Table of Contents

Advertisement

Quick Links

Operator's Manual

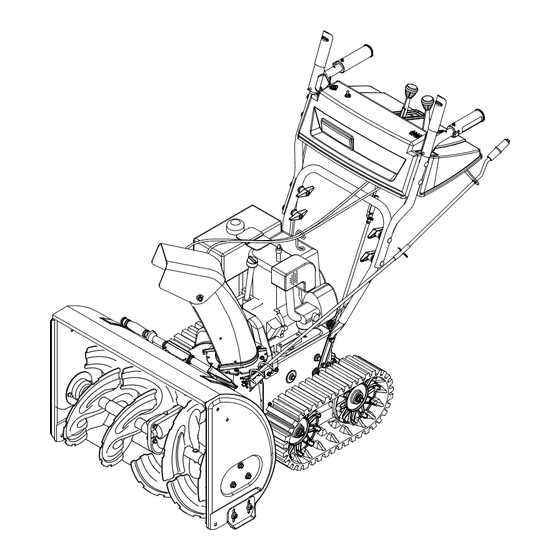

SNOW THROWER

MODEL 31AH7S3G701

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

MTD LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

770-10021G.fm

FORM NO.

(5/05)

Advertisement

Table of Contents

Summary of Contents for MTD 31AH7S3G701

-

Page 1: Snow Thrower

Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019. MTD LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 PRINTED IN U.S.A. -

Page 2: Table Of Contents

You can locate the model plate by looking at the lower frame cover on the rear of your snow thrower. This information will be necessary to use the manufacturer’s web site and/or help from the Customer Support Department or an authorized service dealer. MTD LLC P. O. BOX 361131 CLEVELAND,OH 44136 www.yardman.com... -

Page 3: Section 1: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. -

Page 4: Maintenance And Storage

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas. Do not operate machine while under the influence of alcohol or drugs. Muffler and engine become hot and can cause a burn. Do not touch. -

Page 5: Loose Parts

SECTION 2: ASSEMBLING YOUR SNOW THROWER NOTE: References to right or left side of the snow thrower are determined from behind the unit in the operating position. The “operator’s position” is defined as standing directly behind the snow thrower, facing the handle panel. -

Page 6: Auger Control

• If not already attached, slip the cables that run from the handle panel to the chute into the cable guide located on top of the engine. See Figure 4. Figure 4 SECTION 3: KNOW YOUR SNOW THROWER Drive Control / Auger Control Lock Heated Handles Switch... -

Page 7: Skid Shoe

Chute Tilt Control The distance snow is thrown can be changed by adjusting the angle of the upper chute. Move the chute tilt control forward to decrease the distance, and backwards to increase distance. See Figure 5. Skid Shoe The space between the shave plate and the ground can be adjusted by positioning the skid shoes. -

Page 8: Before Starting

SECTION 4: OPERATING YOUR SNOW THROWER Before Starting WARNING: Read, understand, and follow all instructions and warnings on the machine and in this manual before operating. Gas And Oil Fill-up Service the engine with gasoline and oil as instructed in the separate engine manual packed with your snow thrower. -

Page 9: To Engage Augers

Recoil Starter • With engine running, pull starter rope with a rapid, continuous full arm stroke three or four times. Pulling the starter rope will produce a loud clattering sound, which is not harmful to the engine or starter. • To stop engine, move throttle control to “stop”... -

Page 10: Operating Tips

Drift Cutters (If Equipped) Drift cutters should be used when operating the snow thrower in heavy drift conditions. If your unit is not equipped with drift cutters, contact Customer Support as instructed on page 2 for information regarding price and availability. Snow Thrower Model Drift Cutter Kit All models... -

Page 11: Shift Rod Adjustment

• With the drive control engaged, the friction wheel must contact the drive plate. See Figure 9. If adjustment is necessary: • Loosen the jam nut on the drive cable. Adjust the cable as necessary. Refer to Figure 7. • Retighten the jam nut to secure the cable when correct adjustment is reached. -

Page 12: Section 6: Maintaining Your Snow Thrower

SECTION 6: MAINTAINING YOUR SNOW THROWER WARNING: Before lubricating, repairing, or inspecting, disengage all controls and stop engine. Wait until all moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent unintended starting. Always wear safety... -

Page 13: Belt Removal And Replacement

SECTION 7: SERVICING YOUR SNOW THROWER WARNING: Before servicing, repairing, or inspecting, disengage all clutch levers and stop engine. Wait until all moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent unintended starting. Always wear safety glasses during operation or while performing any adjustments or repairs. -

Page 14: Replacing Friction Wheel Rubber

NOTE: Loosening the six nuts that connect the frame to the auger housing may aid in belt removal. Auger Pulley Idler Pulley Figure 15 • Lift the auger belt from the auger pulley, and slip belt between the support bracket and the auger pulley. -

Page 15: Off-Season Storage

Move the gear shaft to the right and slide the friction wheel assembly from the shaft. See Figure 19. Sprocket Spacer Support Bracket Screws Friction Wheel Rubber Friction Wheel Plates Figure 19 • Remove the four screws from the friction wheel assembly. -

Page 16: Section 8: Troubleshooting

SECTION 8: TROUBLESHOOTING Problem Engine fails to start Fuel tank empty, or stale fuel. Blocked fuel line. Choke not in the ON position Faulty spark plug. Safety key not in ignition switch on engine. Spark plug wire disconnected. Primer button not being used properly. Engine runs erratic Unit running on CHOKE. - Page 17 NOTES...

-

Page 18: Section 9: Parts List For Model 7S3

SECTION 9: PARTS LIST FOR MODEL 7S3 Part of handle panel for reference only... - Page 19 Model 7S3 Ref. Part No. Part Description 684-0008A Shift Arm Assembly 747-0737 Chute Directional Control 710-0449 Carriage Screw 5/16-18 x 2.25 710-0458 Carriage Bolt 5/16-18 x 1.75 710-0643 Hex Bolt 5/16-18 x 1.0 710-0788 Tt Screw 1/4-20 x 1.0 710-1880 Hex Bolt 5/16-18 x 0.75 711-0677 Ferrule...

- Page 20 Model 7S3...

- Page 21 Model 7S3 Ref. Part No. Part Description 731-04870 Spacer, 1.25OD x.75ID x 1.00 Lg 756-0178 Flat Idler 784-5632B Auger Idler Arm 710-0347 Hex Cap Screw 3/8-16 x 1.75 738-0281 Shoulder Screw 736-0174 Wave Washer 732-0611 Extension Spring 712-3068 Hex Nut 5/16-18 05931A Housing 741-0309...

- Page 22 Model 7S3...

- Page 23 Model 7S3 Ref. IMPORTANT: For a proper working machine, use Factory Approved Parts. V-BELTS are specially designed to engage and disengage safely. A substitute (non OEM) V-Belt can be dangerous by not disengaging completely Part No. Part Description 710-1652 Hex Washer Screw 1/4-20 x.625 731-1324 Belt Cover 732-0710...

- Page 24 Model 7L3 32 32 30 31...

- Page 25 Model 7S3 Ref. Part No. Part Description 784-5648 Frame Cover 710-1652 AB Screw 1/4-20 x.625 748-0190 Spacer 732-0264 Extension Spring 712-0711 Jam Nut 3/8-24 736-0105 Bell Washer 684-0021 Friction Whl Support Bracket Ass’y 746-0898B Drive Cable 656-0012A Friction Disc 784-5689A Front Support Guide Bracket 713-0413 10T Sprocket...

- Page 26 Model 7S3...

- Page 27 Model 7S3 Ref. Part No. 720-0223 Grip 710-0604A Tap Screw, 5/16-18 x.625 784-5642 Track Lockout Plate 710-0157 Hex Cap Screw, 5/16-24 x.75 736-0242 Bell Washer 684-0038 Track Lock Handle Assembly 710-0459A Hex Cap Screw, 3/8-24 x 1.5 712-0214 Hex Nut, 3/8-24 748-0353A Lift Shaft Drive 750-0547...

-

Page 28: Warranty

MANUFACTURER’S LIMITED WARRANTY FOR: The limited warranty set forth below is given by MTD LLC with respect to new merchandise purchased and used in the United States, its possessions and territories. “MTD” warrants this product against defects in material and...

Need help?

Do you have a question about the 31AH7S3G701 and is the answer not in the manual?

Questions and answers