Summary of Contents for Napoleon HDX52NT

- Page 1 WARNING HOT GLASS WILL CAUSE BURNS. DO NOT TOUCH GLASS UNTIL COOLED. NEVER ALLOW CHILDREN TO TOUCH GLASS.

- Page 2 TABLE OF CONTENTS INSTALLATION OVERVIEW...

-

Page 3: Installation Overview

1.0 INSTALLATION OVERVIEW See the section “ VENTING - VENTING LENGTHS AND AIR TERMINAL LOCATIONS” See the section “ FRAMING - MINIMUM MANTEL CLEARANCES” See the section “ FRAMING” See the section See the section “ FRAMING - MINIMUM “ FRAMING - MINIMUM CLEARANCE TO CLEARANCE TO COMBUSTIBLE... - Page 4 2.0 INTRODUCTION WARNING...

-

Page 5: General Instructions

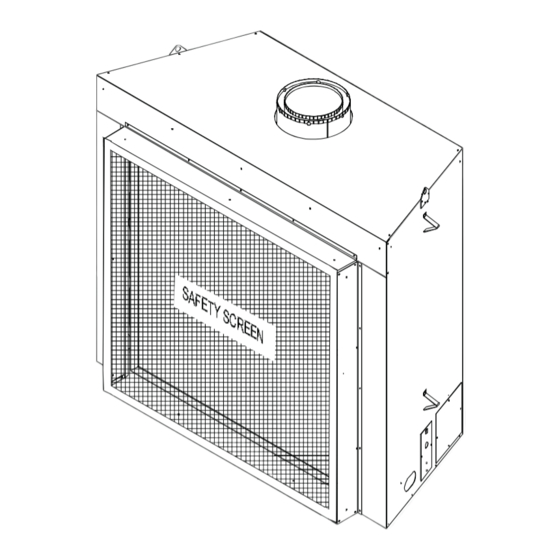

DIMENSIONS SAFETY SCREEN GENERAL INSTRUCTIONS WARNING ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT, WITH THE GLASS DOOR OPENED OR REMOVED. PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE. PROVIDE ADEQUATE VENTILATION. NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE. -

Page 6: General Information

GENERAL INFORMATION... -

Page 7: Rating Plate Information

HDX52 RATING PLATE INFORMATION WARNING THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH LOCAL CODES, IF ANY; IF NONE, FOLLOW THE INSTALLER L’APPAREIL SELON LES CODES D’INSTALLATION ANSI Z223.1 OU CSA-B149 EN VIGUER. CURRENT ANSI Z223.1 OR CSA B149, INSTALLATION CODES. VENTED GAS FIREPLACE. APPROVED FOR FOYER À... -

Page 8: Venting Lengths And Components

3.0 VENTING WARNING RISK OF FIRE, MAINTAIN SPECIFIED AIR SPACE CLEARANCES TO VENT PIPE AND APPLIANCE. IF VENTING IS INCLUDED WITH SPACERS THE VENT SYSTEM MUST BE SUPPORTED EVERY 3FT (0.9m) FOR BOTH VERTICAL AND HORIZONTAL RUNS. USE SUPPORTS OR EQUIVALENT NON-COMBUSTIBLE STRAPPING TO MAINTAIN THE REQUIRED CLEARANCE FROM COMBUSTIBLES. -

Page 9: Typical Vent Installation

TYPICAL VENT INSTALLATION 45.8... -

Page 10: Vent Terminal Clearances

VENT TERMINAL CLEARANCES = 3 feet = 2 x ACTUAL (4.6m) (0.9m) -

Page 11: Vent Application Flow Chart

VENT APPLICATION FLOW CHART TOP EXIT Horizontal Termination Vertical Termination Vertical rise is equal Vertical rise is equal Vertical rise is less Vertical rise is less to or greater than to or greater than than horizontal run than horizontal run the horizontal run the horizontal run Horizontal run +... -

Page 12: Horizontal Termination

HORIZONTAL TERMINATION 40 (12.2) 39 (11.9) REQUIRED 30 (9.1) VERTICAL RISE IN FEET 20 (6.1) (METERS)V 10 (3.1) 12.5 17.5 (0.8) (1.5) (2.3) (3.1) (3.8) (4.6) (5.3) (6.1) HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H 90° 90° 90°... - Page 13 ) > (V See graph to determine the required vertical rise V for the Simple venting configuration (only one 90° elbow) required horizontal run H 150 (3810) (3733.8) REQUIRED VERTICAL RISE 100 (2540) IN INCHES (MILLIMETERS) 57 (1447.8) 50 (1270) 19 1/2 (495.3) 20 (6.1)

-

Page 14: Vertical Termination

VERTICAL TERMINATION ) < (V Simple venting configurations. See graph to determine the required vertical rise V for the required horizontal run H 40 (12.2) 30 (9.1) REQUIRED VERTICAL RISE IN FEET 20 (6.1) (METERS) V 10 (3.1) 3 (0.9) (1.5) (3.1) (4.6) - Page 15 ) > (V Simple venting configurations. See graph to determine the required vertical rise V for the required horizontal run H 20 (6.1) 19 (5.8) REQUIRED VERTICAL RISE IN FEET 10 (3.1) (METERS) V 3 (0.9) (1.5) (3.1) (4.6) (6.1) (7.6) (9.1) HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H...

-

Page 16: Installation

4.0 INSTALLATION WARNING ENSURE TO UNPACK ALL LOOSE MATERIALS FROM INSIDE THE FIREBOX PRIOR TO HOOKING UP THE GAS AND ELECTRICAL SUPPLY. IF YOUR APPLIANCE IS SUPPLIED WITH A REMOTE ENSURE THE REMOTE RECEIVER IS IN THE “ OFF” POSITION PRIOR TO HOOKING UP THE GAS AND ELECTRICAL SUPPLY TO THE APPLIANCE. FOR SAFE AND PROPER OPERATION OF THE APPLIANCE, FOLLOW THE VENTING INSTRUCTIONS EXACTLY. -

Page 17: Horizontal Installation

4.1.1 HORIZONTAL INSTALLATION WARNING THE FIRESTOP ASSEMBLY MUST BE INSTALLED WITH THE VENT SHIELD TO THE TOP. TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE RETURN FLANGE OF THE MOUNTING PLATE. CAULKING FIRESTOP SPACER DETERMINE... -

Page 18: Using Flexible Vent Components

USING FLEXIBLE VENT COMPONENTS WARNING DO NOT ALLOW THE INNER FLEX PIPE TO BUNCH UP ON HORIZONTAL OR VERTICAL RUNS AND ELBOWS. KEEP IT PULLED TIGHT. SPACERS ARE ATTACHED TO THE INNER FLEX PIPE AT PREDETERMINED INTERVALS TO MAINTAIN AN EVEN AIR GAP TO THE OUTER FLEX PIPE. -

Page 19: Vertical Air Terminal Installation

4.2.2 VERTICAL AIR TERMINAL INSTALLATION WARNING MAINTAIN A MINIMUM 2” (51mm) SPACE BETWEEN THE AIR INLET BASE AND THE STORM COLLAR. ROOF SUPPORT INNER PIPE TERMINAL CONNECTOR HIGH TEMPERATURE SEALANT INNER FLEX PIPE OUTER FLEX PIPE 2” (51mm) AIR INLET BASE CAULKING STORM COLLAR... -

Page 20: Appliance Vent Connection

4.2.3 APPLIANCE VENT CONNECTION #8 X 1/2” SELF DRILLING SCREWS 2” (50.8mm) OVERLAP HIGH TEMP SEALANT MOBILE HOME INSTALLATION... -

Page 21: Gas Installation

GAS INSTALLATION WARNING RISK OF FIRE, EXPLOSION OR ASPHYXIATION. ENSURE THERE ARE NO IGNITION SOURCES SUCH AS SPARKS OR OPEN FLAMES. SUPPORT GAS CONTROL WHEN ATTACHING GAS SUPPLY PIPE TO PREVENT DAMAGING GAS LINE. ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT WITH THE GLASS DOOR OPENED OR REMOVED. - Page 22 5.0 FRAMING WARNING RISK OF FIRE! IN ORDER TO AVOID THE POSSIBILITY OF EXPOSED INSULATION OR VAPOUR BARRIER COMING IN CONTACT WITH THE APPLIANCE BODY, IT IS RECOMMENDED THAT THE WALLS OF THE APPLIANCE ENCLOSURE BE “ FINISHED” (IE: DRYWALL / SHEETROCK), AS YOU WOULD FINISH ANY OTHER OUTSIDE WALL OF A HOME.

- Page 23 88" (2235mm) MINIMUM 55 1/4" (1403mm) 57 3/8" (1457mm) 29 3/8" (746mm)*...

-

Page 25: Installing Non-Combustible Board

INSTALLING NON-COMBUSTIBLE BOARD WARNING... -

Page 27: Minimum Clearance To Combustible Enclosures

MINIMUM CLEARANCE TO COMBUSTIBLE ENCLOSURES WARNING NOTE: JOINT COMPOUNDS AND TAPES THAT ARE RESILIENT TO HEAT AND CRACKING SHOULD BE USED WHEN TAPING AND MUDDING SEAMS. SAFETY SCREEN... -

Page 29: Minimum Combustible Mantel Clearances

MINIMUM COMBUSTIBLE MANTEL CLEARANCES WARNING RISK OF FIRE, MAINTAIN ALL SPECIFIED AIR SPACE CLEARANCES TO COMBUSTIBLES. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY CAUSE A FIRE OR CAUSE THE APPLIANCE TO OVERHEAT. ENSURE ALL CLEARANCES (I.E. BACK, SIDE, TOP, VENT, MANTEL, FRONT, ETC.) ARE CLEARLY MAINTAINED. -

Page 30: Screen Door Removal / Installation

6.0 FINISHING WARNING RISK OF FIRE! NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE. THE FRONT OF THE APPLIANCE MUST BE FINISHED WITH ANY NON-COMBUSTIBLE MATERIALS SUCH AS BRICK, MARBLE, GRANITE, ETC., PROVIDED THAT THESE MATERIALS DO NOT GO BELOW THE SPECIFIED DIMENSION AS ILLUSTRATED. DO NOT STRIKE, SLAM OR SCRATCH GLASS. -

Page 31: Latch Door Removal / Installation

LATCH DOOR REMOVAL / INSTALLATION IMPORTANT: Once latches are engaged, test that the door is secure and will not fall forward before letting go. LATCHES... -

Page 32: Glass Door Removal / Installation

GLASS DOOR REMOVAL / INSTALLATION... -

Page 33: Burner Installation

BURNER INSTALLATION NON-COMBUSTIBLE FACING MATERIAL SIDE VIEW TOP VIEW FINISH MATERIAL FINISH FRONT OF MATERIAL APPLIANCE NON-COMBUSTIBLE FACING MATERIAL 3/4” (19mm) NON-COMBUSTIBLE 3/4” (19mm) FACING MATERIAL FRONT OF APPLIANCE WARNING: Non-combustible facing material must not protrude more than 3/4” (19mm) from the top, and/or sides of the appliance. -

Page 34: Electrical Information

7.0 ELECTRICAL INFORMATION WARNING DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER WATER. CALL A QUALIFIED SERVICE TECHNICIAN IMMEDIATELY TO HAVE THE APPLIANCE INSPECTED FOR DAMAGE TO THE ELECTRICAL CIRCUIT. RISK OF ELECTRICAL SHOCK OR EXPLOSION. DO NOT WIRE 110V TO THE VALVE OR TO THE APPLIANCE WALL SWITCH. -

Page 35: Battery Holder Installation

BATTERY HOLDER INSTALLATION... -

Page 36: Wiring Diagram

WIRING DIAGRAM WARNING DO NOT WIRE 110 VOLTS TO THE VALVE OR WALL SWITCH. NIGHT BLOWER LIGHT... -

Page 37: Operation

8.0 OPERATION GENERAL TRANSMITTER LAYOUT Key Lock Low battery alarm Transmission Room Temperature CPI mode Flame ON Night Light Blower INITIALIZING THE TRANSMITTER/BATTERY HOLDER FOR THE FIRST TIME... -

Page 38: Temperature Display

TEMPERATURE DISPLAY FLAME HEIGHT FLAME OFF FLAME AT LEVEL 1 FLAME AT LEVEL 5 FLAME AT “ HI” LEVEL 6 NIGHT LIGHT DIMMER CONTROL... -

Page 39: Continuous Pilot / Intermittent Pilot (Cpi / Ipi) Selection

CONTINUOUS PILOT / INTERMITTENT PILOT (CPI / IPI) SELECTION KEY LOCK LOW BATTERY / MANUAL BYPASS... -

Page 40: For Your Safety Read Before Lighting

9.0 OPERATING INSTRUCTIONS WARNING IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE. ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT WITH THE GLASS DOOR OPENED OR REMOVED. -

Page 41: Restricting Vertical Vents

RESTRICTING VERTICAL VENTS PILOT BURNER ADJUSTMENT PILOT SCREW PILOT ELECTRODE BURNER 3/8” - 1/2” (9.5mm - 12.7mm) FLAME SENSOR FLAME MUST ENVELOP UPPER 3/8” (9.5mm) TO 1/2” (12.7mm) OF FLAME SENSOR Natural Gas Natural Gas Propane Propane Pressure (inches) (millibars) (inches) (millibars) 32.4mb... -

Page 42: Venturi Adjustment

VENTURI ADJUSTMENT This appliance has an air shutter that has been factory set open according to the chart below: VENTURI BURNER Regardless of venturi orientation, closing the air shutter will cause a more yellow flame, but can lead to carboning. Opening the air shutter will cause a more blue flame, but can cause flame lifting from the burner ports. -

Page 43: Annual Maintenance

10.0 MAINTENANCE MAINTENANCE WARNING MAINTENANCE MAINTENANCE TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE. APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED. DO NOT USE ABRASIVE CLEANERS. DO NOT PAINT THE PILOT ASSEMBLY. 10.1 ANNUAL MAINTENANCE WARNING... -

Page 44: Control Access

10.2 CONTROL ACCESS... -

Page 45: Burner Removal

10.3 BURNER REMOVAL 10.4 BRICK PANEL REMOVAL 10.5 PORCELAIN PANEL REMOVAL 10.6 MEDIA TRAY REMOVAL (GLASS ONLY) -

Page 46: Night Light Replacement

10.7 NIGHT LIGHT REPLACEMENT RELIEF DOOR GASKET LENS FRAME RELIEF DOOR GASKET RELIEF DOOR SUPPORT... -

Page 47: Glass / Door Replacement

10.8 GLASS / DOOR REPLACEMENT WARNING DO NOT USE SUBSTITUTE MATERIALS. GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED. CARE MUST BE TAKEN WHEN REMOVING AND DISPOSING OF ANY BROKEN DOOR GLASS OR DAMAGED COMPONENTS. BE SURE TO VACUUM UP ANY BROKEN GLASS FROM INSIDE THE APPLIANCE BEFORE OPERATION. - Page 48 11.0 REPLACEMENTS WARNING FAILURE TO POSITION THE PARTS IN ACCORDANCE WITH THIS MANUAL OR FAILURE TO USE ONLY PARTS SPECIFICALLY APPROVED WITH THIS APPLIANCE MAY RESULT IN PROPERTY DAMAGE OR PERSONAL INJURY.

-

Page 56: Troubleshooting

16.0 TROUBLESHOOTING WARNING ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT, WITH THE GLASS DOOR OPEN OR REMOVED. TURN OFF THE GAS AND ELECTRICAL POWER BEFORE SERVICING THE APPLIANCE. APPLIANCE MAY BE HOT, DO NOT SERVICE UNTIL APPLIANCE HAS COOLED. DO NOT USE ABRASIVE CLEANERS. -

Page 59: Warranty

17.0 WARRANTY NAPOLEON® GAS APPLIANCE PRESIDENT’ S LIFETIME LIMITED WARRANTY CONDITIONS AND LIMITATIONS...

Need help?

Do you have a question about the HDX52NT and is the answer not in the manual?

Questions and answers