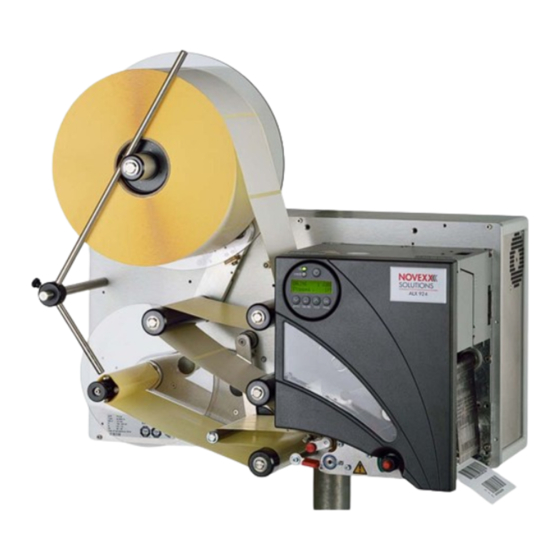

Novexx Solutions ALX 92x Manuals

Manuals and User Guides for Novexx Solutions ALX 92x. We have 1 Novexx Solutions ALX 92x manual available for free PDF download: Service Manual

Novexx Solutions ALX 92x Service Manual (824 pages)

Print & Apply system

Brand: Novexx Solutions

|

Category: Label Maker

|

Size: 29 MB

Table of Contents

-

-

-

Symbols13

-

Title Page14

-

-

Parameters15

-

Index16

-

-

-

-

-

Web Server96

-

FTP Server101

-

-

-

Requirements104

-

Notes104

-

Printer Setup105

-

Connecting105

-

PC Setup106

-

-

-

Setup112

-

Appendix114

-

Internal Fonts

120-

General Notes121

-

Font Size121

-

OCR-Fonts121

-

Customized Fonts122

-

Font Tables130

-

Fixfonts130

-

Speedo Fonts181

-

-

-

Fault Location

190-

Error Sources191

-

Display191

-

Gap Detection192

-

Print Quality194

-

Transport Unit194

-

Memory Card194

-

Fault Location191

-

General Notes195

-

-

-

General Notes202

-

Factory Settings202

-

Key Combinations203

-

Service Data203

-

Maintenance Plan204

-

Cleaning204

-

Performance Test205

-

Housing206

-

Front Screen206

-

Front Hood207

-

DPM Rear Hood207

-

Blower (DPM)209

-

Rear Hood (ALX)210

-

Blower (ALX)210

-

Hood Switch212

-

-

-

Unwinder (ALX)213

-

-

Ribbon Transport226

-

Important Notes226

-

Version Overview227

-

Ribbon Motor244

-

Ribbon Roller245

-

Ribbon Tensioner245

-

-

Print Module246

-

Feed Motor (PEM)247

-

Dispensing Edge261

-

Guiding Profile262

-

Material Guide266

-

Punch Sensor269

-

Printhead272

-

Boards283

-

-

General Notes315

-

Handling Boards316

-

ESD Protection316

-

Handling316

-

-

CPU Boards317

-

Connectors319

-

-

Important Notes323

-

Connectors324

-

-

Option Board325

-

Layout325

-

Connectors325

-

-

USI Board326

-

View327

-

Connectors327

-

Block Diagram332

-

Input Signals333

-

Firmware Update336

-

USI Testbox337

-

Application337

-

View337

-

Operation339

-

-

Power Supplies343

-

Settings357

-

Sensor Setting357

-

-

Sensor Test360

-

Options364

-

-

-

General Notes372

-

Handling Boards373

-

ESD Protection373

-

Handling373

-

-

CPU Board374

-

View374

-

Lithium Battery380

-

-

-

View383

-

Pin Assignment384

-

-

View385

-

Connecting386

-

-

View387

-

-

View388

-

Jumper Settings389

-

Pin Assignments389

-

-

View390

-

Jumper Settings391

-

Pin Assignments392

-

USI Board393

-

View394

-

Connectors395

-

Block Diagram400

-

USI Testbox404

-

I/O Board408

-

View408

-

Nt400414

-

Hme Ps 450421

-

Settings436

-

Sensor Test448

-

-

Firmware

453-

Firmware454

-

-

Installation459

-

-

Procedure462

-

Error Messages463

-

-

Printer Firmware

464-

About Firmware465

-

Appendix474

-

-

-

Pin Assignments500

-

Signal Leds507

-

-

Please Note -5512

-

Installation -7514

-

-

Power Supply -12519

-

Parameter Menu531

-

Printer Status552

-

Memory Status553

-

Font Status554

-

Flashdata Status557

-

Service Status558

-

Dottest Endless559

-

Dottest Punched559

-

Reference Label560

-

Rfid Status561

-

Feed Speed562

-

Print Parameters562

-

Print Speed562

-

Material Length564

-

Material Type564

-

Material Width564

-

Print Direction565

-

Punch Offset565

-

Bar Code Multip566

-

Ean Readline567

-

Cut Mode571

-

Cut Position573

-

Cut Speed573

-

Double Cut573

-

Punch Mode575

-

Punch Level576

-

Spooler Mode577

-

Interface Delay578

-

Offline Mode578

-

Printer ID no578

-

Spooler Size578

-

Serial Port Mode581

-

Usb Select585

-

Net Mask586

-

Ethernet Speed587

-

Gateway Address587

-

Port Address587

-

Snmp Agent587

-

Snmp Password587

-

Ftp Password588

-

Web Display Refr589

-

Web Admin Passw590

-

Web Supervisor P590

-

Time Client591

-

Dhcp Host Name592

-

Time Server Ip592

-

Standalone Input596

-

Foil End Warning599

-

Foil Warn Stop599

-

Print Interpret602

-

Character Sets603

-

Character Filter604

-

Easyplug Error606

-

Error Reprint606

-

Foil Mode606

-

Head Resistance607

-

Single Job Mode607

-

Thin Line Emphas610

-

Voltage Offset610

-

Gap Detect Mode611

-

External Signal613

-

Ram Disk Size615

-

Print Info Mode617

-

Reprint Function617

-

Access Authoriz618

-

Realtime Clock621

-

Dispense Counter624

-

Display Mode624

-

Dispensing Mode625

-

Start Source626

-

Calibration Mode627

-

Start Offset627

-

Break Diameter641

-

Error Polarity644

-

Status Output644

-

Status Polarity644

-

Control Prefix655

-

Delimiter Char655

-

Format Prefix655

-

Label Top656

-

Left Position656

-

Manual Calibrate656

-

Error Checking657

-

Error Indication657

-

Image Save Path657

-

Label Invert658

-

Printer Type660

-

Delete Job662

-

Delete Spooler662

-

Store Diagnosis663

-

Store Parameters663

-

Data Blocks del664

-

Log Files Delete664

-

Cutter Exchange666

-

Head Exchange666

-

Roller Exchange666

-

Easyplug Monitor668

-

Ep Monitor Mode668

-

Cutter Test669

-

Matend Tolerance669

-

Sensor Adjust669

-

Feedadjust Label670

-

Punch y Calibr670

-

Memory Card Test671

-

Send Test672

-

Receive Test673

-

Rewinder Adjust675

-

System Date677

-

System Revision677

-

Cutter Number680

-

Head Run Length680

-

Roll Number680

-

Cuts on Knife681

-

Roll Run Length681

-

Total Cuts681

-

Dispensing Cycl682

-

Foil Diameter682

-

Head Strobes682

-

Head Temperature682

-

Operation Time682

-

Serial Number683

-

Fpga Version684

-

Pcb Revision684

-

Production Date684

-

Board Part Numb685

-

Company Name685

-

Pcb Part Number685

-

Work Place685

-

Card Type686

-

Display Serialnr686

-

Flash Mem Size687

-

Space for Jobs688

-

Material End727

-

Ribbon End728

-

Advertisement