Summary of Contents for Omega Engineering OS550 Series

- Page 1 User’ s Guide MADE IN Shop online at omega.com e-mail: info@omega.com For latest product manuals: omegamanual.info OS550/OS550-BB Series Industrial Infrared Thermometer/Transmitter...

- Page 2 OMEGAnet ® omega.com U.S.A.: One Omega Drive, Box 4047 ISO 9001 Certified Stamford, CT 06907-0047 Tel: (203) 359-1660 FAX: (203) 359-7700 e-mail: info@omega.com Canada: 976 Bergar Laval (Quebec) H7L 5A1, Canada Tel: (514) 856-6928 FAX: (514) 856-6886 e-mail: info@omega.ca For immediate technical or application assistance: U.S.A.

-

Page 3: Unpacking Instructions

Remove the Packing List and verify that you have received all equipment, including the following (quantities in parentheses): OS550 or OS550-BB Series Infrared Thermometer with Sensor Head (1) RS-232 Cable with connector/adapter (OS552, OS553, OS554) only (1) CD Software ( OS552, OS553, OS554) only (1) User’s Guide (1) - Page 4 OS550 Series Industrial Infrared Thermometer This page is intentionally blank...

-

Page 5: Table Of Contents

Introduction ... 1-1 Thermometer Features ... 1-2 1.2.1 Display Details... 1-3 1.2.2 Parts of the Thermometer ... 1-4 Chapter 2 Installing the Handheld Infrared Thermometer ... 2-1 Installation ... 2-1 2.1.1 Sensor Head Installation ... 2-1 2.1.2 Display Electronics Installation ... 2-1 2.1.3... - Page 6 Warnings and Cautions ... 4-1 Description ... 4-2 Operating the Laser ... 4-3 4.3.1 Installing the Laser Sight onto the Thermometer... 4-3 4.3.2 Powering the Laser Sight Accessory ... 4-3 Chapter 5 Maintenance ... 5-1 Cleaning the Lens ... 5-1 Calibrating the Thermometer ...

-

Page 7: Chapter 1 General Description

1.1 Introduction The OS550 Series Industrial Infrared (IR) Thermometers provide non-contact temperature measurement up to 2500°F (1371°C). They offer effective solutions for many non-contact temperature applications, including the following: • Predictive Maintenance: Tracking temperature shifts which indicate pending failure in solenoid valves. -

Page 8: Thermometer Features

• Parameters, such as target material emissivity and alarm setpoints, can be set and remain in memory until reset. This instrument has a rugged and functional design, including: • Sealed keypad display. Table 1-1. OS550 Series Industrial Infrared Thermometer Features Features Accuracy* Range... -

Page 9: Display Details

1.2.1 Display Details ➀ Display Mode displays one of the following: E (Emissivity) MAX (Maximum Temperature) LAL (Low Alarm Setpoint - only on OS552/OS553/OS554) MIN (Minimum Temperature) OS552/OS553/OS554) dIF (Differential Temperature) AVG (Average Temperature) ➁ Data associated with one of the Display Modes ➂... -

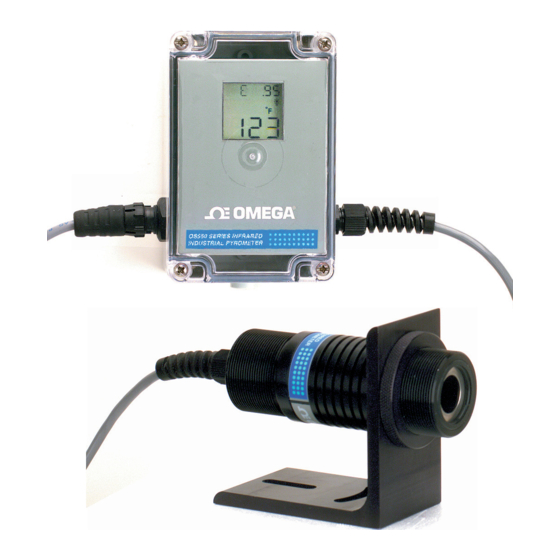

Page 10: Parts Of The Thermometer

Output Electronics (OS550 Series) OS550/OS550-BB Series Industrial Infrared Thermometer Front View The display is shown in more detail in Figure 1-1 and described in Table 1-2. Note: There are no user-serviceable parts in the thermometer. OEM Style Keypad, Display, and Electronics... -

Page 11: Installation

See Chapter 3.1. 2.1.2 OS550 Series Display NEMA Housing Installation The OS550 Series’ main display and electronic’s housing is environmentally sealed and weather tight. Mounting ears are provided making mounting easy. Mount the main electronics assembly in a location that you can easily access to view the LCD and make program changes to the unit. -

Page 12: Sensor Head Dimensions

Installing the Infrared Thermometer 2.2 Sensor Head Dimensions Fig. 2-1. Sensor Head Dimensions ⁄ x 20 THREAD ⁄ x 20 THREAD... -

Page 13: Display Electronics Dimensions

Installing the Infrared Thermometer 2.3 OS550 Display Electronics Dimensions 131.3 (5.17) TYP. Ø 4.37 (0.172) MOUNTING HOLE (4 PLACES) 50.0 (1.97) TYP. Fig. 2-2. Main Display NEMA Housing with Mounting Brackets Dimensions... -

Page 14: Display Mounting Dimensions

Installing the Infrared Thermometer 2.4 OS550-BB Series Display Mounting Dimensions 31.0 (1.22) Fig. 2-3. OEM Style Main Display with Mounting Plate Ø 5.16 (0.203) THRU TYP. (4 PLACES) WILL FIT UP TO A #10 SCREW OR BOLT 26.4 57.4 (1.04) (2.26) -

Page 15: Mounting Bracket Dimensions

2.5 Mounting Bracket Dimensions (OS550-MB) 50.8 (2.00) 57.2 (2.25) TYP. 2 PLACES 25.4 (1.00) 2.6 Mounting Nut Dimensions (OS550-MN) Installing the Infrared Thermometer 88.9 (3.50) 38.61 Ø (1.520) 3.18 R (.125) 22.23 (.875) 28.58 25.4 (1.125) (1.00) Fig. 2-4 .020 x 45... -

Page 16: Mounting Flange Dimensions

Installing the Infrared Thermometer 2.7 Mounting Flange Dimensions (OS550-MF) TYP. 3 PLACES 2.8 Air Purge Collar Dimensions (OS550-AP) 51 (2.0) DIA. Ø 89 (3.5) 3 HOLES ON Ø 71.1 (2.80) BOLT CIRCLE 6.35 (.250) THRU TYP. (3 PLACES) 38 (1.5) - 20 THREAD Fig. -

Page 17: Chapter 3 Using The Infrared Thermometer

Using the Infrared Thermometer 3.1 Using the Infrared Thermometer 3.1.1 Water Cool Jacket Accessory When using the OS550 sensor head in an ambient temperature environment above 50°C (122°F), the OS550-WC Water Cooling Jacket option must be used to maintain the accuracy and response time of the unit. Two ⁄... -

Page 18: How To Power The Thermometer

3.2 How To Power the Thermometer 3.2.1 OS550 Series Cable Connection The OS550 Series thermometer comes with a built-in 4.5 m (15') power/output cable. Power and output connections are made to the cable via stripped wire ends located at one end of the cable. The power/output cable can be shortened or extended in the field if needed. -

Page 19: Operating The Thermometer

“SLEEP” position. Place the switch in the “ON” position to turn your unit on and begin to make measurements. OS550 SERIES KEYPAD PARTIAL VIEW 2. The optical field of view of the thermometers sensor head should fall within the area of the target being measured. -

Page 20: Field Of View Charts

3.3.1 Field of View Charts DISTANCE: SENSOR TO OBJECT (FT) .35" @ 24" 9mm @ 610 mm *SPOT DIAMETER MEASURED AT 90% ENERGY DISTANCE: SENSOR TO OBJECT (M) Figure 3-3. OS550 Series (-1 FOV) Figure 3-4. OS550 Series (-2 FOV) D:S = 68:1... - Page 21 1.0" @ 0" to 20" 1.8" 1.0" 1.2" 1.0" 2.5cm @ 51cm *SPOT DIAMETER MEASURED AT 90% ENERGY DISTANCE: SENSOR TO OBJECT (CM) Figure 3-5. OS550 Series (-3 FOV) Figure 3-6. OS550 Series (-4 FOV) 4.2" 3.6" 3.0" 2.4" D:S = 20:1 10.0 4.8"...

- Page 22 AT 90% ENERGY 3" 0.9" .45" 11.5 *SPOT DIAMETER MEASURED DISTANCE: SENSOR TO OBJECT (FT) DISTANCE: SENSOR TO OBJECT (M) Fig. 3-7. OS550 Series- (-5FOV) DISTANCE: SENSOR LENS TO OBJECT (in.) 6" 9" .39" .15" T 90% ENERGY 15.2 22.9 DISTANCE: SENSOR LENS TO OBJECT (cm.)

-

Page 23: Measurement Techniques

3.4 Measurement Techniques You can use the IR Thermometer to collect temperature data in any one of five different ways: • Spot Measurement — Measures the temperature of discrete objects such as motor bearings, engine exhaust manifolds, etc.: Aim the sensor head at the desired target. - Page 24 To record the temperature profile of the moving surface, connect the IR thermometer to a strip chart recorder or Data logger. • Fixed Point Monitoring Over Time - Monitors the temperature...

-

Page 25: Real Time Mode (Active Operation)

Using the Infrared Thermometer 3.4.1 Real Time Mode (Active Operation) Definition: Real Time Mode is the active operational mode of the thermometer. In this mode, the thermometer constantly measures and displays temperature. Power Applied, Sleep/On Switch in the On Position... - Page 26 Using the Infrared Thermometer/Transmitter Table 3-1. Functional Flow Chart when the Unit is On (Real Time Mode) OS520E & OS520 OS551 OS521 OS552 OS522 OS553, OS554 3-10...

- Page 27 Using the Infrared Thermometer/Transmitter MODE DISPLAY °F ☞ °F ☞ °F ☞ °F ☞ °F ☞ °F ☞ Model OS551 (Model OS520 & OS520E) Figure 3-9 Visual Function Flow Chart While in these 4 modes: key to change temperature from °F to °C or vice versa.

-

Page 28: Adjusting Emissivity

Refer to Appendices B and C for information on emissivity before making your adjustment. °F 1. When the thermometer is powered up, the default emissivity setting will be set to 0.95. 2. If necessary, press the emissivity or press the emissivity. -

Page 29: Calculating Temperature Values

°F To clear the “AVG ---” display, turn off the thermometer. When the thermometer goes from the sleep mode to the real-time mode, the MAX, MIN, dIF and AVG temperatures are updated. 3.5.3 Changing the Temperature from °F to °C (or vice versa) -

Page 30: Using The Alarm Functions

Using the Infrared Thermometer/Transmitter 3.5.5 Using the Alarm Functions The thermometer provides audible and visible alarm indications. • To set the high alarm value: °F If you are not in High Alarm Display Mode (HAL) when the high alarm goes off, you must press the get into the High Alarm Display Mode. - Page 31 Low Alarm Display Mode. Then press The unit maintains its low alarm set point value even when the power is removed. Using the Infrared Thermometer/Transmitter key until the Low Alarm Display key to increment the low alarm value. Press key to decrement the low alarm value.

-

Page 32: Using Ambient Target Temperature Compensation

With power applied to the unit, set the emissivity to 1.0 Press and hold the Mode (AVG) appears. Slowly move the thermometer so that the line of sight sweeps across the area surrounding the target. The thermometer measures the temperature at each point on the surrounding area. -

Page 33: Sending Temperature Data To A Serial Printer

3.5.7 Sending Temperature Data to a Serial Printer (OS552, OS553, OS554) The thermometer can transmit temperature data to a Serial Printer via the RS-232 phone jack and the RS-232 cable. 1. Turn on the Serial Printer and set the following parameters: °F... - Page 34 Using the Infrared Thermometer/Transmitter °F With power applied to the unit, press and hold the until the Print Data Display Mode (PRN) appears. Press the Press the interval (from 1 to 1999 seconds) is the time between data points. The default value is 2 seconds.

-

Page 35: Sending Temperature Data To A Personal Computer

Personal Computer via the RS-232 phone jack and the RS-232 cable. 1. Turn on the Computer. 2. Connect the RS-232 cable between the thermometer and the serial port (RS-232 of the Personal Computer as shown below in Figure 3-11). 3. With power applied to the OS550, press the °F... - Page 36 3. Click on Free Software. Then Click on the Software icon. 4. Now you will see a menu of Free software download for different products. 5. Click on the Infrared Thermometer picture icon. This will start the installation process. 6. Follow the installation instructions as they appear on your screen.

- Page 37 PC can cause damage to communications ports, or other electronic circuitry in your device or computer. 1. With the thermometer device powered down, connect the enclosed serial communications cable to the device. 2. Connect the other end of the serial cable to the desired communications port of the personal computer.

- Page 38 Using the Infrared Thermometer/Transmitter waiting for the thermometer to transmit data through your RS-232 port. 4. Begin transmitting data from the thermometer by pressing and holding the until the Print Data Display Mode (PRN) appears. 5. Press the “UP” key to increment the printing interval.

-

Page 39: Storing The Temperature Data On Command

3.5.9 Storing the Temperature Data on Command (OS553, OS554) The thermometer can store up to 100 temperature data points on command. Each set of temperature data is broken °F down into the temperature value, emissivity, and high alarm setpoint for that temperature. This data is stored in non-volatile memory, so power loss will not affect this data. -

Page 40: Erasing The Temperature From Memory

The display freezes momentarily, and a beep sounds for about 1 second. Now the memory is cleared. The thermometer reverts to real time mode. Erasing the temperature data does not erase or reset your pre-set Emissivity, High and Low Alarm setpoints, printing interval, and Ambient Target Temperature compensation. -

Page 41: Recall Mode (Passive Operation)

3.6 Recall Mode (Passive Operation) Definition: Recall Mode is the passive operational mode of the thermometer. In this mode, you may review the most recently stored temperature data and parameters. Real Time (Table 3-1) Mode (Active) Figure 3-14. General Operational Block Diagram... - Page 42 Using the Infrared Thermometer/Transmitter Table 3-2. Functional Flow Chart (Recall Mode) OS551 OS520 & OS520E OS552 OS521 OS522 OS553, OS554 3-26...

-

Page 43: Reviewing The Last Parameters

3.6.1 Reviewing the Last Parameters The thermometer stores the last temperature measured in the real time mode (refer to Table 3-1). This temperature °F can be recalled by pressing the 1. With power applied to the unit, place the SLEEP/ON switch to the SLEEP position. - Page 44 3-28 To download stored temperature data points from the thermometer, first make certain that it is not in printing mode. Make sure that the IR_TEMPSOFT is installed properly as explained in previous section. On the main menu bar, click on “Command-> Download Stored Data”.

-

Page 45: Reviewing Previously Stored Temperature Data

“----” . To review other stored temperatures, repeat Steps 3 and 4. If no keys are pressed, the thermometer goes back into sleep mode in approximately 10 second Using the Infrared Thermometer/Transmitter key until you see the Memory key to increment the memory location or key to decrement the memory location. - Page 46 Using the Infrared Thermometer/Transmitter Notes 3-30...

-

Page 47: Chapter 4 Laser Sight Accessory

4.1 Warnings and Cautions When using the laser sight accessory OS550-LS, you may receive harmful laser radiation exposure if you do not adhere to the warnings listed below: • USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HERE MAY RESULT IN HAZARDOUS RADIATION EXPOSURE. -

Page 48: Description

To solve this problem, we offer a laser sighting accessory OS550-LS that will install onto the front of the OS550 series sensor head. This compact tool provides the installer with a true line of sight laser dot up to a distance of 12.2 meters (40') in the center of the IR optical path taking the guess work out of proper alignment during the installation. -

Page 49: Operating The Laser

4.3 Operating the Laser Sight 4.3.1 Installing the Laser Sight onto the Thermometer The laser sight accessory (OS550-LS) screws onto the front of the sensor head. Do not over tighten the laser sight accessory onto the sensor head. This accessory is only used during sensor head installation and then removed. - Page 50 Laser Sight Accessory Notes...

-

Page 51: Chapter 5 Maintenance

Do not wipe the surface dry, as this may cause scratching. 5.2 Calibrating the Thermometer The thermometer can not be calibrated by the user. For precise calibration of the thermometer, call our Customer Service Department. It is recommended that the Infrared Thermometer be sent to the factory once a year for recalibration. - Page 52 Maintenance Notes...

-

Page 53: Chapter 6 Troubleshooting Guide

THERMOMETER Problem The thermometer does not turn on (No Display) The thermometer is showing an incorrect temperature The thermometer is “locked up” (the display is “frozen”). Troubleshooting Guide Solution Check for proper power connections, see Section 3.2 Contact our Customer Service Department, unit requires service. - Page 54 You can expect to see and hear the following: • • • • • Clean the thermometer lens. Refer to Section 5.1. Activate the Diagnostic Program in the thermometer as follows: Press the Hold down the displayed. You will see the version number “VER X.X” of the software for about 1 second.

- Page 55 (ambient temperature) to a temperature 10°C colder or warmer. Troubleshooting Guide Solution The thermometer has to stabilize before taking temperature measurements. It takes up to 40 minutes for the thermometer to stabilize. The thermometer has to stabilize before taking temperature measurements.

- Page 56 Troubleshooting Guide Notes...

-

Page 57: Chapter 7 Specifications

(Specifications are for all models except where noted) THERMOMETER Measuring Temperature Range: Accuracy @ 24°C or 75°F Ambient Temperature and at emissivity of 0.95 or greater: Distance to Spot Size Ratio: Display Repeatability: Display Resolution: Display Response Time: Spectral Response:... - Page 58 Specifications Emissivity: Calculated Temperature Values: Ambient Target Temperature Compensation: RS-232 Output (for personal computers and serial printers): RS-232 Cable: Power/Analog Output Cable: Sensor Head Cable Alarm: Data Storage: Dimensions: Main Electronics: Sensor Head: Weight: Main Electronics: Sensor Head: 0.10 to 1.00 in 0.01 increments, set via keypad Maximum (MAX), Minimum (MIN), Average (AVG), Differential (dIF)

- Page 59 1 mV/degree C or F Analog Output: Accuracy: 0-5 Vdc Analog Output: Accuracy: Scaling: Minimum Load: 4-20 mA Analog Output: Accuracy: Scaling: Maximum Load: ± 2 mV referenced to the temperature display ± 0.25% of full scale (Referenced to display reading) Fixed (scaled to match full temperature range of model selected) 600 ohms...

- Page 60 Specifications LASER SIGHT ACCESSORY (OS550-LS) Wavelength (Color): Operating Distance: Laser Dot Max. Output Optical Power: European Classification: Maximum Operating Current: FDA Classification: Beam Diameter: Beam Divergence: Operating Temperature: Operating Relative Humidity: Power Switch: Power Indicator: Power: Identification Label: Warning & Certification Label: 630-670 nanometers (red) 152 mm to 12 m (6"...

-

Page 61: Chapter 8 Glossary Of Key Strokes

Key(s) Press and hold down the key & then press the keys pressed in rapid sequence Glossary of Key Strokes Key(s) Functions • Selects one of the following Display Modes: E , MAX, MIN, dIF, AVG, HAL, LAL, AMB, PRN, or MEM. •... - Page 62 Glossary of Key Strokes Notes...

-

Page 63: Appendix A How Infrared Thermometry Works

Figure A-1 shows a block diagram of an infrared radiation thermometer. Energy from the object is focused by the lens onto the detector. As the detector heats up, it sends out an electrical signal, which in turn is amplified and sent to the circuitry of the thermometer. - Page 64 Appendix: How Infrared Thermometry Works Blackbody When thermal radiation falls on an object, part of the energy is transmitted through the object, part is reflected and part is absorbed. A blackbody is defined as an ideal object that absorbs all the radiation incident upon it.

- Page 65 T = temperature of object in Kelvin = temperature of ambient surroundings in Kelvin The infrared thermometer uses this equation directly in calculating the temperature of an object. The incident power is measured by the infrared detector. The emissivity of the object is determined by the user.

- Page 66 FOV, within which they see all objects. In particular, the thermometer will measure a fixed proportion of the energy radiated by all objects within its FOV. The user must guarantee that the distance between the thermometer and the object is defined so that only that object fills the FOV of the instrument.

-

Page 67: Appendix B Emissivity Values

Table B-1 provides guidelines for estimating the emissivity of various common materials. Actual emissivity, especially of metals, can vary greatly depending upon surface finish, oxidation, or the presence of contaminants. Also, emissivity or infrared radiation for some materials varies with wavelength and temperature. To determine the exact emissivities for most applications, follow the procedures in Appendix C. - Page 68 Appendix: Emissivity Values Material Emissivity (ε) Asbestos Board ......... . 0.96 Asphalt, tar, pitch .

-

Page 69: Appendix C Determining An Unknown Emissivity

Heat the object (or at least a sample of the object material) on top of a heating plate to a known temperature. Make sure the thermometer and the air surrounding the heating plate are at the same temperature. Measure the temperature of the object material with the thermometer. - Page 70 FOV of the thermometer. Area “A” Target Aim the thermometer at Area “B” as shown in Figure C-1 Make sure that Area “B” is as close as possible to Area “A”. Adjust the emissivity of the thermometer until the temperature reading equals the temperature found in Step 3.

- Page 71 C-1. Make sure that the painted area of object material fills the FOV of the thermometer. Aim the thermometer at another spot on the target - Area “B” in Figure C-1. Adjust the emissivity of the thermometer until the temperature reading equals the temperature found in Step 2.

-

Page 72: Addendum

• Power must be disconnected before making any electrical connections. • The power supply used to power the thermometer should be VDE or UL approved with the following ratings: Power: 7-24 Vdc @ 80 mA. Overload Protection: Current limited to 500 mA. - Page 73 - - - - - - - - - - - - - - - TYPICAL INSTALLATION SCHEMATIC - - - - - - - - - - - - - - - SENSOR HEAD OS550 ADDENDUM TO OS550/OS550-BB MANUAL 1 +PWR (RED) 2 -PWR (BLACK) 3 +O/P (WHITE)

-

Page 74: Index

Index Air Purge Collar ... 2-6 Alarms ... 3-14, 3-15 Ambient Target Temperature Compensation ... 3-16 Backlighting Icon ... 1-3 Blackbody ... A-2, C-3 Computer: Parameters: Speed, Data, Parity, Stop Bit ... 3-17 Personal, Hookup ... 3-19 Program (IRP.EXE) ... 3-20 Communications Program (IRP.EXE) ... - Page 75 Key Strokes ... 8-1 Label Layout: Danger & Certification ..Inside Back Cover Laser Sight Installing onto Thermometer ... 4-3 Line of Sight ... 4-2 Power ..4-3 Power Indicator LED ... 4-2 Warnings and Cautions ... 4-1 LCD, Backlighting ... 3-12 Lens Cleaning ...

- Page 76 OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 25 months from date of purchase on the base unit and 13 months from date of purchase on Laser Sight Module. OMEGA WARRANTY adds an additional one (1) month grace period to the normal product warranty to cover handling and shipping time.

-

Page 77: Data Acquisition

Where Do I Find Everything I Need for Process Measurement and Control? OMEGA…Of Course! Shop online at omega.com TEMPERATURE Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies Wire: Thermocouple, RTD & Thermistor Calibrators & Ice Point References Recorders, Controllers & Process Monitors Infrared Pyrometers PRESSURE, STRAIN AND FORCE Transducers &...

Need help?

Do you have a question about the OS550 Series and is the answer not in the manual?

Questions and answers