Summary of Contents for Novexx Solutions ALS 20 series

- Page 1 USER MANUAL ALS 20x /ALS 256 /ALS 272 Labeler Edition 6 - 7/2017 - A104087 - Translation of original version...

-

Page 3: Table Of Contents

ALS 20x/256/272 User Manual Contents Please note General notes Validity and binding effect of this manual Illustrations and descriptions Safety instructions Information and qualifications Operational safety of the unit Warning notes on the unit Product description Overview Design models Mode of operation Operating components Control panel Connection arrangement... - Page 4 ALS 20x/256/272 User Manual Narrow label spring kit Splice table Signal beacon Operating modes Dispensing mode Configuration mode Function descriptions Overview of functions Notes LABEL SETUP menu MACHINE SETUP menu Before operation Electrical connections Power supply connection Connecting sensors Inserting label material Inserting a label roll Threading the label roll Mechanical settings...

- Page 5 ALS 20x/256/272 User Manual Operational failures Status messages Types of status messages List of warnings List of error messages EU Declarations EU Declaration of Conformity EU Declaration of Incorporation Appendix regarding the Declaration of Incorporation 07/2017 Contents...

- Page 6 ALS 20x/256/272 User Manual 07/2017 Contents...

- Page 7 Technical state: 5/2017 Software version: 2.60 SR1 Liability NOVEXX Solutions reserves the right: – To make modifications to construction parts, components and software, as well as to employ comparable components in place of the parts specified, in keeping with technical advances.

- Page 8 ALS 20x/256/272 User Manual Copyright NOVEXX Solutions holds all rights to this manual and its appendices. Reproduction, reprinting or any other types of duplication, even of portions of this manual, may only be carried out with express written consent. Printed in Germany...

- Page 9 ALS 20x/256/272 User Manual Button symbols – The buttons of the control panel are depicted as symbols. – The symbols are depicted with a ‘+’ (PLUS SIGN) between them if more than one button is to be pressed. Functions Functions are displayed in grey in the text with the following structure, MENU NAME >...

- Page 10 ALS 20x/256/272 User Manual SAFETY INSTRUCTIONS Information and qualifications Ensure the required qualifications are met Ensure that only trained and authorized personnel operate, configure and service the unit. Only allow qualified and well-trained expert personnel or service technicians to perform config- urations.

-

Page 11: Please Note -7

ALS 20x/256/272 User Manual Tasks System integrator Operator Service technician Manual: Service manual Operating Manual Service manual, spare parts catalogue [Tab. 1] An example of the distribution of tasks among different qualified personnel 1) For example faults when detecting labels 2) For example incorrect labelling Follow the instructions WARNING! - Page 12 ALS 20x/256/272 User Manual WARNING! Improper usage of the unit can cause accidents, property damage and production downtime! Only use the unit in accordance with the instructions specified in this manual. Do not operate the unit without the required safeguards. ...

- Page 13 ALS 20x/256/272 User Manual Protection against injuries by mechanical action WARNING! Risk of injury due to moving and rapidly rotating parts! Maintain a safety clearance from the machine when it is in operation. Never reach into a machine that is running. ...

-

Page 14: Warning Notes On The Unit -14

ALS 20x/256/272 User Manual Due diligence of the user Check that the safety installations are working properly. Inspect the machinery for any visible damage. Report any ascertained defects immediately. Use the required personal protective equipment correctly, for example, wear a hairnet. ... -

Page 15: Product Description

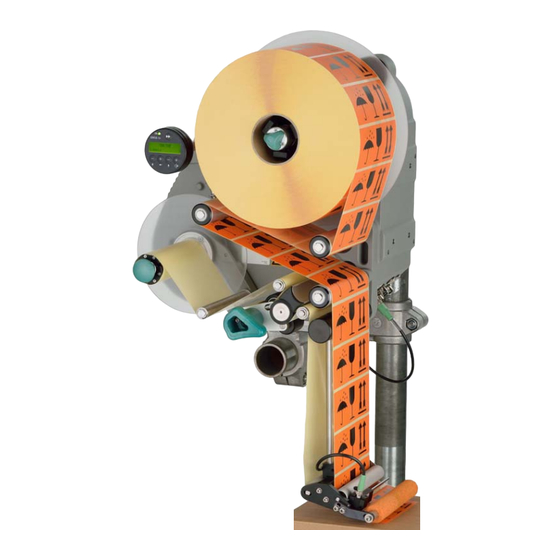

ALS 20x/256/272 User Manual Product description OVERVIEW Design models ALS 20x/256/272 ALS 204 ALS 256 ALS 272 [4] Comparison of the three versions of the ALS 2xx. – ALS 20x (ALS 204/206/209) differ only in the width (4“/6“/9“) – ALS 256 have the same width (6“) as ALS 206, but dispense with a higher speed –... - Page 16 ALS 20x/256/272 User Manual RH/LH Each of the ALS 20x, ALS 256 and ALS 272 label dispensers are available as right-hand (RH) or left-hand (LH) version. – ALS 2xx RH: The label exits the machine on the right – ALS 2xx LH: The label exits the machine on the left [5] Left: Left-handed version;...

-

Page 17: Mode Of Operation -17

ALS 20x/256/272 User Manual Mode of operation In labelling mode, the strip is first pulled from the label roll around the dancer arm [6A], which con- sistently maintains even tension in the label strip. The feed roller [6D] behind the dispensing edge [6C] draws the strip across the dispensing plate. -

Page 18: Operating Components -18

ALS 20x/256/272 User Manual Operating components [7] Operating components at the ALS 204 RH. The operating components described here are equal at all ALS 2xx versions. A Control panel – For sending commands to the device and for displaying operating states and error messages. –... - Page 19 ALS 20x/256/272 User Manual H Label sensor – Stops the label feed after a label has been dispensed. Pressure roller – Prints the label once it is stuck to the product. J Dispensing edge – Standard: (non-adjustable) L-shaped dispensing edge –...

-

Page 20: Control Panel -20

ALS 20x/256/272 User Manual Control panel STATUS Online Labels – – [8] The ALS 2xx control panel (in dispensing mode) A Operating LED B Error LED C LCD display D Buttons Operating LED Lights up green when the device is switched on. Error LED Lights up red when an error occurs. -

Page 21: Connection Arrangement -21

ALS 20x/256/272 User Manual Connection arrangement Connections on the back of the device [9] Connections on the back of the device (example: ALS 20x) A Power supply connection B Network connection (Ethernet 10/100) C Serial interface (RS232) D Connection for external control panel (RS485) E Plug-in card slot (SD/MC cards) F USB-A (host) interface (USB stick) G USB-B (device) interface... -

Page 22: Sensor Connections

ALS 20x/256/272 User Manual Sensor connections [10] Sensor connections on the ALS 20x (RH) PLC-IN PLC-OUT PLC-OUT PLC-IN START START ROTARY ROTARY ENCODER ENCODER LABEL LABEL CAP for 256 CAP for 256 [11] Arrangement of the sensor connections (schematic) on the LH (left) and RH (right) devices: A Product sensor B Signal outputs (optional) C Signal inputs (optional) -

Page 23: Characteristics -23

ALS 20x/256/272 User Manual TECHNICAL DATA Characteristics Dispensing speed ALS 204 max. 40 m/min ALS 206 max. 30 m/min ALS 256 max. 50 m/min ALS 209 max. 25 m/min ALS 272 max. 70 m/min Labelling halt precision at the peeling edge: ALS 272 ±0.5 mm all other machines... -

Page 24: Label Sensor -24

ALS 20x/256/272 User Manual Label sensor Distance to peel edge L-shape dispensing edge: 19 mm V-shape dispensing edge (ALS 204): 77 mm Sensor type: Transmission sensor; NPN/PNP (switchable) Power supply System voltage: ALS 20x 110 V (AC) at 60 Hz power frequency (permissible tolerance ±10%) 230 V (AC) at 50 Hz power frequency (permissible tolerance ±10%) -

Page 25: Internal Interfaces -25

ALS 20x/256/272 User Manual Internal sensor interfaces: Material unwider Light barrier Pressure roller not used Dancer arm bi-phase light barrier encoder PLC interface Sub D15, optically insulated, optionally via two 8-pin M12 (separate inputs/outputs in each case) Outputs: 4x PNP, 24 V, a maximum of 500 mA/channel, total permissible output current: 1500 mA Inputs: 3x PNP/NPN, 24 V... - Page 26 ALS 20x/256/272 User Manual Dimensions Width x height x depth: ALS 204 492 x 488 x 371 mm ALS 206 492 x 488 x 402 mm ALS 256 492 x 488 x 402 mm ALS 209 492 x 488 x 505 mm ALS 272 492 x 488 x 352 mm Weight:...

-

Page 27: User Manual Als 20X/256/272

ALS 20x/256/272 User Manual – The FCC regulation demands the following information text for class A devices: „NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial envi- ronment. - Page 28 ALS 20x/256/272 User Manual OPTIONS External control panel – An external control panel can be connected in addi- tion to the integrated control panel. – An external control panel is useful if the standard control panel is difficult to access due to the position in which the unit is installed.

- Page 29 ALS 20x/256/272 User Manual Pneumatic dispensing edge – The dispensing edge is pivoted in the dispensing head. Compressed air presses the dispensing edge onto the surface of the product. – Allows compensation for height differences be- tween the products or on the product surface. [16] Pneumatic dispensing edge V-shape dispensing edge –...

- Page 30 ALS 20x/256/272 User Manual Outer Diameter control sensor The outer diameter control sensor [19A] (OD sensor) triggers a warning, if the label roll outer diameter falls below a certain, adjustable value. [19] OD sensor (A) Dust/Splash guard Only for ALS 20x. Additional sealing of the electrical connections and of the housing fulfils the requirements of the IP65 protec- tion class [20A].

-

Page 31: Narrow Label Spring Kit -31

[22] Capacitive label sensor. Printer – If necessary, you can mount a hot stamp printer (not available from NOVEXX Solutions) onto the holder brackets of the dispensing edge. – Example of use: Printing consecutive numbers onto labels. -

Page 32: Splice Table -32

ALS 20x/256/272 User Manual Splice table With the splice table option, the end of the preceding material roll can be taped to the beginning of the new roll. Thus, the material doesn´t have to be fed through the whole machine for each new material roll, what reduces the downtimes for material change. -

Page 33: Operating Modes -33

ALS 20x/256/272 User Manual OPERATING MODES Dispensing mode This is the operating mode of the unit when switched on. You can carry out the functions listed in the sections STATUS below. Online If text such as ‘Prof 5 xxxxxxxx’ is displayed Labels instead of ‘ONLINE’: –... - Page 34 ALS 20x/256/272 User Manual Online settings The machine is in dispensing mode. To switch to the online settings mode: STATUS Press the button. – The display shows the dispensing speed [27A] and Speed Offset 12.2 fix 15.0 the start offset [27C]. –...

-

Page 35: Configuration Mode -35

ALS 20x/256/272 User Manual Configuration mode The machine is in dispensing mode. Switching to configuration mode: STATUS Press the button twice. – Display: OFFLINE OFFLINE – – Press the button. – Display: LABEL SETUP – LABEL SETUP is the name of the first menu that is LABEL SETUP currently active. - Page 36 ALS 20x/256/272 User Manual Functions Every submenu contains functions for setting the unit controls. Figure [29] shows the button functions for changing set- MACHINE SETUP > Language tings using the function as an example (English is the preset language, so you most probably don´t have to change this setting.

-

Page 37: Function Descriptions -37

ALS 20x/256/272 User Manual FUNCTION DESCRIPTIONS Overview of functions LABEL SETUP MACHINE SETUP (continued) INTERFACE PARA (continued) Load prod.profil Labeler type Labelsen. InType >EASYPLUGINTERPR DHCP host name Gap detect. mode Store prod.prof. Startsen. In.Type Interface FTP server Dispense speed Del. prod.profil Start disp. - Page 38 ALS 20x/256/272 User Manual SIGNAL INTERFACE (continued) SERVICE/DIAGNOS. SERVICE DATA (continued) Interface mode >AI BOARD SIGNAL Service >MODULE FW VERS. Work place >PLC SIGNALS Applicator type Serv. data reset System version Company name End dispense mod Apply mode Sensor Test System revision Disp.

-

Page 39: Notes -39

ALS 20x/256/272 User Manual Notes Function descriptions The following chapters only describe those functions that are necessary for operating an ALS 2xx/272 that has been configured and set up. These functions are highlighted in grey in the overview. Settings of functions that are not described in the following may only be changed by quali- fied service technicians. - Page 40 ALS 20x/256/272 User Manual Slew speed function – Feed speed at which the label material is driven if missing-label-gaps occur and during the au- tomatic measuring of the label length – Setting range: ALS 204: [1.0…40.0] m/min; default: 1.0 ALS 206: [1.0…30.0] m/min; default: 1.0 ALS 256: [1.0…50.0] m/min;...

-

Page 41: Machine Setup Menu -41

ALS 20x/256/272 User Manual Label 3 offset function – Only appears if LABEL SETUP > Multi label mode = „3 labels/start“. LABEL SETUP > Multi label mode – Defines the distance of the 3rd label for the function (see above). The distance is measured from the front label edge of the preceding label. - Page 42 ALS 20x/256/272 User Manual Language function – Language of display text – Settings: [German, English, French, Spanish, Dutch, Danish, Italian, Polish, Turkish, Russian] Materialend err function – Refers to the internal OD control. – Settings: [Off, „Mat.diam < x mm“] –...

- Page 43 ALS 20x/256/272 User Manual Rewinder full function Defines the maximum permissible diameter of the wound backing paper on the backing paper rewinder. If the diameter is exceeded, the following status message appears: Status num: 5064 Rewinder full – Setting range: [50…500] mm; Default setting: 202 mm 07/2017 | 00 Product description...

-

Page 44: Before Operation

ALS 20x/256/272 User Manual Before operation ELECTRICAL CONNECTIONS Power supply connection WARNING! This machine operates using mains voltage! Touching live electrical parts may expose you to hazardous electrical currents and may lead to burns. Make sure that the device is switched off before you connect the power cable. Only connect the unit to a grounded power socket fitted to authorised standards. - Page 45 ALS 20x/256/272 User Manual Checking the power supply setting ALS 256/ALS 272: A power supply setting is not required. The ALS 20x Label Dispenser is suitable for operation with a power supply of 230 V (AC) or 110 V (AC). Make sure that the power cable is disconnected.

-

Page 46: Connecting Sensors -46

ALS 20x/256/272 User Manual Connecting sensors WARNING! The machine operates using mains volt- age! Touching live electrical parts may expose you to hazardous electrical cur- rents and may lead to burns. Only link the unit to devices that fulfil the SELV (safety extra-low voltage) cir- cuit requirements specified in EN 60950. -

Page 47: Inserting Label Material -47

ALS 20x/256/272 User Manual INSERTING LABEL MATERIAL Inserting a label roll WARNING! Risk of injury due to moving and rapidly rotating parts! Before inserting the label roll, ensure that the device is in offline mode. Danger of injury caused by falling label roll! ... -

Page 48: Threading The Label Roll -48

ALS 20x/256/272 User Manual Threading the label roll Threading diagrams Solid line: Path for label rolls with labels facing out- wards. Dottet line: differing path for label rolls with labels facing inwards. ALS 20x/256 [41] Threading diagram for ALS 20x/256 with L-shape disp. edge. ALS 272 [42] Threading diagram for ALS 272 with L-shape disp. - Page 49 ALS 20x/256/272 User Manual ALS 204 [43] Threading diagram for ALS 204 with V-shape disp. edge. 07/2017 | 01 Before operation...

- Page 50 ALS 20x/256/272 User Manual Threading the label roll at the dispensing edge Fixed [44] (standard) and pivotable L-Shape dispens- ing edges: Unroll around 1 m of label strip and remove the la- bels from it. Pass the backing paper around the first deflection roller [44A] and through the slot in the sensor [44B].

- Page 51 ALS 20x/256/272 User Manual Threading the label roll onto the drive roller Open the pressure roller. To do so, rotate the lever [47D] in a clockwise direction. Feed the backing paper around the deflection roller [47B], drive roller [47C] and the dancer arm [47A]. ...

-

Page 52: Mechanical Settings -52

ALS 20x/256/272 User Manual MECHANICAL SETTINGS Adjusting the unwinder’s core diameter Tool: – 3 mm hexagon (Allen) screwdriver The unwinder can be adjusted with core adapters [50B] to fit the inner diameter of the label roll. The adapters must be fitted and dismantled in different ways depend- ing on this diameter: –... -

Page 53: Positioning The Label Sensor -53

ALS 20x/256/272 User Manual Positioning the label sensor Release the thumb screw [53B]. Position the sensor along the axle in such a way as to allow it to register the spaces between the labels. The LEDs [53A] light up when the sensor is positioned over a gap. -

Page 54: Operation -54

ALS 20x/256/272 User Manual Operation START-UP AND SHUTDOWN Turning on the unit [55] Main switch (A) of the ALS 20x. [56] Main switch (A) of the ALS 256/ALS 272. Set the main switch [55A][56A] of the unit to ‘I’ (On). ... -

Page 55: Starting Label Dispensing -55

ALS 20x/256/272 User Manual Starting label dispensing Dispensing with a product sensor Once switched on, the ALS 2xx/272 is in dispensing mode; this means that triggering the product sensor will cause a label to be dispensed. Prerequisites: – The label length must be specified. –... -

Page 56: Configuration And Monitoring -56

ALS 20x/256/272 User Manual CONFIGURATION AND MONITORING Function menu settings Label pitch Switch to configuration mode Calibrating the label pitch automatically: Hold down the button for a while (longer than two seconds). Or: Enter the label pitch manually: ... - Page 57 ALS 20x/256/272 User Manual Prerequisites: – The label length must be specified. The next label to be dispensed waits in the label stop position. Here it is useful if the label protrudes over the dispensing edge a little [59]. The labeler was pre-configured ex works for use with the supplied label sensor. If this sen- sor is used, the label stop position setting will only require minimal correction.

- Page 58 ALS 20x/256/272 User Manual Suppressing start signals A start signal can be prematurely triggered by the shape of the product or reflective surfaces, what can cause erroneous labelling. In case of a product causing unwanted additional start signals while the product passes the dispensing edge, those signals can be suppressed by setting function LABEL SETUP >...

-

Page 59: Monitoring Functions -59

ALS 20x/256/272 User Manual [61] Distance between the product sensor (left) and the dispensing edge (right). [62] Distance (A) between the label and the product’s front edge. Monitoring functions While in dispensing mode, an electronic controller monitors the following functions: Material end / Roll diameter (OD = outer diameter) To enable a quick renewal of the material roll, the machine can alarm the operator before the end... - Page 60 ALS 20x/256/272 User Manual Material end Critical OD reached Error message Warning Error message No OD-control Status num: 5001 none none No gap found Internal OD-control Status num: 5072 ONLINE Status num: 5071 Material end unw Material low Material end unw External OD-control none ONLINE...

- Page 61 ALS 20x/256/272 User Manual – Material is torn between feed roller and rewinder [64C]: Status num: 5140 Rewinder control See chap. Operational failures on page 69. [64] Material tear off in sections A, B or C leads to different error messages. Rewinder full If the diameter of the rewound backing paper [65A] exceeds the admissible diameter (202 mm), the following message appears:...

-

Page 62: Using Product Profiles -62

ALS 20x/256/272 User Manual USING PRODUCT PROFILES What are product profiles? Product profiles are memory locations that can store all the settings for the machine controls. For recurring production jobs, they allow you to quickly set the machine to the respective product. –... -

Page 63: Storing A Product Profile -63

ALS 20x/256/272 User Manual Storing a product profile Selecting the memory location MACHINE SETUP > Store prod.prof. Call the function. – Display shown when all memory locations are unoccupied: Store prod.prof. Prof 1 Product 1 – When memory locations are already occupied, the memory location that was last active is dis- played: Store prod.prof. -

Page 64: Deleting A Product Profile -64

ALS 20x/256/272 User Manual Deleting a product profile Call the MACHINE SETUP > Del. prod.profil function. – The memory location that was active last is displayed. Press the or the button until you retrieve the memory location you require (1–16). ... -

Page 65: After Operation

ALS 20x/256/272 User Manual After operation MAINTENANCE AND CLEANING Replacing fuses This section counts only for ALS 20x. The fuses at the ALS 256 and the ALS 272 cannot be replaced. WARNING! The machine operates using mains voltage! Touching live electrical parts may expose you to hazardous electrical currents and may lead to burns. - Page 66 ALS 20x/256/272 User Manual [67] Fuse holder (A) at the ALS 20x. 07/2017 | 01...

-

Page 67: Cleaning Agents

ALS 20x/256/272 User Manual Cleaning agents Cleaning agents for rubber rollers [68A]: – Roller cleaner, order number 98925. If other cleaning agents are used, there is a chance the rubber may corrode. Cleaning agents for metal deflexion rollers [68B]: – Cleaning solvent, alcohol-based solvent, isopropyl alcohol, spray for removing labels Cleaning the unit’s housing: –... -

Page 68: Regular Maintenance

ALS 20x/256/272 User Manual Regular maintenance The label dispenser is designed to be maintenance-free. However, you should service the unit reg- ularly in order to ensure reliable long-term operating results. Removing paper debris Depending on operating conditions, you should perform the following at least once a week: ... -

Page 69: Operational Failures

ALS 20x/256/272 User Manual Operational failures STATUS MESSAGES Types of status messages Error messages When an error occurs, the machine stops immediately and displays an error message on the con- trol panel. Error messages are displayed as follows: Status num: 5144 Rewinder init [70] An example of an error message:... -

Page 70: List Of Warnings -70

ALS 20x/256/272 User Manual List of warnings Displayed text Meaning Productstartwarn New start signal during the dispensing operation. Several missing labels on the web, which can not be compensated. APSF speed warn. The conveyor speed exceeded the max. speed of the dispenser. OD sensor warn. -

Page 71: List Of Error Messages -71

ALS 20x/256/272 User Manual List of error messages Status Status text Cause Action to take 5000 Bus device Device at I C Bus cannot be contact- Delete the message by pressing the -key. In most cases, this message appears Switch the machine off, wait 30 sec- as the first in a series of two or three onds and switch it back on. - Page 72 ALS 20x/256/272 User Manual Status Status text Cause Action to take 5072 Material end unw Occurs during operation with activated Check the material feeding; if neces- internal OD control. sary, replenish the material roll. The message appears, if no rotation of the mate-rial roll has been registered during at least 600 mm of material feeding.

- Page 73 ALS 20x/256/272 User Manual Status Status text Cause Action to take 5145 Rewinder full This error can only occur if the Remove the rewound backing paper end of a new label roll was Press the key to confirm the error glued on to backing paper that message.

- Page 74 ALS 20x/256/272 User Manual Status Status text Cause Action to take 6207 No ext. memory No external memory medium was Check whether an external memory found. medium (e. g. USB thumb drive) is connected. If the memory medium was not connected until after the machine was switched on: Switch the machine off and back on again.

-

Page 75: Eu Declarations

ALS 20x/256/272 User Manual EU Declarations EU DECLARATION OF CONFORMITY (Translation of original version) Novexx Solutions GmbH Ohmstraße 3 D-85386 Eching Germany hereby declare that we have designed and built the machine designated below so that it is in conformity with... -

Page 76: Eu Declaration Of Incorporation -76

ALS 20x/256/272 User Manual EU DECLARATION OF INCORPORATION (Translation of original version) Novexx Solutions GmbH Ohmstraße 3 D-85386 Eching Germany hereby declare that the partly completed machine designated below has been designed and built in such a way as to be in conformity with the safety and health protection requirements of directive 2006/42/EC, annex I, which are marked „fulfilled“... - Page 77 ALS 20x/256/272 User Manual APPENDIX REGARDING THE DECLARATION OF INCOR- PORATION List of the essential health and safety requirements applied and fulfilled for the product named in the declaration of incorporation, relating to the design and construction of machinery. Number Not appli- Designation Fulfilled...

- Page 78 ALS 20x/256/272 User Manual Number Not appli- Designation Fulfilled Remark Annex I cable 1.5.4. Errors of fitting 1.5.5. Extreme temperatures 1.5.6. Fire 1.5.7. Explosion 1.5.8. Noise 1.5.9. Vibrations 1.5.10. Radiation 1.5.11. External radiation 1.5.12. Laser radiation 1.5.13. Emissions of hazardous materials and substances 1.5.14.

- Page 80 Novexx Solutions GmbH Ohmstraße 3 85386 Eching Germany +49-8165-925-0 www.novexx.com...

Need help?

Do you have a question about the ALS 20 series and is the answer not in the manual?

Questions and answers