Summary of Contents for Olympus DSX510

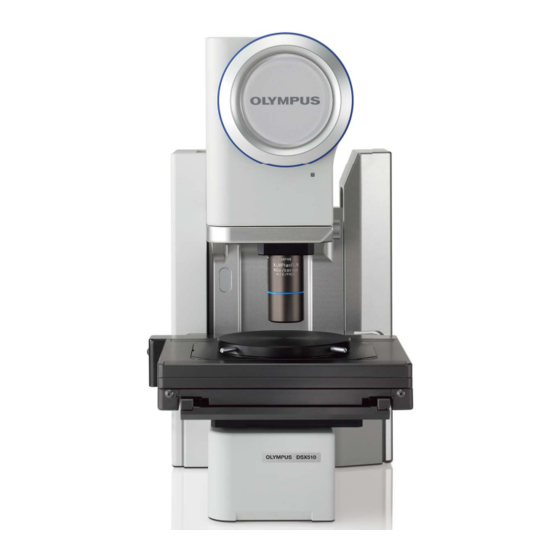

- Page 1 Digital Microscope DSX510/DSX510i Discover Another Dimension D S X 5 1 0 D S X 5 1 0 i...

- Page 2 High-resolution Digital Microscope Olympus introduced the world to a new dimension in industrial microscopy with the DSX Series digital microscope system. Today, with the unique combination of time-tested Olympus optics and today’s newest digital imaging technology, the Olympus DSX Series sets a new standard in industrial microscopes.The Olympus DSX Series digital microscopes allow even...

- Page 3 Measurement, and Sharing — All in One. Effi cient Observation Thanks to higher-quality optics and more advanced digital technology, the DSX510 delivers effi cient observation, intuitive magnifying operation, a variety of observation methods, and reproducibility. Easy Image Capturing Various image capturing methods provide easy, intuitive operation — as simple as using a smartphone or tablet.

- Page 4 The microscope minimizes glare, delivers accurate color reproduction, and eliminates fl are and distortion. Every sample is reproduced with such accuracy that it’s simply stunning, and stunningly simple. Take a closer look at the DSX510, and see what other digital microscopes cannot.

- Page 5 With lenses that have higher NA and lower aberration than current digital microscopes, plus improved evenness of light With the advanced LED illumination of DSX510, color does not intensity, the DSX510 series of digital microscopes offer high change with the LED’s intensity, minimizing the need for white resolution equal to the very best light microscopes.

- Page 6 Optical Zoom: Get Closer to the Sample Nosepiece Change the magnifi cation to fi t requirements — the DSX510 offers Two lenses can be mounted at once for an even greater optical zoom of up to 13X and digital zoom of up to 30X.

- Page 7 A Variety of Observation Methods, Freely Usable Quickly and Easily Acquire the Images Required for Observation Ideal for any industrial microscopic observation method, the DSX510 offers a variety of observation modes that deliver the high- resolution images users expect from high-end optics.

- Page 8 (HDR) Required the LCD pattern (Normal) The color enhancement feature of DSX510 allows color to be placed where it is needed while leaving the rest of the image in black-and-white, making it much easier to locate defects. Ideal for focusing on one particular defect.

- Page 9 The mechanisms of DSX510 fully digitalized so that every image taken or saved has the conditions it was taken under recorded with the image. If an image is captured with the DSX510, the operator can retrieve the conditions of capture from the image data with one click, enabling additional observations under the same conditions and settings.

- Page 10 Low Center of Gravity, Sturdy Frame A low center of gravity, sturdy frame, and low underslung body provide the DSX510 with high stability at high magnifi cation. An anti- vibration function signifi cantly reduces any vibration that might affect inspection or measurement.

- Page 11 Operation Modes to Match the Observation Objective or Operator Experience Three User Modes Meet Operator Experience Levels and Job Demands Select Tutorial, Operator or Advanced mode to best match the experience of the operator and the job at hand. Operator mode can be customized to speed up routine work.

- Page 12 fi t precisely suit the requirements. In the past, only experts with years of experience could adjust microscopes in a way that allowed the capture of optimal images. Today, the DSX510 enables any operator to do so with an easy-use interface and advance image capture technology — in a few simple steps, the ideal image for inspection or analysis is attained.

- Page 13 EFI: View Uneven Samples in Focus Across the Entire Image With its EFI (Extended Focal Image) capability, the DSX510 can obtain a clear, in-focus image of an entire sample with one click — no matter how uneven the surface. During EFI, several images are taken while the point of focus is moved up and down. From these images, the areas where the sample was in focus are combined into one image where the whole sample is in focus, allowing precise inspection of uneven surfaces.

- Page 14 Live Panorama Capturing Covers Large Areas Fast Live Panorama There is no longer such a problem as “outside the fi eld of view.” With Live panorama, simply move the observation position on the screen, and the motorized stage will move the sample to that position. As the stage moves, the system automatically stitches images into a large single fi...

- Page 15 Automatic Stitching Gives High-Quality, High Value-Added Image High Quality Panorama Set the number of images, the length, and the starting point, then start the image stitching process. This executes pattern matching and corrects shading, resulting in a high-quality and high value- added image.

- Page 16 Large Amounts of Data Automatically Captured Programmed Recipes: Automatically Capture Independent Points Through a convenient programmed recipe function, the DSX510 can automatically capture images of several registered points with autofocus. Motorized stage with 100 mm × 100 mm stroke Stage coordinates...

- Page 17 Convenient Functions Support Image Capturing Annotation After capturing an image, annotations of important information and graphics can be saved with it. As position and explanation of defects can be saved and shown, this feature is excellent for sharing data with other people concerned. Automatic Save Function Video Capturing Any image captured can be automatically saved to the folder...

- Page 18 Unmatched Performance. Olympus’s unwavering commitment to accurate measurement is evident in every aspect of the DSX510, from telecentric optics to a stabilized frame design to auto-calibration that eliminates user error. Delivering reproducible measurement, traceable accuracy, and guaranteed Z measurement repeatability, the DSX510 cannot be matched by any conventional digital microscope.

- Page 19 Lower point of focus DSX510/DSX510i DSX510 Automatic Magnifi cation Recognition To issue certifi cates, calibration work must be undertaken by Olympus’s dedicated • service staff To reduce human error, DSX offers automatic magnifi cation *Differs according to national and regional statutes recognition, with a motorized zoom system so the system always knows which lens is being used.

- Page 20 The Features Required to Ensure Optimal Measurement Results All fundamental industrial microscope measurement capabilities are standard features of DSX510 software, making it easy to obtain optimal measurement results. Optional software is available for 3D measurement, caliper measurement, and particle analysis.

- Page 21 OLYMPUS Stream image analysis software. With one click, Stream can access all DSX510 fi le data, including basic calibration data, and deliver a diverse, fl exible workfl ow that moves from measurement to...

- Page 22 Easy Sharing Custom Reports. Easy to Create. With the DSX510, in one simple click the report function is in motion, recording images and measurements and turning them into detailed custom reports. Perform the observation or measurement — the system automatically generates the reports required. The DSX510 also allows easy sharing of these reports, with the option to export to a variety of convenient formats (rtf, PDF, Excel).

- Page 23 Build Reports from the Offi ce Designates Printing Magnifi cation from OLYMPUS Stream The DSX510 also offers free offl ine software which allows performing of measurements and building reports at the offi ce. Measurement results can be easily transferred to optional OLYMPUS Stream image analysis software, which offers advanced editable reporting.

- Page 24 Applications D S X 5 1 0 Upright High-resolution Digital Microscope Electrode pad Blade Diced surface of IC chip Punch mark MEMS Fractured metal surface Hair Horny cell layer...

- Page 25 D S X 5 1 0 i Inverted High-resolution Digital Microscope Ferrite Ferrite Martensite (Martensite) Carburized structure Cast iron Nodular graphite cast iron Cross section of bump Multilayer board Glass fi ber...

- Page 26 DSX510/DSX510i System diagram Basic Component DSX-HRSU DSX-CB DSX-CTRL-E DSX-TLCD Control box for DSX system Controller English OS 23” touch panel display High resolution zoom head DSX-BSW Software License Option DSX-ASW-3D DSX-ASW-PAM Software 3D measuring software Particle analysis DSX-ASW-EDM DSX-ASW-SHDR Edge detecting measurement...

- Page 27 100-120 V/220-240 V, 300 V A, 50/60 Hz *1 Cannot be used with the embedded standard LED. *2 Calibration by Olympus or dealer specialists necessary. *3 When the objective lens MPLFLN50XBDP or MPLAPON50X is attached, the stroke is 25 x 25 mm.

- Page 28 Shinjuku Monolith, 2-3-1 Nishi-Shinjuku, Shinjuku-ku, Tokyo 163-0914, Japan 10F, K. Wah Centre, 1010 Huai Hai Road (M), Xuhui District, Shanghai, 200031 P.R.C. 8F Olympus Tower, 446 Bongeunsa-ro, Gangnam-gu, Seoul, 135-509 Korea 48 Woerd Avenue, Waltham, MA 02453, U.S.A. 491B River Valley Road, #12-01/04 Valley Point Office Tower, Singapore 248373...

Need help?

Do you have a question about the DSX510 and is the answer not in the manual?

Questions and answers