Subscribe to Our Youtube Channel

Summary of Contents for Optimum OptiGrind DG 20

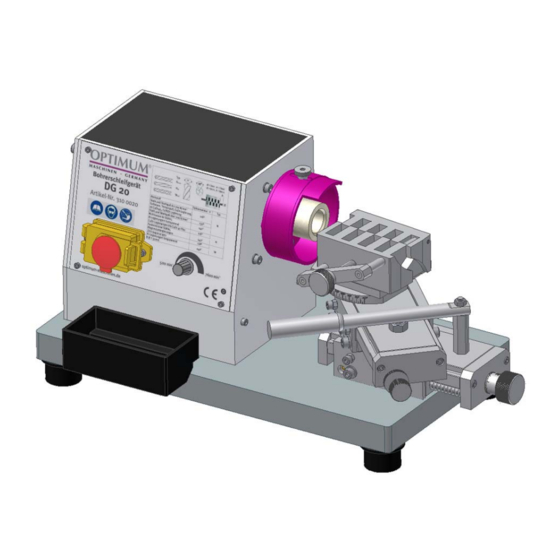

- Page 1 OPTIMUM M A S C H I N E N - G E R M A N Y Operating manual Version 1.3.2 Drill bit grinder Item No. 310 0028...

-

Page 2: Table Of Contents

OPTIMUM M A S C H I N E N - G E R M A N Y Table of contents Safety Type plate ..............................5 Safety warnings (warning notes) ......................6 1.2.1 Classification of hazards...........................6 1.2.2 Other pictograms ............................7 Proper use ..............................8 Possible dangers caused by the drill bit grinder ..................8... - Page 3 OPTIMUM M A S C H I N E N - G E R M A N Y Maintenance Safety ..............................24 5.1.1 Preparation............................. 24 5.1.2 Restarting ............................... 24 Inspection and maintenance ........................25 5.2.1 Replacing the cup wheel ........................25 Repair ..............................

- Page 4 Dear customer, Thank you very much for purchasing a product made by OPTIMUM. OPTIMUM metal working machines offer a maximum of quality, technically optimum solutions and convince by an outstanding price performance ratio. Continuous enhancements and product innovations guarantee state-of-the-art products and safety at any time.

-

Page 5: Safety

OPTIMUM M A S C H I N E N - G E R M A N Y Safety This part of the operating instructions explains the meaning and use of the warning references contained in the operating manual, ... -

Page 6: Safety Warnings (Warning Notes)

OPTIMUM M A S C H I N E N - G E R M A N Y Safety warnings (warning notes) 1.2.1 Classification of hazards We classify the safety warnings into various levels. The table below gives an overview of the classification of symbols (pictograms) and warnings for the specific danger and its (possible) consequences. -

Page 7: Other Pictograms

OPTIMUM M A S C H I N E N - G E R M A N Y 1.2.2 Other pictograms Warning of automatic Disconnect main power! start-up! Activation forbidden! Use ear protection! Use protective boots! Use protective gloves! Wear a safety suit! -

Page 8: Proper Use

OPTIMUM M A S C H I N E N - G E R M A N Y Proper use The drill bit grinder is designed and manufactured to be used in environments where there is no potential danger of explosions. The drill bit grinder is designed and manufactured exclusively for repointing twisted drills or sintered carbide drills. -

Page 9: Qualification Of Personnel

OPTIMUM M A S C H I N E N - G E R M A N Y All additional installations carried out by the operator must incorporate the safety devices prescribed. This is your responsibility as the operator! ... -

Page 10: User's Position

OPTIMUM M A S C H I N E N - G E R M A N Y check dead circuit User’s position The user must stand in front of the drill bit grinder. INFORMATION The electrical power plug of the drill bit grinder must be freely accessible. -

Page 11: Safety Check

OPTIMUM M A S C H I N E N - G E R M A N Y Safety check Check the drill bit grinder at least once per shift. Inform the person responsible immediately of any defect or change in operation. -

Page 12: Personal Protective Equipment For Special Works

OPTIMUM M A S C H I N E N - G E R M A N Y 1.10 Personal protective equipment for special works Protect your face and your eyes: wear a safety helmet with a face guard for all work, espe- cially during a task where your face and eyes are exposed to hazards. -

Page 13: Technical Data

OPTIMUM M A S C H I N E N - G E R M A N Y Technical data The following information provides you with the the dimensions and weights of the machine. It also refers as manufacturer’s authorized service information. -

Page 14: Dimensions

OPTIMUM M A S C H I N E N - G E R M A N Y Other processes proceeding nearby and the period during which the operator is exposed to the noise. Consult OSHA, state and local regulations in order to determine compliance, dangers and risks to the operator. -

Page 15: Assembly 3.1 Delivery Volume

OPTIMUM M A S C H I N E N - G E R M A N Y Assembly Delivery volume When the machine is delivered, please check immediately that it has not been damaged during transport and that all components are included. Take all parts off and compare them to the fol- lowing list. -

Page 16: Installation And Assembly

OPTIMUM M A S C H I N E N - G E R M A N Y Installation and assembly 3.3.1 Site requirements Organize the working space around the drill bit grinder according to the local safety regulations. INFORMATION In order to provide for good functionality and high machining accuracy as well as long durability of the machine the site should fulfill certain criteria. -

Page 17: Operation

OPTIMUM M A S C H I N E N - G E R M A N Y Operation Safety Operate the drill bit grinder only under the following conditions: The drill bit grinder is in proper working condition. ... -

Page 18: General

OPTIMUM M A S C H I N E N - G E R M A N Y General 4.3.1 Bit geometry Bit grinding terms: Ψ Chisel edge angle The chisel edge angle depends on the kind of relief produced by grinding. An angle of 55° is ... -

Page 19: Adjusting The Angles On The Drill Bit Grinder

OPTIMUM M A S C H I N E N - G E R M A N Y Adjusting the angles on the drill bit grinder The chisel edge angle of about 55° is adjusted by properly placing the drill bit into the bit ... -

Page 20: Before Starting The Work Cycle

OPTIMUM M A S C H I N E N - G E R M A N Y 4.5.2 Before starting the work cycle Before starting to repoint the drill, always check that the drill is free from oil, grease and paint. -

Page 21: Adjustment Of Limit Stop And Infeed Of Drill

OPTIMUM M A S C H I N E N - G E R M A N Y 4.5.4 Adjustment of limit stop and infeed of drill Do not turn on the drill bit grinder. Motion lever Adjust the position of the drill using the infeed screw and the limit stop screw. -

Page 22: Repointing The Drill

OPTIMUM M A S C H I N E N - G E R M A N Y Repointing the drill To repoint the drill, the bit holder must be turned by 180° on the base. ATTENTION! When you turn the infeed screw, the bit holder will approach the cup wheel. Check and correct the adjusted limit stop in short intervals. -

Page 23: Reduction Of The Chisel Edge

OPTIMUM M A S C H I N E N - G E R M A N Y Reduction of the chisel edge Also refer to "Bit geometry“ on page 18 The reducing of the chisel edge is only performed by infeed. The motion lever is not actuated. -

Page 24: Maintenance

long service-life of the drill bit grinder and the quality of the products manufactured. Installations and equipment of other manufacturers must also be in optimum condition. Safety WARNING! The consequences of incorrect maintenance and repair work may include: ... -

Page 25: Inspection And Maintenance

Should technical assistance be required, contact LDS Industries at (630) 785-6437. Optimum Maschinen - Germany and LDS Industries are not liable for, nor do they guarantee against, damage or operating malfunctions resulting from alteration, abuse, lack of main- tenance or this product’s use for other than its intended purpose. -

Page 26: Spare Parts - Dg20

OPTIMUM M A S C H I N E N - G E R M A N Y Spare parts - DG20 Spare parts 1 of 2 Fig.6-1: DG20 - 1 of 2 DG20 Spare parts - DG20 Original operating instructions Version 1.3.2... -

Page 27: Spare Parts 2 Of 2

OPTIMUM M A S C H I N E N - G E R M A N Y Spare parts 2 of 2 Fig.6-2: DG20 - 2 of 2 Spare parts - DG20 DG20 Version 1.3.2 2015-01-22 Original operating instructions... -

Page 28: Spare Parts List

OPTIMUM M A S C H I N E N - G E R M A N Y 6.2.1 Spare parts list Description Qty. Size Item no. Hexagon head cap screw DIN4762/M8x16 031000201 Washer DIN125/8 031000202 Oil-port 0372038 Washer DIN125/6... - Page 29 OPTIMUM M A S C H I N E N - G E R M A N Y Description Qty. Size Item no. Hexagon head cap screw DIN4762/M4x12 0310002081 Coolant tray 0372039 Washer DIN125/8 0310002083 Hexagon head cap screw DIN4762/M8x20...

-

Page 30: Wiring Diagram

OPTIMUM M A S C H I N E N - G E R M A N Y Wiring diagram Fig.6-3: Wiring diagram DG20 Spare parts - DG20 Original operating instructions Version 1.3.2 2015-01-22... -

Page 31: Spare Parts List Electrical Components

OPTIMUM M A S C H I N E N - G E R M A N Y 6.3.1 Spare parts list electrical components Designation Qty. Size Item no. 1F1/1F2 Fuse 031000201F1 Line filter 03100020LF Control board 031002073 Potentiometer 031002079... -

Page 32: Appendix 7.1 Copyright

OPTIMUM M A S C H I N E N - G E R M A N Y Appendix Copyright This documentation is copyright. All derived rights are also reserved, especially those of trans- lation, re-printing, use of figures, broadcast, reproduction by photo-mechanical or similar means and recording in data processing systems, neither partial nor total. -

Page 33: Limited Warranty

OPTIMUM assumes no obligations or liability on account of any unauthorized recommendations, opinions or advice as to the choice, installation or use of products. -

Page 34: Ec Declaration Of Conformity

OPTIMUM M A S C H I N E N - G E R M A N Y EC Declaration of Conformity Machinery Directive 2006/42/EC Annex II 1.A Optimum Maschinen Germany GmbH The manufacturer / Dr.-Robert-Pfleger-Str. 26 retailer: D - 96103 Hallstadt... - Page 35 OPTIMUM M A S C H I N E N - G E R M A N Y Index Assembly ............15 Classification of hazards ........6 Control and indicating elements ......17 Copyright .............32 Dimensions ............14 EC Declaration of Conformity ......34 Emissions ............13 Environmental conditions ........13...

- Page 36 OPTIMUM M A S C H I N E N - G E R M A N Y DG20 Page 36 Original operating instructions Version 1.3.2 dated 2015-01-22...

Need help?

Do you have a question about the OptiGrind DG 20 and is the answer not in the manual?

Questions and answers