Defining the operating position ..... 2 Installing options ..........23 Space requirement ........2 Options overview ........23 Admissible operation positions ....3 Remote operator panel ......24 Unpacking and assembling the machine ..4 Pressure roller .........25...

-

Page 28: Defining The Operating Position

Space requirement For machine dimensions read the user manual ALX 92x, chapter „Product description“ > „Technical data“ > „Dimensions“. On the machine side facing the operator must be left at least 1 m free space for loading and changing of sup- plies. -

Page 29: Admissible Operation Positions

Defining the operating position ALX 92x Admissible operation positions The ALX 92x may be used in all operation positions, in which the axle of the unwinder doesn´t show down- wards [3A][4A]. Those are typically the positions for: • Top labelling [3] •... -

Page 30: Unpacking And Assembling The Machine

07/15 Rev. 03 SERVICE MANUAL Unpacking and assembling the machine ALX 92x Unpacking and assembling the machine WARNING! Acute risk of injury and long-term bodily injury from working with heavy loads! Lift or carry the machine with a minimum ... -

Page 31: Mounting The Machine On A Support Stand

07/15 Rev. 03 SERVICE MANUAL Unpacking and assembling the machine ALX 92x Mounting the machine on a support stand WARNING! Risk of injury from a tipping over support stand. When installing the machine on a support stand, make sure that it can not tip over. - Page 32 07/15 Rev. 03 SERVICE MANUAL Unpacking and assembling the machine ALX 92x Rotating the machine: In some installation situations, it may be adequate to turn the machine or the head joint. WARNING! Danger of injury by the machine falling to ground.

-

Page 33: Installing The Unwinder

07/15 Rev. 03 SERVICE MANUAL Unpacking and assembling the machine ALX 92x Installing the unwinder The material unwinder and the guide rods are delivered separately with the machine. The fixing screws are turned into the base plate at the mounting position [9A]. -

Page 34: Installing The Od Sensor

Unpacking and assembling the machine ALX 92x Installing the OD sensor If the ALX 92x was ordered with OD sensor, the sensor bracket comes loosely enclosed. The sensor cable is already connected. For retrofitting the OD sensor, the sensor cable has to be connected first. -

Page 35: Electrical Connections

1. Ensure that the machine is switched off (mains power switch [15A] in position "O"). 2. Connect the machine to a mains power socket [15C] using the provided power cable [15B]. [15] Connecting the ALX 92x. to a mains power socket. -

Page 36: Connecting To A Data Host

Electrical connections ALX 92x Connecting to a data host According to the factory settings, the ALX 92x is set for data transfer via USB interface. Print data can also be transferred via a serial interface, Ethernet or an option- al Centronics interface. -

Page 37: Connecting Sensors

USI is recommended. Because AI and USI cannot be driven both at a time, the sensor has to be connected to the AI, if the ALX 92x is operated with an applicator. Product sensor at USI Prerequisite: Machine is equipped with optional signal interface (USI). - Page 38 B Datasensor S51-PA-5-C10-PK (PNP); article no. A7112 • A5069 (connector set for AI) [20] Required parts for a NPN sensor: • A2682 (product sensor for ALX 92x at USI) • A5069 (connector set for AI) [20] Replacing the connector: 1. Cut off the connector [19A] from the cable.

- Page 39 07/15 Rev. 03 SERVICE MANUAL Electrical connections ALX 92x Sensor for OD detection Installation see chapter Installing the OD sensor page 8. Connection: • USI: internal • AI: internal or external (connector) If the machine was ordered with OD sensor, the sensor cable is already internally connected at delivery [24].

-

Page 40: Rotary Encoder Intallation

• Order no.: 045565 Suitable mounting [25B]: • Type: 9213 • Order no.: 045492 [25] Recommended rotary encoder by Pepperl+Fuchs. Novexx Solutions article number for the above men- A Measuring wheel tioned encoder including measuring wheel and mount- B Mounting C Rotary encoder ing: A7770. - Page 41 07/15 Rev. 03 SERVICE MANUAL Electrical connections ALX 92x Connecting the rotary encoder CAUTION! +24 V Impulse B To avoid damage to the electronics: Impulse A Switch the machine off before connecting the rotary encoder. [26] Pin assignment rotary encoder connection ...

-

Page 42: Installing Apsf

07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x Installing APSF Principle of operation APSF = Automatic Product Speed Following. [29] Rotary encoder (A) on the conveyor line (schematic) The automatic dispensing speed adjustment makes it possible to automatically adapt the dispensing speed to the speed of the conveyor belt. -

Page 43: Mounting The Rotary Encoder

07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x Mounting the rotary encoder Rotary encoder with measuring wheel at the conveyor belt [30] Mounting the rotary encoder with measurement wheel at the conveyor belt. D = Diameter of the measurement wheel. -

Page 44: Entering The Rotary Encoder Resolution

07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x [32] Mounting the rotary encoder on the motor axle. Entering the rotary encoder resolution DISPENSER PARA > Encoder Resol. 1. Call 2. Enter the resolution of the rotary encoder to be used. -

Page 45: Entering The Rotary Encoder Type

07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x Entering the rotary encoder type Depending on the features of rotary encoder and label dispenser, there are different ways to count the impulses generated by the rotary encoder: DISPENSER PARA > Encoder Type. -

Page 46: Calibrating The Belt Speed

07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x Calibrating the belt speed DISPENSER PARA > Encoder Diameter Aftercalling the following is displayed: Encoder Diameter yy.y var • x.x = diameter of measuring wheel • yy.y = belt speed according to current measurement •... - Page 47 07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x In the rightmost column appear warning notes, if questionable values are entered [34B]. Read the calculation results [34D]. In the rightmost column appear warning notes, if questionable values are entered [34E].

- Page 48 07/15 Rev. 0 SERVICE MANUAL Installing APSF ALX 92x Calculations Size Symbol Calculation Note π π d ⋅ 3 1415926 Wheel circumference 1000 -------- - -------- - ⋅ ----------- - Max. speed 1000 mm = 1 m; 60 s = 1 min ≤...

-

Page 49: Installing Options

24 Connection for rotary See service manual, topic section Mechanics > APSF A8382 encoder Rotary-Encoder > Assembly of internal cables (ALX 92x) Centronics interface A6758 See service manual, topic section Mechanics > Boards RS232/422/485 interface A8259... -

Page 50: Remote Operator Panel

07/15 Rev. 01 SERVICE MANUAL Installation / Deinstallation ALX 92x Installing options Option Article number Installation instructions See service manual, topic section Mechanics > Housing > Dust filter A6206 Dust filter (ALX) See service manual, topic section Advanced Applications ... -

Page 51: Pressure Roller

Tool: Hex socket screwdriver 4 mm Assembly: 1. Screw the pressure roller to the base plate of the ALX 92x [3]. Don´t tighten the screw. 2. Align the pressure roller [4]. ... -

Page 52: Selecting Consumables

ALX 92x Selecting consumables Thermal transfer / direct thermal printing The ALX 92x can print onto label material using the direct thermal mode or thermal transfer mode. Direct thermal Direct thermal printing is done without ribbon. The direct thermal process requires la- bel material with a temperature-sensitive coating. -

Page 53: Thermal Transfer Ribbon

07/15 Rev. 00 SERVICE MANUAL Selecting consumables ALX 92x Thermal transfer ribbon The following is recommended for thermal transfer ribbons: • The back of the ribbon should be coated so that it produces no static or friction (Backcoating). If this isn’t the case, the printhead may be damaged by static dis- charge coming off the ribbon surface. -

Page 54: Decommissioning, Dismantling, Disposal

07/15 Rev. 6.01-00 SERVICE-MANUAL Installation / Deinstallation ALX 92x Decommissioning, Dismantling, Disposal Decommissioning, Dismantling, Disposal Take the machine out of operation Disconnecting the machine from the compressed air supply (only machines with in- stalled applicator): 1. Switch off the compressed air supply of the applicator. -

Page 55: Machine Disposal

07/15 Rev. 6.01-00 SERVICE-MANUAL Installation / Deinstallation ALX 92x Decommissioning, Dismantling, Disposal Machine disposal It is advisable to remove reusable machine components as long as the machine is firmly mounted. 1. Remove machine parts which can be reused (e. g. applicator, applicator interface, dispensing edge holder, dispensing edge). - Page 56 06/16 Vers. 05 USER + SERVICE MANUAL DPM – PEM – ALX 92x Technical Data Device types, use .......... 2 Connection, device data ......16 General Notes ........... 2 Ambient conditions ........16 DPM ............2 Interfaces (Electronics Gen. 2) ....16 PEM ............2 Interfaces (Electronics Gen.

-

Page 57: Device Types, Use

For details refer to chapter „Technical Specifications“ > Performance data page 8. RH/LH DPM and ALX 92x are both available in a righthand (RH) as well as a lefthand (LH) version. Distinguishing feature: • LH-version: Printed Labels leave the machine on the lefthand side (line of vision towards the display). -

Page 58: Options (Electronics Gen. 2)

Applicator Interface Programmable applicator interface, designed to control nearly all applicator types. The (AI) AI can be integrated into the ALX 92x. For application with the DPM, an external ap- plicator box is available. Applicator-PLC (ALX 92x only) PLC for control of Novexx applicators of the types LTP/LTPV/LTSI. -

Page 59: Options (Electronics Gen. 3)

Programmable applicator interface, designed to control nearly all applicator types. The (AI) AI can be integrated into the ALX 92x (max. over all output current: 1 A). For applica- tion with the DPM, an external applicator box is available. Applicator-PLC (ALX 92x only) PLC for control of Novexx applicators of the types LTP/LTPV/LTSI. - Page 60 06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x OD control [2] OD control mounted. (ALX 92x only) The „Outer diameter (OD) control“ for the label roll detects early if the machine is going to run out of labelling material - how early this happens can be adjusted.

-

Page 61: Technical Specifications

06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Technical specifications Dimensions DPM/ PEM 261,4 (6”) 221,7 207,4 (4/5”) 245,5 131,30 11,50 [4] Dimensions of the DPM as L-version. The PEM has the same measures. - Page 62 205,8 (4/5”) 238,0 (6”) 162,70 103,50 206 (4/5”) 153,50 260 (6”) 305,75 611,50 11,25 [5] Dimensions of the ALX 92x (L-version). Dimensioned drawings of the ALX 92x in DXF format (Autocad) can be found on the Documentation-CD in directory „\Dimensional Drawings“.

-

Page 63: Performance Data

17kg DPM / PEM 6“ 18kg ALX 924/925 35kg ALX 926 39kg [Tab. 2] Weights of DPM / PEM and ALX 92x. Performance data Print technology Thermal direct printing, thermal transfer printing Print head "Corner Edge" type Resolution 12 Dot/mm (300 dpi) - Page 64 1 to 9 N (given that the backing paper is strong enough not to tear off). Punch detection • DPM, ALX 92x: Self-initializing light-through sensor for punched label material. • PEM: Self-initializing combination sensor, which can detect punches as well as re- flex marks on the material bottom side.

- Page 65 06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Impression accuracy • In printing (y-) direction: The impression accuracy depends on the print position. With the printout starting directly at the punch position, the accuracy is ±0.5 mm. A distance between punch (that is label start) and print position will add ±1% of this distance to the accuracy...

-

Page 66: Thermotransfer Ribbon

06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Bar codes Codabar Code 128 A, B, C Code 128 Code 128 UPS Code 128 pharmacy Code 2/5 matrix Code 2/5 interleaved EAN 13 add-on 2... -

Page 67: Automatic Ribbon Economy

USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x CAUTION! - If huge ribbon rolls (run length of 1000m) are supposed to be used with activated ribbon economy function, there is a hazard of the ribbon tearing off. - Page 68 06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Minimum length of Consumed ribbon per Print speed unprinted area saving action in mm/s (Inch/s) in mm in mm 51 (2) 76 (3) 102 (4)

-

Page 69: Labelling Material

DPM – PEM – ALX 92x Labelling material Material types • DPM/ALX 92x: All common self-adhesive labelling materials, suitable for printing in thermal direct and thermal transfer process. • PEM: All common cardboard and self-adhesive labelling materials, suitable for printing in thermal direct and thermal transfer process. -

Page 70: Mechanical Features

06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Punch measures [10] Punches and reflex marks at different material types. A Punch position B Reflex mark position (PEM only) C Punch length D Punch width... -

Page 71: Connection, Device Data

06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Connection, device data Protection category Mains voltage 100-240V (AC) Mains frequency 60-50 Hz Power consumption 450W Input current 3.5 -1.5 A Ambient conditions Operating temp. -

Page 72: Interfaces (Electronics Gen. 3)

06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Interfaces (Electronics Gen. 3) This section counts for machines, which are equipped with CPU board A6621. The interfaces can not be combined in any way (Tab. 10)! Centronics 2. -

Page 73: Electronics Gen. 2

Realtime clock Standard External Sensors Start sensor Connection to USI or AI (Options) OD sensor (ALX 92x only) Material roll outer diameter (OD) sensor Connection to USI (Option) Rotary encoder for Connection to M12 plug (Option) APSF Admissible rotary encoder types: Rot. -

Page 74: Operation

• (DPM Gen. 2 / ALX 92x Gen. 2) – 4-key control panel – 2-line, 32-figure, illuminated LCD display (5 mm character height) • (DPM Gen. 3 / PEM / ALX 92x Gen. 3) – 5-key control panel – graphical, 128 x 32 Dot, illuminated LCD display... - Page 75 06/16 Vers. 05 USER + SERVICE MANUAL Technical Data DPM – PEM – ALX 92x Limitations DPM 6“ Rewinder construction Consider the following critical points, when building a rewinding unit for the DPM: • The rewinder must be fast enough to rewind the backing paper tight even when printing at high speeds.

- Page 76 04/16 Rev. 06 USER MANUAL AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Advanced Applications Printing with temperature compensation ..2 Access via Web/FTP server .......21 Requirements ..........2 Web server ..........21...

-

Page 77: Advanced Applications

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Printing with temperature compensation Requirements • Suitable printers: All devices listed in the headline of this document •... - Page 78 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Drive performance print head TR=0 TR=20% TR=40% TR = “SYSTEM PARAMETERS / Temp. reduction”...

-

Page 79: Printing With Start Signal

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Printing with start signal Application notes Print-and-Apply systems are normally triggered by an external start signal, which typ- ically comes from a product sensor placed at the conveyor. -

Page 80: Connecting The Signal Source

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Connecting the signal source Product sensor The 3 accessory boards USI, AI and I/O provide each a signal interface shaped as a D-Sub connector [2B] [3A]. - Page 81 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x [3] USI signal connector (A) and singlestart connector (B) at a 64-xx. If the printer is operated with a LTSI applicator, the footswitch...

-

Page 82: Settings In The Parameter Menu

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Settings in the parameter menu Setting Interface Printer Parameter Value Accept start si- SYSTEM PARAMETER >... -

Page 83: Standalone Operation

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Standalone Operation Requirements Printer Suitable printers: all devices listed in the headline of this document, except for AP 4.4... -

Page 84: Functional Description

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Keyboard On request, a keyboard can be connected to the printer. This considerably simplifies entry of variable data, especially when dealing with text. -

Page 85: Selecting Files From Memory Card

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Features Standalone operation in brief: • Printing without computer connection • Data entry via control panel or keyboard •... -

Page 86: Executing Printjobs

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x 3. Press the Online button to start proceeding the file In case of a printjob file, the printjob is started, in case of a firmware file, the firm- ware upload starts. - Page 87 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x mation about the job is displayed in the "Print control" console. While the print job is processed, it is started newly in the „Standalone“...

-

Page 88: Executing Firmware Files

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Executing firmware files Files with the extension .S3B are firmware files. Selecting a firmware file means start- ing a firmware download. -

Page 89: Insert Input Field In Printjob

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Insert Input Field in Printjob Input fields can be defined in the following Easy Plug field types: •... - Page 90 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x 7. Simultaneously press the Online and ESC keys. The first file on the memory card is displayed: Choose a file NOVEXX.FOR...

-

Page 91: Data Input By Interface

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Data input by interface Available with firmware x.33 or a later version. Apart from putting in data by operation panel or by external keyboard, the data can be sent via interface. -

Page 92: Data Transmission With Ethernet

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Data Transmission with Ethernet System Requirements CAUTION! - Unqualified manipulations of a data network can disturb or stop its pro- per functioning. -

Page 93: Integration Of Ethernet Interface

C LED green lights = High transmission rate (100 Mbit/s) [6] Position of the signal LEDs at AP 5.4, AP 7.t, ALX 73x and 64-xx, DPM, PEM, ALX 92x (each Gen. 3) A LED yellow lights = Printer is connected to network; LED flashes =Network traffic B LED green lights = High transmission rate (100 Mbit/s) [7] Position of the signal LEDs at AP 5.4 Gen. -

Page 94: Setting The Ip Parameters

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Setting the IP Parameters The IP-parameter settings can either be set fix, or they can be requested from a DHCP server with every start of the printer. -

Page 95: Transmission With Lpd Server

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Transmission with LPD Server Printing data can be transmitted to the printer using the LPR/LPD (Line Printer Dae- mon) protocol (“BSD Spooler”). -

Page 96: Access Via Web/Ftp Server

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Access via Web/FTP server Web server Applications The web server makes it possible •... - Page 97 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x [9] Login dialogue of the web server A Link to the web server home...

- Page 98 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Changing a setting in Click on the names of submenus and parameters to open them so that you can the parameter menu change the settings they contain.

- Page 99 Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x [11] Information (A): Changes made to the parameter setting do not come into effect until after a reset.

- Page 100 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x The virtual operator panel [12] The virtual operator panel After the “Display view” link is clicked, an image of the operator panel (= virtual oper- ator panel) appears on the screen [12].

-

Page 101: Ftp Server

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x D Status line [13E] In order to avoid putting an operating person at the machine at risk by sudden starting up of the machine, the virtual operator panel is locked as soon as a button at the machine operator panel is pressed. - Page 102 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x 4. Enter user name and password. A user name can be chosen at will; preset password = “avery”...

- Page 103 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x If the login was successful, separate folders appear in the FTP client, one for the in- ternal RAM disk and one for each connected memory medium [13]: •...

-

Page 104: Data Transmission With Wlan

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Data transmission with WLAN According to standard IEEE 802.11b Requirements Suitable printers Printer Firmware AP 5.4, AP 7.t... -

Page 105: Printer Setup

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Printer setup CAUTION! - Network manipulations can disturb or avoid proper network operation. -

Page 106: Pc Setup

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x PC setup 1. In Windows XP call: Start > Settings > System > Network. -

Page 107: Testing The Connection

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Testing the connection 1. Call the input window: Start > Programs > Accessories > Input prompt. -

Page 108: Storing And Transferring Parameter Settings

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Storing and transferring parameter settings Recommendations • Suitable printers: All printers listed in the headline, apart from the AP 4.4 (which has no card slot) •... -

Page 109: Storing Settings On Memory Card

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Storing settings on memory card SPECIAL FUNCTION > Store parameters 1. Call parameter ... -

Page 110: Loading Settings From Memory Card

USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Loading settings from memory card All files with parameter settings, which are stored in the \FORMATS directory, can be read out using the standalone mode. -

Page 111: Verifying Bar Codes With Olv

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Verifying Bar Codes with OLV System Requirements Printer • Suitable printers: 64-xx / DPM / PEM / ALX 92x. -

Page 112: Setup

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Setup 1. Place the printer on the OLV mounting plate as illustrated. ... - Page 113 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x [22] 64-05 with OLV mounted (side view).

-

Page 114: Appendix

04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x Appendix Example: Setup file for AP 5.4 #!A1 #G Machine Setup for AP 5.4 300 Dpi Version: V3.10... - Page 115 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x #G------------------------------------------------------------------- #G COM2 Port Parameter #G------------------------------------------------------------------- #PC1302/5 Baud rate : 9600 Baud #PC1303/8 No.

- Page 116 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x #G------------------------------------------------------------------- #G Options Parameter #G------------------------------------------------------------------- #PC5300/0 Remote Display : Disabled #G------------------------------------------------------------------- #G Printer System Menu #G------------------------------------------------------------------- #PC2001/24.5...

- Page 117 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x #G------------------------------------------------------------------- #G Peripheral Parameter Menu #G------------------------------------------------------------------- #PC2512/1 Rewinder Motor : Generation 2 #PC2501/0...

- Page 118 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x #G MLI Parameter Menu #G------------------------------------------------------------------- #PC4002/15 Darkness : 15 #PC4003/126 Control Prefix : 7EH...

- Page 119 04/16 Rev. 06 USER MANUAL Advanced Applications AP 4.4 – AP 5.4 – AP 5.6 – AP 7.t – 64-xx – DPM – PEM – ALX 92x #G------------------------------------------------------------------- #G Operational Data #G------------------------------------------------------------------- #G readonly ID=30014 #G Serv. operations : 0...

- Page 120 09/12 Rev. 5.08-01 USER MANUAL All printers Internal Fonts General notes ..........2 System Requirements ....... 2 Font size ............ 2 OCR-fonts ..........2 Parameter settings ........3 Fixfonts and Speedo fonts ......3 Customized Fonts ........3 Font presentation .......... 6 Font coding comparison ........

-

Page 121: General Notes

06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers General notes System Requirements The internal fonts are available in the following printer types: • TTX 450/650/674/675/950/1050 • TDI • TTK • 64-04/05/06/08 • DPM/PEM • PM 3000 • ALX 73x/92x •... -

Page 122: Parameter Settings

• Free flash memory of the required amount. Loading fonts Files with customized fonts can be ordered at Novexx Solutions. Such font files carry the extension *.s3b (as firmware files) and have to be loaded in the same way as firm- ware files. - Page 123 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers After successfully loading a font file, the following message appears: Data done KBytes: xx Restart the printer to activate the fonts. If not enough unused flash memory is available, the following message appears: Data update Flash full Followed by:...

- Page 124 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [1] Example of status printout „Flashdata status“ - in this case, the same font file was loaded twice. The result is, that in Block 2 and Block 3 are the same fonts, but with different font numbers. Deleting fonts Fonts can be deleted from the flash memory by calling parameter SPECIAL FUNCTION >...

-

Page 125: Font Presentation

06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers Font presentation [2] Each character of the font is depicted with its hexadecimal (first line) and decimal (second line) code. A Hexadecimal code. B Decimal code. -

Page 126: Font Coding Comparison

06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers Font coding comparison Not valid for TTX 67x, TTK, TDI Selecting the font coding: • Parameter menu: SYSTEM PARAMETERS > Character sets • Easy-Plug: #N [3] Speedo font 101 (#YN101) with coding „similar IBM“ (#N9). - Page 127 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [4] Speedo font 101 (#YN101) with coding ANSI CP1252 (#N10).

- Page 128 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [5] Speedo font 101 (#YN101) with coding ANSI CP1250 (#N11)

- Page 129 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [6] Speedo font 101 (#YN101) with coding ISO 8859-2 (#N12)

-

Page 130: Font Tables

06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers Font tables Coding: IBM Fixfonts YT100 [7] Fixfont YT100 (IBM), ASCII no. 000-095. - Page 131 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [8] Fixfont YT100 (IBM), ASCII no. 096-191.

- Page 132 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [9] Fixfont YT100 (IBM), ASCII no. 192-255.

- Page 133 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT101 [10] Fixfont YT101(IBM), ASCII no. 000-095.

- Page 134 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [11] Fixfont YT101 (IBM), ASCII no. 096-191.

- Page 135 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [12] Fixfont YT101 (IBM), ASCII no. 192-255.

- Page 136 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT102 [13] Fixfont YT102 (IBM), ASCII no. 000-095.

- Page 137 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [14] Fixfont YT102 (IBM), ASCII no. 096-191.

- Page 138 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [15] Fixfont YT102 (IBM), ASCII no. 192-255.

- Page 139 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT103 [16] Fixfont YT103 (IBM), ASCII no. 000-095.

- Page 140 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [17] Fixfont YT103 (IBM), ASCII no. 096-191.

- Page 141 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [18] Fixfont YT103 (IBM), ASCII no. 192-255.

- Page 142 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT104 [19] Fixfont YT104 (IBM), ASCII no. 000-095.

- Page 143 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [20] Fixfont YT104 (IBM), ASCII no. 096-191.

- Page 144 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [21] Fixfont YT104 (IBM), ASCII no. 192-255.

- Page 145 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT105 [22] Fixfont YT105 (IBM), ASCII no. 000-095.

- Page 146 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [23] Fixfont YT105 (IBM), ASCII no. 096-191.

- Page 147 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [24] Fixfont YT105 (IBM), ASCII no. 192-255.

- Page 148 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT106 [25] Fixfont YT106 (IBM), ASCII no. 000-095.

- Page 149 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [26] Fixfont YT106 (IBM), ASCII no. 096-191.

- Page 150 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [27] Fixfont YT106 (IBM), ASCII no. 192-255.

- Page 151 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT107 [28] Fixfont YT107 (IBM), ASCII no. 000-095.

- Page 152 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [29] Fixfont YT107 (IBM), ASCII no. 096-191.

- Page 153 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [30] Fixfont YT107 (IBM), ASCII no. 192-255.

- Page 154 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT108 [31] Fixfont YT108 (IBM), ASCII no. 000-095.

- Page 155 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [32] Fixfont YT108 (IBM), ASCII no. 096-191.

- Page 156 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [33] Fixfont YT108 (IBM), ASCII no. 192-255.

- Page 157 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT109 [34] Fixfont YT109 (IBM), ASCII no. 000-095.

- Page 158 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [35] Fixfont YT109 (IBM), ASCII no. 096-191.

- Page 159 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [36] Fixfont YT109 (IBM), ASCII no. 192-255.

- Page 160 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT110 [37] Fixfont YT110 (IBM), ASCII no. 000-095.

- Page 161 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [38] Fixfont YT110 (IBM), ASCII no. 096-191.

- Page 162 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [39] Fixfont YT110 (IBM), ASCII no. 192-255.

- Page 163 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT111 [40] Fixfont YT111 (IBM), ASCII no. 000-095.

- Page 164 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [41] Fixfont YT111 (IBM), ASCII no. 096-191.

- Page 165 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [42] Fixfont YT111 (IBM), ASCII no. 192-255.

- Page 166 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT112 [43] Fixfont YT112 (IBM), ASCII no. 000-095.

- Page 167 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [44] Fixfont YT112 (IBM), ASCII no. 096-191.

- Page 168 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [45] Fixfont YT112 (IBM), ASCII no. 192-255.

- Page 169 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT113 [46] Fixfont YT113 (IBM), ASCII no. 000-095.

- Page 170 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [47] Fixfont YT113 (IBM), ASCII no. 096-191.

- Page 171 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [48] Fixfont YT113 (IBM), ASCII no. 192-255.

- Page 172 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT114 [49] Fixfont YT114 (IBM), ASCII no. 000-095.

- Page 173 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [50] Fixfont YT114 (IBM), ASCII no. 096-191.

- Page 174 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [51] Fixfont YT114 (IBM), ASCII no. 192-255.

- Page 175 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT115 [52] Fixfont YT115 (IBM), ASCII no. 000-095.

- Page 176 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [53] Fixfont YT115 (IBM), ASCII no. 096-191.

- Page 177 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [54] Fixfont YT115 (IBM), ASCII no. 192-255.

- Page 178 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YT116 [55] Fixfont YT116 (IBM), ASCII no. 000-095.

- Page 179 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [56] Fixfont YT116 (IBM), ASCII no. 096-191.

- Page 180 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [57] Fixfont YT116 (IBM), ASCII no. 192-255.

-

Page 181: Speedo Fonts

06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers Speedo fonts YN100 [58] Speedo font YN100 (IBM), ASCII no. 000-095. - Page 182 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [59] Speedo font YN100 (IBM), ASCII no. 096-191.

- Page 183 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [60] Speedo font YN100 (IBM), ASCII no. 192-255.

- Page 184 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YN101 [61] Speedo font YN101 (IBM), ASCII no. 000-095.

- Page 185 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [62] Speedo font YN101 (IBM), ASCII no. 096-191.

- Page 186 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [63] Speedo font YN101 (IBM), ASCII no. 192-255.

- Page 187 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers YN102 [64] Speedo font YN102 (IBM), ASCII no. 000-095.

- Page 188 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [65] Speedo font YN102 (IBM), ASCII no. 096-191.

- Page 189 06/15 Rev. 5.08-01 USER MANUAL Internal Fonts All printers [66] Speedo font YN102 (IBM), ASCII no. 192-255.

- Page 190 07/15 Rev. 02 SERVICE MANUAL DPM – PEM – ALX 92x Fault Location Error sources ..........2 Reading out diagnosis data ......6 Notes about fault location ......2 General notes ..........6 Data transmission ........2 Reading out via serial interface ....7 Display ............

-

Page 191: Fault Location

07/15 Rev. 02 SERVICE MANUAL Fault Location DPM – PEM – ALX 92x Error sources Notes about fault location Status reports should be printed to check the mechanical and electronic function capabil- ities – provided that no obvious no defects are evident. -

Page 192: Gap Detection

07/15 Rev. 02 SERVICE MANUAL Fault Location DPM – PEM – ALX 92x Gap detection Problem Possible cause Solution Check with SERVICE FUNCTION > Sensor test, if Photoelectric switch defective necessary replace the photoelectric switch Use SYSTEM PARAMETER > Sens. punch-LS to alter... -

Page 193: Feed Roller, Print Roller

07/15 Rev. 02 SERVICE MANUAL Fault Location DPM – PEM – ALX 92x Problem Possible cause Solution Check setting of print contrast (press Prog. button Ribbon tears during Printhead temperature is too in on-line mode or parameter PRINT PARAMETER >... -

Page 194: Print Quality

07/15 Rev. 02 SERVICE MANUAL Fault Location DPM – PEM – ALX 92x Print quality Problem Possible cause Solution Clean or replace thermal bar, see topic section Printhead dirty or defective Maintenance Check settings (e.g. print contrast, print head resi-... -

Page 195: Reading Out Diagnosis Data

07/15 Rev. 02 SERVICE-HANDBUCH Reading out diagnosis data DPM – PEM – ALX 92x Reading out diagnosis data General notes With the diagnose dump function, device internal ope- ration states can be read via serial connection and be saved in a text file. This way, the last device internal communication can be captured and analysed (compa- rable to the black box in an airplane). -

Page 196: Reading Out Via Serial Interface

07/15 Rev. 02 SERVICE-HANDBUCH Reading out diagnosis data DPM – PEM – ALX 92x Reading out via serial interface Prerequisites • Firmware (at least): Hardware Firmware Electronics Gen. 2 4.22 Electronics Gen. 3 5.02 • Terminal program, e. g. „Hyperterminal“ (is deliver- ed with Windows operating systems). - Page 197 07/15 Rev. 02 SERVICE-HANDBUCH Reading out diagnosis data DPM – PEM – ALX 92x [4] Read out data. Send the generated files with a descriptioin of the circumstances in which the error occured per email to the technical support at Avery Dennison.

-

Page 198: Storing On Memory Card

07/15 Rev. 02 SERVICE-HANDBUCH Reading out diagnosis data DPM – PEM – ALX 92x Storing on memory card Prerequisites • Firmware (at least): Hardware Firmware Electronics Gen. 2 4.31 Electronics Gen. 3 5.31 • Memory card plugged into the card slot. - Page 199 06/16 Rev. 09 SERVICE MANUAL DPM – PEM – ALX 92x Service Mechanics Safety Instructions ........3 Setting belt tension ........42 General Notes ..........4 Setting braking torque ......43 Illustrations and Descriptions ....4 Ribbon motor ...........46 Factory Settings ........4 Ribbon roller ..........47...

- Page 200 Exchanging or retrofitting the HME/ME500 power supply ......... 106 Remote operator panel ......109 Prerequisites ......... 109 Assembly of internal cable (ALX 92x) ..109 Assembly of internal cable (DPM/PEM) 110 Wall mounting the remote operator panel ............. 112 APSF-Rotary Encoder ......113 Prerequisites .........

-

Page 201: Safety Instructions

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Safety Instructions WARNING! The machine operates using mains voltage! Touching electrically live parts can cause exposure to hazardous electrical currents and may lead to burns. Only authorised service technicians are permitted to disassemble the housing. -

Page 202: General Notes

The following descriptions are largely applicable both to DPM and to ALX 92x. The latter will be referred to as "ALX" below. Some sections apply to only one of the two types of machine. In such cases the machine type will be shown after the heading in brackets. -

Page 203: Key Combinations

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Key Combinations Access to certain of the printer’s functions should be reserved for authorised service technicians. Access to these functions has been restricted. In order to access them, the operator must restart the printer while pressing a specific key combination for several seconds. -

Page 204: Maintenance Plan

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Maintenance plan Performance interval Maintenance should be carried out • annually or • after 250 km printhead running time Printhead runtime: Call parameter SERVICE DATA >OPERATION DATA > Head run... -

Page 205: Performance Test

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Performance test repl. Part Check If defective... Springs Deformations? Replace spring Ribbon mandrels Scoring, groove marks? Replace ribbon mandrel Bearing clearance outside the normal range? Sensors Check values ( Clean / replace sensor;... -

Page 206: Housing

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Housing The DPM housing consists of the parts shown in the illustrations [1]. The front and rear hoods each consist of several sheet metal components connected with hinges [8]. -

Page 207: Front Hood

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Front hood Tools • Torx screwdriver T20, 20 cm long • Small screwdriver • Allen key 2.5 mm. Dismantling 1. Open up the front hood [4]. 2. Unscrew hood switch [4A] ... - Page 208 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 2. Open rear hood [7]. To do this carefully pull the entire rear hood back as shown and at the same time open up the right-hand lateral part.

-

Page 209: Blower (Dpm)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Blower (DPM) Tools • 2.5 mm allen key • Size 7 open-ended wrench Dismantling 1. Open rear hood (see above). 2. Disconnect blower cable from USI board and power supply. -

Page 210: Rear Hood (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Rear hood (ALX) The rear hood of the ALX 92x consists of two identical plastic parts. Tools Allen key 3 mm. Dismantling 1. Remove four screws on each half of the housing [12A], [13A]. -

Page 211: Dust Filter (Alx)

Medium size screwdriver Assembly 1. Put a filter liner [15C] into the filter housing [15B]. [15] Assembled dust filter for the ALX 92x power supply 2. Press the filter housing onto the filter frame [15A]. Turn the screw [15D] by a quarter-turn. -

Page 212: Hood Switch

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Hood switch WARNING! The hood switch is there for your safety! Putting it out of operation in- creases the risk of hair, jewellery etc. being caught. Do not disable the hood switch! [19] Hood switch dismantled. -

Page 213: Material Transport

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Material transport Unwinder (ALX) Tools Screwdriver, medium Dismantling 1. Remove locking ring [[23A]. 2. Move the guide rod to the side, and pull the unwinder off the axle. -

Page 214: Material Dancer Lever (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Material dancer lever (ALX) Tools • Screwdriver, medium • 2.5 mm hexagon spanner Dismantling 1. Dismantle material unwinder (see above). 2. Remove locking ring [25B]. 3. Unhook the spring [25A]. -

Page 215: Contact Pressure Axle At Drawing Roller

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Contact pressure axle at drawing roller Tools 2.5 and 3 mm allen keys Dismantling the pressure roller • ALX 924/925: One pressure roller. • ALX 926: Two pressure rollers. -

Page 216: Contact Axle Sensor

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Contact axle sensor For details on testing the light barrier: see topic section Service Electronics: ’Set- tings’, ’Sensor test’. Tools 3 mm allen key Dismantling 1. Open (DPM) or dismantle (ALX) the rear hood. -

Page 217: Backing Paper Dancer Lever (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Backing paper dancer lever (ALX) Tool 3 mm allen key Dismantling 1. Unhook spring [32B]. 2. Remove screw [32A]. Take off the dancer lever [32C]. To replace the roller, take off the locking ring [32D]. -

Page 218: Dancer Lever Light Barrier (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Dancer lever light barrier (ALX) Position detection of the rewinder dancer lever was done up to 08/2013 by a combi- nation of a light barrier and a light barrier wedge. -

Page 219: Dancer Lever Hall Sensor (Alx)

Service Mechanics DPM – PEM – ALX 92x Dancer lever Hall sensor (ALX) In ALX 92x which were built later than 09/ 2013, the position detection of the dancer lever is done by a Hall sensor. This implies the following advantages: –... -

Page 220: Retrofitting A Hall Sensor Control Unit (Alx)

(ALX) Prerequisites – Retrofitting kit A105985 (RH) or A105984 (LH) [38] – ALX 92x with „Gen. 3“ electronics and CPU board A6621 with index -05 or hig- – Firmware version 6.43 – Stepper motor output stage board M4A (A2742) oder M5A (A7579) ... - Page 221 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 6. Disconnect and remove the sensor cable. 7. Haltewinkel [41A] abschrauben (2 Schrau- ben [41B]). [41] Unscrew the sensor holder (A). Assembling the retrofitting kit 1. Disassemble the dancer lever and the old sensor (see above).

- Page 222 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 4. Attach the sensor board [45A] to the board holder with 2 lens head screws. The screws must be centered in the long holes. [45] Attaching the sensor board (A).

- Page 223 The PIC version of the output stage can be queried by the following parameter: SERVICE DATA > MODULE FW VERS. > Rewinder [49] Rewinder output stage board (A) in the ALX 92x. Stepper motor output stages: See topic section Electronics Gen.

-

Page 224: Backing Paper Rewinder (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Backing paper rewinder (ALX) Tools • 2.5 and 3 mm allen keys • Size 17 open-ended wrench Dismantling the drive belt 1. Take off the winder guide plate [[50A]. To do this, unscrew the two screws [50B]. -

Page 225: Rewinder Motor (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Completely dismantle the winder 5. Dismantle the ALX rear hood. See chapter Rear hood (ALX) on page 12. 6. Unscrew nut [[53A]. The nut can be acces- sed from below (between power supply and base plate). -

Page 226: Ribbon Transport

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon transport Important Notes The components for ribbon transport are the same for DPM and ALX. Lubricating plastic parts All plastic parts pictured below must be greased at the inner diameter [55 arrow] before assembling it. -

Page 227: Version Overview

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Version Overview [56] Type 2 of ribbon drive (A) and ribbon brake (B). Built-in until serial number 074315 (12/2007). [57] Type 3 of ribbon drive (A) and ribbon brake (B). -

Page 228: Ribbon Unwinding Mandrel (Type 2)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon unwinding mandrel (type 2) Tools • 2.5 and 2 mm Allen key • Size 7 and 8 socket wrenches • Plastic hammer Dismantling 1. Pull the cap [58B] off the ribbon mandrel. - Page 229 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 4. Dismantle the ribbon sensor by removing screw [61A]. 5. Remove nut [61B]. At the same time brace the threaded rod with the red hexagonal head at the other end of the rod.

- Page 230 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Assembly To assemble the device, follow the steps in the reverse order. Make sure to do the following: Mount the buffer disc [64H] with the lar- ger chamfer pointing outwards.

-

Page 231: Ribbon Unwinding Mandrel (Type 3)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon unwinding mandrel (type 3) Tools • 2.5 and 2 mm Allen key • Size 7 and 8 socket wrenches • Plastic hammer Preparing for dismantling 1. Pull the cap [66B] off the ribbon mandrel. - Page 232 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x [69] Type 2 ribbon brake (RH). Disassembly 6. Turn the threaded rod by the red hexago- nal head out of the cap [69A] and pull it out of the ribbon mandrel.

- Page 233 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x The distance X is crucial for the max. setable brake torque of the unwinder. The table shows only reference values, which can differ from printer to printer.

-

Page 234: Ribbon End Sensor

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon end sensor For details on testing the sensor: see topic section Service Electronics: ’Settings’, ’Sensor test’. Tools 3 mm allen key Dismantling 1. Open (DPM) or dismantle (ALX) the rear hood. -

Page 235: Ribbon Rewinding Mandrel (Type 1/2)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon rewinding mandrel (type 1/2) Tools • Size 7 and 8 socket wrenches • Allen key 2 mm. • Plastic hammer • Torx screwdriver size 20 Dismantling 1. - Page 236 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 8. Undo the 2 set screws on the buffer disc [74F]. Remove the buffer disc. 9. Push the ribbon mandrel through to the opposite side. If necessary, force the ribbon mandrel out by tapping it lightly with the plastic ham- mer.

-

Page 237: Ribbon Rewinding Mandrel (Type 3)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon rewinding mandrel (type 3) Tools • Size 7 and 8 socket wrenches • Allen key 2 mm. • Plastic hammer • Torx screwdriver size 20 Dismantling 1. - Page 238 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x [78] Type 3 rewinding mandrel (RH). Disassembly 5. Turn the threaded rod by the red hexagonal head out of the cap [78A] and pull it out of the ribbon mandrel.

- Page 239 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x The distance X is crucial for the max. seta- ble brake torque of the rewinder. The table shows only reference values, which can differ from printer to printer.

-

Page 240: Setting Belt Tension

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Setting belt tension 1. Press the belt tightener against the belt. Tigh- ten screw [79A]. 2. Measure the belt tension using one of the methods described below. -

Page 241: Setting Braking Torque

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Setting braking torque The braking torques of the ribbon mandrels can be set by turning the red hexagon on each mandrel. Turn clockwise to increase the torque. - Page 242 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Setting the maximum brake force 1. Screw in the threaded rod until it stops. 2. Measure the brake force as described above. If the value measured is lower than the specified range, ...

- Page 243 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Printhead Unwinding mandrel Winding mandrel width min. (N) max. (N) min. (N) max. (N) 4"/5" 6" [Tab. 1] Minimum and maximum setting values for the traction on the winding and unwinding mandrels (1“...

-

Page 244: Ribbon Motor

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon motor Tools Torx screwdriver size 20 Dismantling 1. Remove the drive parts from the ribbon rewinding mandrel [86]. See chapter Ribbon rewinding mandrel (type 3) on page 39. -

Page 245: Ribbon Roller

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Ribbon roller Tools • Allen key 2.5 mm. • Large and medium-sized screwdrivers Dismantling 1. Open (DPM) or dismantle (ALX) the rear hood. See chapter Housing on page 8. -

Page 246: Print Module

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Print module Feed motor (DPM, ALX) Tools • 4 mm allen key • Torx screwdriver size 20 Dismantling 1. Open (DPM) or dismantle (ALX) the rear hood. -

Page 247: Feed Motor (Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Feed motor (PEM) Tools 5 mm allen key Dismantling 1. Open the rear hood. See chapter Housing on page 8. [91] Feed motor positioning (A) in the PEM (LH. -

Page 248: Brake Roller Version Overview

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Brake roller version overview Parts kit for retrofitting from type 1 to type 2: • A9138 (LH) • A9139 (RH) [94] Type 1 of the brake mechanics (with wrap around spring) (A). -

Page 249: Brake Roller (Type 1 - Dpm, Alx)

• 2 mm allen key • Small screwdriver Dismantling [96] Brake roller (arrow) at an ALX 92x (RH). 1. Unhook and remove the brake spring [97A]. 2. Loosen the screw at the belt tightener [97B]. [97] Type 1 brake mechanism at the brake roller. - Page 250 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 8. Remove the locking ring [99A]. [99] A Locking ring on the brake roller. 9. Remove locking plate [100A]. 10. Press in lever [100B] and pull out the brake roller [100C] along with the bearings.

-

Page 251: Brake Roller (Type 2 - Dpm, Alx)

Size 7 and 8 socket wrenches • 2 mm allen key • Small screwdriver [102] Brake roller (arrow) at an ALX 92x (RH). Dismantling 1. Loosen the screw at the belt tightener [103A]. 2. Unscrew nut [103C]. At the same time... - Page 252 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 6. Remove the retaining ring [105A]. [105] A Locking ring on the brake roller. 7. Remove locking plate [106A]. 8. Press in lever [106B] and pull out the brake roller [106C] along with the bearings.

- Page 253 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Assembly To assemble the device, follow the steps in the reverse order. Do the following: Insert a shim ring 0.5 mm thick both in front and behind the t-belt pulley [107A]! ...

- Page 254 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x [107] Position of the parts on the brake roller axle.

-

Page 255: Setting The Braking Torque

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Setting the braking torque • Measuring the break force 1. Insert material strip [108]. Material size: 110 mm. 2. Fit spring balance [108A] onto the material strip. -

Page 256: Print Roller (Dpm, Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Print roller (DPM, ALX) Tools 2 mm allen key Dismantling 1. Remove locking plate [111B]. 2. Pull out the print roller [112]. [111] A Print roller B Locking plate... -

Page 257: Print Roller (Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Print roller (PEM) Tools • 2 mm allen key Dismantling 1. Remove the locking plate [91A].. [113] Locking plate (A) on the print roller (PEM LH). 2. Loosen both set screws [114A] at the print roller coupling. -

Page 258: Print Roller Drive Belt (Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Print roller drive belt (PEM) Tools 2 and 5 mm allen keys Dismantling 1. Dismantle belt tightener [95A] and roll [95B]. 2. Remove print roller. See chapter Print roller (PEM) on page 59. -

Page 259: Feed Roller Drive Belt (Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Feed roller drive belt (PEM) Dismantling 1. Dismantle drive belt from the print roller. See chapter Print roller drive belt (PEM) page 60. 2. Disassemble the feed motor. -

Page 260: Feed Roller (Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Feed roller (PEM) Tools 2 mm allen key Dismantling 1. Dismantle drive belt from the print roller. See chapter Print roller drive belt (PEM) page 60. -

Page 261: Dispensing Edge

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Dispensing edge The dispensing edge [123A] is held at both ends in side panels [123B]. Tools 2.5 mm allen key Dismantling 1. Dismantle the print roller (see above). -

Page 262: Guiding Profile

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Guiding profile Tools Allen key 3 mm. Dismantling 1. Undo the screws [124B]. 2. Pull the guiding profile [125A] out to the side. [124] A Guiding profile B Fastening screws [125] Pull the guiding profile (A) out. -

Page 263: Pressure Roller Unit

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Pressure roller unit The pressure rollers [128C] press the label material onto the brake roller. The unit in- cludes the axle [128B] with the two pressu- re rollers and a lever at each end of the axle. -

Page 264: Pressure Roller (Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 6. Thread the axle out, back and to the side [131]. [131] Thread the pressure roller axle (A) out, back and to the si- Pressure roller (PEM) - Page 265 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 5. Lift the pressure roller. Unscrew the locking plate [134A]. 6. Remove the ball bearing [134B] from the pressure roller wing (outside direction). [134] Locking plate (A) at the pressure roller wing.

-

Page 266: Material Guide

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Material guide The material end sensor is located in the inner material guide [137A]. Tools • Retaining ring pliers • 2 mm allen key Dismantling 1. Undo the set screw on the inner material guide [137A]. - Page 267 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Assembly To assemble the device, follow the steps in the reverse order. Assure the following: Spacer sleeves behind the rear materi- al guide: – ALX, DPM: each axle 1x A3629 (6.7 mm) –...

-

Page 268: Material End Sensor

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Material end sensor The material end sensor recognises when no more material is there and thus protects the printhead from unnecessary wear. The error is displayed, and the machine stops. -

Page 269: Punch Sensor

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Punch sensor For details on testing the light barrier sen- sor: see topic section Service Electronics: ’Settings’, ’Sensor test’. Tools • 2.5 mm allen key •... - Page 270 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Fit the cylindrical moulding [148A] into the groove on the guiding profile [148B]. Dismantling (PEM) 1. Open the rear hood. [148] A Cylindrical moulding on the sensor fitting...

- Page 271 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Assembly (PEM) To assemble the device, follow the steps in the reverse order. Make sure to Fix the sensor onto the belt as shown [152]. The right-hand edge of the clip [152C] "points"...

-

Page 272: Printhead

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Printhead General Notes CAUTION! - Electrostatic discharges or contact with sharps edges can da- mage the printhead. Protect the printhead from electrosta- tic discharges when performing main- tenance work or cleaning. -

Page 273: Overview Of Printhead Settings

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Overview of printhead settings There are electronic and mechanical prin- thead settings: Electronic Parameter When required? settings Print contrast Blackening of the printout is too low (depends on SYSTEM PARAMETER >... -

Page 274: Replacing The Printhead

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Replacing the printhead Dismantling 1. Switch off the machine and unplug it. 2. Disconnect the printhead cable [157B] (2 units). [157] Detach the printhead cable. 3. Undo the wingscrews [157A] and take off the print head [158]. -

Page 275: Replacing The Printhead Cable

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Replacing the printhead cable Dismantling 1. Disconnect cable (2 units) from the print head (see above). 2. Open (DPM) or dismantle (ALX) the rear hood. 3. Pull the end of the cable line (printhead side) through the opening in the base plate [158A]. -

Page 276: Printhead Adjustment

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Printhead adjustment Adjusting the printhead gap When the machine is switched on and the ribbon is in place, there should be a gap of between 0.75 and 1.00 mm between the printhead and the print roller. - Page 277 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Setting 7. Turn the connecting link [164A] to the lowest position (printing position). [164] Connecting link (A) on the mounted head lifting motor (ALX/ 8. Clamp 0.1 mm thick material [165C] bet- ween the connecting link and the pressure arm [165B].

- Page 278 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 10. Shift the pressure tool [167A], [168A] onto the printhead axle. The pressure tool suits for both machi- ne types, RH and LH. 11. Press the lever of the pressure tool [168A]...

-

Page 279: Adjusting The Printhead Position

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Adjusting the printhead position In this chapter, „Printhead position“ means the position of the printhead [170A] at the printhead bracket [170B] in printing directi- The printhead position is factory-adjusted and hasn´t to be changed in most of the ap-... -

Page 280: Adjusting The Printhead Contact Pressure

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Adjusting the printhead contact pressure Tools • Spring balance 0 to 50 N (Part number 93665-00-0) • Size 7 open-ended wrench • Coupling piece (allows the spring balance... -

Page 281: Printhead Lifting Mechanism

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Printhead lifting mechanism Printhead pressure setting knob The printhead press-on unit is used to en- sure that the printhead presses on the print roller at a defined and consistent rate. -

Page 282: Printhead Lift Sensor

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Printhead lift sensor For details on testing the sensor: see topic section Service Electronics: ’Settings’, ’Sensor test’. The light barrier [175A] is fastened to the head lifting motor [175D] with a mount [175B]. -

Page 283: Boards

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Boards USI board (ALX) Tools 2 mm allen key Dismantling 1. Remove rear hood. See chapter Rear hood (ALX) on page 12. 2. Disconnect all cables from the board [178] USI board [179A]. - Page 284 See: topic section Electronics Gen. 2 Electronics Gen. 3, chapter "USI board". Power supply [181] Connecting scheme USI to CPU boards A2292 and A2293 in ALX 92x. Power supply [182] Connecting scheme USI to CPU board A6621 in ALX 92x.

-

Page 285: Cpu Board (Alx)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x CPU board (ALX) The CPU board was revised in 2006: • --> 6/2006, article no. A2292 („Gen. 2“) • 7/2006 -->, article no. A6621 („Gen. 3“) The Gen. 2 board is no longer available since 7/2011. - Page 286 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Assembly To assemble the device, follow the steps in the reverse order. Make sure to Check any new board before mounting: – Circuit board version – Jumper settings ...

-

Page 287: Usi Board (Dpm/Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x USI board (DPM/PEM) Tools 2 mm allen key Dismantling 1. Open the rear hood. See chapter DPM rear hood on page 9. 2. Disconnect all cables from the board. - Page 288 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Assembly To assemble the device, follow the steps in the reverse order. Make sure to Check any new board before mounting: – Circuit board version – Controller version –...

-

Page 289: Cpu Board (Dpm/Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x CPU board (DPM/PEM) The CPU board was revised in 2006: • --> 6/2006, article no. A2292 („Gen. 2“) • 7/2006 -->, article no. A6621 („Gen. 3“) The Gen. 2 board is no longer available since 7/2011. - Page 290 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x [194] Mounted position of CPU board (A) (DPM LH). Assembly A B C D To assemble the device, follow the steps in the reverse order. Make sure to ...

-

Page 291: Stepper Motor Output Stages

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Stepper motor output stages Since 1/2012, the PMA is delivered with the newly developped M5A output stages, which replace the M4A output stages, which were built-in previously [196]. Ma-... -

Page 292: Retrofitting M5A Output Stages

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Retrofitting M5A output stages Prerequisites • Feed-, headlift, ribbon motor: Defective M4A output stages (article no. A2742 or A6713) can be replaced by M5A output stages, if the retrofitting kit is applied that is offered for this purpose. - Page 293 Rewinder dancer arm motor sensor A9798 [201] Connecting the M5A output stage belonging to the ALX 92x rewinder motor to the CPU board A6621. 5. Remove the jumper that sets the rotation direction [202A]. Always remove this jumper when retrofit- ting M5A output stages.

-

Page 294: Operator Panel Board

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Operator panel board Dismantling 1. Open the front cover. 2. Carefully remove the front part of the ope- rator panel housing [203A]. This does not require tools. -

Page 295: Power Supplies (Dpm/Pem)

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Power supplies (DPM/PEM) Further information about applying the dif- ferent power supply types can be found in topic section Electronics Gen. 3, chapter "Power supplies". Exchanging the HME power... - Page 296 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x 5. Remove the power supply. 6. (RH only) Unscrew the fixing bracket fromt the power supply. Assembly WARNING! Hazard caused by dangerous contact voltage! Attach the PE cable to the machine [210] Connecting the power supply: housing.

-

Page 297: Exchanging The Me500 Power Supply

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Exchanging the ME500 power supply WARNING! Hazard caused by dangerous contact voltage! After switching off the printer, wait at least 1 minute before touching any electric contacts at the power supply. -

Page 298: Retrofitting A Me500 Power Supply

06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Retrofitting a ME500 power supply Until approx. 03/2014, the HME PS 450 po- wer supply (brief „HME“) was installed in DPM/PEM machines, afterwards the ME500 power supply took its place. If a HME turns out to be defective in the future, it must be replaced by a ME500. - Page 299 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x The surfaces to be bonded to must be clean, dry and free from dust and grease. 5. (RH only) Insert a cable strap into each of the cable sockets [217D].

- Page 300 06/16 Rev. 09 SERVICE MANUAL Service Mechanics DPM – PEM – ALX 92x Installing the ME500 1. Insert the power supply into the DPM/PEM housing [221]. [221] ME500 inserted (left: LH; right: RH). 2. Screw the power supply with its fixing bra- cket to the fan [222][223].