Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Subaru EH72D

- Page 1 EH72D LPG / NATURAL GAS Fueled Engine 2ZZ9020143 北米...

-

Page 2: Air Index

Protection Agency) and CARB (California Air Resources Board) emission regulations in the U.S.A. Notice : To the engines/generators exported to and used in the countries other than the U.S.A., warranty service shall be performed by the distributor in each country in accordance with the standard Subaru engine/generator warranty policy as applicable. -

Page 3: Federal Emissions Component Defect Warranty

FEDERAL EMISSIONS COMPONENT DEFECT WARRANTY EMISSIONS COMPONENT DEFECT WARRANTY COVERAGE This emission warranty is applicable in all States, except the state of California. Fuji Heavy industries Ltd. and Robin America, Inc., Lake Zurich, Illinois, (herin “ROBIN AMERICA”) warrant(s) to the initial retail purchaser and each subsequent owner, that this Nonroad engine (herein “engine”) has been designed, and equipped to conform at the time of initial sale to all applicable regulations of the U.S. - Page 4 Please fi ll in the following blanks after checking the specifi cation number on your engine. SPEC NO. SERIAL NO. For your nearest SUBARU distributor (and/or dealer), you are able to check at our SUBARU website of the following URL; http://www.subarupower.com...

-

Page 5: Table Of Contents

CONTENTS SAFETY PRECAUTIONS ........................... 1 COMPONENTS ............................4 PRE-OPERATION CHECKS ........................5 BATTERY INSTALLATION ......................... 7 OPERATING YOUR ENGINE ........................9 EASY TROUBLESHOOTING ........................10 MAINTENANCE SCHEDULE ........................12 “HOW-TO” MAINTENANCE ........................14 PREPARATIONS FOR STORAGE ......................17 SPECIFICATIONS ............................. 18... - Page 6 SYMBOLS Read the owner’s manual Stay clear of the hot surface Exhaust gas is poisonous. Do not operate in an unventilated area. Stop the engine before refueling Fire, open fl ame and smoking prohibited Fire Explosion Explosive Pressure Plus ; On (Run) positive polarity Off (Stop)

-

Page 7: Safety Precautions

SAFETY PRECAUTIONS ▲ The safety alert symbol ( ) is used with a signal ▲ WARNING word (DANGER, CAUTION, WARNING), a pictorial and/or a safety message to alert you to hazards. DANGER indicates a hazard which, if not avoided, Propane and Natural Gas are extremely fl... - Page 8 SAFETY PRECAUTIONS Please make sure you review each precaution carefully. EXHAUST PRECAUTIONS • Never inhale gas. It contains carbon monoxide, a colorless, orderless and extremely dangerous gas which can cause unconsciousness or death. • Never operate the engine indoors or in a poorly ventilated area, such as tunnel, cave, etc.

- Page 9 PROTECTIVE COVER Place the protective covers over the • rotating parts. If rotating parts such as the drive shaft, pulley, belt, etc. are left exposed, they are potentially hazardous. To prevent injury, equip them with protective covers or shrouds. • Be careful of hot parts. The muffl...

- Page 10 • Disconnect the LP/NG fuel line before transporting the engine. • Do not move the engine while in operation when it has been removed from the equipment. • Keep the unit dry (do not operate it in rainy conditions). PRE-OPERATION CHECKS •...

-

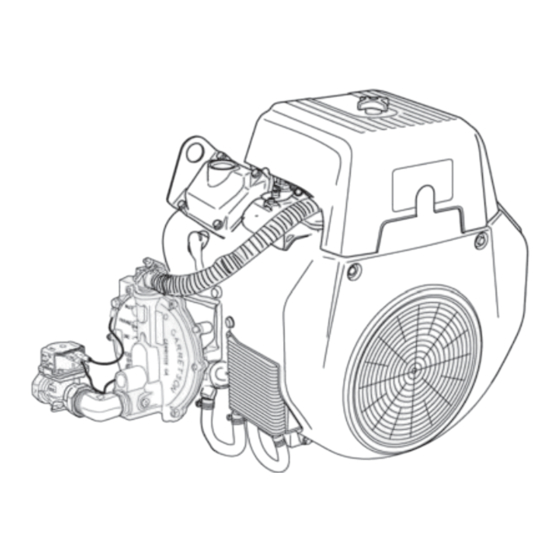

Page 11: Components

COMPONENTS Hook Air cleaner cover Regulator Blower housing Oil Cooler Mixer Oil fi ller cap Spark plug cap Governor lever Voltage regulator Oil fi lter Oil gauge PTO shaft Electric starter Oil drain plug (on both sides) REMARKS: • Fuel tank, valve, (sediment bowl type is recommended), fuel hoses, and fuel fi lter are required for connecting fuel source to this engine. -

Page 12: Pre-Operation Checks

PRE-OPERATION CHECKS ENGINE OIL (CHECK DAILY) Before checking or refi lling engine oil, be sure the engine is not running and is located on a stable, level surface. • If the oil level is below the lower level line on the oil gauge, refi ll with the proper oil (see table) to the upper level. -

Page 13: Fuel Recommendations

GASEOUS FUEL ▲ WARNING Do not refuel while smoking, near an open fl ame or other potential hazards. Fuel Recommendations Propane content of 95% of higher NATURAL GAS Methane content of 90% or equivalent INSTRUCTIONS FOR CONVERTING TO NATURAL GAS OPERATION The engine is optimized for LP operation from the factory. - Page 14 VAPOR WITHDRAWL With a vapor withdrawal system, the LP fuel is vaporized in the fuel tank by heat input from the ambient temperature. The pressure is reduced to about 11” water column (0.4psi) on the outlet side of the primary regulator. The vaporized fuel is then brought to the engine and demand regu- lator on the engine reduces the pressure even further before it engine the carburetor (mixer).

-

Page 15: Battery Installation

BATTERY INSTALLATION For electric starter operation, proper electric wiring arrangements are needed before normal engine operation. PARTS NEEDED • Use a battery rated 12V-36AH or larger. • Use a proper cable and ground wire to connect battery and key switch and electric starter. -

Page 16: Wiring Diagram

WIRING • Connect positive terminal of electric starter and positive terminal of the battery with battery cable. • Ground negative terminal of the battery to the body of engine or machine with ground wire. Cable NOTE Tighten bolts and nuts on terminals Electric starter Battery terminal... -

Page 17: Operating Your Engine

OPERATING YOUR ENGINE STARTING STOPPING ELECTRIC STARTER FUEL VALVE (Provided by the equipment manu- facturer) Open the fuel valve. Turn the key switch to the “STOP” position. ELECTRIC STARTER FUEL VALVE (Provided by the equipment manu- facturer) Turn the key swtich to the “START” position. -

Page 18: Easy Troubleshooting

EASY TROUBLESHOOTING Perform the following checks before you take the engine to your Subaru dealer. If you still have trouble after completing the checks, take the engine to your nearest Subaru dealer. Checking Items Possible Cause Correction • Engine will not start... - Page 19 3. The ignition system is faulty if there is no spark with a new spark plug. Take your engine to your nearest Subaru dealer. Is your battery will charged? Check the battery, it may be discharged and unable to operate the electric starter.

- Page 20 EASY TROUBLESHOOTING DAILY INSPECTION Before funning the engine, check the following service items. Enough Fuel Excessive vibration, noise Clean air cleaner element Safe surroundings Enough clean engine oil Leakage of fuel and engine oil Loose or broken bolt and nuts PERIODIC MAINTENANCE Periodic maintance is vital to safe and effi...

-

Page 21: Maintenance Schedule

Your local zoning or environmental regulations will give you more detailed instructions on proper disposal. *Note 2 : As to the procedures, please refer to the Service Manual or consult your nearest SUBARU service dealer. -

Page 22: How-To" Maintenance

“HOW-TO” MAINTENANCE SPARK PLUG • Clean and remove carbon deposits off from the spark plug electrode, using a plug cleaner or wire brush. • Check if the electrode gap is in the proper range. Adjust gap to the specifi cations: 0.7mm to 0.8mm 0.7 to 0.8 mm •... - Page 23 ENGINE OIL FILTER • Initial engine oil fi lter replacement should be performed after 20 hours of operation. Thereafter replace the engine oil fi lter every 200 hours. • When installing a new oil fi lter, apply oil to O-ring, attach the oil fi lter in position and tighten 2/3 turns by hand or with wrench after touching the O-ring to the sealing surface of engine.

- Page 24 • Paper element Clean by taping gently to remove dirt and blow off dust. Never use oil. Clean or replace paper element every 50 hours of operation, and replace element set every 200 hours or once a year. Clean and replace air cleaner elements more often when operation in dusty environments.

-

Page 25: Preparations For Storage

PREPARATIONS FOR STORAGE ENGINE OIL • Change the engine oil with fresh oil. • Remove the spark plug, pour about 5cc of engine oil into the cylinder, slowly start the engine for 2 or 3 seconds, and re-install the spark plug. CLEAN AND STORE •... -

Page 26: Specifications

SPECIFICATIONS MODEL EH72 LP/NG Air-Cooled, 4-stroke, V-Twin Cylinder, Horizontal P.T.O. shaft, Type OHV, LPG/NATURAL GAS Fueled Engine Bore x Stroke mm(in) 2-84 x 65 (3.31 x 2.56) Displacement cm³(cu.in) 720 (43.9) 39.5 N•m @ 2500rpm Maximum Torque N•m (Propane content of 95% or higher) : 25hp18.6kw@3600rpm Maximum Output Natural Gas (Methane content of 90% or equivalent) : 21hp15.7kw@3600rpm... - Page 28 ISSUE EMD-EU2415...

Need help?

Do you have a question about the EH72D and is the answer not in the manual?

Questions and answers